Process for forming lining plastic core pipe of round thin-film capacitor by heat sealing

A technology for film capacitors and plastic cores, which is used in film/thick film capacitors, multilayer capacitors, wire wound capacitors, etc., to achieve the effects of easy realization of process equipment, short production cycle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the present invention easier to understand, we will describe the present invention in more detail below in conjunction with the accompanying drawings and specific embodiments.

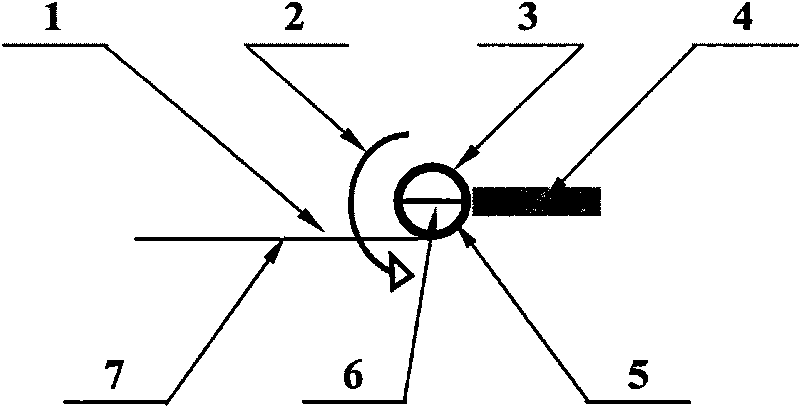

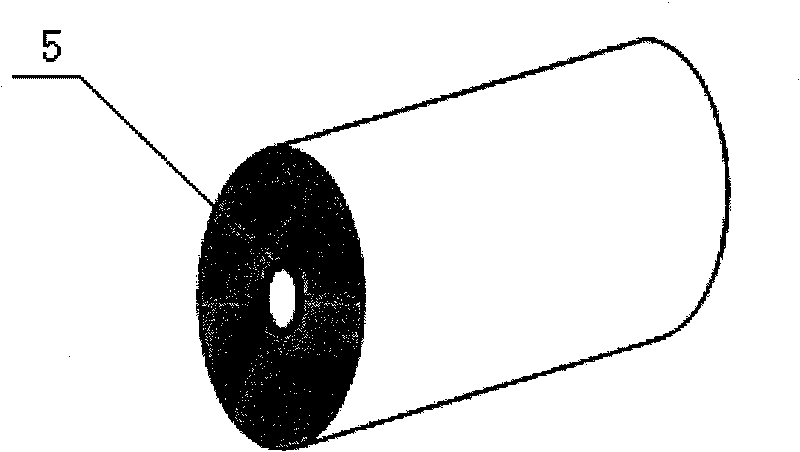

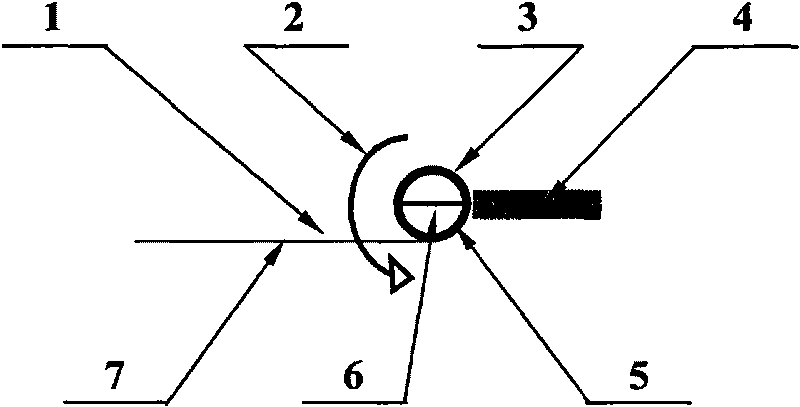

[0010] refer to figure 1 , figure 2 , a process of forming a circular film capacitor lined core tube by heat sealing, the process heats the outer surface 3 of the inner envelope film 7 wound onto the core 6 at the initial stage of the capacitor winding process, so that The film layers are hot-melt bonded to form a hollow plastic tube 5 with a wall thickness of 0.20-1.20 mm, that is, a plastic-lined core tube. The size of the hollow plastic tube 5 changes synchronously with the winding core 6, and is not limited by the size of the capacitor. After the inner sealing heating device 4 leaves, the inner plastic core tube has just been formed.

[0011] Wherein, the inner encapsulating film 7 for the capacitor is a plastic film among polypropylene, polyphenylene sulfide, polyester, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com