Dual aluminum film composite embossing flame retardant curtain fabric and manufacturing method thereof

A double-aluminum film and curtain technology, applied in the field of curtain fabrics, can solve problems such as poor flame retardancy, poor UV resistance, firefighting, escape, and lifesaving difficulties, and achieve high-efficiency flame retardancy and smoke suppression, uniform internal stress, The effect of the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

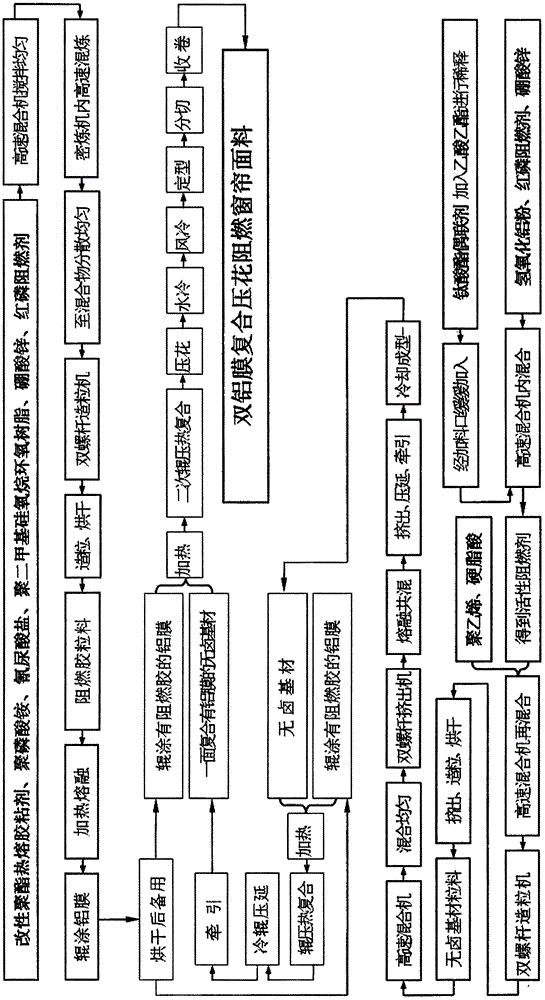

[0027] see figure 2 , the preparation method of the double-aluminum film composite embossed flame-retardant curtain fabric, comprising the following steps:

[0028] (1) Weigh aluminum hydroxide powder, red phosphorus flame retardant and zinc borate according to the above parts by weight, add them to a high-speed mixer and mix together; weigh titanate coupling agent, add ethyl acetate in proportion to dilute for 2 minutes , slowly enter the high-speed mixer from the feeding port, together with aluminum hydroxide powder, red phosphorus flame retardant, and zinc borate, mix for 15 to 25 minutes, and perform activation treatment to form a mixed activated flame retardant; then proportionally Add polyethylene and stearic acid, and mix in a high-speed mixer for 5-8 minutes, and after discharging, add it to a twin-screw granulator to extrude, granulate, and dry to make halogen-free base material pellets; then add In another high-speed mixer, pre-mix at 60-70°C, after mixing evenly, ...

