Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Uniform coating on the surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photo-cured medical catheter hydrophilic lubrication coating and preparation method thereof

ActiveCN109966560AReduce harmImprove adhesionPharmaceutical delivery mechanismPretreated surfacesPolyesterPolymer science

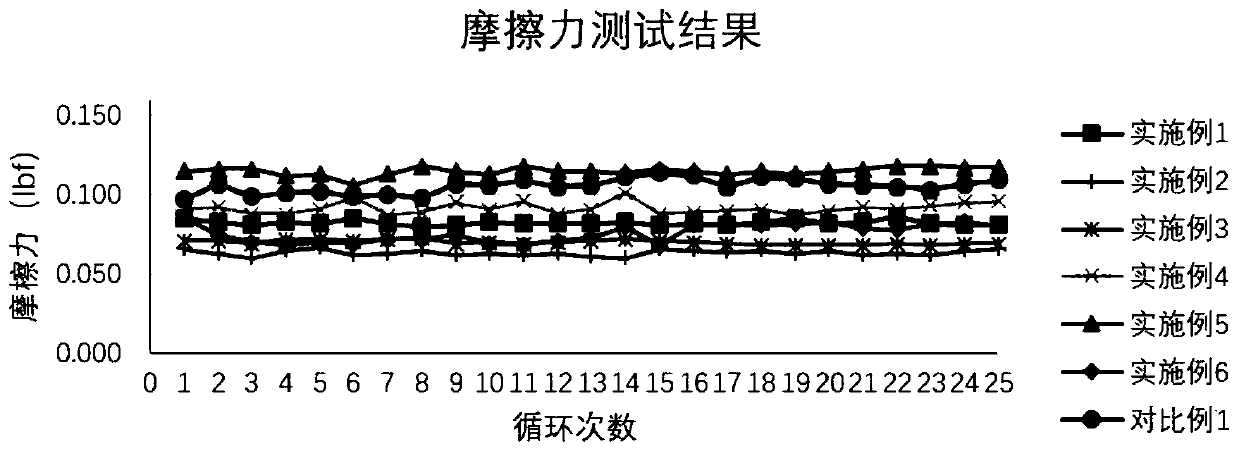

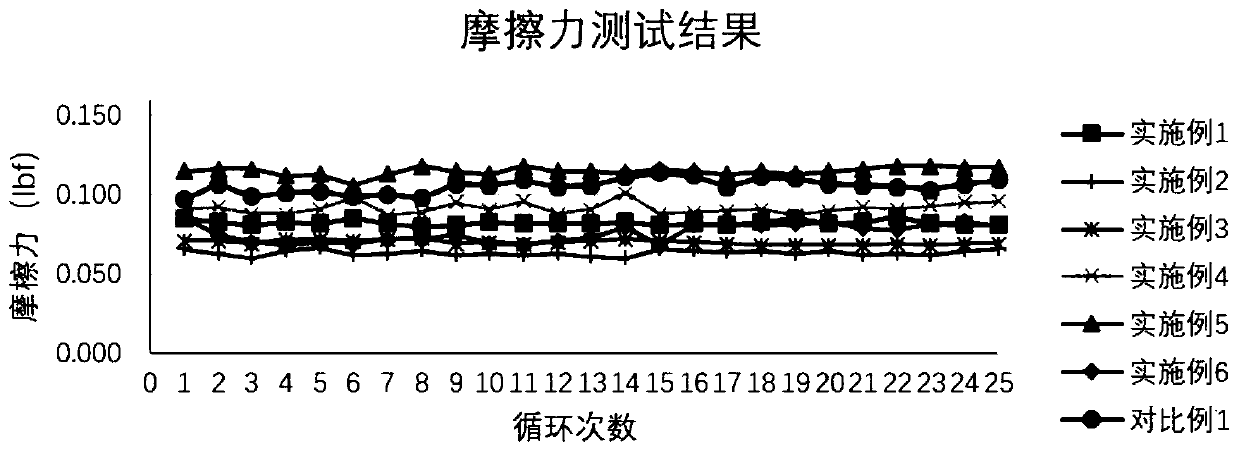

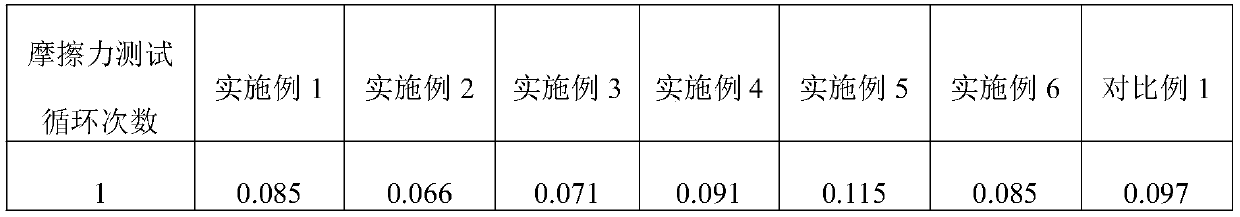

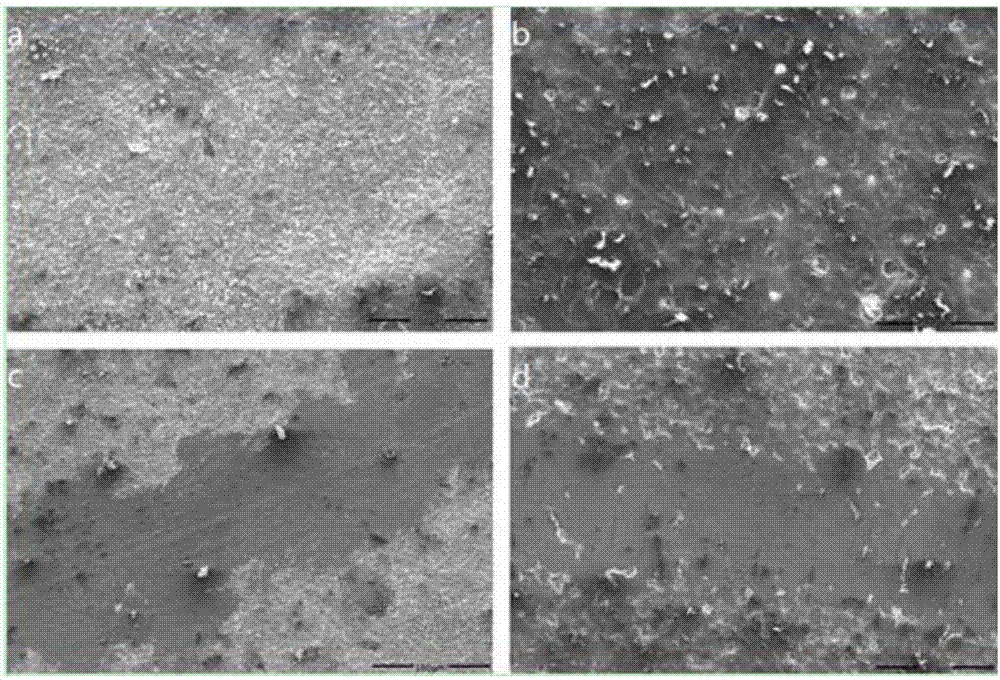

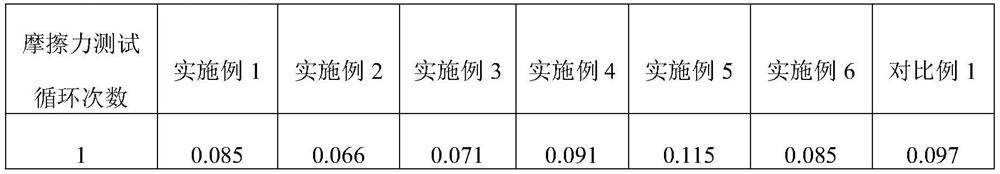

The invention discloses a photo-cured medical catheter hydrophilic lubrication coating and a preparation method thereof. The hydrophilic lubrication coating comprises a bottom coating and a lubrication coating, wherein the bottom coating is attached to the surface of an instrument, and the lubrication coating is attached to the bottom coating. The bottom coating comprises 1-10 parts of polyester acrylate, 50-90 parts of solvents, 0.5-5 parts of photoinitiators, 0.5-2 parts of wetting agents and 0.5-5 parts of reactive diluents; the lubrication coating comprises 1-10 parts of water soluble macromolecules, 1-5 parts of crosslinking macromolecules, 0-1 part of photoinitiators, 0.1-1 part of surfactants and 50-98 parts of mixed solvents. The preparation method of the hydrophilic lubrication coating is simple and easy in operation, substance residues caused by complicated high-temperature chemical reaction are avoided, the cured coating forms a crosslinking structure, has good adhesion on the surface of a medical catheter and has excellent and lasting lubricity in an aqueous medium, the friction coefficient of the surface of the medical catheter is reduced, and harm to human tissues andadhesion of macromolecules in blood are decreased.

Owner:ORBUSNEICH MEDICAL SHENZHEN CO LTD

Self-lubricating wear-resistant compound coating on surfaces of titanium and titanium alloy and preparation method thereof

InactiveCN107281544AHigh bonding strengthReduce wearSurface reaction electrolytic coatingPretreated surfacesPlasma electrolytic oxidationDoped graphene

The invention discloses a self-lubricating wear-resistant compound coating on surfaces of titanium and titanium alloy and a preparation method thereof. The compound coating comprises a surface of a titanium and titanium alloy substrate, an oxidized ceramic coating and a self-lubricating coating which are successively connected. The titanium and titanium alloy substrate has a textured surface pre-treated by a Nd:YAG pulse laser puncher, the oxidized ceramic coating is a hard oxidized ceramic coating generated by means of plasma electrolytic oxidation, and the self-lubricating coating is an ultra high molecular weight polyethylene coating doped with graphene. By adding graphene into the ultra high molecular weight polyethylene coating to form a laminar compound structure, the surface wettability of the coating is improved, the frictional coefficient and the wear rate of the coating are reduced, and the frictional property of the surface of the coating is improved. According to the invention, the wear-resistant compound coating which is high in hardness and low in frictional coefficient and the wear rate can be prepared on the surface of the titanium and titanium alloy, and the coating is level, smooth and compact in surface and has good wear-resistant and corrosion-resistant properties.

