Ultrasonic detection method of ultrahigh-strength steel thin-wall spinning cylinder

A technology of ultra-high-strength steel and detection methods, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as difficult processing, large initial sensitivity calibration errors, and low initial sensitivity, so as to improve quality and reliability And the effect of safe use, fast and accurate positioning, and high defect detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

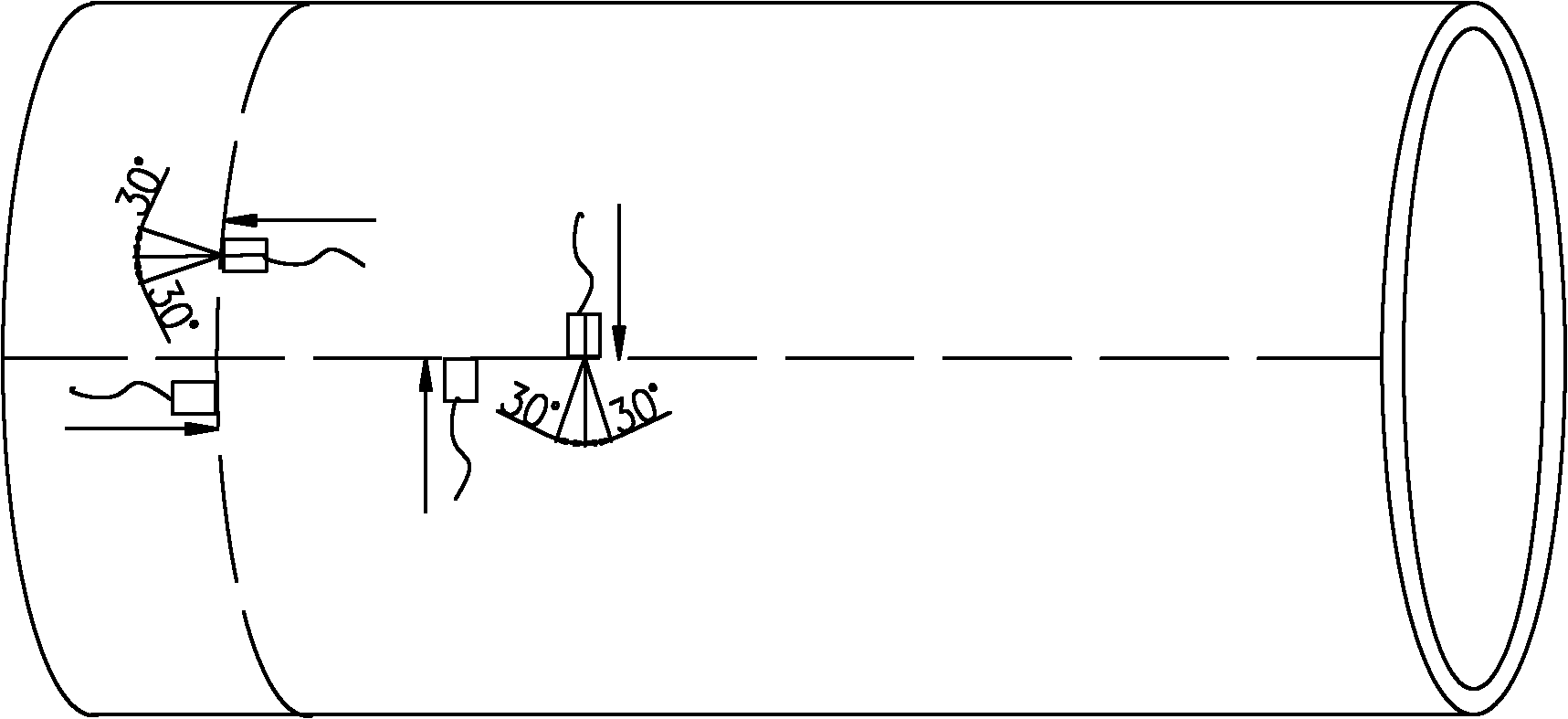

