Power module internal connection copper sheet, preparation method thereof, and power semiconductor module

A power semiconductor and internal connection technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc. Small secondary molding difficulty, improved molding yield, and reduced effect of mechanical fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

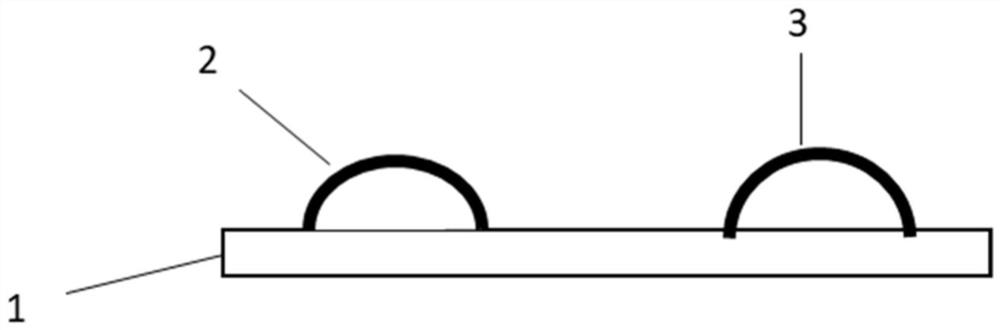

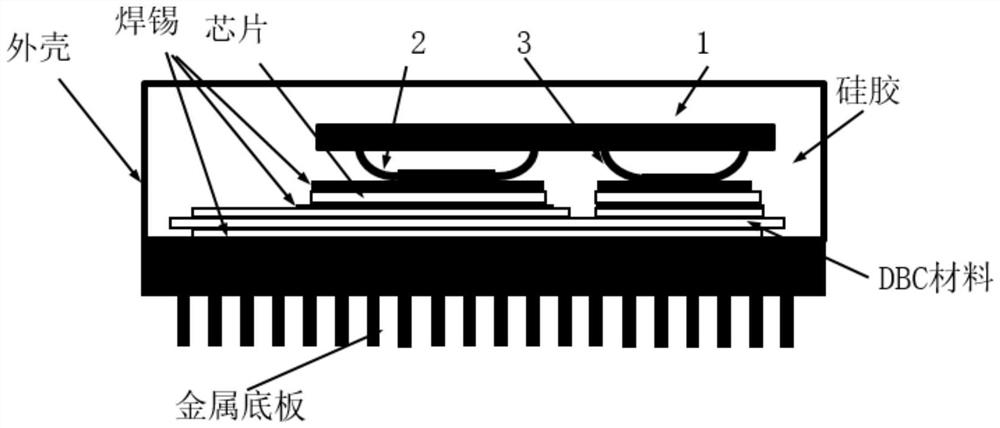

[0045] Such as Figure 1~3 As shown, a power module internal connection copper sheet provided by the present invention includes a copper plate 1, a first copper strip 2 and a second copper strip 3, the first copper strip 2 and the second copper strip 3 are arranged on the copper plate 1 at intervals, Both the first copper strip 2 and the second copper strip 3 are arc-shaped; The copper plate 1 is hollow. The width of the first copper strip 2 is 2000um, and the thickness of the first copper strip 2 is 200um. The width of the second copper strip 3 is 2000um, and the thickness of the second copper strip 3 is 200um.

[0046] The present invention also provides a preparation method based on the above-mentioned internal connection copper sheet of the power module, comprising the following steps:

[0047] Step 1: connecting the arc-shaped first copper strip 2 and the arc-shaped second copper strip 3 to the copper plate 1 by bond bonding process;

[0048] Step 2: Insert correspond...

Embodiment 2

[0053] Such as Figure 4~6 As shown, the difference from Embodiment 1 is that a through hole 4 is provided on the copper plate 1 corresponding to the position below the first copper strip 2 and the second copper strip 3 .

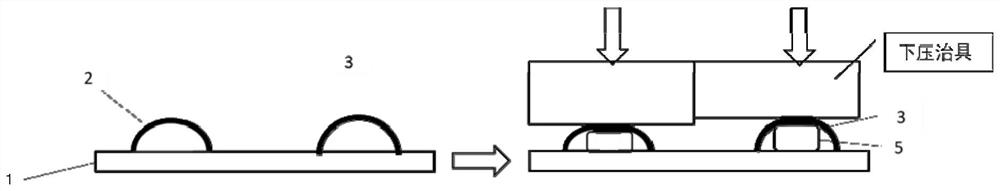

[0054] The present invention also provides a preparation method based on the above-mentioned internal connection copper sheet of the power module, comprising the following steps:

[0055] Step 1: place the arc-shaped first copper strip 2 and the arc-shaped second copper strip 3 corresponding to the perforation 4 on the copper plate 1,

[0056] Step 2: Connect the first copper strip 2 and the second copper strip 3 to the copper plate 1 by bond bonding process;

[0057] Step 3: pass and fix the metal strip 5 that needs to support the first copper strip 2 and the second copper strip 3 through the perforation 4, and support the first copper strip 2 and the second copper strip 3;

[0058] Step 4: Position the copper plate 1 on the forming jig, and carry out pr...

Embodiment 3

[0062] Such as image 3 and Figure 7 As shown, the difference from Embodiment 1 is that the first copper strip 2 and the second copper strip 3 are integrally formed.

[0063] The present invention also provides a preparation method based on the above-mentioned internal connection copper sheet of the power module, comprising the following steps:

[0064] Step 1: Install a looper on the welding head;

[0065] Step 2: Bind the copper strip to the copper plate 1;

[0066] Step 3: Draw wire arcs on the copper tape and form it into the final platform shape at one time.

[0067] In this embodiment, in the process of welding the binding wire or ribbon to the copper plate, loop forming is added to the wire bonding equipment for one-time forming, and no secondary forming process is required.

[0068] In a preferred example, during the process of welding the binding wire or ribbon to the copper plate, a loop former is installed on the welding head of the wire welding equipment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com