Owner:NANJING UNIV OF SCI & TECH

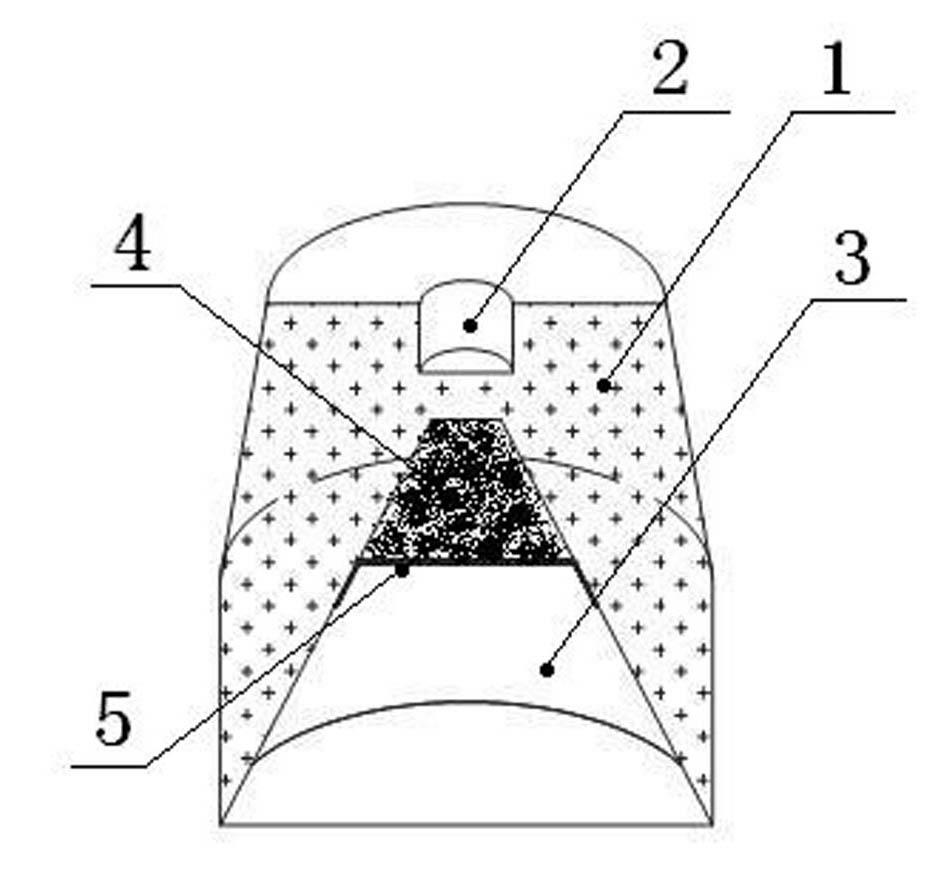

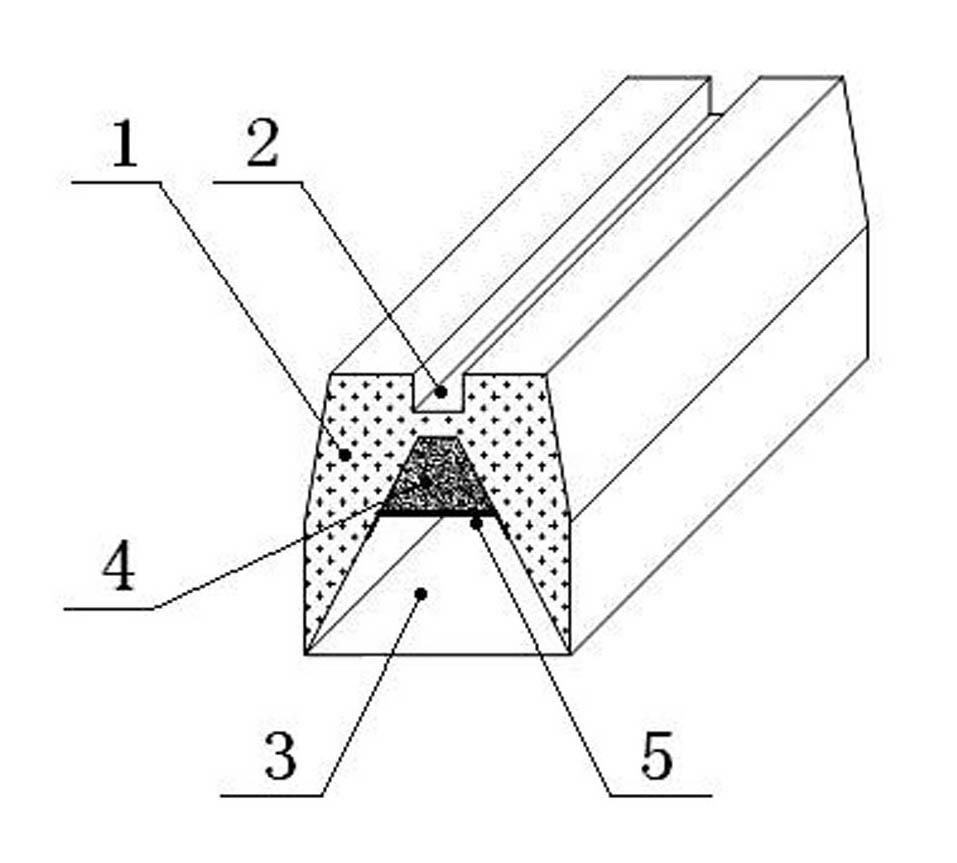

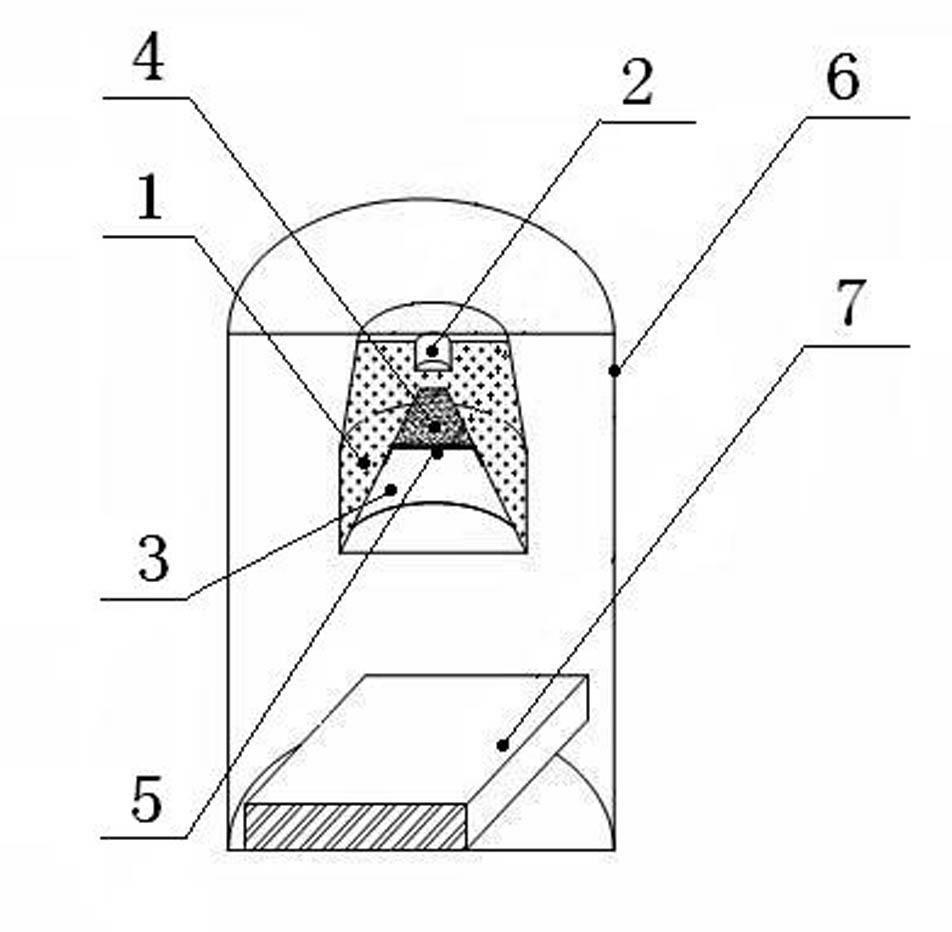

New technology for preparing hard wear resistant coating through shaped charge detonation gun spraying

The invention relates to a new technology for preparing a hard wear resistant coating through shaped charge detonation gun spraying and solves the defects of the conventional shaped charge detonation gun spraying technology that the workpiece to be sprayed is easy to have pits, the coating is uneven and the spraying area is small. The technology comprises the following steps: pressing shaped charge of which the density is 1.3-1.6g / cm<3> and the energy focusing cave cone angle is 40-60 degrees, then filling the WC-Co mixed powder of which the mass is 10-30% of the shaped charge and the density is 2-3g / cm<3> in the top of the energy focusing cave, fixing with a film, then arranging the shaped charge 200-400mm above the workpiece, covering a protective cover filled with inert gas outside the shaped charge and workpiece, and finally detonating the shaped charge to complete the spraying of the workpiece. The coating sprayed by the technology has the advantages of uniform surface, large area, low porosity, hardness, wear resistance and the like. In addition, the technology is simple, does not require large operation equipment and is suitable for industrialized spraying production.

