Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about "Leather softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing process of semi-vegetable tanned wrinkled leather of cow leather

InactiveCN102080134AQuality assuranceReduce contentTanning treatmentPre-tanning chemical treatmentPulp and paper industryHexavalent chromium

The invention relates to a manufacturing process of the semi-vegetable tanned wrinkled leather of cow leather, which comprises the working procedures of initial tanning, deacidifying, vegetable tanning, filling and dry finishing. In the method provided by the invention, firstly tanning is carried out on raw hide by a small quantity of chromium tanning agent and then by a vegetable tanning agent, thereby under the premise of guaranteeing the quality of the leather, greatly reducing the content of chromium in tanning waste liquid, lightening the pollution of the chromium to the environment and effectively inhibiting the generation of hexavalent chromium through the vegetable tanning agent in the leather; and meanwhile, the granule surface of the leather is tightened through the working procedures of dry finishing and coating, and natural winkles are formed on the granule surface, thereby covering the injury of the granule surface of the leather and improving the additional value of the leather.

Owner:锦兴皮业科技有限公司

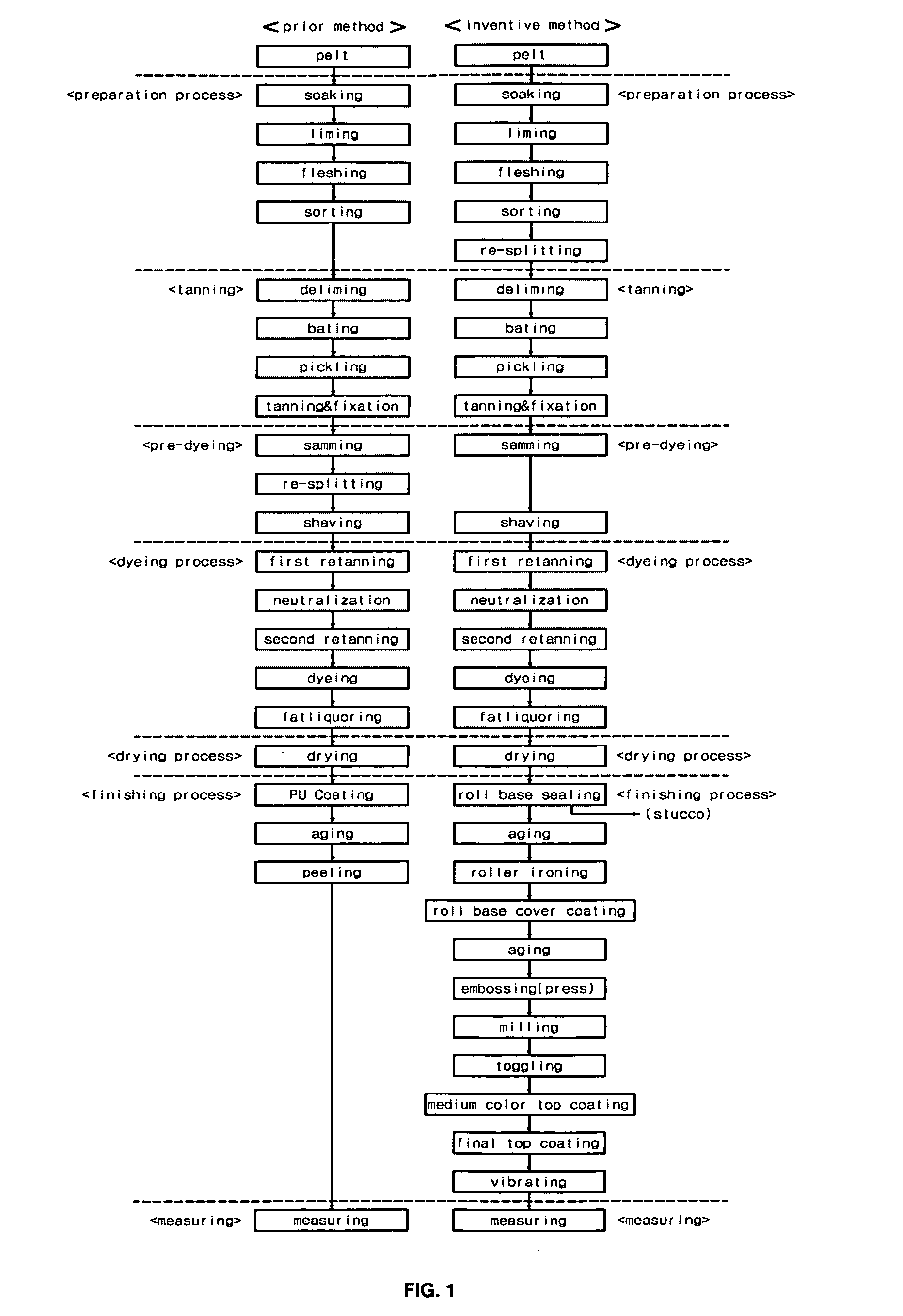

Split Leather for Car Seats and Manufacturing Method Thereof

InactiveUS20080299406A1Maximally maintain propertyCost advantageVehicle seatsTanning treatmentCar seatEngineering

Disclosed herein are split leather for car seats and a manufacturing method thereof. The method comprises a preparation process, a tanning process, a pre-dyeing process, a dyeing process, a drying process and a finishing process, wherein the method comprises, after the preparation process, but before the tanning process, a re-splitting process of splitting pelt into an upper grain layer and a split layer, having a thickness of 2.5-4 mm, and re-splitting the split layer to have a thickness of 1.8-2.5 mm starting from the upper side thereof, thus obtaining split leather, and the finishing process comprises sequentially forming a roll base sealing layer, a roll base cover layer, a medium color top coating layer and a final top coating layer on the split leather, thus treating the surface of the split leather. The split leather for car seats has a luxuriousness close to that of full-grain leather and a soft touch and feel, and can give customers a cost advantage. Also, the range of selection of raw material for manufacturing car seat leather can be widened, and waste can be recycled to thus reduce the generation of waste, thus being helpful to the environment. In addition, leather seats can be diversified and a new product group can be created.

Owner:NAM CHUNG

Production process of automobile interior decorative leather with ultralow total carbon emission

ActiveCN102732649ALeather tightGood wear and abrasion resistanceTanning treatmentPre-tanning chemical treatmentPulp and paper industryVolatile organic compound

The invention relates to a production process of automobile interior decorative leather with ultralow total carbon emission. The process comprises the steps of: cow leather fleshing, hair-saving, and unhairing, softening, tanning, retanning, dyeing, fat liquoring, drying, vibration staking, and finishing. The process of the invention controls the additive required in the steps so as to make the automobile interior decorative leather produced by the process has reduced total carbon emission and fogging value. Volatile organic compounds are under control, and the process is healthy and environment friendly.

Owner:HAINING SENDE LEATHER

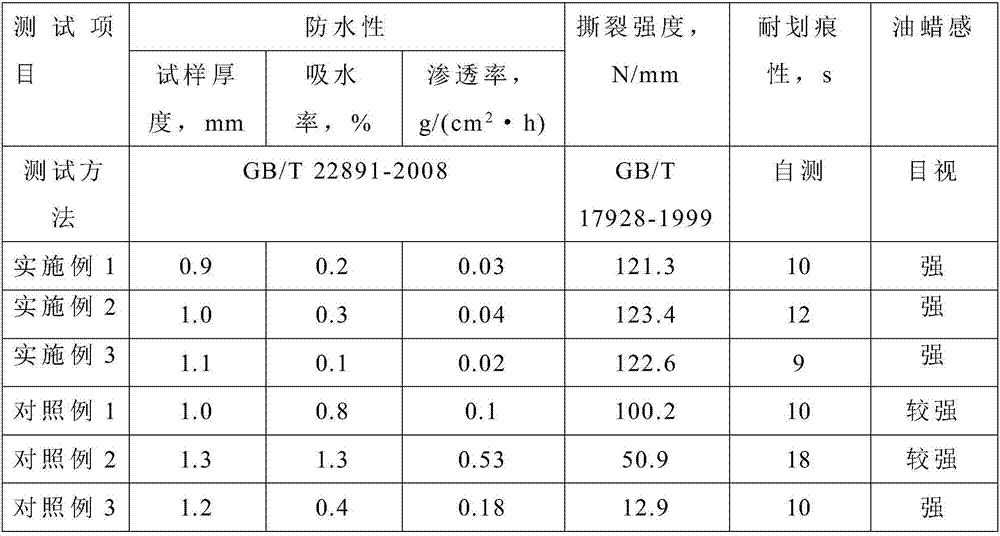

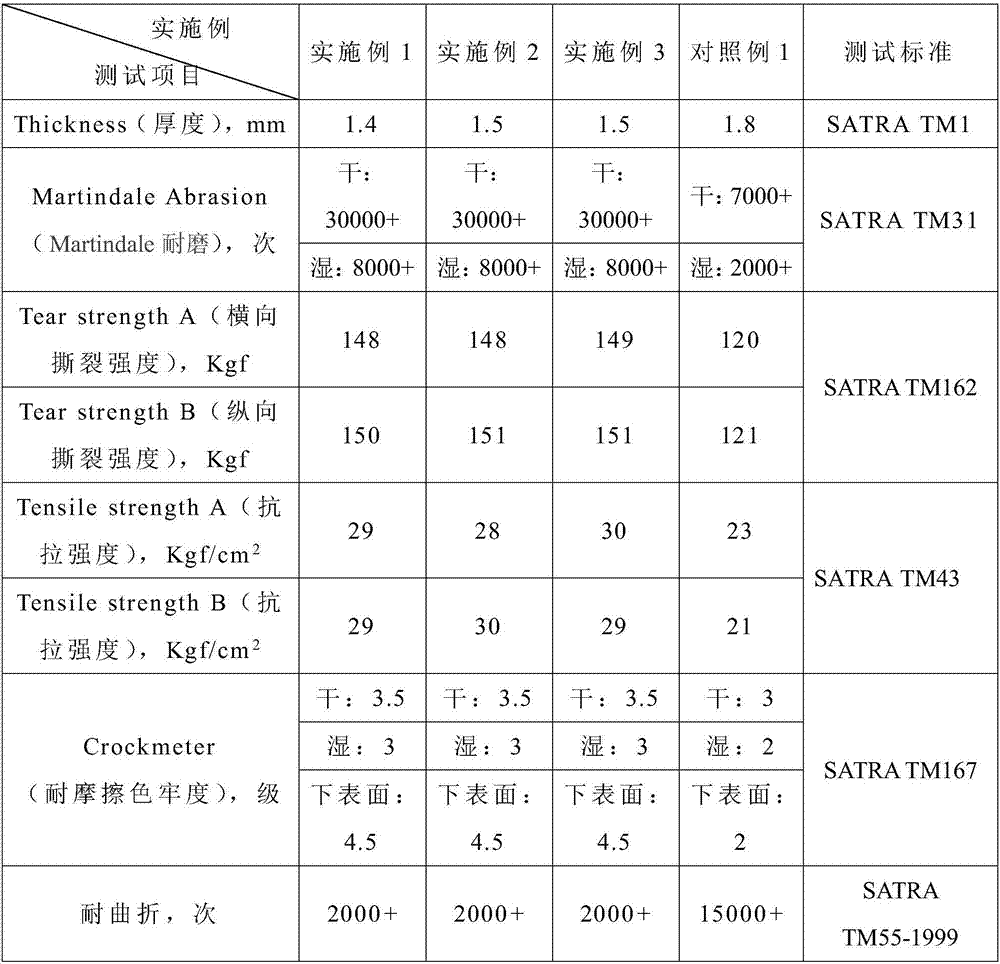

Production method for split-layer oil wax waterproof leather

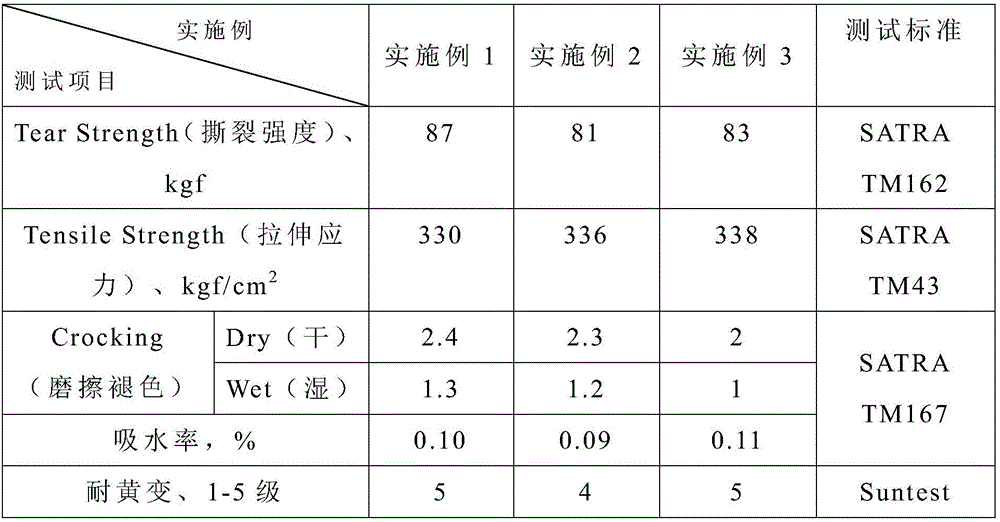

ActiveCN106957932AImprove waterproof performanceHigh tear strengthLeather softeningLeather surface mechanical treatmentMaterials science

The invention relates to a production method for split-layer oil wax waterproof leather and belongs to the technical field of leather. The production method for the split-layer oil wax waterproof leather includes the following steps that a split-layer leather blank is taken, dried and then subjected to leather grinding, first time of milling, spraying, oil wax roll painting, roll finishing, secondary milling and feeling agent spraying, and then the split-layer oil wax waterproof leather is obtained. The split-layer oil wax waterproof leather prepared through the production method has good waterproof performance and wet rubbing resistance and meanwhile has relatively high tearing strength; in addition, the split-layer oil wax leather prepared through the production method is relatively high in oil wax sense and chromatic aberration sense, the antiquing effect of the leather is effectively improved, scratching resistance of the leather is good, and scratches can disappear by themselves once happening to the surface of a leather material; and the performance of the split-layer oil wax waterproof leather prepared through the production method can rival the performance of top layer oil wax leather.

