A kind of preparation method of quartz glass

A technology of quartz glass and quartz body, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of high energy consumption, low purity and uniformity of quartz glass, prolonging the production cycle, etc., and achieve simple preparation process , increase the preparation cost, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of quartz glass provided by the invention comprises the following steps:

[0030] Pre-deposition: The quartz particles are heated and melted at an ambient temperature between 1500°C and 1800°C, sprayed on the substrate and completely melted to form a transparent quartz glass base layer.

[0031] Preferably, the ambient temperature is between 1550°C and 1700°C; the feed rate is lower than 100g / min, more preferably between 8g / min and 40g / min by means of rotary spraying; the height of the transparent quartz glass base layer is above 10mm , preferably more than 15mm.

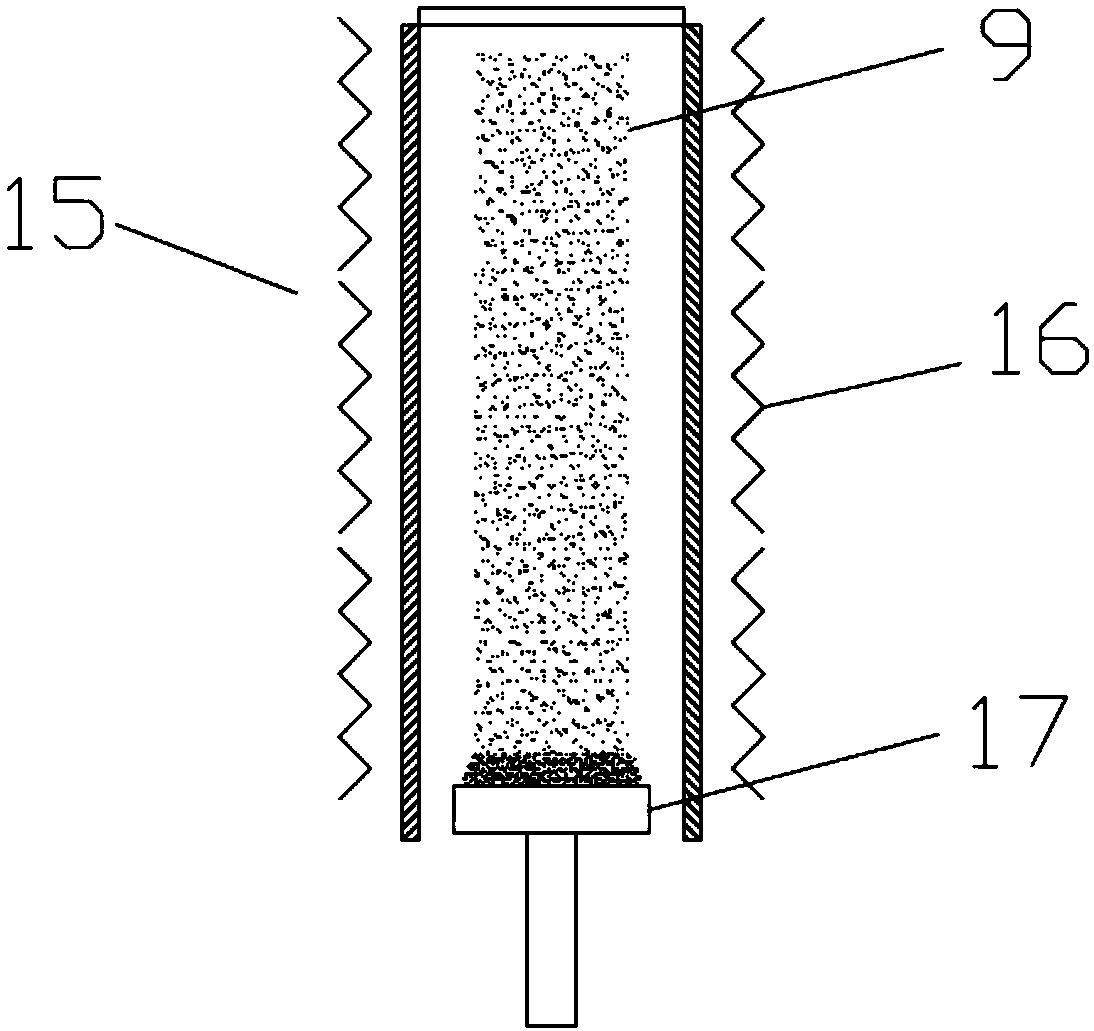

[0032] (a) heating the quartz particles to partially melt to form a porous quartz body; specifically:

[0033] The quartz particles are heated by a hydrogen-oxygen flame until they are partially melted, and then sprayed on the substrate to form a porous quartz body.

