Display front housing and manufacturing method thereof

A display and front cover technology, applied to the front cover of a flat panel display and its manufacturing field, can solve the problems of low product qualification rate, weak firmness, many molding defects, etc., and achieve safe and reliable connection, low investment cost, and uniform internal stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

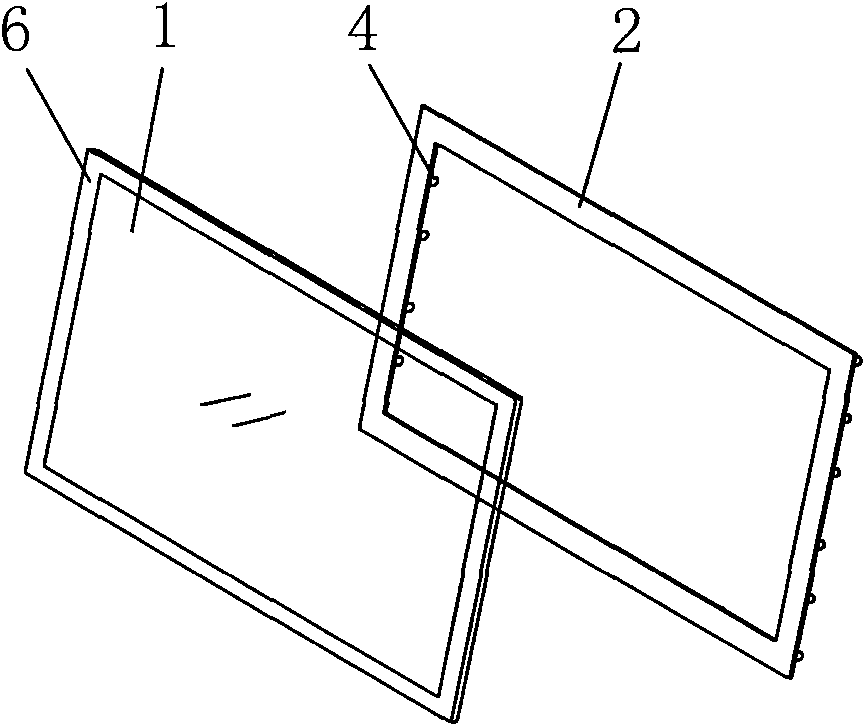

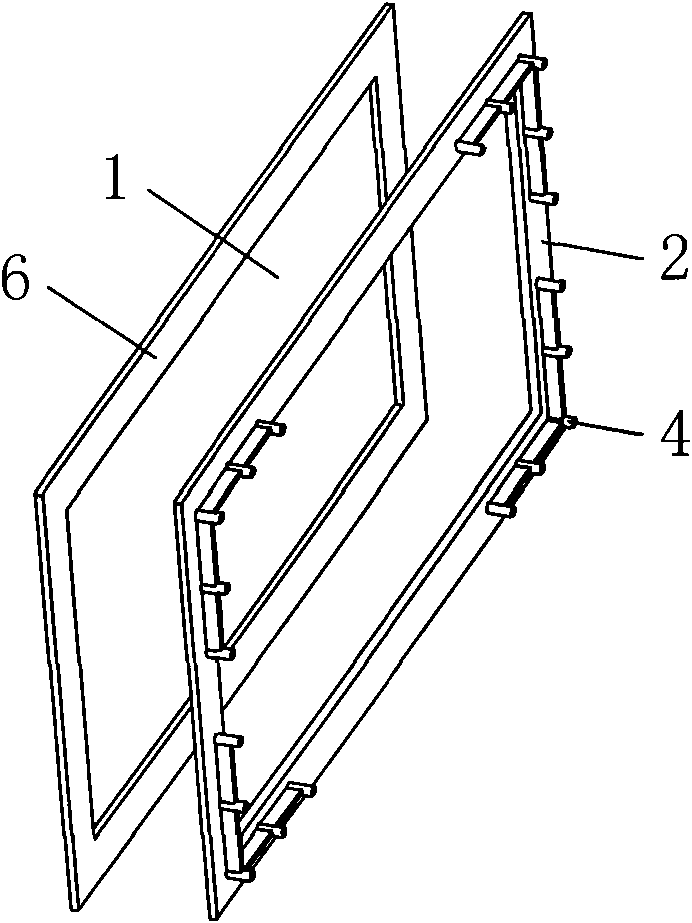

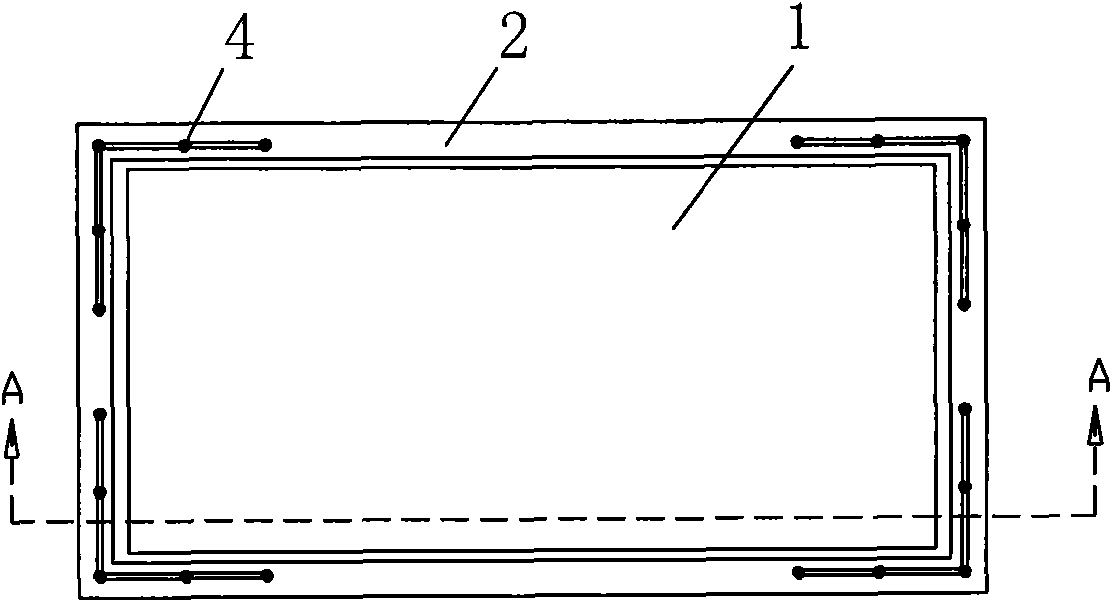

[0023] see figure 1 , 2 , 3. The front case of the display according to the present invention includes: an extruded panel 1 , a decorative layer 6 printed on one side of the panel 1 around the edge, and a side frame 2 .

[0024] The surface frame 2 is injection molded and connected to the surrounding edges of the side of the panel 1 , forming a space for placing a display screen in the middle area of the side of the panel 1 , and the decorative layer 6 is just located between the surface frame 2 and the joint surface of the panel 1 . The front frame is provided with a connecting column 4 for fixing the display screen and connecting other required screws such as the back cover.

[0025] The decorative layer 6 includes several layer groups stacked one after the other, and each layer group includes an ink layer and a high-temperature adhesive layer.

[0026] There are three kinds of structures for the injection molding connecting part of the panel 1 and the surface frame 2. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com