Owner:漳州香洲皮革有限公司

Leather surface coating and finishing process

InactiveCN102690904ALeather softeningLeather surface mechanical treatmentSurface coatingCeramic materials

The invention provides a leather surface coating and finishing process. The process comprises the following steps: a, resin impregnation: a leather is impregnated in a resin impregnation liquid consisting of a resin emulsion and an impregnating agent to make the resin impregnation liquid permeates deep parts of the leather; b, primary coating: surfaces of the leather are coated with a primary coating liquid; c, first mechanical finishing: surface finishing is performed on the primary-coated leather; d, middle coating: the surfaces of the first mechanical-finished leather are coated with a middle coating liquid; e, second mechanical finishing: polishing, patterning and coloring finishing are performed on the middle-coated leather in turn; f, final coating: the surfaces of the second mechanical-finished leather are coated with a final coating liquid; g, third mechanical finishing: brightness adjustment and surface hand-feel adjustment are performed on the final-coated leather; h, ironing; i, softness finishing: hand-feel finishing is performed on the ironed leather by using a vibration machine for softening leathers. The process consumes less chemical raw materials, has advantages of low pollution and environmental protection, and can improve quality of the leather significantly.

Owner:赣州华坚鞋业集团有限公司

Making technology of natural dry milled leather

ActiveCN104988248ASimple processImprove flat finenessTanning treatmentPre-tanning chemical treatmentEngineeringColor processing

The invention relates to the technical field of making technologies of leather, and provides a making technology of natural dry milled leather. The making technology of the natural dry milled leather shortens the production time, improves the plumpness and uniformity of the pattern of the natural dry milled leather and enlarges the application range of leather sources through physical technologies. The making technology of the natural dry milled leather comprises the following steps: preparing wet blue leather, selecting, squeezing and spreading, weighing, returning the wet blue leather to a drum and immersing the wet blue leather in water, squeezing and spreading, carrying out vacuum treatment, drying, rinsing and neutralizing, carrying out closed washing, filling and dyeing, fatliquoring, carrying out color processing, washing by using water and discharging the obtained leather from the drum, carrying out stacking standing, squeezing and spreading, carrying out vacuum treatment, naturally hanging for airing, spraying water to regain moisture, standing, carrying out vibration softening, milling, and finishing.

Owner:XINGYE LEATHER TECH CO LTD

Waterproof chrome-free tanning leather manufacturing process

ActiveCN109628654AImprove waterproof performanceGood physical and chemical propertiesTanning treatmentPre-tanning chemical treatmentPollutionPolymer

The invention relates to the technical field of leather manufacturing process, and provides a waterproof chrome-free tanning leather manufacturing process. The manufacturing process comprises the steps that firstly, organic silicone modified polyurethane resin, an organic synthetic tanning agent and a polymetallic complex tanning agent are used for pickling-free and chrome-free combined tanning; then chrome-free retanning and chrome-free fixing are carried out by using the polymetallic complex tanning agent, and a waterproof polymer and a waterproof fatliquoring agent are used for filling andfatliquoring; the obtained chrome-free tanning leather has excellent waterproofing performance, and has both good physical and chemical properties and subsequent processing performance. During the process of implementation of the waterproof chrome-free tanning leather manufacturing process, by using cleaner production technologies such as ammonia-free deliming and softening co-bath, pickling-freeand chrome-free combined tanning and chrome-free retanning and chrome-free fixing, the prepared waterproof chrome-free leather is ecological and environmentally-friendly and excellent in waterproofingperformance, and pollution of heavy metal chromium is eliminated from a source; and the technical process is simple, the practicability is high, and the waterproof chrome-free tanning leather manufacturing process is suitable for industrial application.