Owner:ZHONGBEI UNIV

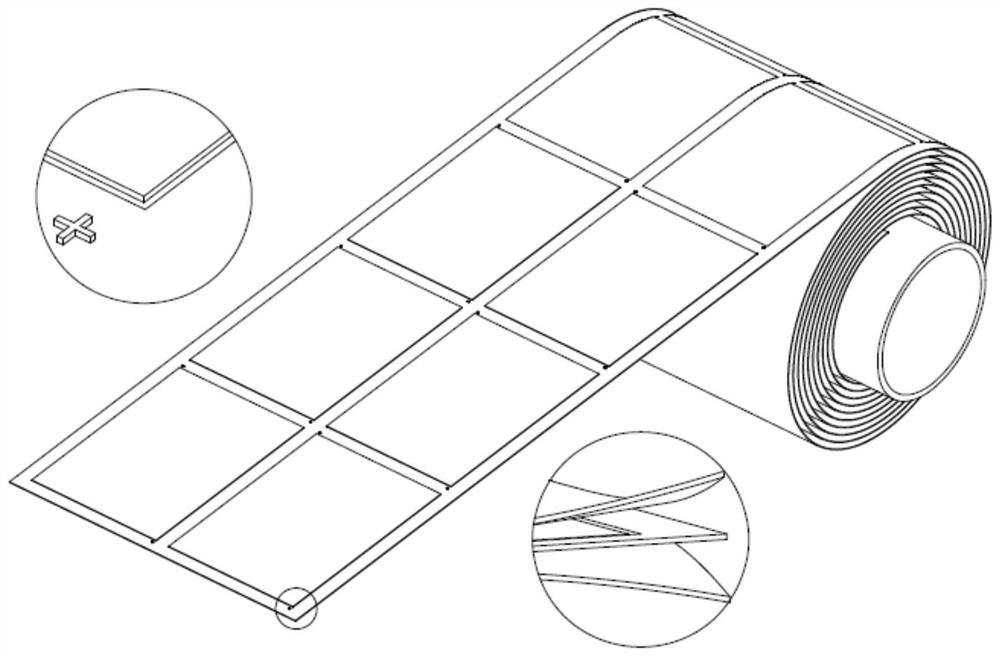

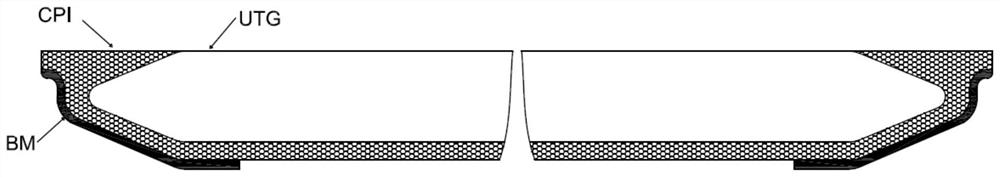

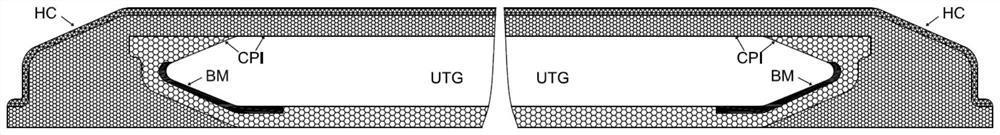

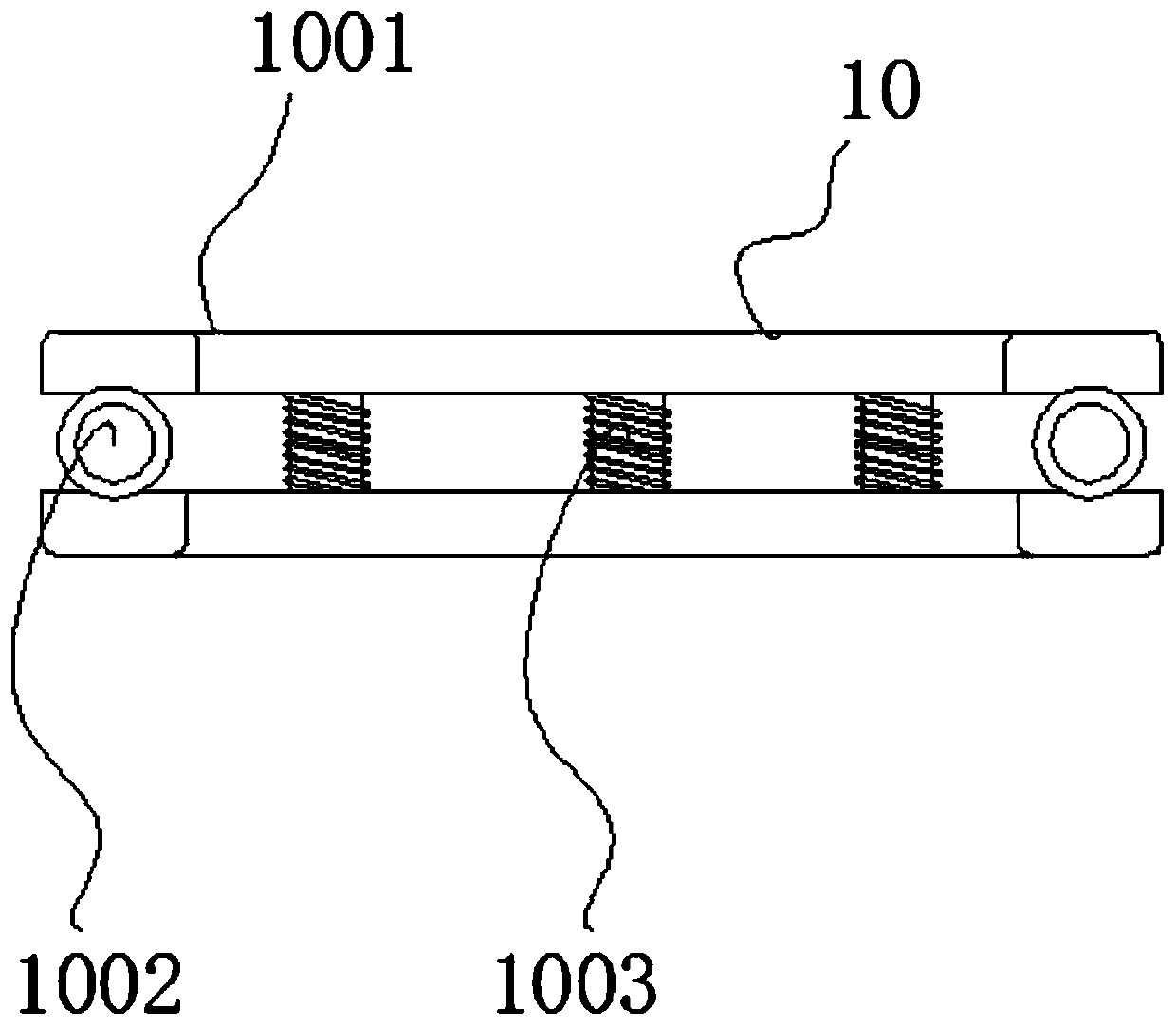

Ultrathin glass-organic film composite cover plate based on roll-to-roll process and manufacturing method thereof

ActiveCN112248581ASolve the problem of stiffnessUniform coating on the surfaceLamination ancillary operationsSynthetic resin layered productsOrganic filmLaser cutting

The invention discloses an ultrathin glass-organic film composite cover plate based on a roll-to-roll process and a manufacturing method thereof, the composite cover plate comprises ultrathin glass, afirst organic film layer at least formed on the surface of one side of the ultrathin glass and a black pattern layer located on the surface of the first organic film layer or below the first organicfilm layer, and the composite cover plate is manufactured by adopting the roll-to-roll process. According to the manufacturing method, the UTG stiffness problem is solved by attaching the UTG to the surface of the support, and meanwhile, the support can also be used as a part of a product protective film so that the manufacturing process can be reduced, and the cost can be saved; the thickness balance dielectric layer is increased around the UTG, and the UTG is subjected to surface treatment so that the surface energy of the UTG and the surface energy of the balance dielectric layer are unified, and it is ensured that a whole surface coating film of the UTG is uniform and consistent; a side coating is naturally wrapped so that the influence of UTG side microcracks is weakened, and the product performance is improved; laser cutting ensures that the edge of a product is tidy, the defects of residual films, burrs and the like are avoided, and compared with a piece-to-piece mode, the roll-to-roll manufacturing mode is large in productivity and high in benefit.

Owner:CHENGDU TOMI SHUANG DU OPTOELECTRONICS CO LTD

Antistatic thermal control coating composition, preparation method and applications thereof

ActiveCN104774510AGood heat control effectEasy constructionElectrically-conductive paintsOmegaThermal control

The invention discloses an antistatic thermal control coating composition, a preparation method and applications thereof. The coating composition comprises priming paint and finish paint. The priming paint is composed of a matrix namely organic fluorine resin and a filling material namely modified zinc oxide powder; wherein the zinc oxide is capable of forming vertical channels in the priming paint layer. The finish paint is composed of a matrix namely methyl silicone resin with multiple functional groups and a filling material namely modified zinc oxide powder; wherein part of the filling material penetrates the interface between the priming paint layer and the finish paint layer. The prepared antistatic thermal control coating has a white color, a thickness of 130 to 200 [mu]m, a solar absorption ratio of 0.20 to 0.25, a hemispherical emissivity of 0.85 to 0.91, a total mass loss (TML) not more than 1%, collectable volatile condensed mass (CVCM) not more than 0.1%, and a volume resistivity ([rho]v) not more than 107 [omega].m. The coating does not have the phenomenon of cracking, peeling, bubbling, and fading after 100 times of high-low temperature thermal cycle experiments in a temperature range of -100 to 100 DEG C, the optical properties of the coating is stable, and the adhesive force of the coating is high.