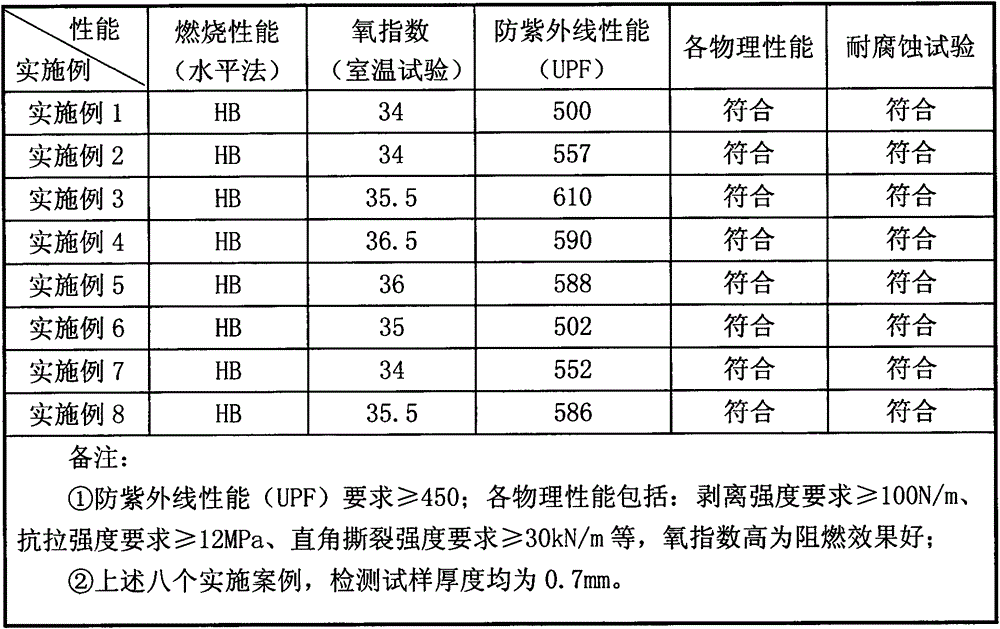

Embodiment 1

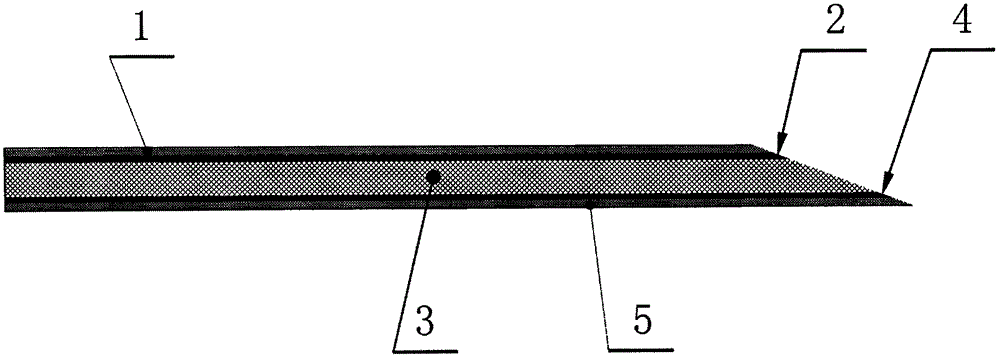

[0035] In an embodiment of the present invention, a double-aluminum film composite embossed flame-retardant curtain fabric is made of five layers of aluminum film, flame-retardant glue, halogen-free substrate, flame-retardant glue, and aluminum film.

[0036] The said halogen-free substrate, raw materials by weight are 55 parts of aluminum hydroxide powder, 1.2 parts of red phosphorus flame retardant, 25 parts of polyethylene, 1.1 parts of stearic acid, 0.4 part of ethyl acetate, titanate diacetate It consists of 0.7 part of joint agent and 0.5 part of zinc borate.

[0037] Described flame-retardant glue, all by weight raw material is made of 60 parts of modified polyester hot-melt adhesives, 15 parts of ammonium polyphosphate, 5 parts of cyanurate, 10 parts of polydimethylsiloxane epoxy resins, Composed of 1 part of zinc borate and 1.2 parts of red phosphorus flame retardant.

[0038] The preparation method of the double-aluminum film composite embossed flame-retardant curta...

Embodiment 2

[0045] In an embodiment of the present invention, a double-aluminum film composite embossed flame-retardant curtain fabric is made of five layers of aluminum film, flame-retardant glue, halogen-free substrate, flame-retardant glue, and aluminum film.

[0046] The said halogen-free substrate, raw materials by weight are 57 parts of aluminum hydroxide powder, 1.0 parts of red phosphorus flame retardant, 27 parts of polyethylene, 1.2 parts of stearic acid, 0.3 parts of ethyl acetate, titanate diacetate It consists of 0.7 part of joint agent and 0.4 part of zinc borate.

[0047] Described flame-retardant glue, all raw materials by weight are by modified polyester hot-melt adhesive 70 parts, ammonium polyphosphate 10 parts, cyanurate 10 parts, polydimethylsiloxane epoxy resin 5 parts, Composed of 1.5 parts of zinc borate and 0.8 parts of red phosphorus flame retardant.

[0048] According to the preparation method described in Example 1, a double-aluminum film composite embossed fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com