Owner:XINGYE LEATHER TECH CO LTD

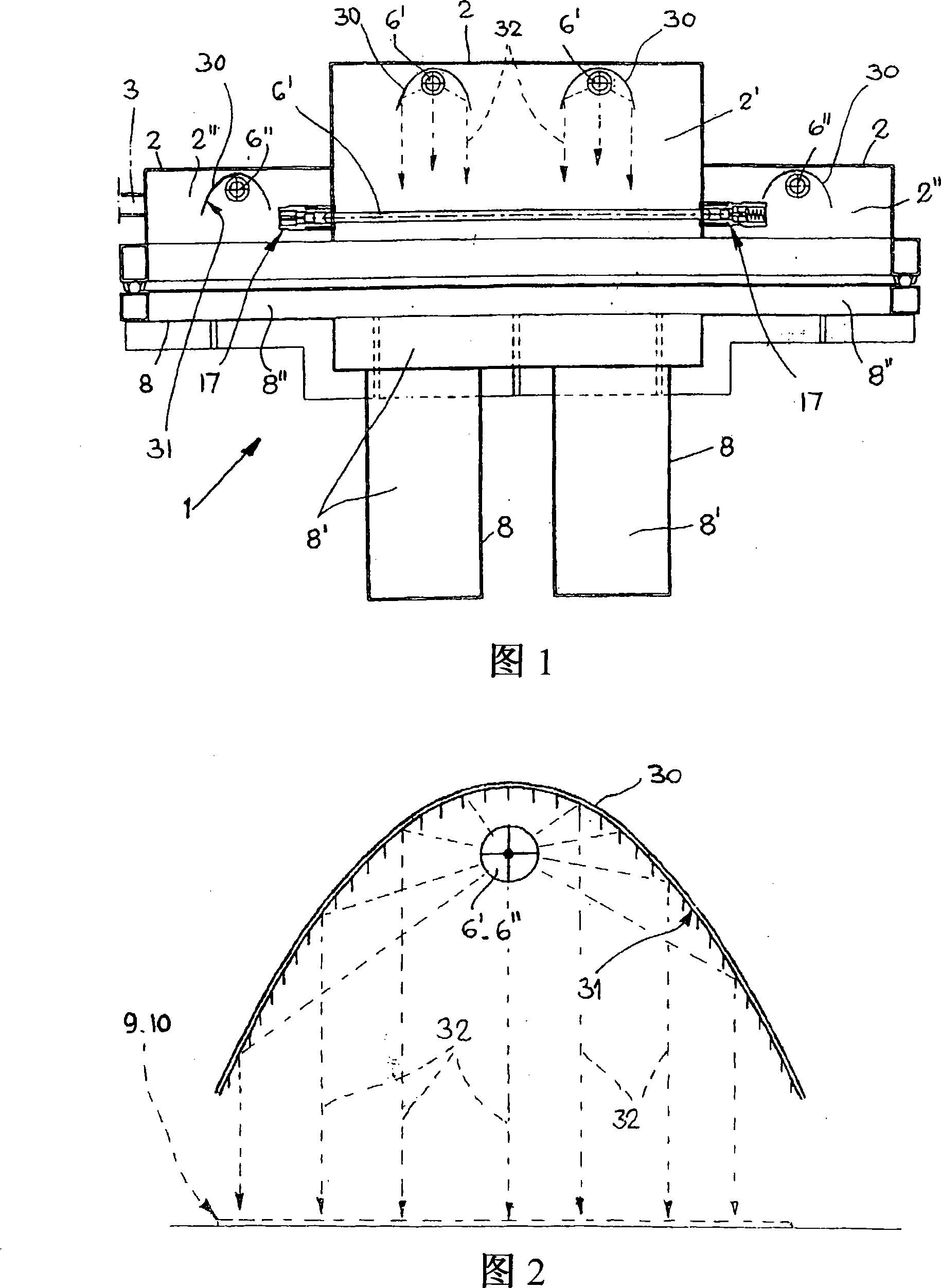

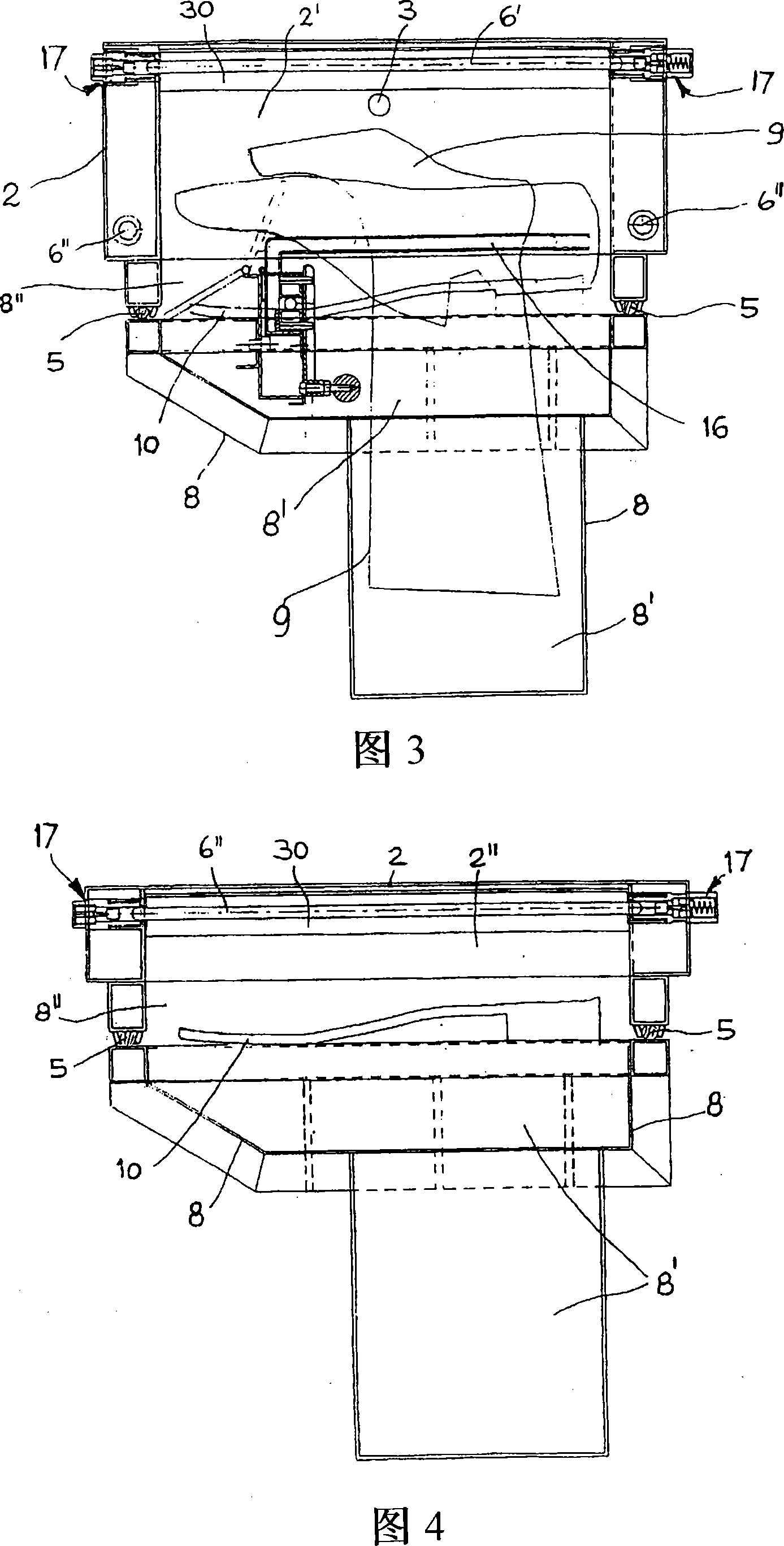

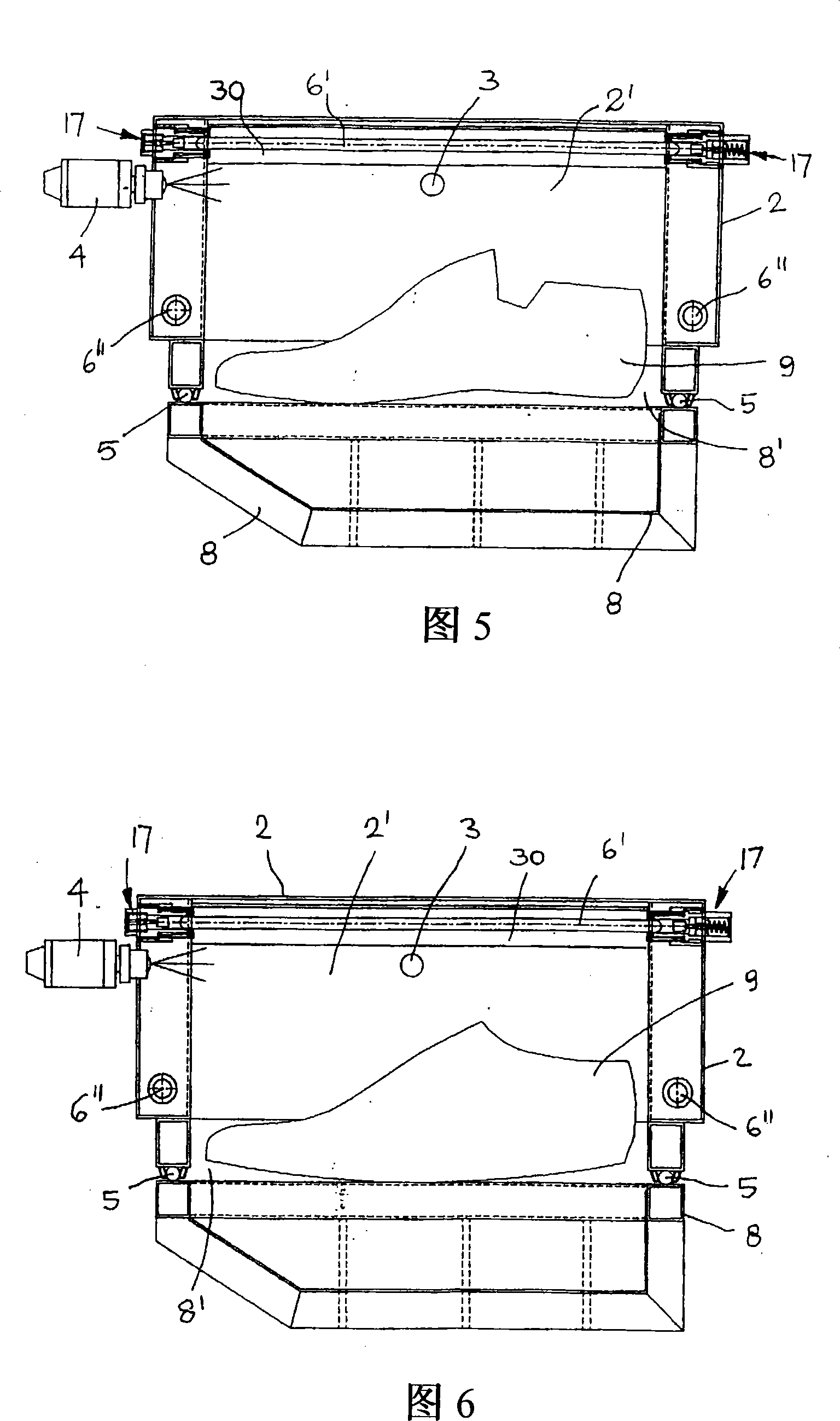

Multifunctional leather goods processing workstation

InactiveCN101176577AImprove quality reliabilityAccurate graspShoemaking devicesLeather softeningInfraredAutomatic control

A multifunctional station for leather product treatment includes at least a cavity with inner part and at least an upper cover casing of a air exhaust port connected with a vacuum pump. The upper cover casing is predetermined to connect with at least a steam interface of peripheral steam generator. Each cavity is provided with at least a near infrared radiation type heating lamp, and a reflection plate with parabolic profile and with inner reflection surface treated through mirror, which is disposed around the middle luminous part of the heating lamp. Each upper cover casing is capable of combining temporarily with corresponding lower carrying tray for putting the treated leather products. No matter the multifunctional station for leather product treatment is set independently, or disposed along continuous production line, the operation of upper cover casing is capable of being programmed through an automatic control element, and performing treatment to the leather products, e.g. drying activation of agglutinant or softening, setting of leather products, etc.

Owner:蓝法兰可·安札尼 +1

Environmentally-friendly and high-grade sofa leather production process

ActiveCN109628653ARaise the pHReduce formaldehyde contentTanning treatmentPre-tanning chemical treatmentOrganic solventAcrylic resin

The invention relates to the technical field of leather manufacturing processes, and provides an environmentally-friendly and high-grade sofa leather production process. According to the environmentally-friendly and high-grade sofa leather production process, an organic pretanning agent F-90 is adopted to pretreat softened leather, main tanning is carried out on pre-tanned white wet leather by adopting an aldehyde tanning agent, a vegetable tanning agent, an aromatic synthetic tanning agent, an amino resin tanning agent and an acrylic resin tanning agent are adopted for retanning, cross-linking can be formed among the vegetable tanning agent, collagen and the aldehyde tanning agent, and a vegetable-aldehyde synergistic tanning effect is achieved, so that the water-washing resistance, organic solvent resistance and shrinkage temperature of obtained crust leather are improved; moreover, the environmentally-friendly and high-grade sofa leather production process is a technical skill integrating tanning, neutralization, retanning and dyeing, uniform patterns are easy to produce on the grain surface of obtained sofa leather, and the process is suitable for the mill operation; and the shrinkage temperature is higher than 85 DEG C, and physical and mechanical properties and sensory properties meet the standard of chrome-free tanning leather.