Owner:SHANGHAI INST OF SATELLITE EQUIP

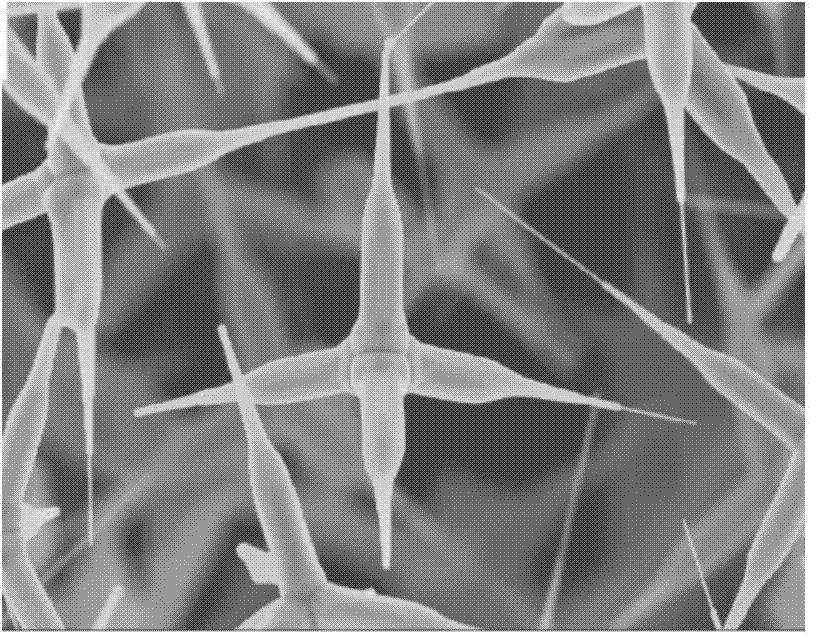

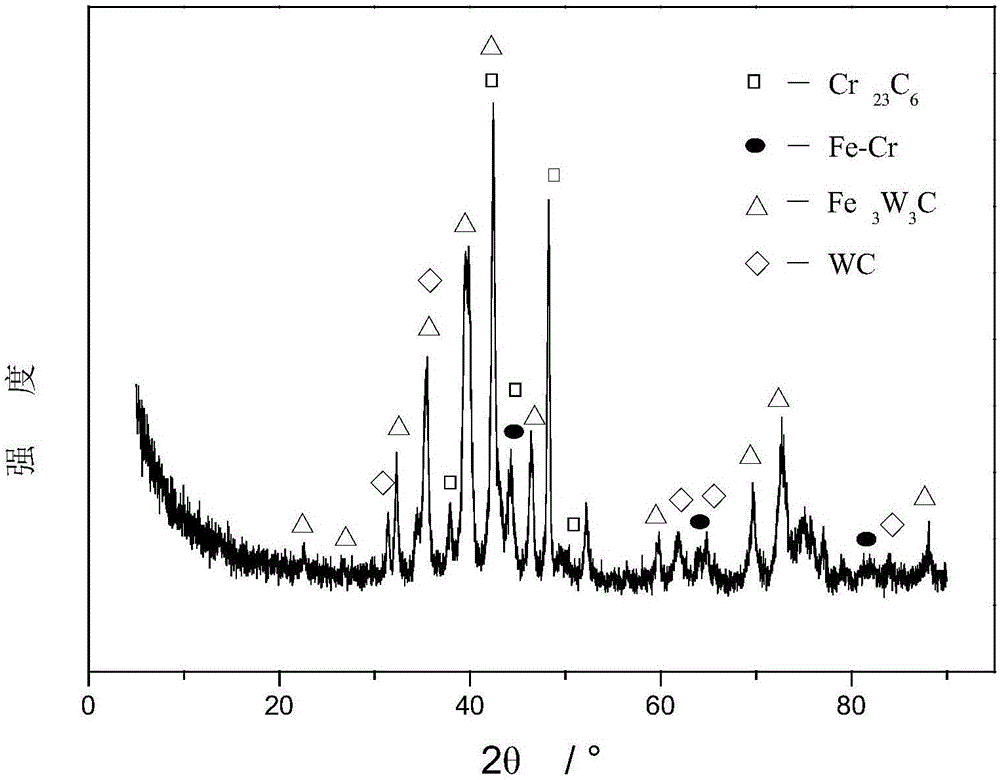

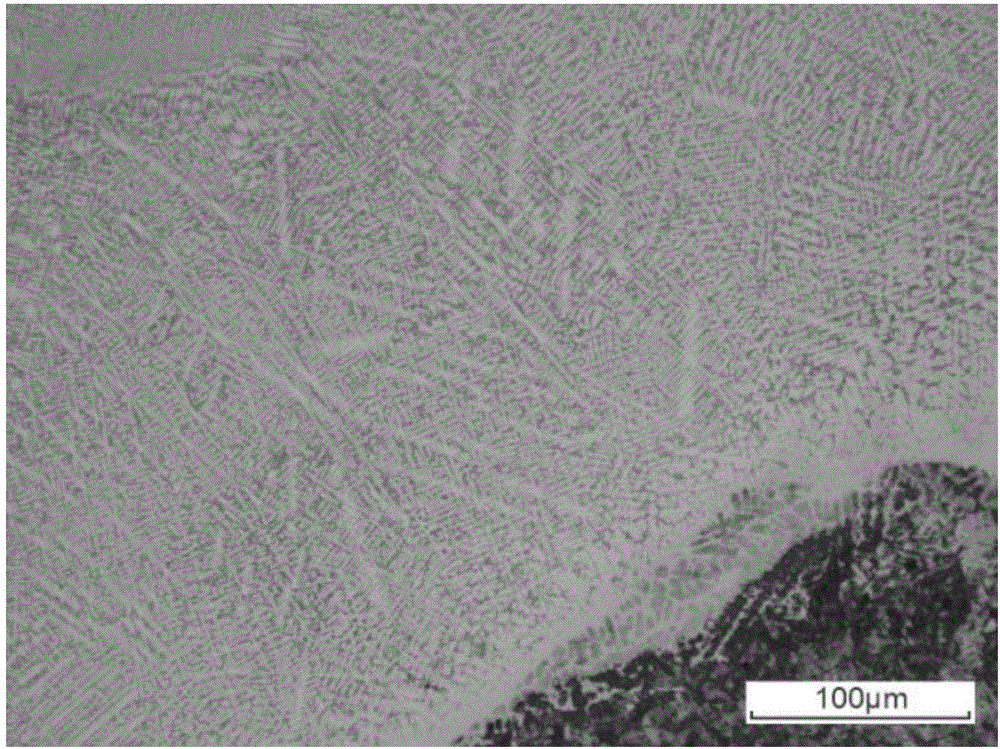

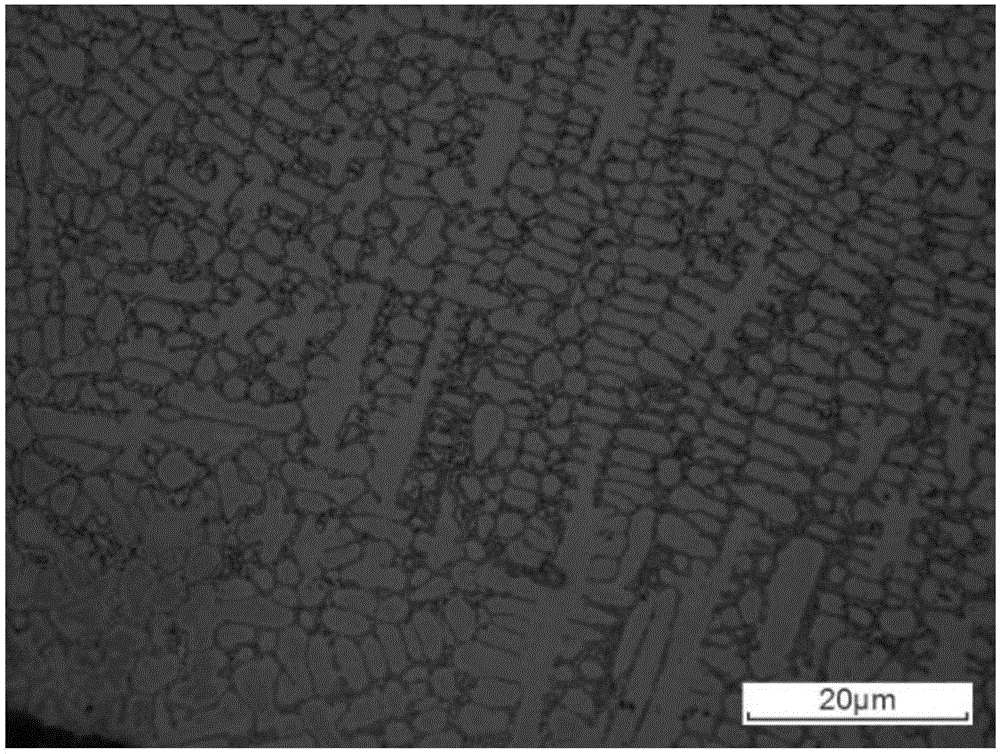

WC/Fe-based argon arc cladding alloy powder

InactiveCN106222652AImprove performanceGood workmanshipMetallic material coating processesIron powderHardness

The invention belongs to the technical field of materials, and discloses a WC / Fe-based argon arc cladding alloy powder which is composed of, by weight, 10-20% of high carbon-chromium iron powder, 1-3% of high carbon-manganese iron powder, 45-60% of WC powder and the balance iron powder. After the WC / Fe-based argon arc cladding alloy powder is clad, the hardness of a base material is not obviously changed, and the hardness variation of a cladding layer is large. The hardness of the base material-interface joint-cladding layer is improved stably, that is, the hardness of the surface cladding layer is highest, and the surface hardness is between 400 HV and 900 HV.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