[0034] Preferably, spraying is applied on a pre-deposited transparent quartz glass substrate, and the substrate can mo...

Embodiment 1

[0046] A method for preparing quartz glass, comprising the steps of:

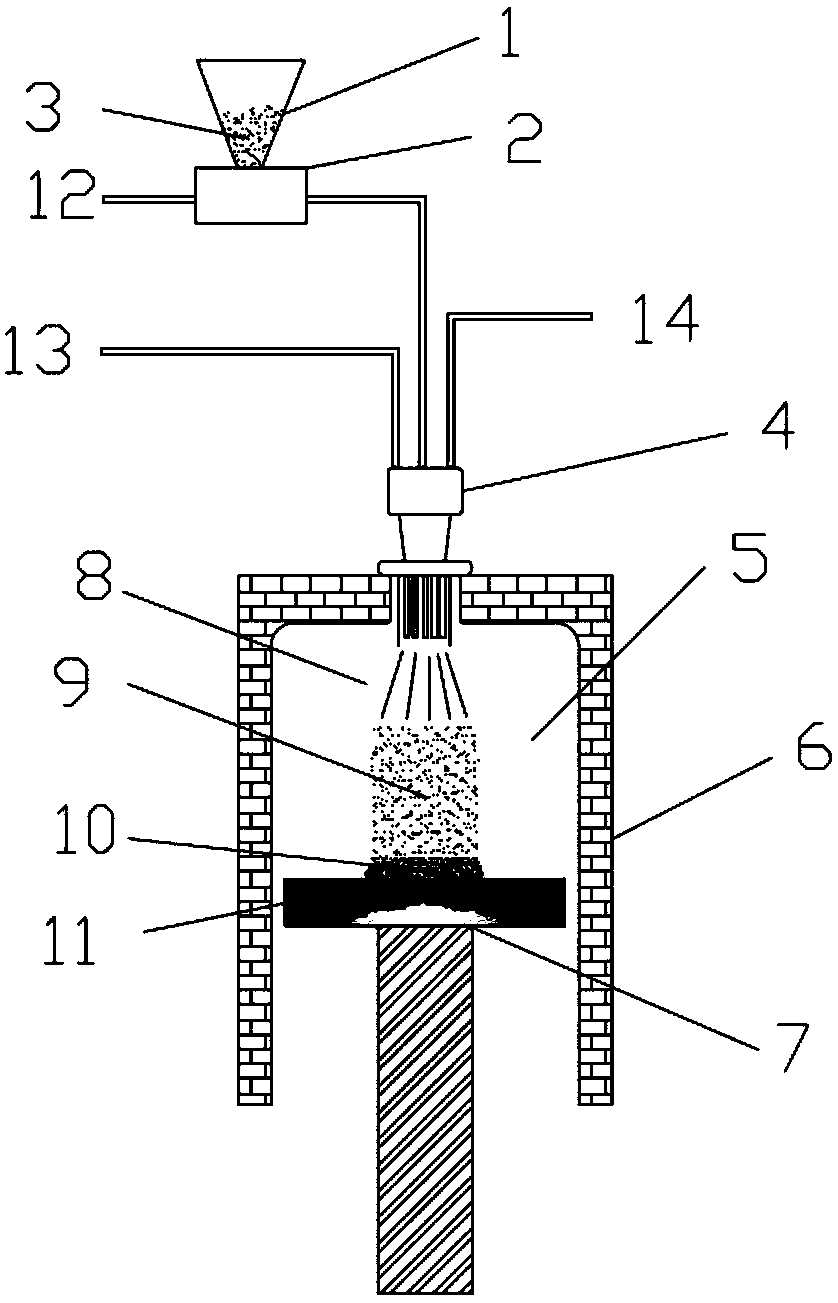

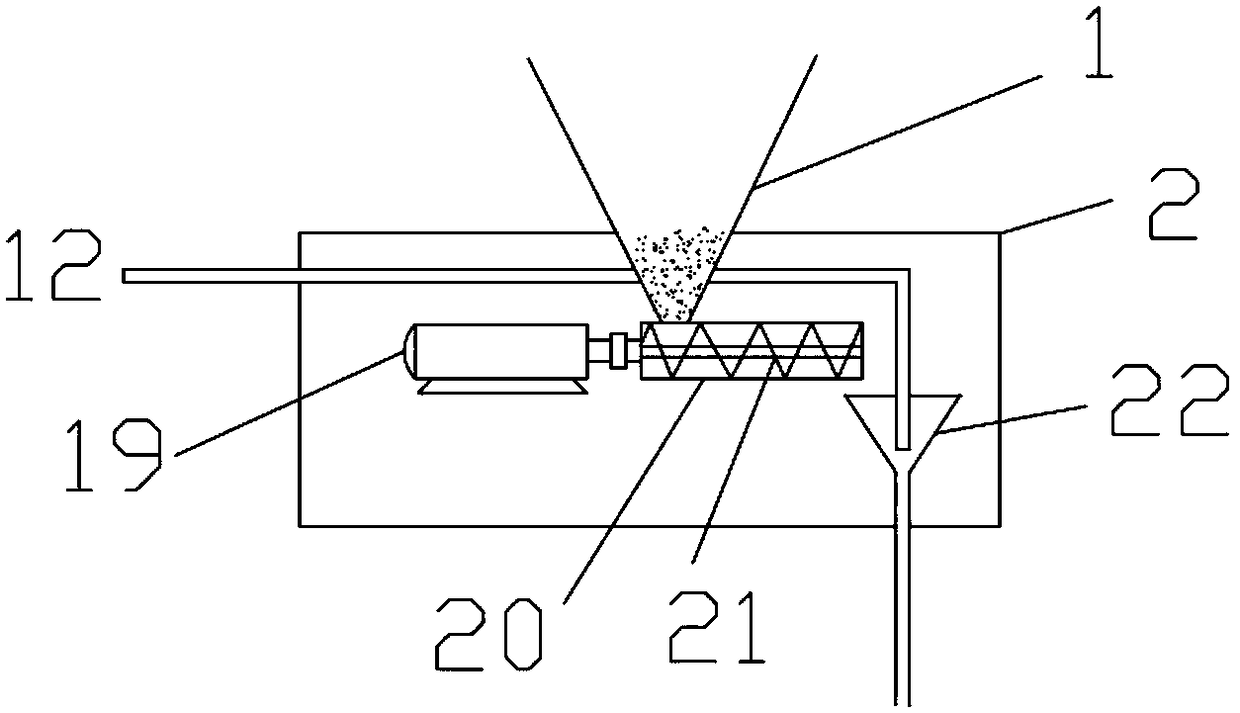

[0047] Pre-deposition: as figure 1 As shown, the blowtorch (4) is connected to H at the same time 2 pipe(13) and O 2 Pipeline (14), hydrogen and oxygen are ignited to form hydrogen-oxygen flame (8), and the theoretical reaction ratio of hydrogen and oxygen is 2:1. In the present invention, in order to ensure the full combustion of hydrogen, the ratio of hydrogen to oxygen is controlled at 1.0:1~1.8 : 1, so that the oxygen is relatively excessive. Place the blowtorch in the furnace chamber (5), the blowtorch is located on the central axis of the furnace chamber, and the flame is downward to heat the furnace chamber. When the temperature of the furnace chamber reaches above 1500°C, adjust the gas supply speed to stabilize the temperature of the furnace chamber . The furnace chamber is maintained between 1500°C and 1800°C, more preferably between 1550°C and 1700°C. Inert gases such as nitrogen can be intr...

Embodiment 2

[0062] Pre-deposition: as figure 1 As shown, the quartz sand with an average particle size of 120 μm is loaded into the hopper, and a slight sinusoidal vibration is applied to the hopper for use. Introduce hydrogen and oxygen into the blowtorch successively to ignite to form a hydrogen-oxygen flame. The flow rate of hydrogen is 55L / min, and the flow rate of oxygen is 40L / min. Heat the furnace to 1700°C, open the carrier gas valve and pass into the blowtorch, and the carrier gas is hydrogen. , the flow rate is 7L / min, after the airflow is stable, open the feeder, adjust the rotation speed of the feeding screw, control the feeding speed at 45g / min, and open the rotating bracket at a speed of 18rpm / min, the quartz sand is gradually deposited on the substrate and form transparent quartz glass under the high temperature of the flame. After 15 minutes, a 12mm thick quartz base layer is formed on the substrate.

[0063] (a) heating the quartz particles to partially melt to form a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com