Owner:XINGYE LEATHER TECH CO LTD

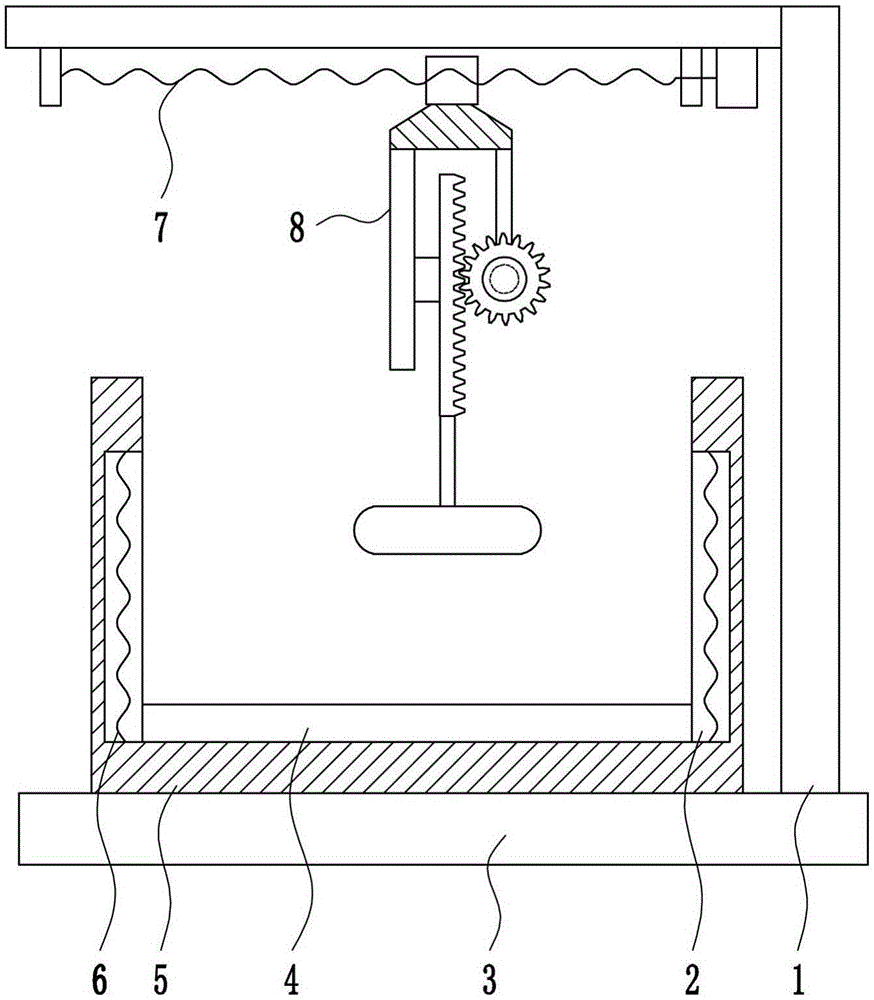

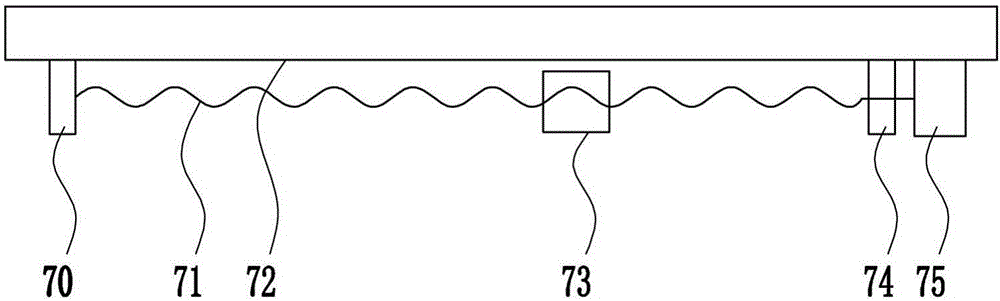

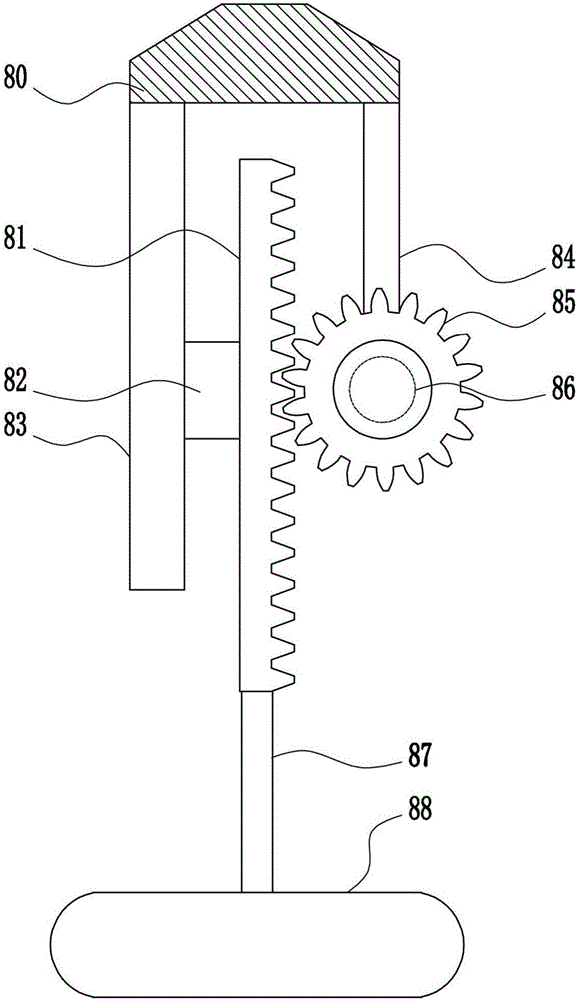

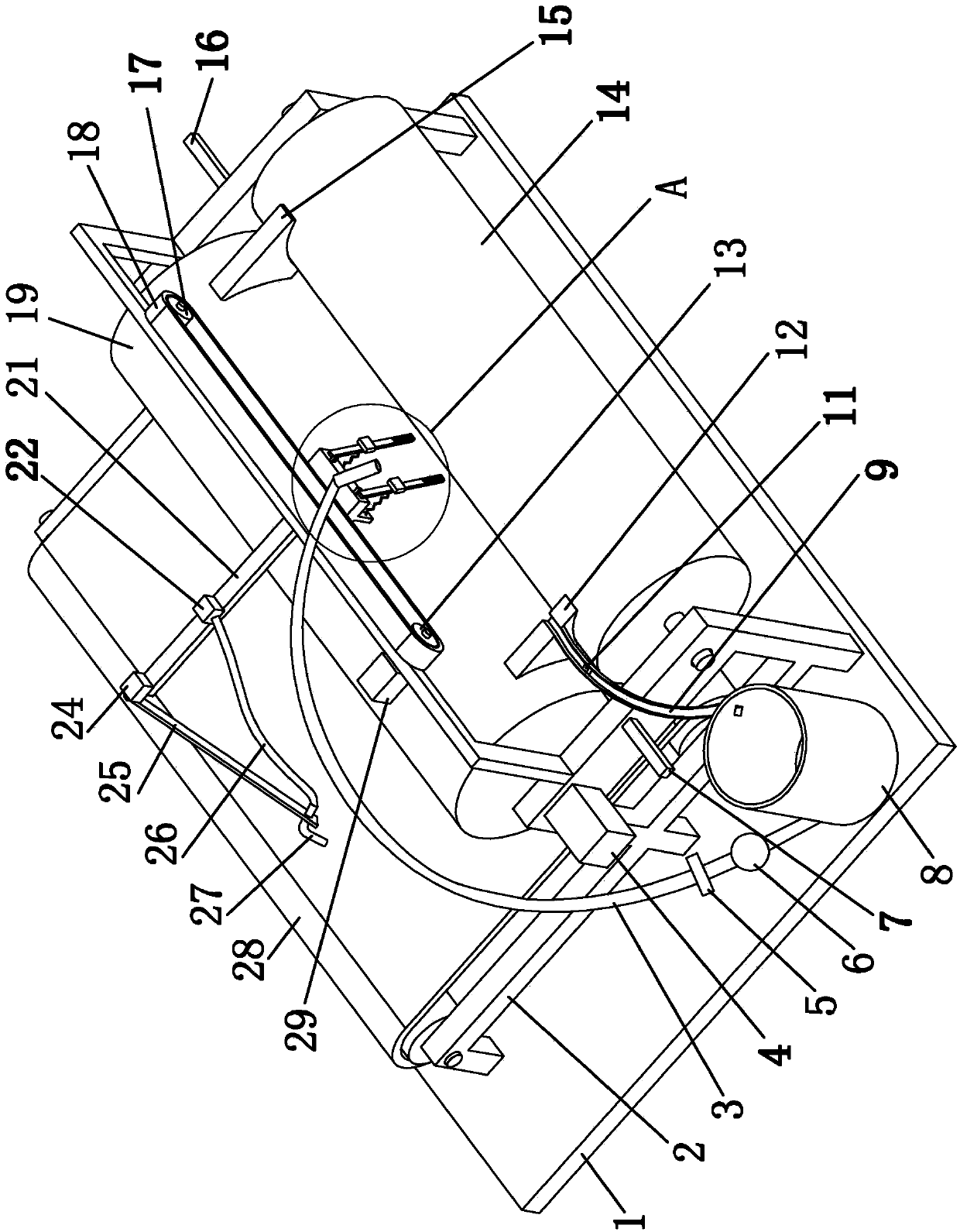

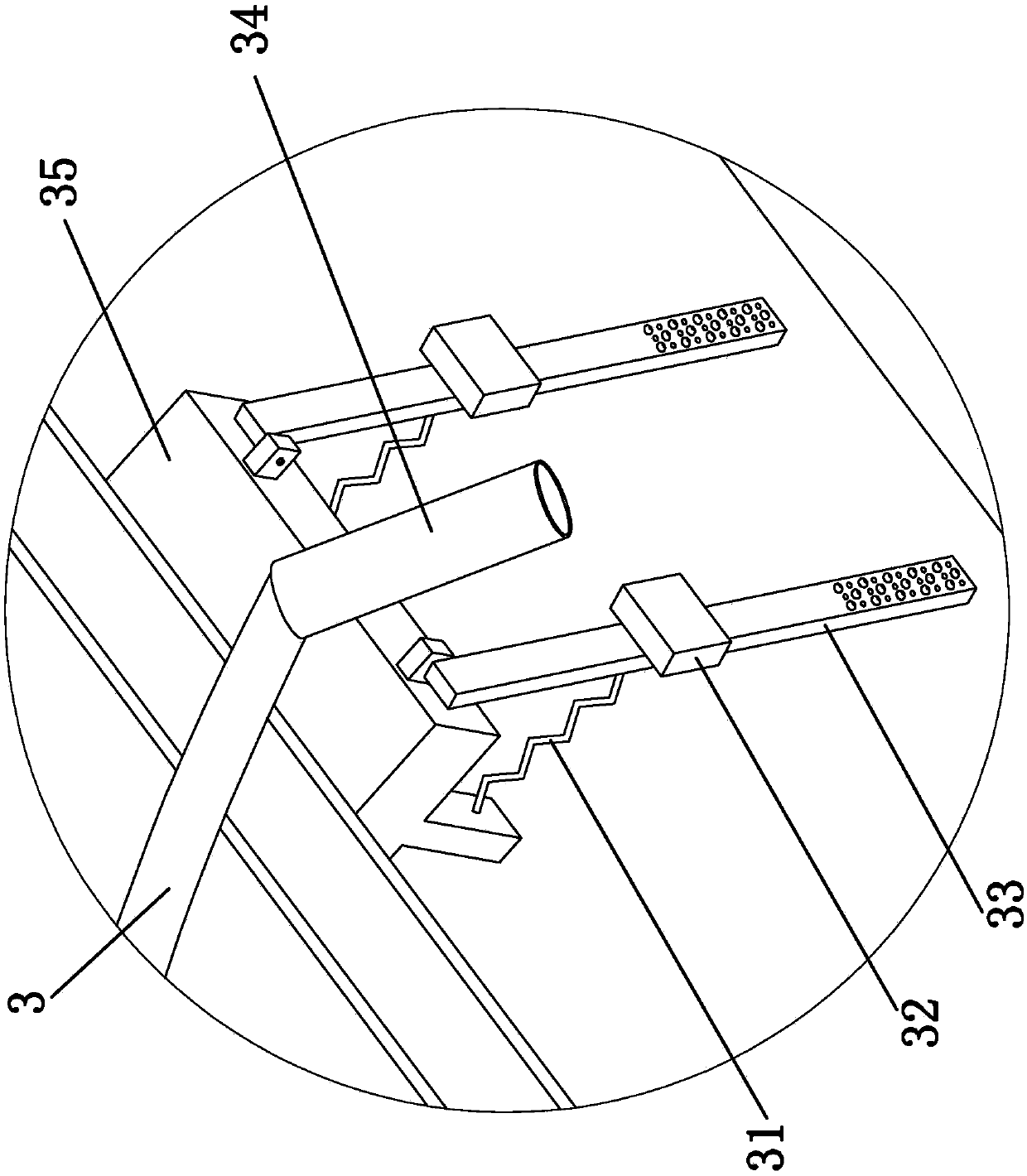

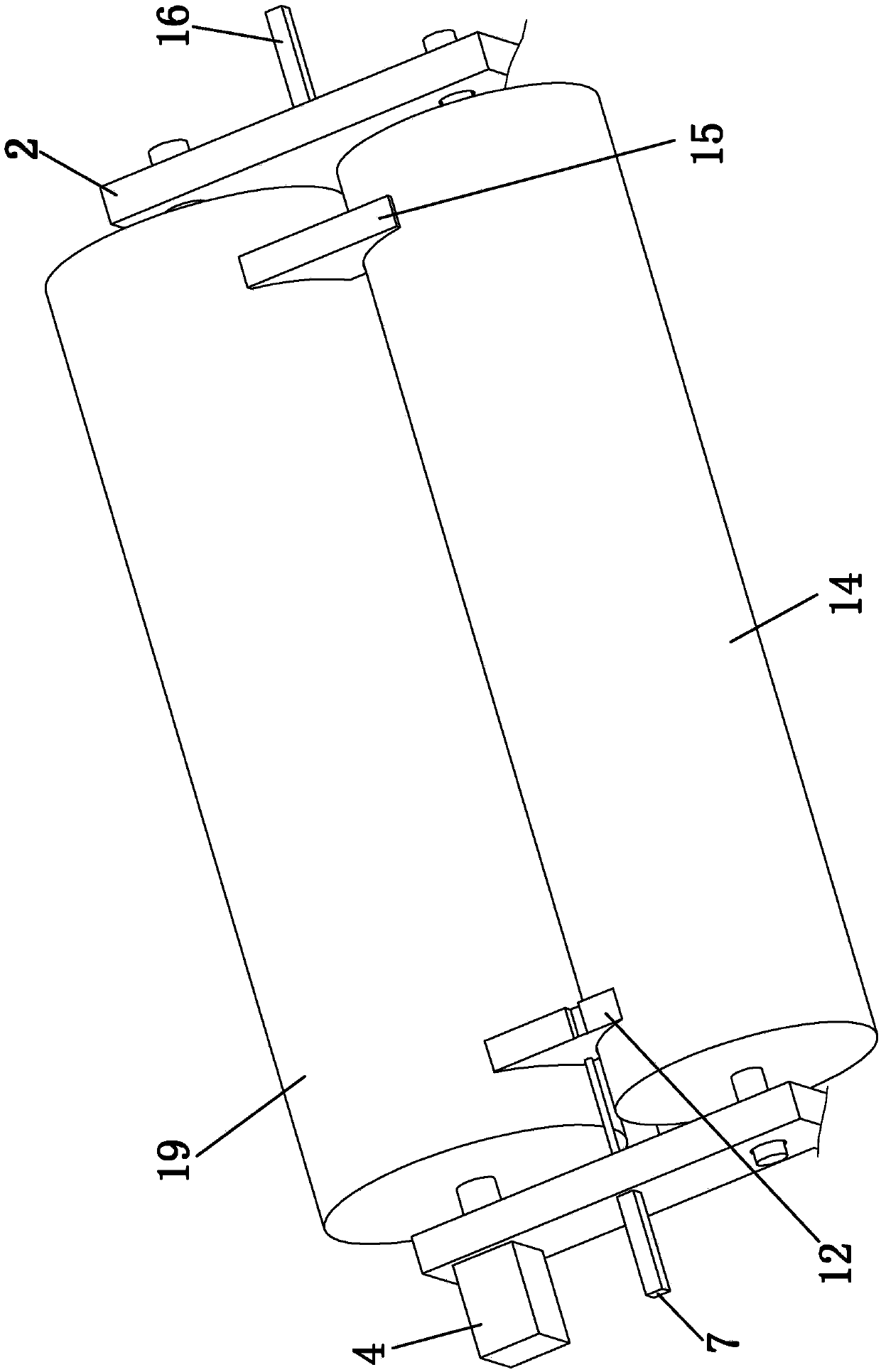

Leather softening device

ActiveCN106676207APromote softeningReduce workloadPre-tanning chemical treatmentLeather softeningSafety coefficientHIT device

The invention relates to a machining device, in particular to a leather softening device to achieve the technical purpose. To achieve the technical purpose, the leather softening device is provided and comprises a support, a base, a protective layer, a softening groove, heating wires, a moving mechanism, a pressing and hitting device and the like. The softening groove is formed in the top of the base. Cavities are formed in the right side of the left wall and the left side of the right wall of the softening groove. The heating wires are arranged in the cavities. The protective layer is arranged on the inner bottom of the softening groove. The support is arranged on the right side of the top of the base. The moving mechanism is arranged on the top of the left side of the support. The pressing and hitting device is arranged on the bottom of the moving mechanism. The bottom of the pressing and hitting device is located in the softening groove. The leather softening device achieves the effects that mechanical pressing and hitting replaces manual treading to relieve the working burden of workers, and the working efficiency and safety coefficients are high.