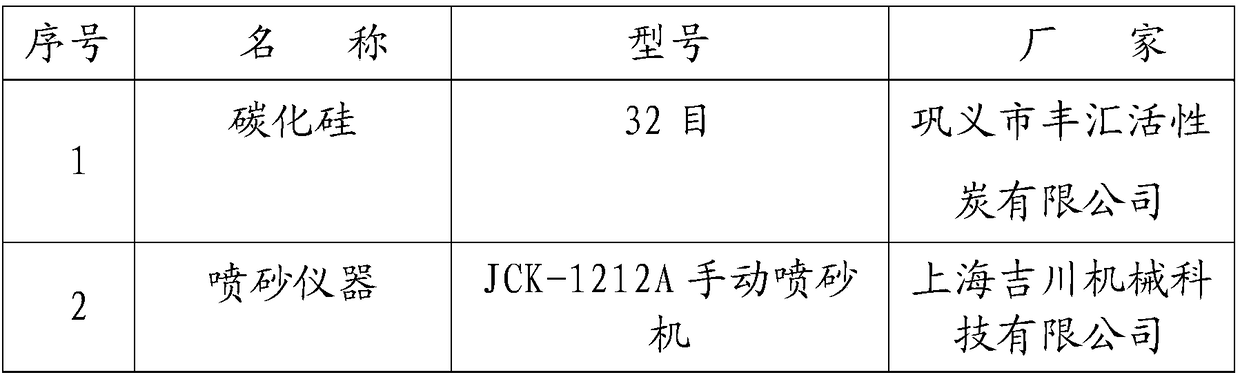

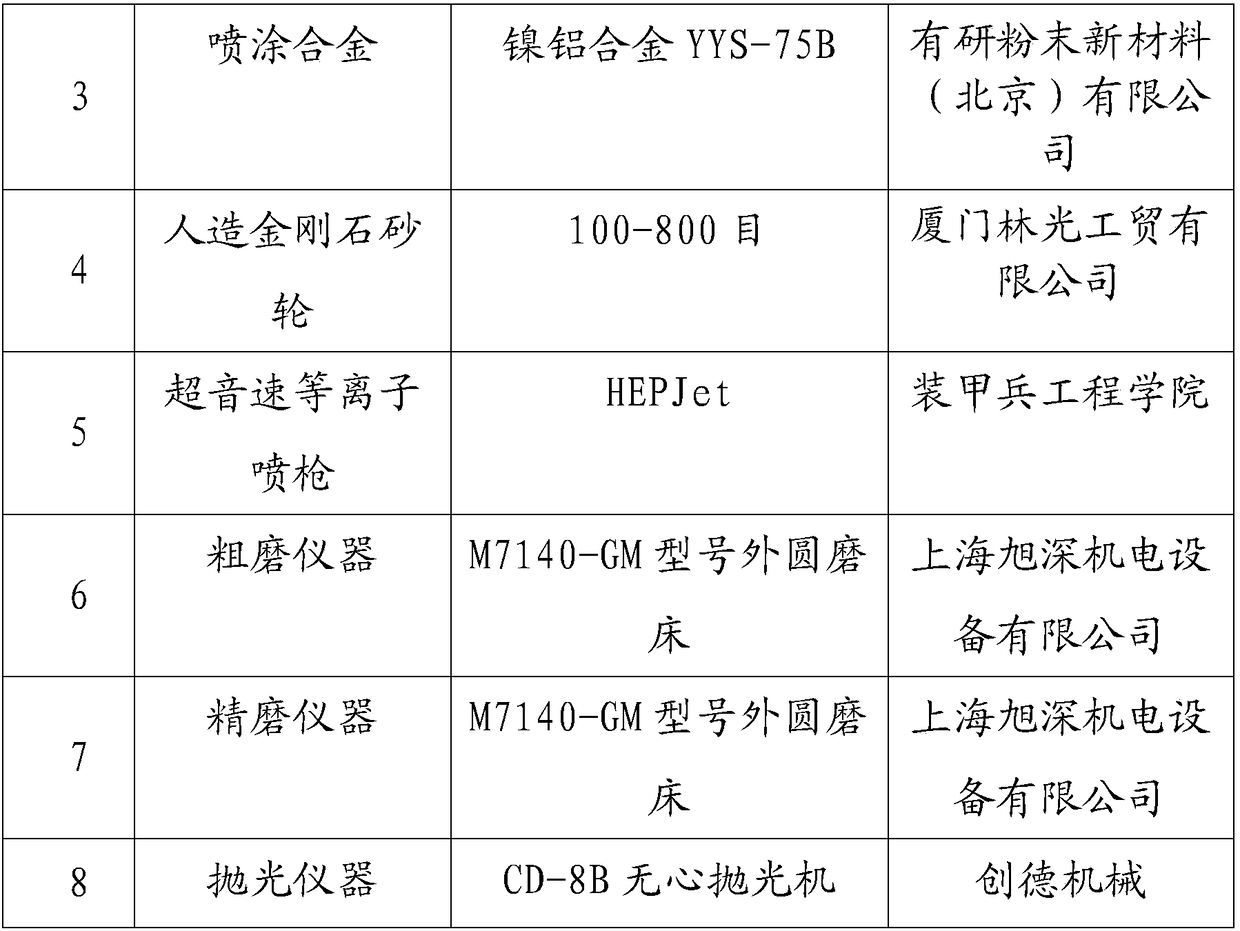

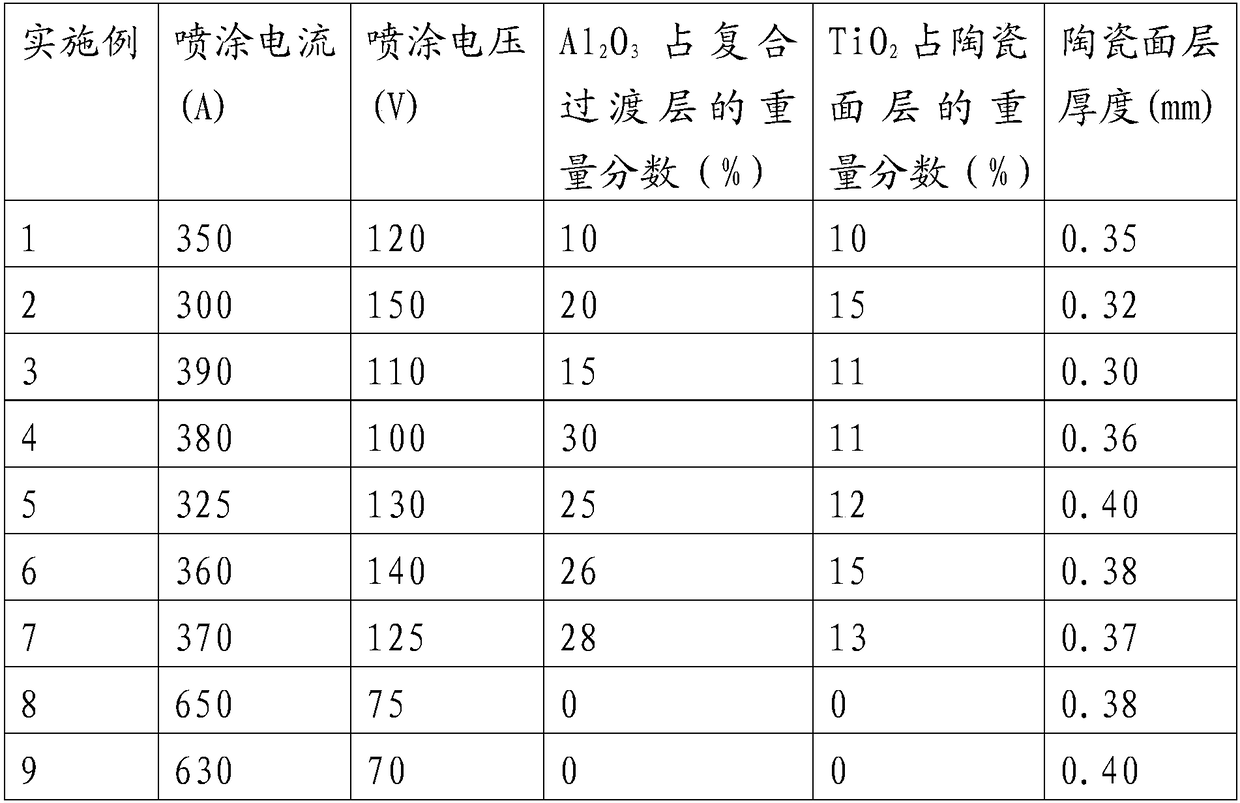

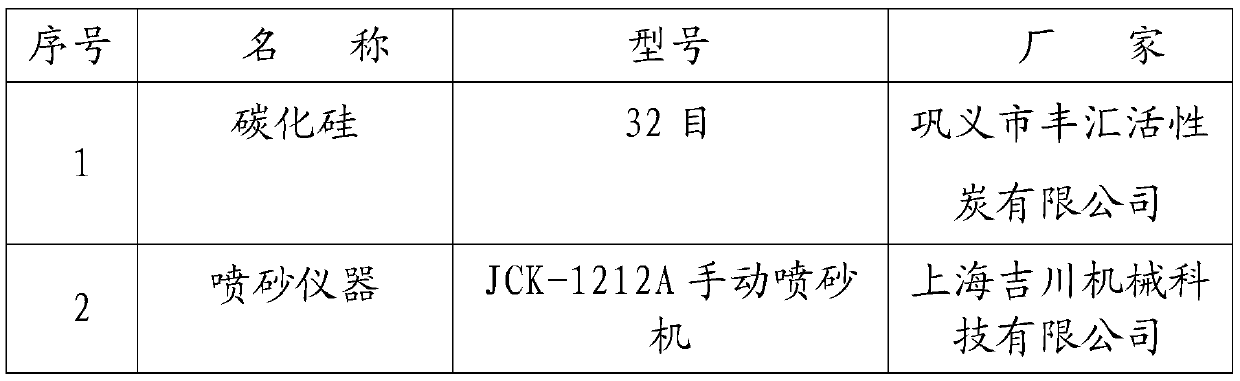

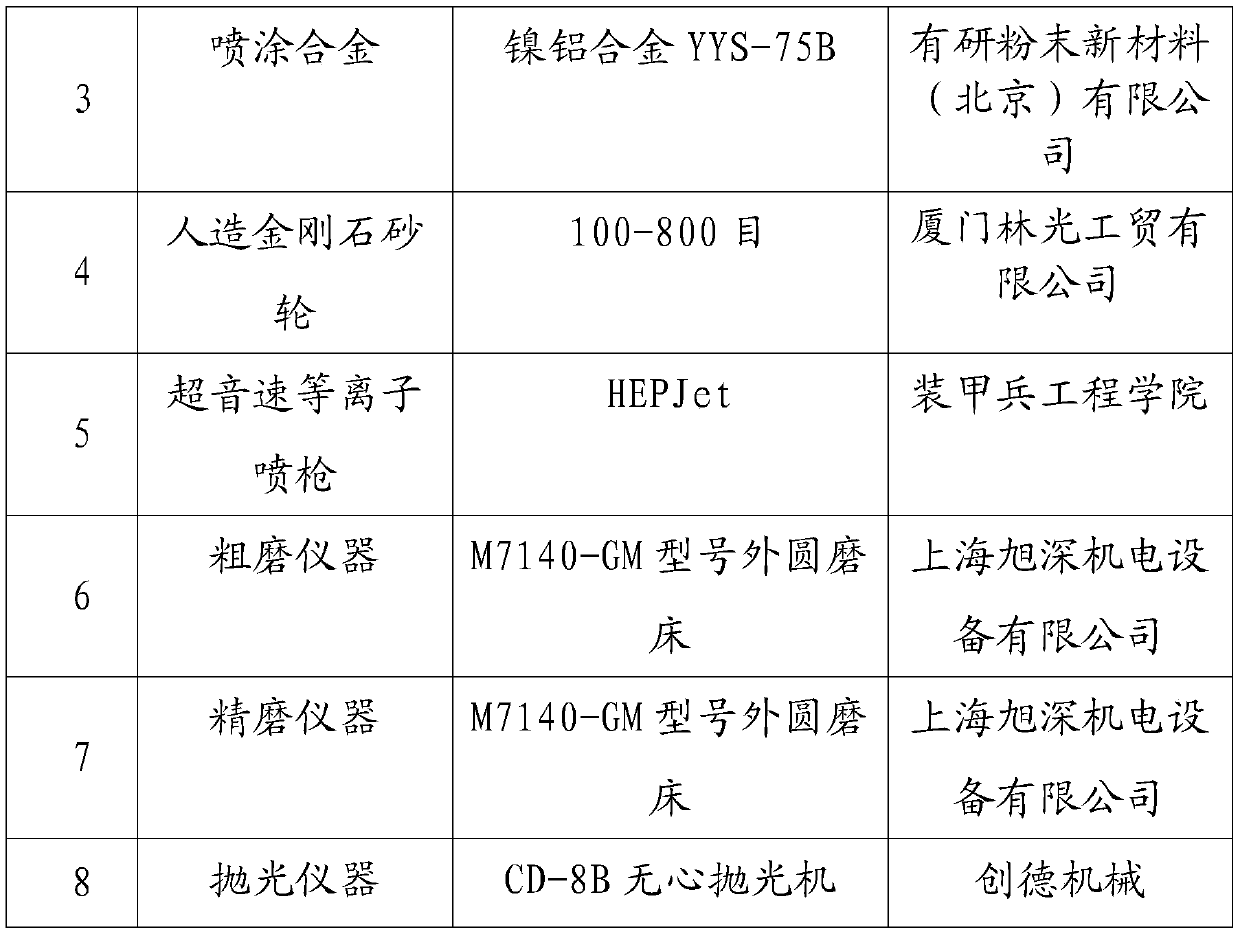

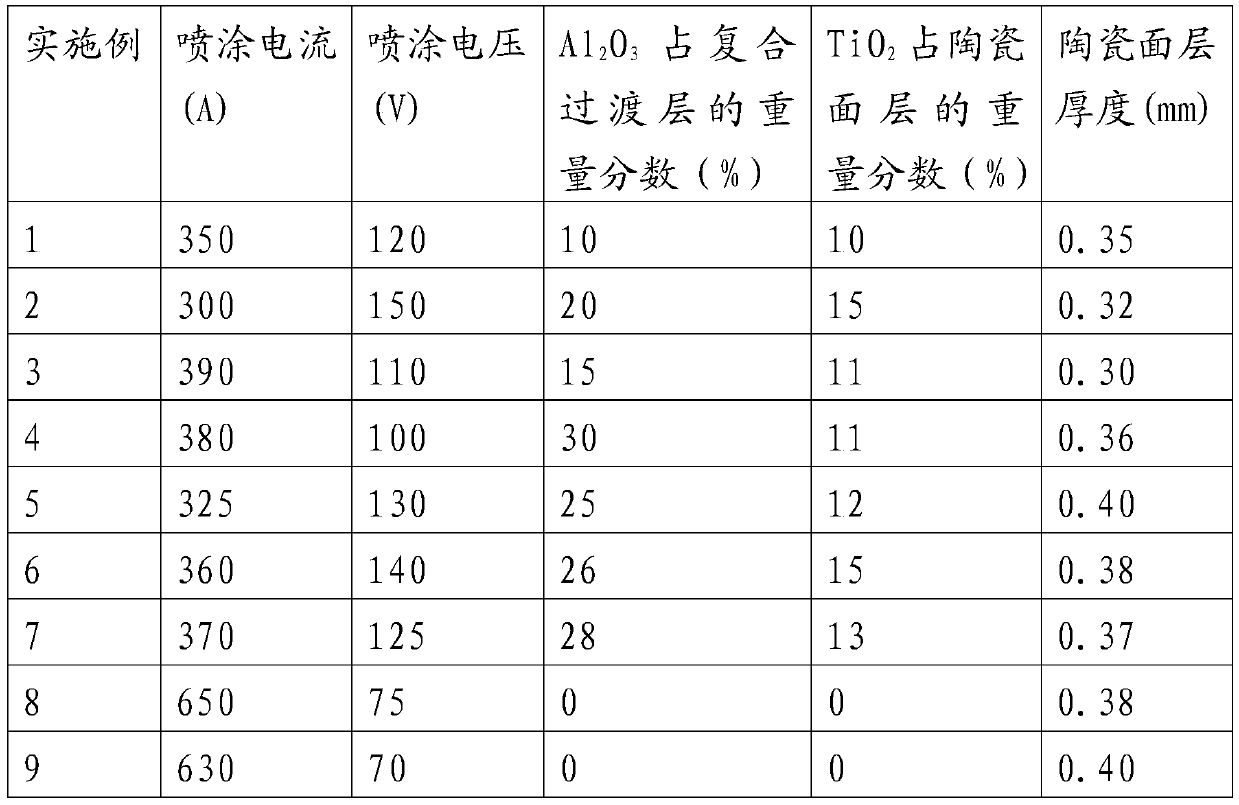

Method for spraying composite coating onto emulsification pump plunger and plunger including composite coating

The invention discloses a method for spraying a composite coating onto an emulsification pump plunger. The method comprises the following steps that (1) a metal plunger matrix is subjected to oil removal treatment, and sand blasting is carried out after drying; (2) a metal plunger obtained after sand blasting is preheated, and a NiCrAl and Al2O3 containing composite transition layer is sprayed onto the metal plunger through supersonic plasma; (3) after the composite transition layer is sprayed, a Al2O3 and TiO2 composite ceramic face layer is sprayed onto the surface of the composite metal transition layer through supersonic plasma; and (4) the metal plunger with the ceramic face layer sprayed is subjected to rough grinding, accurate grinding and polishing treatment, and the composite coating is obtained. Through the adoption of the method, a supersonic plasma method is utilized, the contents of Al2O3 and TiO2 in the composite coating are controlled, and the obtained coating is high inbonding strength, even in coating surface and high in density and hardness; and compared with a full ceramic plunger, the plunger is not prone to being damaged, the binding force of the coating and the matrix is high, the plunger is repairable, and the application range of the plunger is widened.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A kind of photocured medical catheter hydrophilic lubricating coating and preparation method thereof

ActiveCN109966560BReduce harmImprove adhesionPharmaceutical delivery mechanismPretreated surfacesPolyesterActive agent

