Method for producing hard wood composite floor

A technology of solid wood composite flooring and boards, applied in the direction of chemical instruments and methods, layered products, wood layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. First, pre-press the substrate:

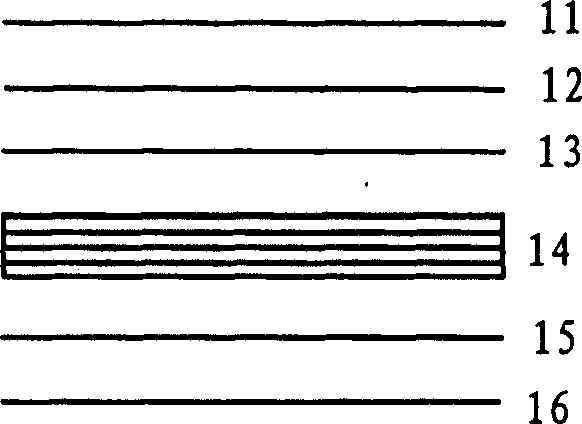

[0023] The base material of this embodiment adopts 11.6mm five-layer whole meranti multi-layer plywood, and the base plate is sent into a hot press to be hot-pressed at a temperature of 175 degrees Celsius and a pressure of 25 MPa for 35 seconds. After pressing, the warpage of the plate 1220mm×2440mm is 4%, and the thickness tolerance is ±0.5mm.

[0024] 2. Second, perform sanding treatment:

[0025] Cool the pre-pressed plate for 15 minutes and then put it into the sander, and use the 180-mesh abrasive belt to sand the plate to determine the thickness, and the sanding amount is 0.30mm. Then select the side with better quality of the plate as the decorative surface, sand the surface of the plate twice with a 300-mesh abrasive belt, and the sanding amount is 0.10mm, so that the warpage of the plate is less than 1.5%, and the thickness tolerance is ±0.2mm within.

[0026] 3. Third, carry out the decorative layer finish:

[0027] Sa...

Embodiment 2

[0037] 1. First, pre-press the substrate:

[0038] What the base material of present embodiment adopts is the composite board of the medium density fiberboard (MDF) of 6mm five-layer whole poplar wood multi-layer plate that is pressed and glued up and down respectively, and total thickness is 12mm. The temperature and the pressure of 20MPa are hot pressed, and the time is 45 seconds. After pressing, the warpage of the plate 1220mm×2440mm is 4%, and the thickness tolerance is ±0.6mm.

[0039] 2. Sanding treatment:

[0040] Cool the pre-pressed board for 15 minutes and send it to the sander. Select the side with better quality as the decorative surface, and sand the surface of the board twice with a 300-mesh abrasive belt, and the sanding amount is 0.40mm , so that the thickness tolerance of the plate is within ±0.2mm.

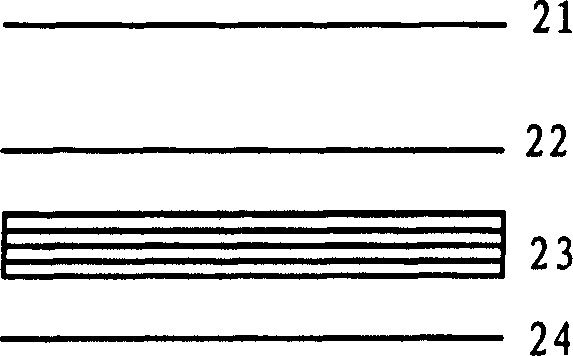

[0041] 3. Press and paste the protective layer of the facing:

[0042] The sanded panels were treated with figure 2 The structure shown, that is, 30 grams o...

Embodiment 3

[0048] 1. Substrate pre-pressing treatment:

[0049] The base material used is 11.6mm seven-layer poplar wood-mixed wood multi-layer plywood, and the base plate is sent into a hot press at a temperature of 130 degrees Celsius and a pressure of 15 MPa for 40 seconds. After the plate is cooled for 30 minutes, it is sent into the hot press again to press at a temperature of 185 degrees Celsius and a pressure of 24 MPa for 30 seconds.

[0050] 2. Sanding treatment:

[0051] Cool the pre-pressed plate for 15 minutes and send it to the sander, and sand the plate with a 200-mesh abrasive belt to determine the thickness of the plate, and the sanding amount is 0.40mm. Then select the side with better quality of the plate as the decorative surface, sand the surface of the plate twice with a 300-mesh abrasive belt, and the sanding amount is 0.10mm, so that the thickness tolerance of the plate is within ±0.2mm.

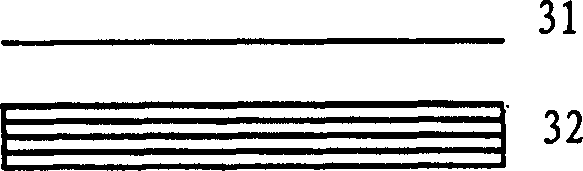

[0052] 3. Decorative layer finish:

[0053] The sanded panels were treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com