Owner:浙江宝瑞皮业有限公司

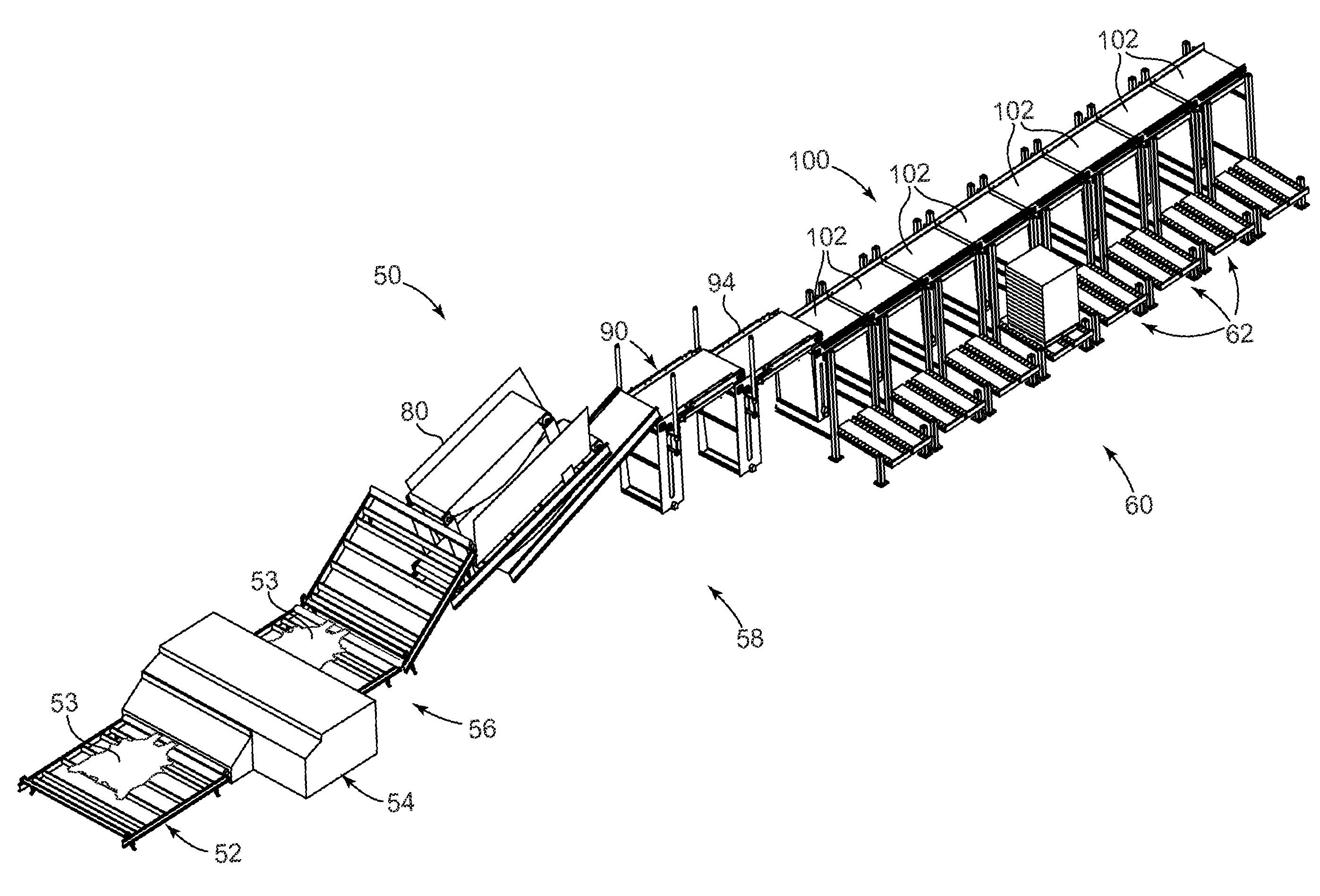

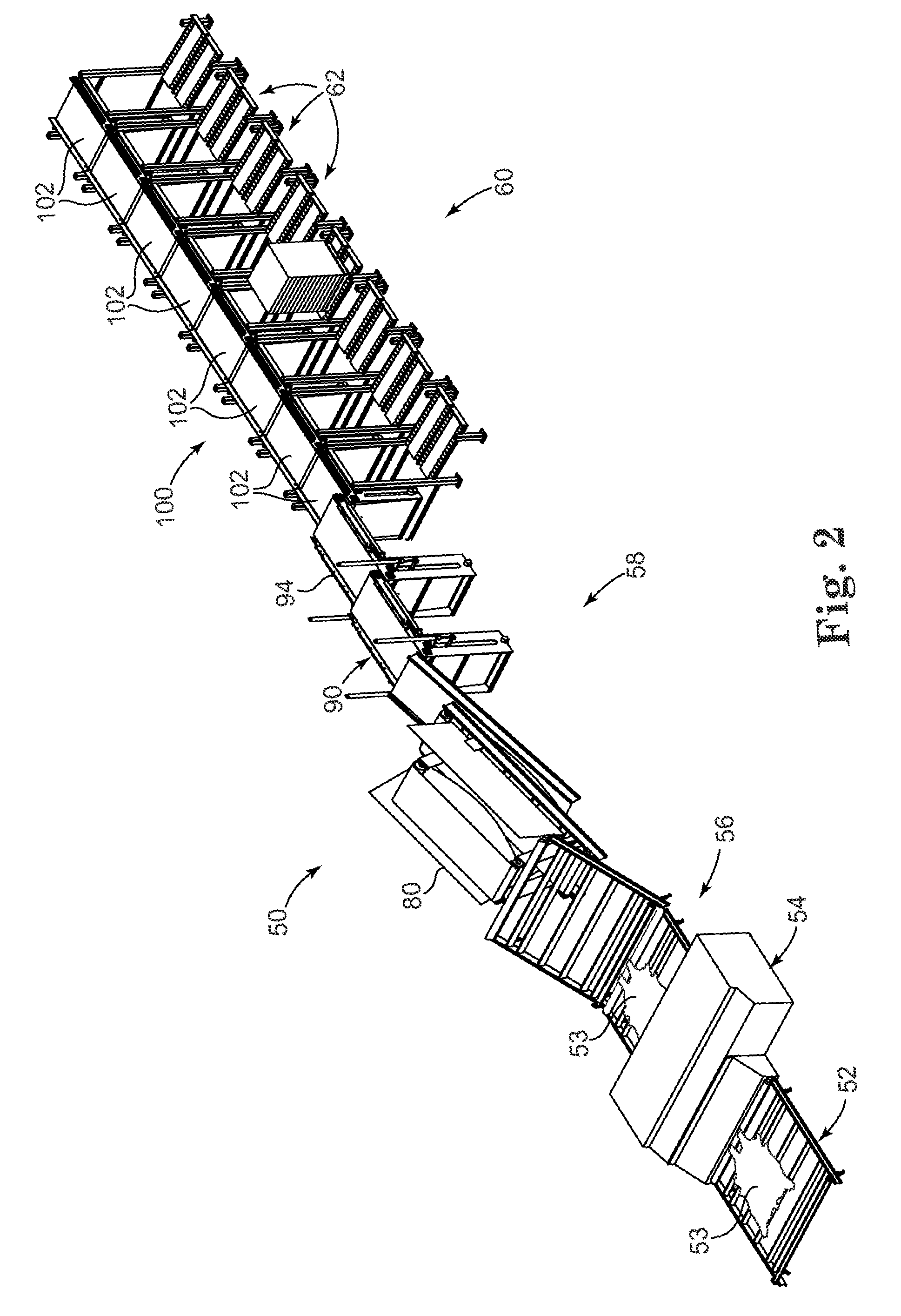

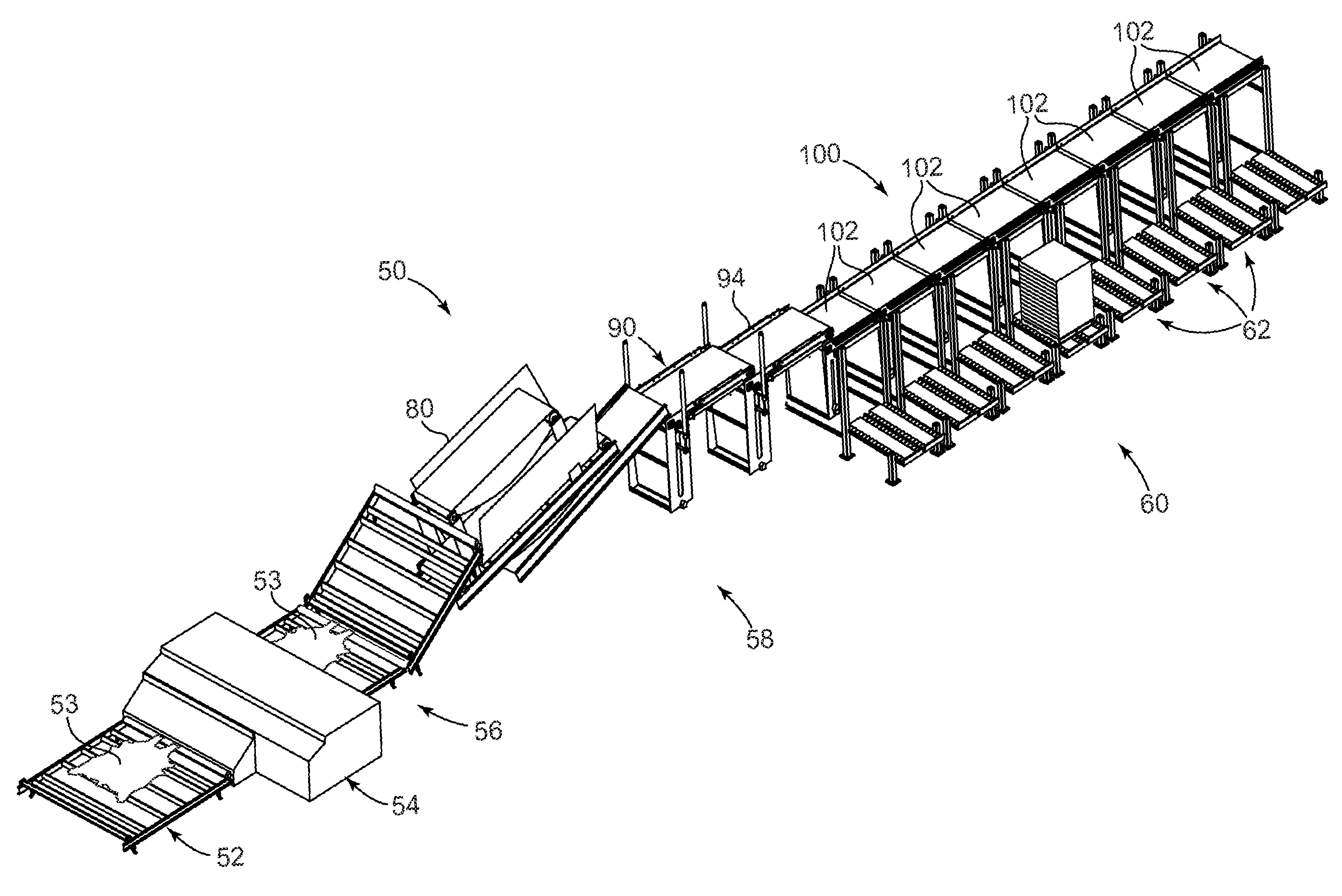

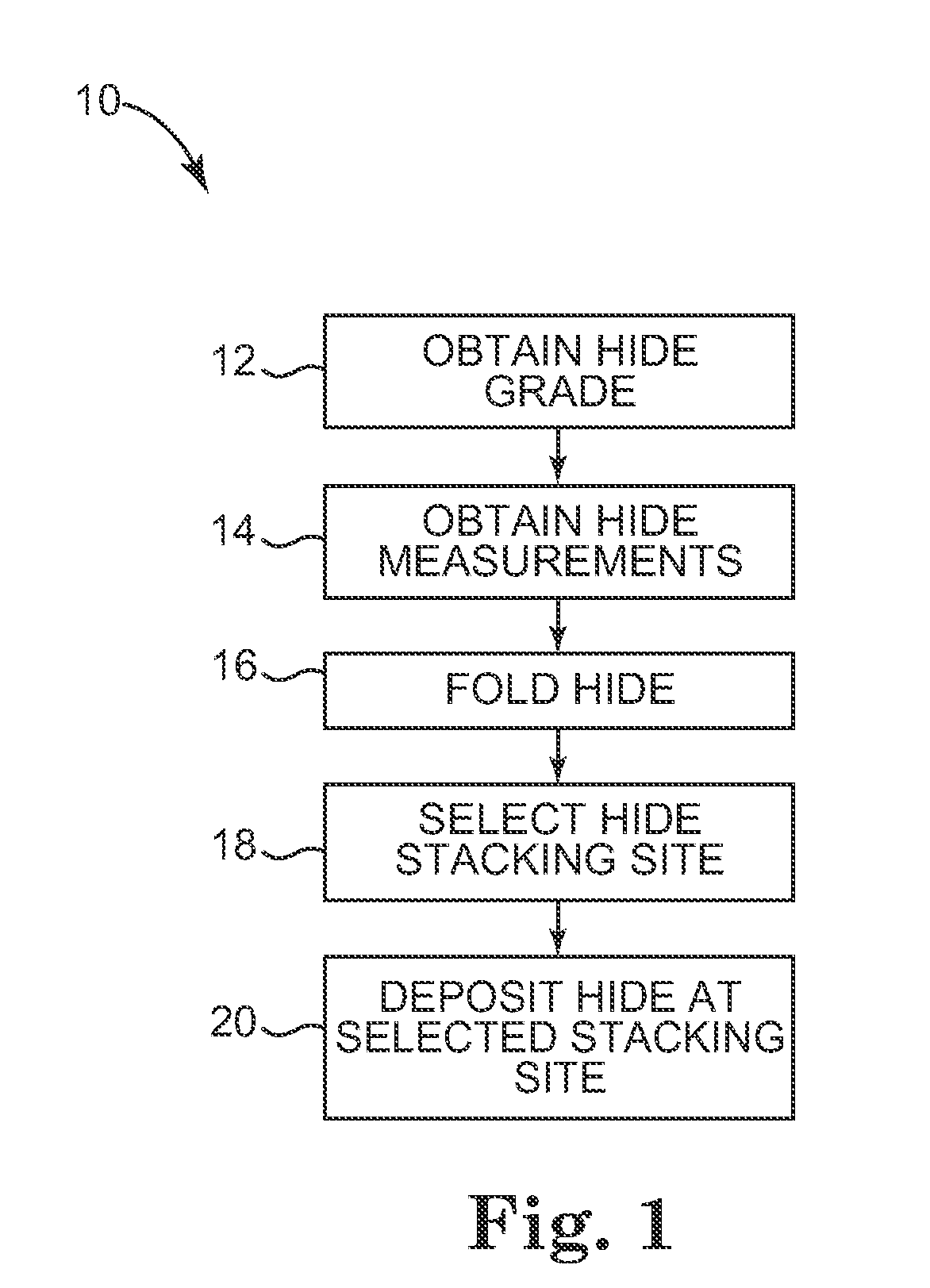

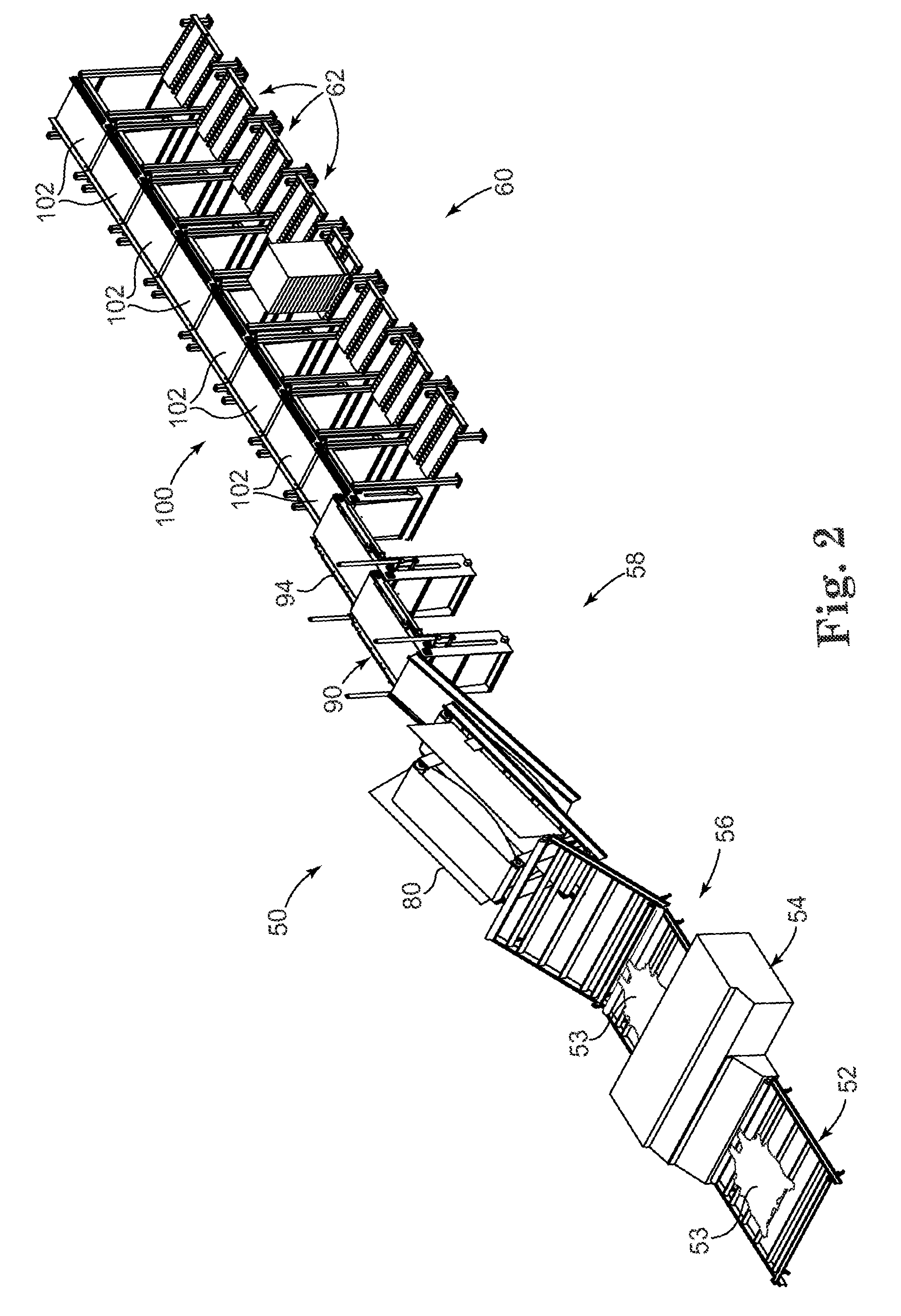

Hide folding system and method

InactiveUS8091390B2Engine sealsSkins/hides/leather/fur manufacturing apparatusControl systemEngineering

The present invention is a method and system for processing animal hides in a meat processing facility. In one embodiment, the system the system includes a grading station for determining hide grades, a measuring station for determining at least one hide dimension of the animal hide, a hide folding station, a stacking station adapted to deposit hides at a plurality of stacking sites, a conveyor system and a control system.

Owner:CARGILL INC

Preparation method for half-vegetable tanning knurled soft leather

ActiveCN103805721AUniform thicknessImprove dyeing uniformityTanning treatmentPre-tanning chemical treatmentMaterials scienceDyeing

The invention relates to a preparation method for leather and provides a preparation method for half-vegetable tanning knurled soft leather which is high in finished leather area yield, uniform in thickness and high in leather production performance. The soft leather prepared by adopting the preparation method disclosed by the invention has natural lines; the loose surface rate is reduced, the using amount of grease is lowered, and the leather production cost can be effectively reduced; the finished leather area yield is increased, and the leather production economical benefit is improved. The preparation method comprises the following technical steps of (1) preparing blue wet leather; (2) treating the blue wet leather; (3) performing preliminary uniform cutting; (4) performing bleaching and preliminary retanning dyeing; (5) performing secondary cutting; (6) performing secondary retanning dyeing; (7) performing aftertreatment.

Owner:XINGYE LEATHER TECH CO LTD

Product line for soft veins of leather

InactiveCN101343673AIncrease production speedSave human effortPre-tanning chemical treatmentLeather softeningVeinProduction line

The invention provides a leather soft rubbing vein production line, which belongs to the technical field of leather post-treatment. The structure of the production line is composed of an unreeling machine, a water tank, a rubbing vein roller, a fan, a heat exchanger, a saddle, a breaking machine frame and a crimping machine, wherein, the leather is positioned into the water tank after being unfolded by the unreeling machine and enters the rubbing vein roller to be treated after being soaked, stoked and dried, when the stoking process is completed, the leather is dried and cooled under the effect of the fan and the heat exchanger, the dried and cooled leather is positioned into the breaking machine frame through the saddle