Owner:ORBUSNEICH MEDICAL SHENZHEN CO LTD

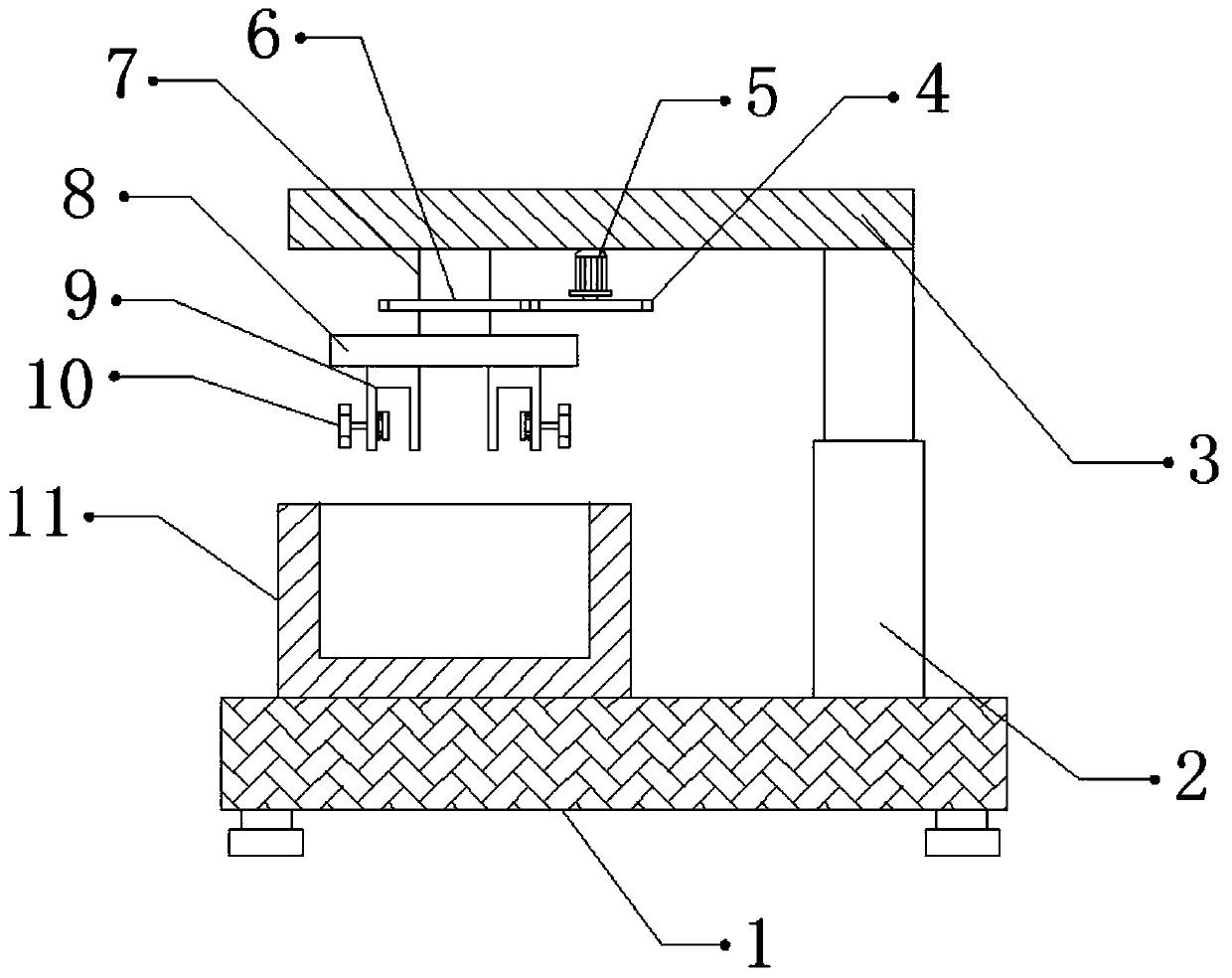

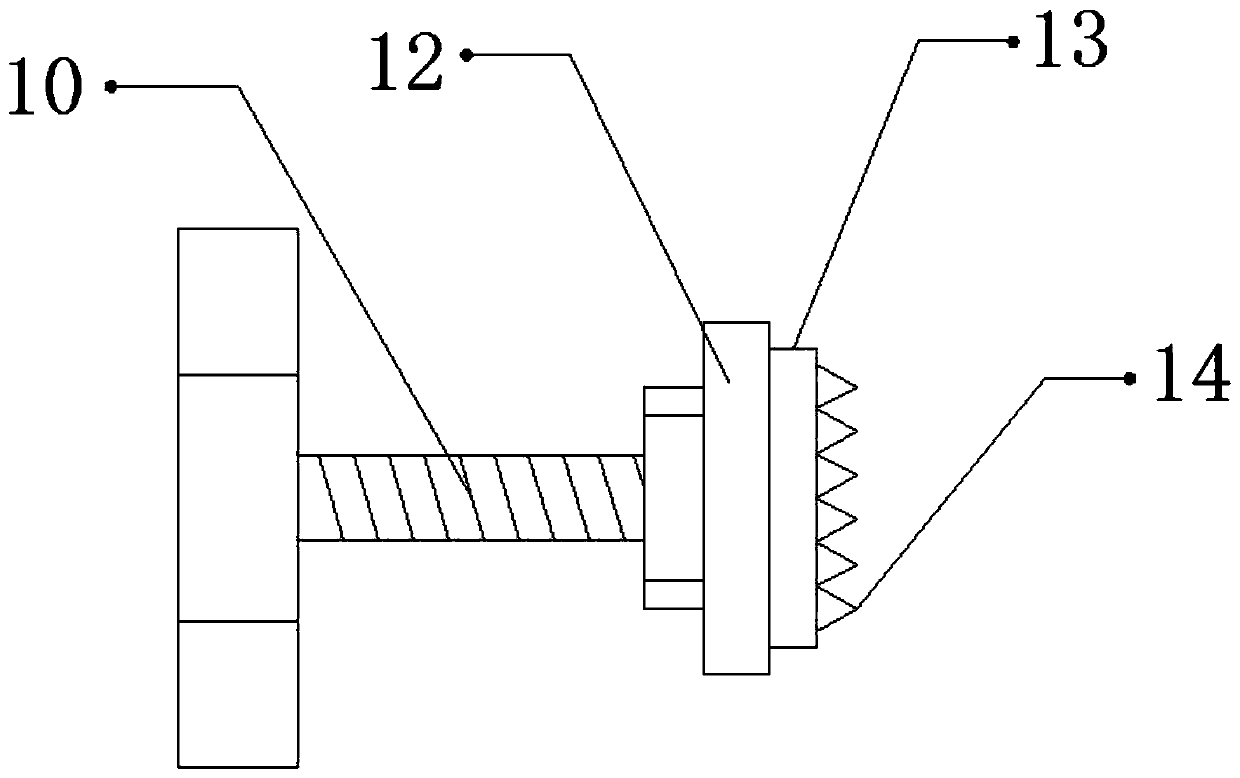

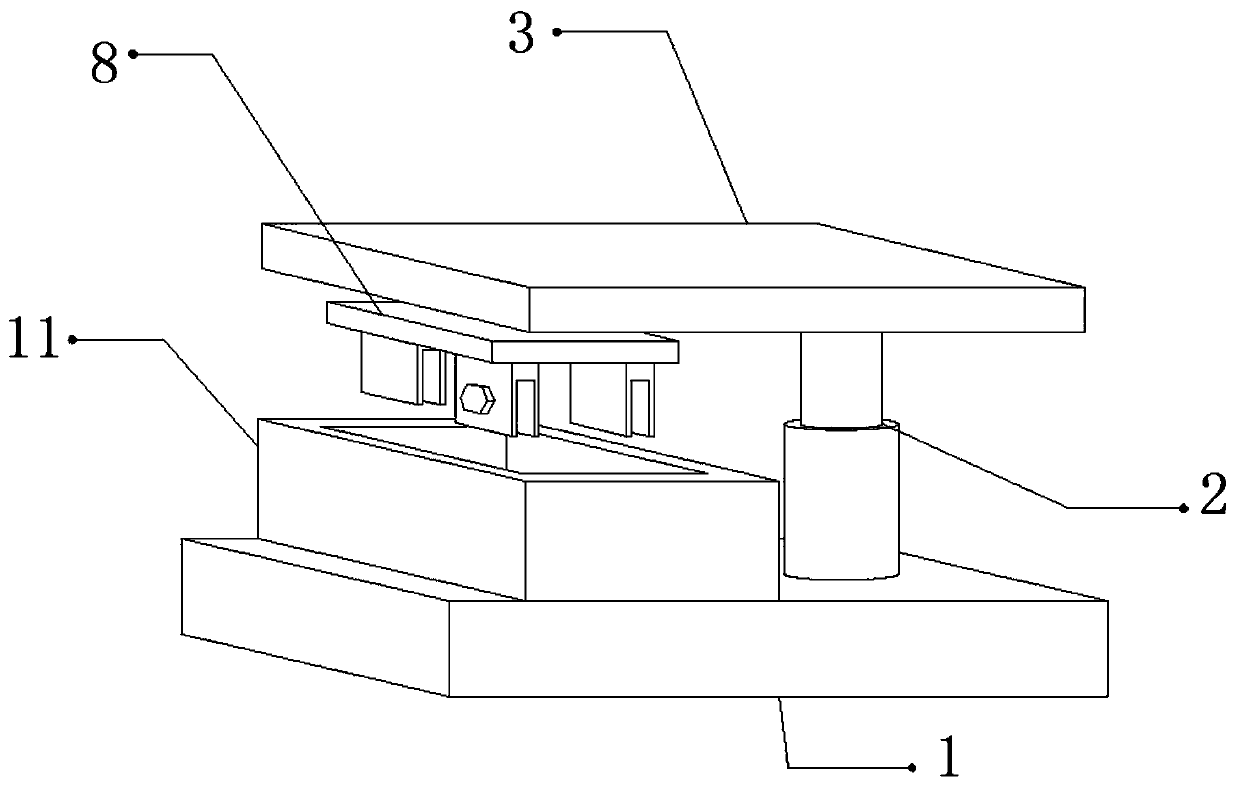

Printing device for packaging box production

InactiveCN110893718AUniform coating on the surfaceProduction impactRotary pressesPrinting press partsStructural engineeringManufacturing engineering

The invention discloses a printing device for packaging box production. The device comprises a fixed seat, fixing rods are fixed to the two sides of the outer wall of the top of the fixing base respectively, a top plate is fixed to the outer walls of the tops of the two fixing rods correspondingly, an electric telescopic rod is fixed to the outer wall of the bottom of the top plate, a fixing plateis fixed to the outer wall of the bottom of the electric telescopic rod, an electric sliding rail is fixed to the outer wall of the bottom of the fixing plate, a sliding block is slidably connected to the inner wall of the electric sliding rail, a fixing shaft is fixed to the outer wall of the bottom of the sliding block, a fixing frame is fixed to the outer wall of the bottom of the fixing shaft, and a template is arranged on the inner wall of the fixing frame. According to the invention, influence of blurred printed handwriting on packaging box production can be prevented, the bottom of thetemplate can be prevented from being abraded to influence printing of the packaging box, deviation of printing of the device on the packaging box can be prevented, and deviation of printing of the packaging box caused by movement between the packaging box and the clamping due to vibration can be prevented.