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

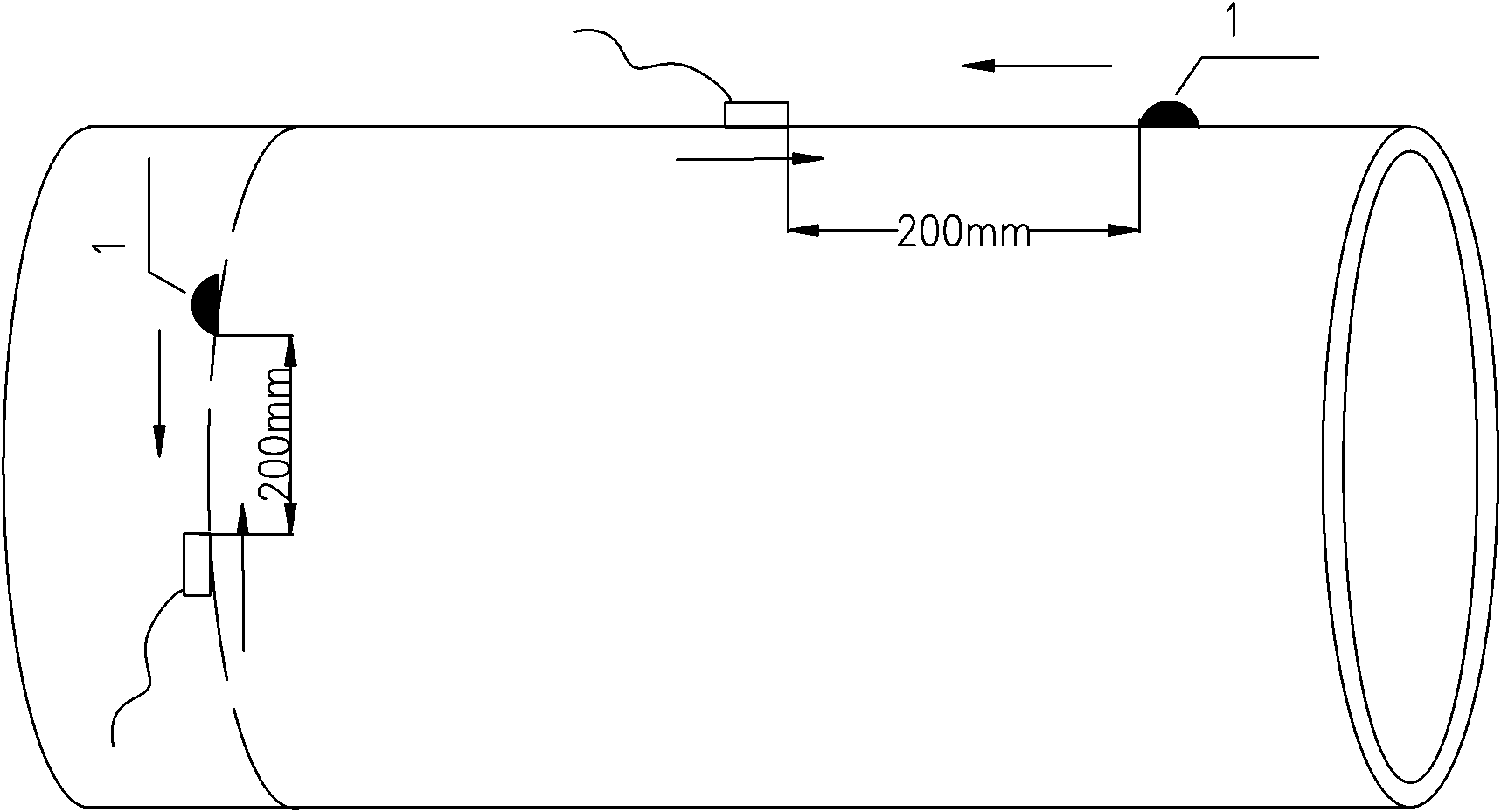

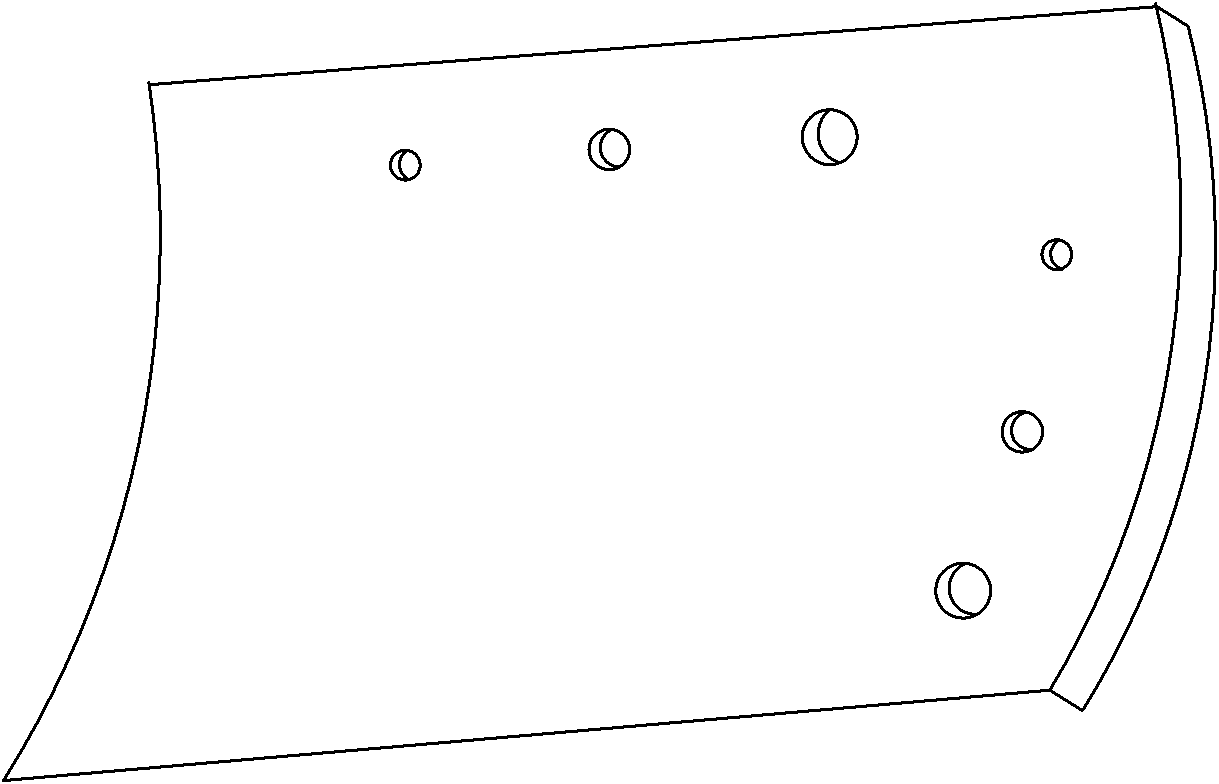

[0023] The embodiment of the present invention provides an ultra-high-strength steel thin-walled spinning cylinder ultrasonic detection method, on the premise of the preparatory work of probe selection, including artificial defect comparison sample processing, initial sensitivity calibration, ultra-high-strength steel thin-walled cylinder The steps of cylinder scanning detection and defect location are described in detail below.

[0024] Preparations: Probe selection, the following aspects need to be considered:

[0025] (1) The detection frequency of the probe. Generally, the detection frequency of the probe should be the fixed frequency of each probe, which is determined according to the sound attenuation characteristics such as sound velocity and acoustic impedance of the material and state of the ultra-high-strength steel thin-walled spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com