to finish the rag hemming procedure, and finally the furling procedure is finished by the crimping machine. Compared with the prior art, the leather soft rubbing vein production line is suitable for clothing leather, luggage leather, sofa leather, shoe leather and superfiber leather; direct vein rubbing and crimping are implemented from the starting of the unreeling production, the products can be treated without being divided into sections, the finished product ratio and the time efficiency are improved, and both the labor force and the material resource are saved, so economic benefits are brought to enterprises.

Owner:姚凤英

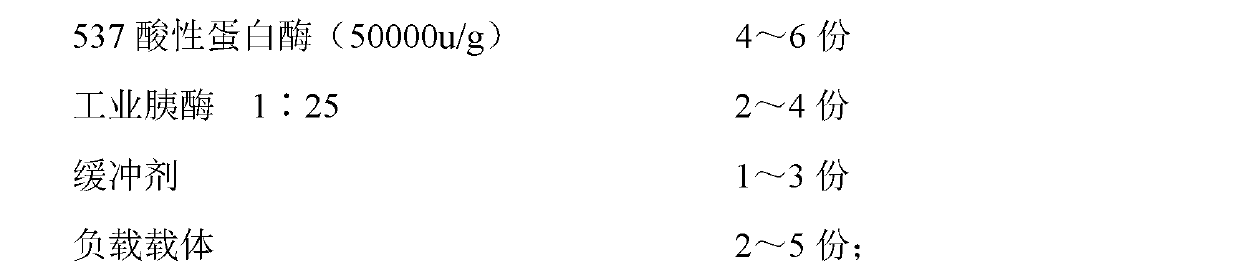

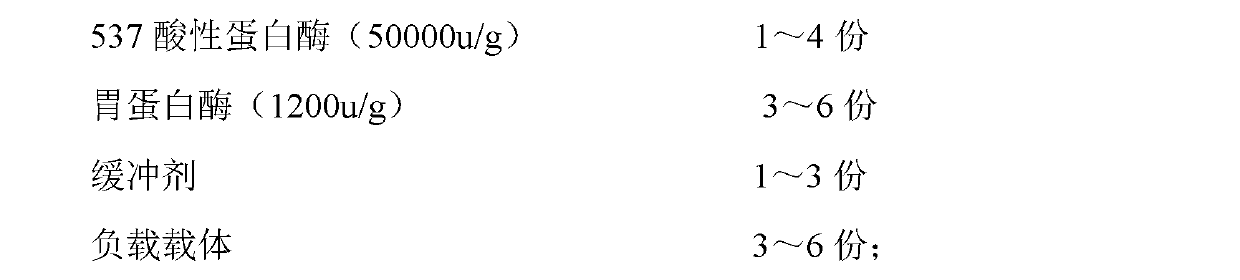

Method for processing sheepskin into fur or leather in multiple steps by using biological enzyme

ActiveCN103276117AReduce dosageLow costTanning treatmentPre-tanning chemical treatmentBiotechnologyBiochemical engineering

The invention discloses a method for performing multiple-step treatment on sheepskin by using biological enzymes, which is characterized in that industrial pancreatic enzymes, composite enzymes TA for acid pickling and softening and composite enzymes TB for acid pickling and softening are respectively used for performing softening treatment on sheepskin in an enzyme softening procedure and an acid pickling procedure; and the treated sheepskin is processed through the conventional process, thereby obtaining the very soft and lightweight sheepskin. Thus, the quality and added values of the sheepskin and products thereof are greatly improved.

Owner:SICHUAN UNIV +1

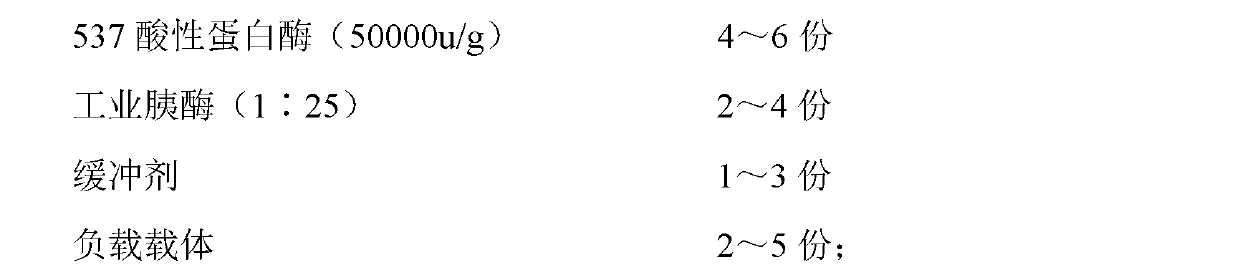

Manufacturing method of bicolor wax-texture crack split leather

ActiveCN107236833AStrong two-color contrast effectImprove performanceLeather/skins/hides/pelt chemical treatment apparatusLeather softeningWaxCrazing

The invention relates to a manufacturing method of bicolor wax-texture crack split leather and belongs to the technical field of leather. The manufacturing method of the bicolor wax-texture crack split leather comprises the following steps that processed and dyed split leather is obtained, dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with oil wax and milled in sequence, and thus the bicolor wax-texture crack split leather is obtained. According to the manufacturing method of the bicolor wax-texture crack split leather, the processed and dyed split leather is dried, ground, milled, sprayed for the first time, roll-finished, sprayed for the second time, vibration-softened, rolled with the oil wax and milled, and the technological conditions of the steps and the chemical therapy ratio are strictly controlled and optimized, so that the low-level split leather is manufactured into the high-level crack leather with the wax texture, and the crack leather further has the strong bicolor contrast effect.

