Plate material, solid wood composite floor base material and column material made from branch materials and round rod materials, and manufacturing method

A technology of round rods and plates, applied in the joints of wooden veneers, building materials, columns, etc., to achieve the effects of saving wood resources, overcoming easy deformation, and increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A kind of embodiment of the sheet material that is made with round mandrel stock of the present invention:

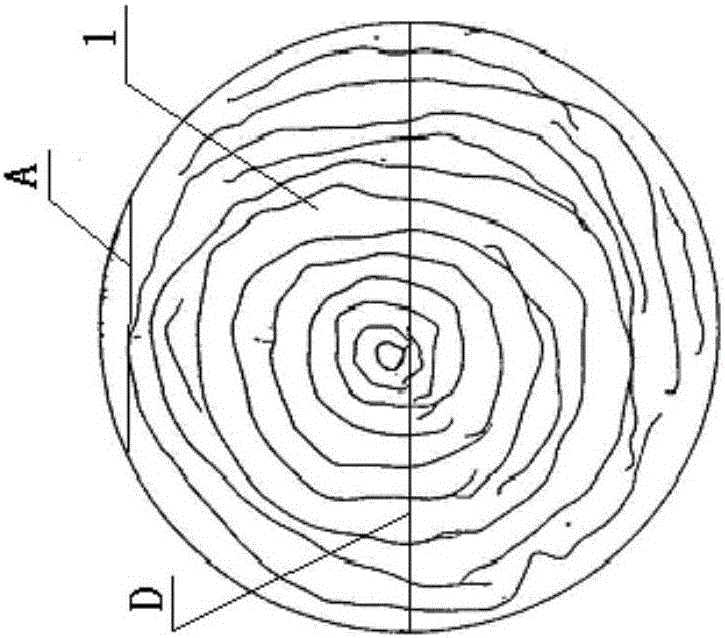

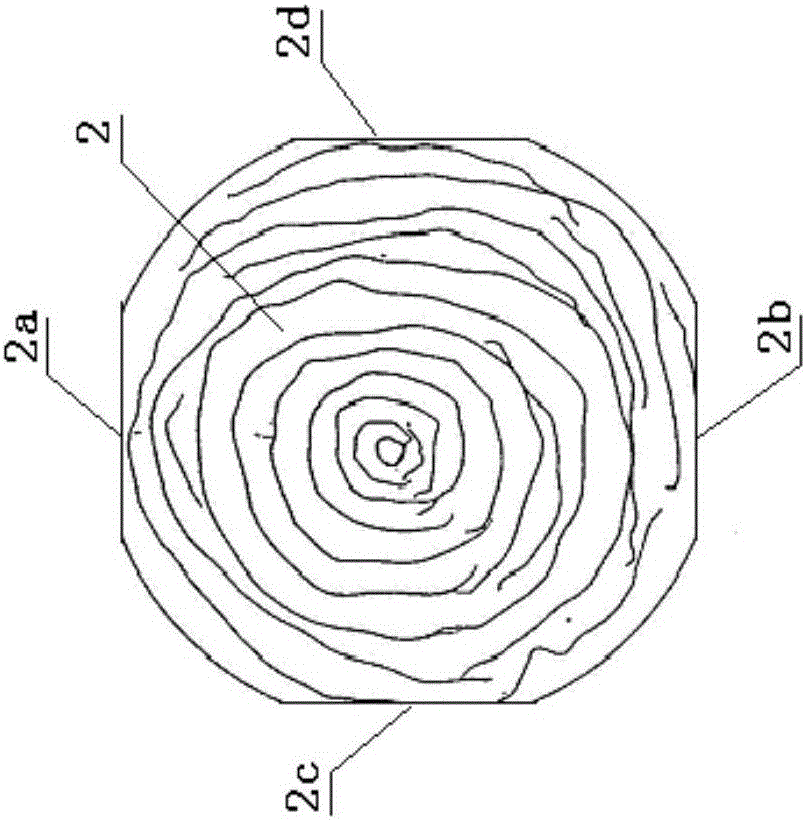

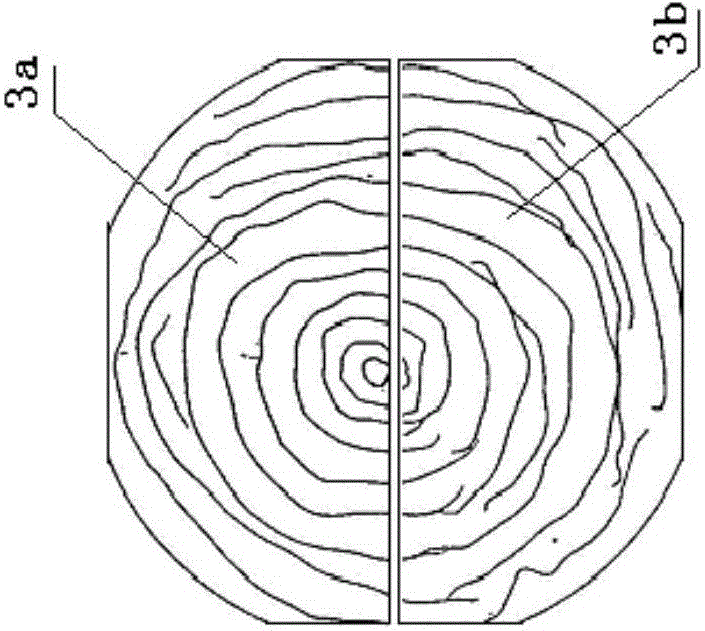

[0045] The board is the core material of splicing, and the core material is spliced by half square round wooden strips. Such as figure 1 , figure 2 , image 3 Shown: the described semi-circular wooden bar is to cut the four sides of the circular bar 1 into the string surface, and the circular bar 2 is a circular arc between the adjacent string surfaces, such as figure 2 Shown 2a, 2b, 2c, 2d are four string surfaces. The square and round bar 2 is longitudinally sawed into two symmetrical halves through the central axis and a chord plane midline, and becomes two semi-square and round wooden bars 3a, 3b with the same cross-section. The width of the cut chord surface, that is, the chord length A is one-third to five-ninth of the diameter D of the circular bar, such as figure 1 .

[0046] Such as Figure 5 As shown; a plurality of semicircular wooden strips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com