Production technology of cow rug

A production process and fur technology, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, leather impregnation, etc., can solve uneven thickness, inconsistent softness, Moth-eaten and other problems, to achieve the effect of storage resistance, consistent coat density, and reduce thickness difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Separation of raw hides: separate the raw hides according to different origin areas, and distinguish the required origin hides again: select salted cow fur with coat color, beautiful pattern, complete coat and firmly combined with the skin plate;

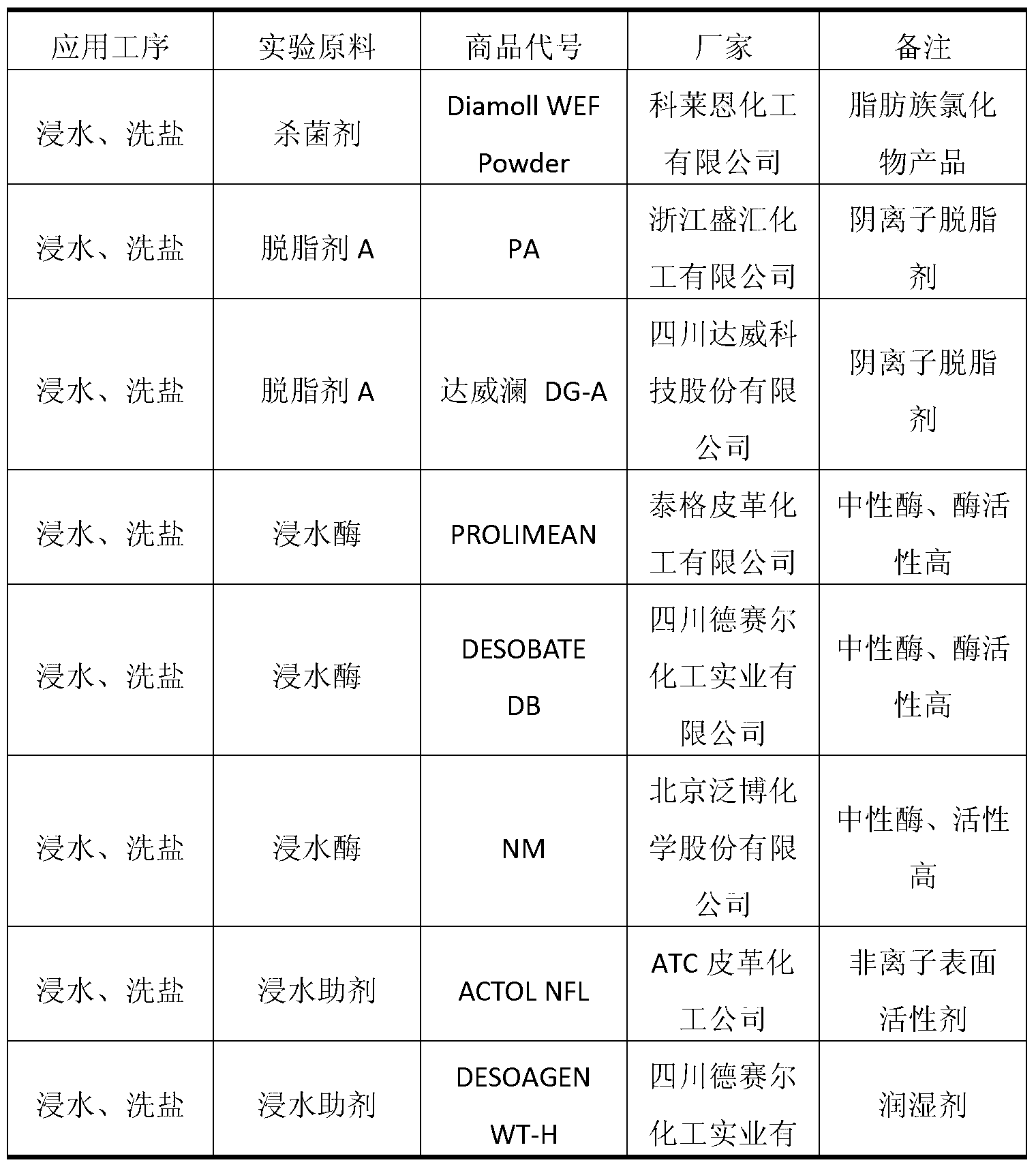

[0027] 2) Soaking in water and salt washing: Put the cow fur selected by the raw hide branch into the soaking liquid at 25°C, first soak it for 2 hours, then rotate it for 15 minutes every hour, and rotate it intermittently for 16 hours; among them, the soaking liquid is made of fungicides and degreasing agents. A. Composition of water-soaking enzyme, water-soaking aid and water, wherein the concentration of fungicide is 0.3g / L, the concentration of degreasing agent A is 0.5g / L, the concentration of water-soaking enzyme is 0.2g / L, and the concentration of water-soaking aid is 2.5g / L L; the mass ratio of water and cow fur in the soaking liquid is 10:1;

[0028] 3) One-time mechanical de-fleshing: the cow fur soaked in water...

Embodiment 2

[0050] 1) Separation of raw hides: separate the raw hides according to different origin areas, and distinguish the required origin hides again: select salted cow fur with coat color, beautiful pattern, complete coat and firmly combined with the skin plate;

[0051] 2) Soaking in water and salt washing: Put the cow fur selected by the raw hide branch into the immersion liquid at 25°C, soak it statically for 2 hours, then rotate it for 15 minutes every hour, and rotate it intermittently for 18 hours; among them, the immersion liquid is composed of fungicides and degreasing agents A. Consists of immersion enzyme, immersion aid and water, wherein the concentration of bactericide is 0.2g / L, the concentration of degreasing agent A is 0.2g / L, the concentration of immersion enzyme is 0.3g / L, and the concentration of immersion aid is 4g / L ; The mass ratio of water and cow fur in the soaking liquid is 10:1;

[0052] 3) One-time mechanical de-fleshing: the cow fur soaked in water and was...

Embodiment 3

[0074] A production process for a cow fur carpet, comprising the following steps:

[0075] 1) Separation of raw hides: separate the raw hides according to different origin areas, and distinguish the required origin hides again: select salted cow fur with coat color, beautiful pattern, complete coat and firmly combined with the skin plate;

[0076] 2) Soaking in water and salt washing: Put the cow fur selected by the raw hide branch into the immersion liquid at 30°C, soak it statically for 1.5 hours, then rotate it for 15 minutes every hour, and rotate it intermittently for 10 hours; among them, the immersion liquid is composed of fungicides and degreasing agents A. Composed of water-soaking enzyme, water-soaking aid and water, wherein the concentration of fungicide is 0.3g / L, the concentration of degreasing agent A is 1.0g / L, the concentration of water-soaking enzyme is 0.1g / L, and the concentration of water-soaking aid is 2g / L ; The mass ratio of water and cow fur in the soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com