Owner:漳州香洲皮革有限公司

Leather production process

InactiveCN104894299AIncreased durabilityLow costTanning treatmentPre-tanning chemical treatmentFiberEngineering

The invention discloses a leather production process, which comprises the steps of 1) lot grouping: classifying the raw hides of leathers similar in width size and thickness; 2) soaking in water: soaking the raw hides in water after the lot grouping step; 3) unhairing and degreasing: removing grease in hide cells and hairs on the surfaces of the raw hides; 4) liming: adding alkali to expand the hides to a certain thickness for facilitating the splitting operation; 5) deliming and pickling: removing redundant alkali in the raw hides during the liming step; 6) tanning: connecting collagen groups in hide fibers by means of trivalent chromic ions, and enhancing the tensile strength and the anti-tear intensity of the leather; 7) re-tanning: selecting a retanning agent of better in filling effect to retan the tanned leather; 8) dyeing; 9) fatliquoring; 10) drying; 11) staking; 12) finishing; 13) examining and warehousing finished products. The leather production process is simple in operation, and the produced leather is good in durability. Meanwhile, the cost of manufacturers is saved, and the requirements of customers can be met at the same time.

Owner:卢家雄

Manufacturing method of sofa leather

ActiveCN107937632AAchieve preparationEasy to manufactureLeather softeningLeather surface mechanical treatmentKnurlingEngineering

The invention provides a manufacturing method of sofa leather, and solves the technical problems of more complicated steps, need of spending a lot of manufacturing time, complicated manufacturing andthe like in a traditional manufacturing method. The manufacturing method of the sofa leather comprises the following steps: (a) a leather blank is flatly paved on a passing water extruder to for waterextrusion to remove 78-96% of water in the leather blank; (b) the leather blank is dried through a drying device; (c) a repair agent is coated on the leather blank; (d) the leather blank is polishedthrough a leather polishing machine; (e) the leather blank is sized through a roller coating device; (f) paint is sprayed to the leather blank through a spraying device to obtain leather; (g) the leather is embossed or printed by two modes of knurling and plate pressing; (h) fall softening or pull softening is performed by a pull softening machine and a fall softening rotating drum; (i) the leather is ironed through high temperature to obtain finished sofa leather; and (j) the leather is measured, detected and warehoused. The manufacturing method of the sofa leather has the advantage of convenience to manufacture.

Owner:德州兴隆皮革制品有限公司

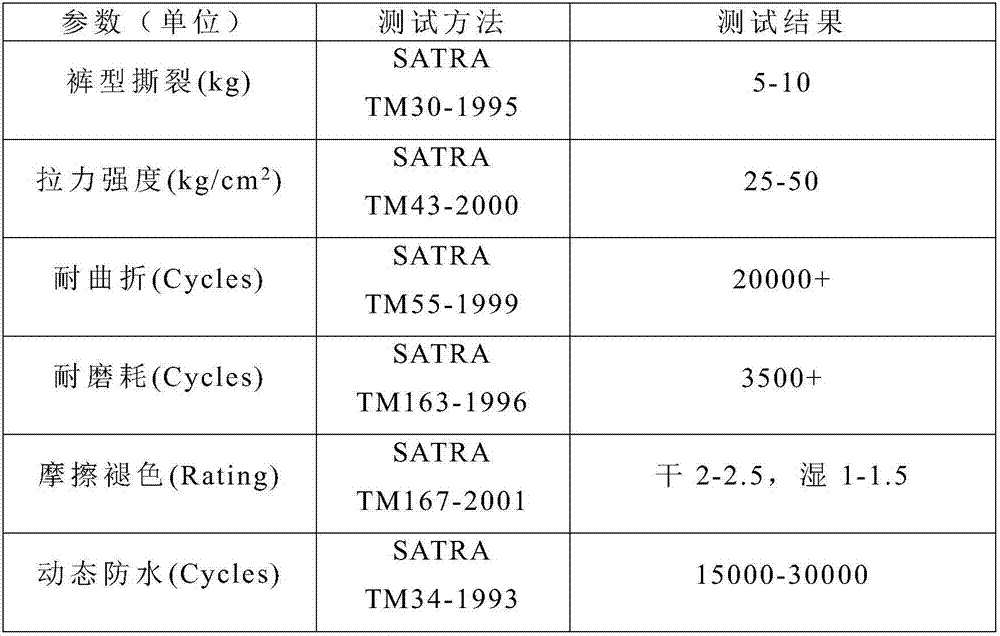

Production technique of xanthochromia-resisting and illumination-resisting two-layer leather

ActiveCN107523655AEnhanced yellowing resistance and light resistanceEasy to stretchTanning treatmentPre-tanning chemical treatmentSofteningXanthochromia

The invention relates to a production technique of xanthochromia-resisting and illumination-resisting two-layer leather, and belongs to the technical field of leather. The production technique of the xanthochromia-resisting and illumination-resisting two-layer leather includes steps of taking two-layered leathers, and orderly performing rewetting, retanning, alkali extraction, neutralizing, dyeing, fat liquoring, fixation, drying, softening, leather grinding, milling to obtain the xanthochromia-resisting and illumination-resisting two-layer leather. The xanthochromia-resisting and illumination-resisting two-layer leather has the advantages of being excellent in stretching performance, good in wear and fading resistance, good in waterproof property, and excellent in xanthochromia resistance and illumination resistance.

Owner:漳州香洲皮革有限公司

Manufacturing technology for waterproof long fur

ActiveCN107217110AEasy to cleanGood flexibilityTanning treatmentPre-tanning chemical treatmentColour fastnessManufacturing technology

The invention relates to a manufacturing technology for waterproof long fur and belongs to the technical field of two-layer leather. The manufacturing technology for the waterproof long fur comprises the following steps of water returning, retanning, basification, neutralization, dyeing, color fixing, waterproofing, washing, drying, softening and milling. According to the manufacturing technology for the waterproof long fur, water returning is conducted on leather, and ammonium sulfate and a degreasing agent are added, so that impurities in the leather are effectively removed, and the cleaning effect on the leather is good; in the subsequent retanning and basification processes, the softness of the leather is effectively strengthened through step-by-step operation, so that the leather surface is plump, the leather surface fiber fineness is enhanced, a full preparation is made for subsequent dyeing, dye completely infiltrates into leather fibers, and the color fastness is high; in addition, a filler is added, so that the bursting force of the leather is strengthened; through subsequent color fixing treatment and waterproofing treatment, the color fastness is effectively strengthened, and the waterproofness is improved; later, the impurities in the color fixing process are effectively removed through washing; and then drying, softening and milling are conducted, so that the softness of the leather is improved.

Owner:漳州香洲皮革有限公司

Production technology of cow rug

InactiveCN103290150AImprove bindingQuality assuranceTanning treatmentPre-tanning chemical treatmentCow dungChemistry

The invention discloses a production technology of a cow rug. The production technology of the cow rug comprises the following steps of: soaking and salt-leaching cow fur after original skin branching, and degreasing once after fleshing mechanically once; pickling, tanning, extracting alkaline, once washing the cow fur after degreasing once, and wringing, thereby obtaining the skin after being wrung; brushing and stuffing, drying, wetting back, staking and fluffing the skin after being wrung, thereby obtaining the cow rug. The production technology of the cow rug provided by the invention pays attention to original skin branching and selection, is suitable for producing skin of the high-grade cow rug, and guarantees the quality of the cow rug; the produced cow rug can be stored, and cannot be damaged by worms due to long-time placing and the like; the cow skin is subjected to degreasing and stuffing treatment pertinently, and oil grease in the fur is removed, and high-permeability stuffing agents are added, so that the flexibility degree of each part of the cow rug is consistent and each part has texture; a method for staking after stuffing is adopted, and the skin thickness difference is reduced.

Owner:伊犁霍尔果斯枣索制革厂 +1

Technology for producing multi-vein-mark low-grade split leather into high-grade wax leather

ActiveCN108977589AFeel goodCover up the traces of bloodLeather softeningLeather surface mechanical treatmentCooking & bakingLower grade

The invention relates to the technical field of leather and in particular relates to a technology for producing multi-vein-mark low-grade split leather into high-grade wax leather. The technology comprises the following steps: putting vein-mark leather subjected to dyeing treatment into a baking oven and baking to obtain dried leather; putting the dried leather into a steel drum, and vibrating andmilling to obtain a milled leather blank; carrying out dull polishing on the milled leather blank for one time by utilizing 180#, 280# and 220# abrasive paper; putting the polished leather blank intothe steel drum; then vibrating and milling again for 1h, and putting into a rolling coating machine; coating wax in a rolling manner; ironing and flattening the rolling-coated leather blank by utilizing an ironing machine; putting the leather blank on a slurry spraying machine; continuously spraying for two times and putting the leather blank into the ironing machine and ironing and flattening again, so as to carry out secondary waxing on the leather blank; putting the leather blank subjected to secondary ironing and flattening into the steel drum and vibrating and milling again, so as to obtain the high-grade wax leather with a vintage feeling. The high-grade wax leather produced by the technology has the advantages of good stretching performance, wearing resistance, no easiness of de-coloring and relatively low cost.

Owner:漳州香洲皮革有限公司

Production method for flex resistant leather

The invention relates to the technical field of leather production, in particular to a production method for crease resistant leather. Soft leather is taken, and the crease resistant leather can be obtained after base coating, tumbling ironing, middle coating, top coating, ironing and drum milling in sequence. In the base coating step, a cationic wax agent and acrylic resin are dissolved in water for spraying treatment; in the tumbling ironing step, a tumbling mill is used for tumbling ironing; in the middle coating step, leather adhesive resin is dissolved in water for spraying treatment; and in the top coating step, acrylic resin ISN, acrylic resin JS, leather cracking resin and leather colorants are dissolved in water for spraying treatment. By the adoption of the production method, the obtained finished leather is resistant to flex and marks are not prone to leave on the leather in the use process of the leather.

