Manufacturing method for fiber tubes

A manufacturing method and a fiber-based technology, applied in the field of rackets, can solve the problems of low molding yield and low operation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Please refer to Figure 1 to Figure 7 Shown, it has shown the concrete structure of preferred embodiment of the present invention, comprises the following steps:

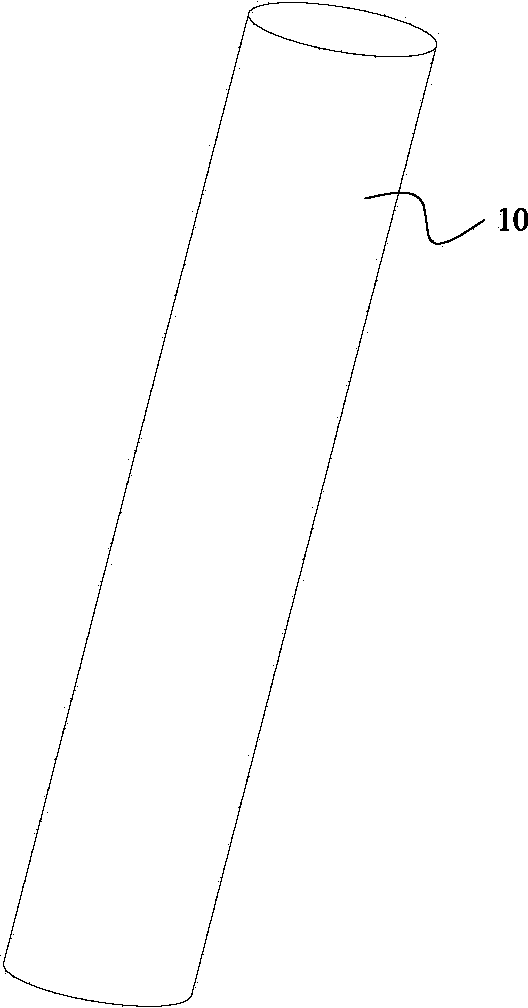

[0030] (1) Prefabricated block foaming powder 10, according to the shape of the required prepared pipe, the foaming powder is made into a block foaming powder 10 with the same shape as the pipe (such as figure 1 shown).

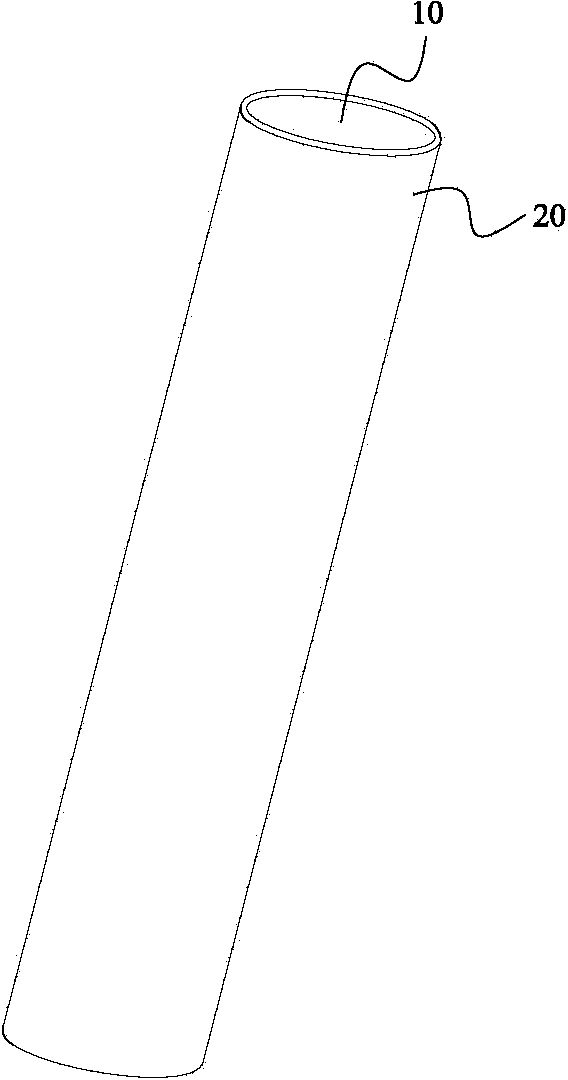

[0031] (2) Wrap a plastic interlayer 20, and wrap at least one plastic film interlayer 20 outside the bulk foam powder 10 (such as figure 2 shown), in this embodiment, the bulk foaming powder 10 is packed into a plastic film bag to form the aforementioned plastic film layer 20 outside the block foaming powder 10, which is not limited thereto.

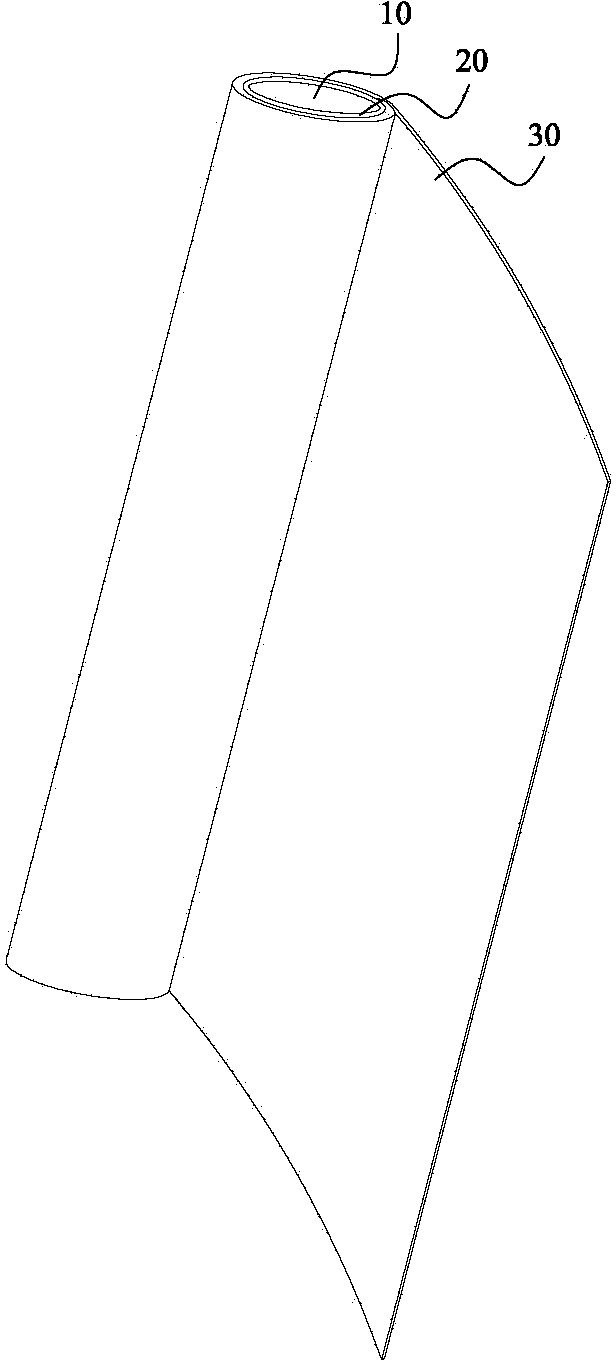

[0032] (3) Roll the fiber cloth 30, choose the fiber cloth 30 and wrap the fiber cloth 30 around the plastic interlayer 20 to form a semi-finished pipe (such as image 3 shown), in this embodiment, the fiber cloth 30 is made of carbon fiber, but n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com