Owner:ZHANGZHOU XIANGZHOU LEATHER CO LTD

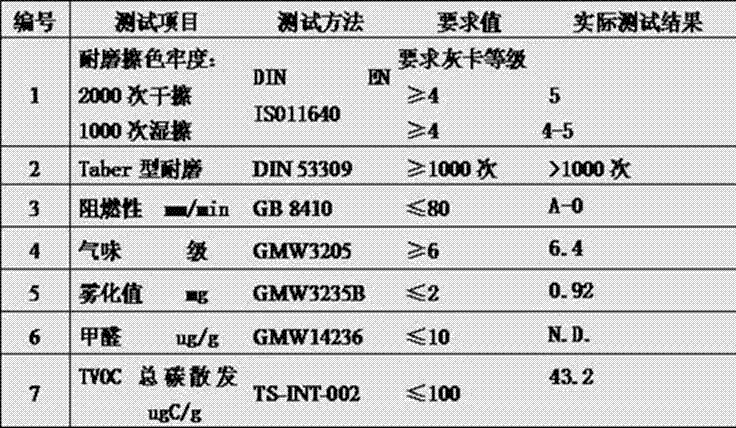

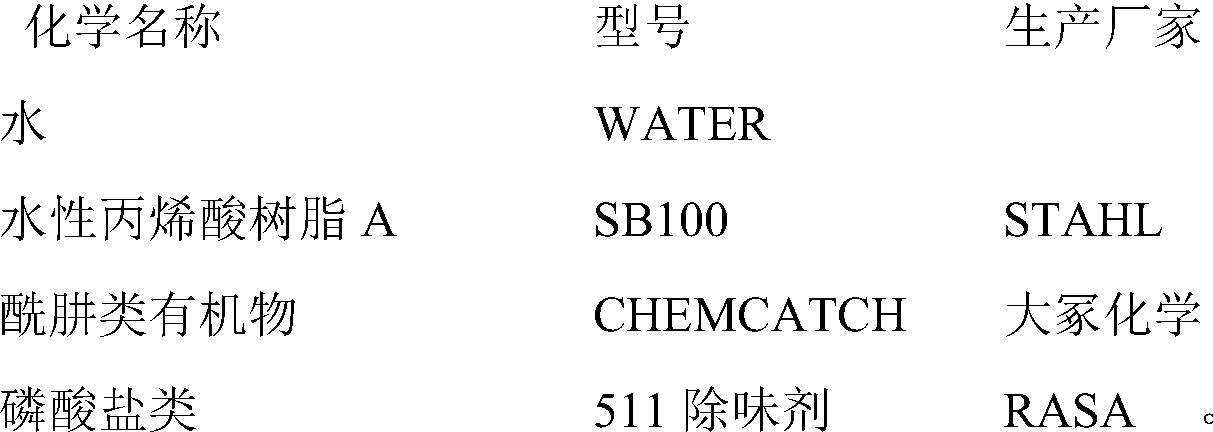

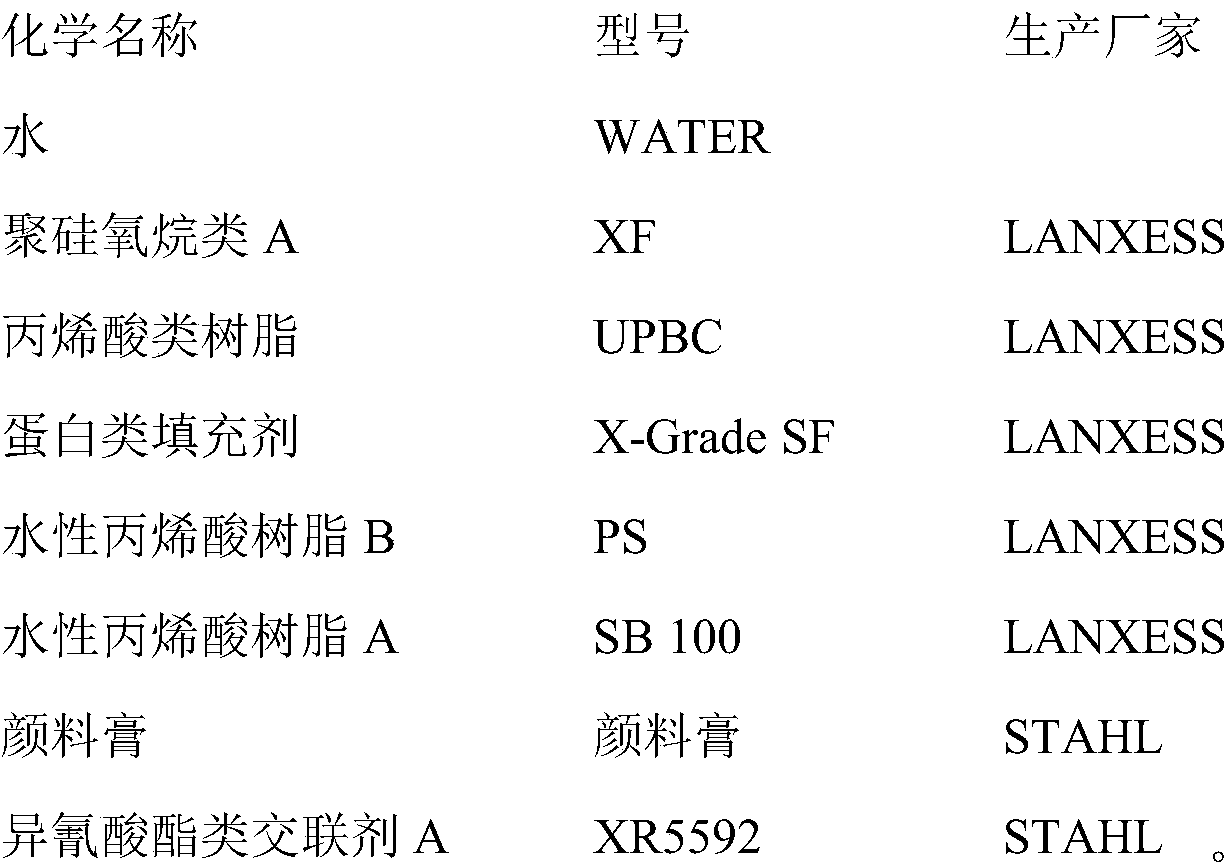

Environmental-friendly ecological vehicle leather process with low total volatile organic compounds (TVOC) and low odor

ActiveCN111500796AReduce bad smellResidue reductionLeather/skins/hides/pelt chemical treatment apparatusLeather softeningSimple Organic CompoundsOrganic solvent

The invention relates to an environmental-friendly ecological vehicle leather process with low total volatile organic compounds (TVOC) and low odor, and belongs to the field of vehicle leather manufacturing. The environmental-friendly ecological vehicle leather process with the low TVOC and low odor is used for processing leather according to the processes such as leather blank sorting, splitting,milling, dedusting, lining-banding, prime coating, hanging and ventilating, embossing, processing a mixing layer, hanging and ventilating, top coating, and hanging and ventilating sequentially, so that the vehicle leather with the low TVOC and low odor is obtained. According to the environmental-friendly ecological vehicle leather process with the low TVOC and low odor provided by the invention,in the formula, a water-based material with the low TVOC for coating is adopted, so that the use of an organic solvent-containing cross-linking agent and an organic solvent-containing resin is avoided; in the coating engineering, the leather is ventilated and hung, so that the volatilization of the volatile organic compounds in the leather is accelerated, a leather TVOC emission test result is remarkably superior to leather produced by a conventional production process, the odor is remarkably improved, the limit value requirements of vehicle main engine plants on the volatile organic compoundsand the odor of a vehicle interior leather material can be met, a riding environment is improved, and the harm on a human body is reduced.

Owner:柏德皮革(中国)有限公司

Production method of solvent resistant leather

InactiveCN105200170AGood solvent resistanceImprove aging resistanceLeather stretching/tensioningLeather softeningPolymer sciencePolymer chemistry

The invention relates to a production method of solvent resistant leather and belongs to the technical field of leather. The production method of the solvent resistant leather comprises steps as follows: a leather crust is prepared and processed sequentially according to steps as follows: softening through vibration, toggling, filling, vacuum pumping, mending, leather buffing, soot blowing, spraying of an adhesive agent, primary roll coating, primary plate pressing, secondary roll coating, secondary plate pressing, spraying, primary spraying of polyurethane gloss oil, tertiary plate pressing, secondary spraying of the polyurethane gloss oil, roll finish and spraying of a feeling agent. The leather produced with the method not only has excellent solvent resistance, but also has good aging resistance.

Owner:FUJIAN JINJIANG ANHAI QIUXIA LEATHER CO LTD

Ecological environment-friendly vegetable tanning yellow cattle upper leather production process

ActiveCN109628659AMeet the requirementsEasy to fixTanning treatmentPre-tanning chemical treatmentCross-linkOrganic solvent

The invention relates to the technical field of leather manufacturing, and provides an ecological environment-friendly vegetable tanning yellow cattle upper leather production process. According to the ecological environment-friendly vegetable tanning yellow cattle upper leather production process, an organic pre-tanning agent is used for pretreating softened leather, the tanning agent based on avegetable tanning agent is used for tanning, wherein the vegetable tanning agent is mainly a condensed vegetable tanning agent, and then an aldehyde tanning agent is combined for retanning; the vegetable tanning agent, collagen, the aldehyde tanning agent can form cross-linking to produce a vegetable-aldehyde synergistic tanning effect, the fixation effect of the vegetable tanning agent is improved to improve the absorptivity of the vegetable tanning agent, the washing resistance, organic agent resistance performance and shrinkage temperature of the obtained green leather are improved, and thedistribution of vegetable tanning agent on each layer of green leather is more uniform; and the green leather has fine grain size, good compactness, good softness, good fullness and good elasticity,and accords with the characteristics of upper leather products.

Owner:XINGYE LEATHER TECH CO LTD

Hide folding system and method

InactiveUS20100058818A1Engine sealsSkins/hides/leather/fur manufacturing apparatusControl systemEngineering

The present invention is a method and system for processing animal hides in a meat processing facility. In one embodiment, the system the system includes a grading station for determining hide grades, a measuring station for determining at least one hide dimension of the animal hide, a hide folding station, a stacking station adapted to deposit hides at a plurality of stacking sites, a conveyor system and a control system.

Owner:CARGILL INC

Preparation process for sofa leather

InactiveCN108265128AWon't spoilAvoid damageTanning treatmentPre-tanning chemical treatmentHair removalEnzyme inhibitor

The invention discloses a preparation process for sofa leather. According to the preparation process, a series of processes of curing, soaking, fleshing, degreasing, depilating, tanning, acid-alkali treatment, extrusion flattening, drying and milling, dyeing, coating and embossing are adopted, so that fur is made into a sofa leather body; curing of the fur is used for killing microorganisms and bacteria on the surface of the fur, so that the fur is guaranteed to be prevented from going bad in the processing process; soaking of the fur is used for enabling the fur to regain water lost in the curing process; a hair removal enzyme inhibitor is utilized to prevent the hair removal enzyme from damaging a fur body during the hair removal process; the substance state of the sofa leather is adjusted by means of acid-alkali treatment, so that the sofa leather is better colored; and the preparation process has the advantages that the process is strictly controlled, industrial production can be realized, the fur is guaranteed to be prevented from going bad in the fur processing process, resource waste is avoided, cost is saved, preparation time of the sofa leather is shortened, and the factory income is improved.

Owner:ZHEJIANG HUAXIANG LEATHER

Planar waxy split leather and manufacturing method thereof

ActiveCN107287363ASmooth leatherStrong waxy feelingLeather softeningLeather surface mechanical treatmentColour fastnessWax

The invention relates to a kind of planar waxy split leather and a manufacturing method thereof and belongs to the technical field of leathers. The manufacturing method of the planar waxy split leather comprises the following steps of selecting a split leather subjected to processing and dyeing treatment, conducting primary drying, vibration softening, primary leather buffing, roll coating, primary knurling, secondary leather buffing, water wax spraying, secondary drying, water wax rolling, tertiary drying, dye spraying and secondary knurling, and then obtaining the planar waxy split leather. The planar waxy split leather has good color fastness good water repellency and wet-dry friction resistance and is soft in hand feel and free of oily feel.

Owner:漳州香洲皮革有限公司

Blood-vein-exposure-proof double-layer suede and manufacturing method thereof

ActiveCN108251579AImprove permeabilityGood dispersionTanning treatmentPre-tanning chemical treatmentSolubilityVein

The invention relates to blood-vein-exposure-proof double-layer suede and a manufacturing method thereof and belongs to the technical field of leather manufacturing. The manufacturing method of the vein-exposure-proof double-layer suede comprises the following steps: rewetting; retanning; neutralizing; filling; dyeing; grease feeding; acid immobilizing; drying; hanging and airing; softening in a vibrating way; leather grinding; and milling. According to the manufacturing method provided by the invention, a manufacturing technique and used chemical materials are improved so that the phenomenonof exposure of blood veins at the bottom surface of the leather is effectively prevented, and the leather yield is increased. Meanwhile, liquid chemical materials used in all steps are relatively goodin water solubility and good in environmental friendliness; and the manufacturing method provided by the invention is mild in condition, convenient to operate and suitable for being popularized and applied to the field of leather manufacturing.

Owner:漳州香洲皮革有限公司

Tan sheep fur tanning treatment process

InactiveCN105441598AReduce softeningShorten the timeTanning treatmentPre-tanning chemical treatmentMechanical equipmentSubcutaneous tissue

The invention discloses a tan sheep fur tanning treatment process, comprising branching, cleaning, fur soaking, fleshing, enzyme dipping, secondary fleshing, acid dipping and enzyme softening, aldehyde tanning, neutralizing, airing, dry shoveling, fur grinding and toggling molding; during fur soaking, mixed liquid of formaldehyde and water is used for soaking furs; the weight ratio of water to formaldehyde is 580-650: 1; in the enzyme dipping process, the weight ratio of water to water dipping enzyme is 1800-2200: 1; after tan sheep furs are neutralized, the airing is performed; the dry shoveling and the bur grinding are performed for the tan sheep furs by mechanical equipment; and the toggling molding is performed after dry grinding and fur grinding. Tan sheep bur boards tanned by the process are still soft, are bright in color, and are free of influencing the hair dying. The subcutaneous tissues of tan sheep furs are further destroyed through two times of fleshing to create conditions for subsequent enzyme softening and neutralizing process; and the process makes up the hair removing phenomenon caused by cancel of nitre dipping, shortens the tanning period, and achieves the purposes of energy conservation and consumption reduction.

Owner:QINGTONGXIA LINSHENG FUR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com