Owner:株洲蓝海包装有限公司

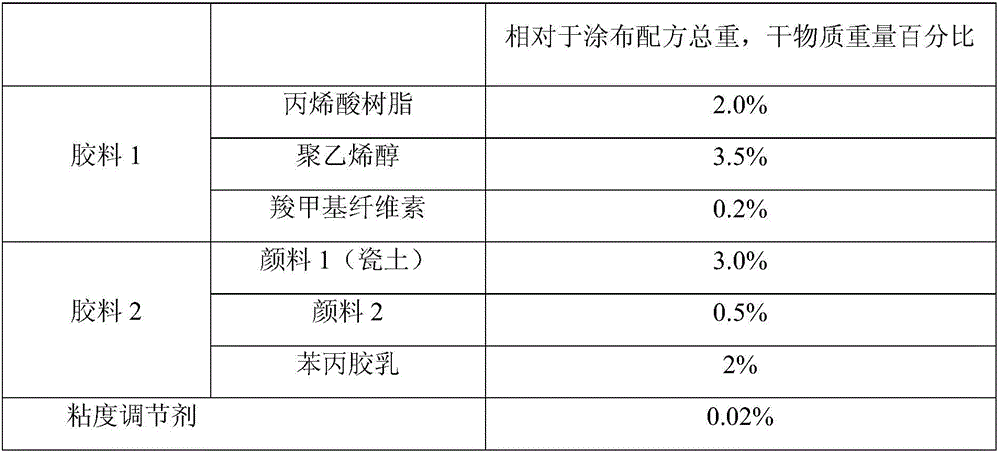

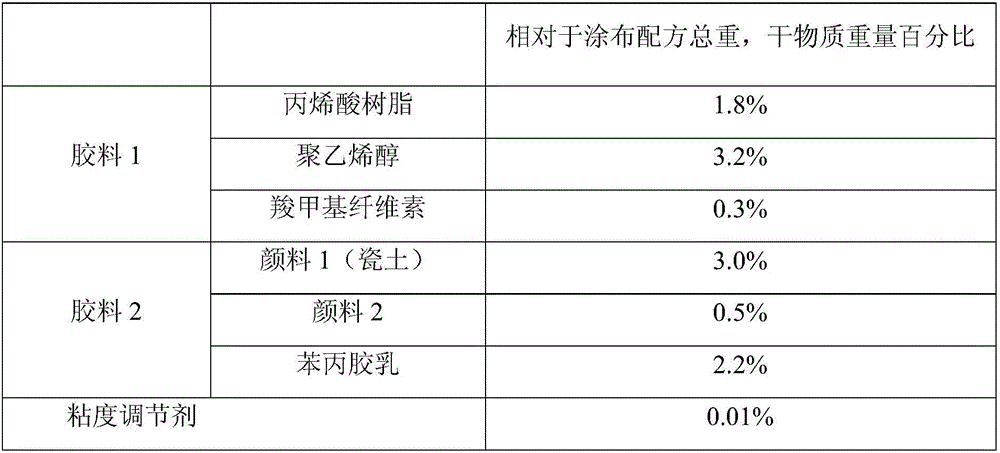

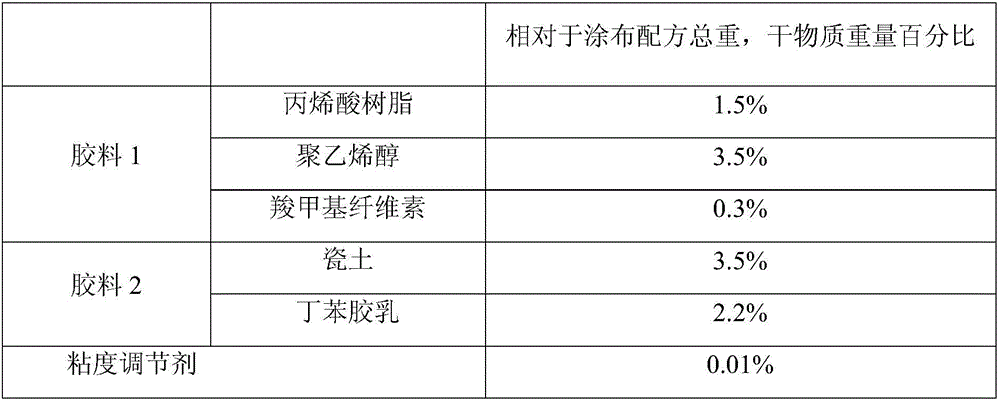

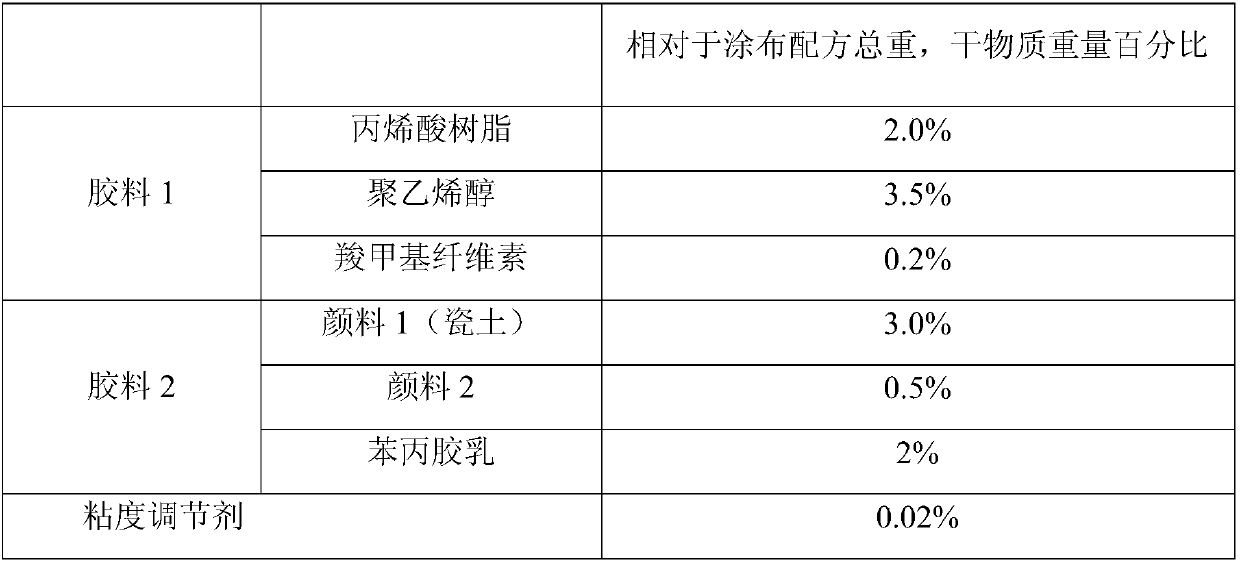

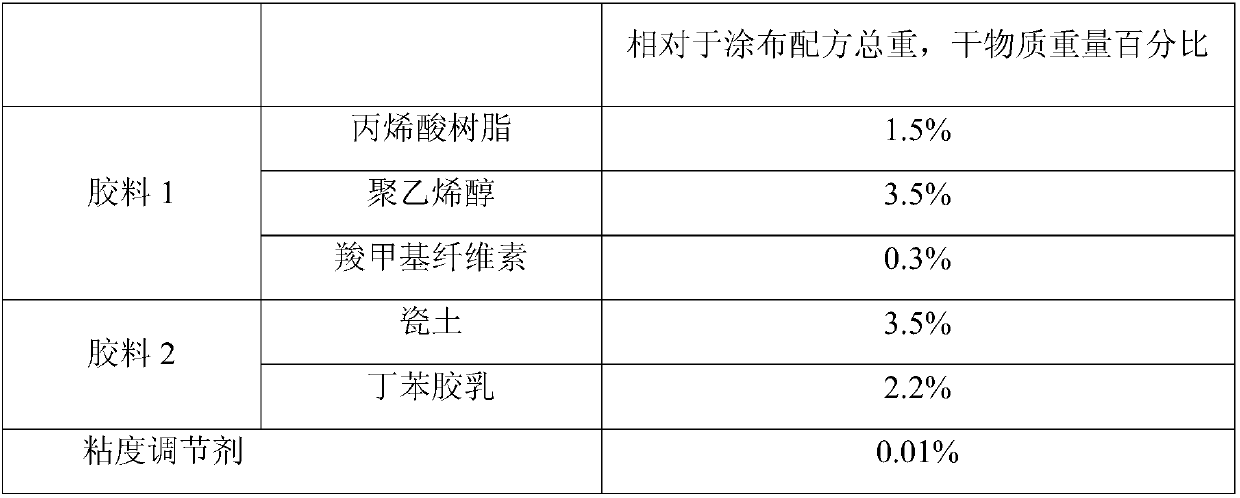

Glassine coating material

ActiveCN106638150AReduce consumptionUniform coating on the surfaceCoatings with pigmentsPaper/cardboardPolyvinyl alcoholAcrylic resin

A glassine coating material is prepared from, by total coating formulation weight, 3-5% of at least one or two pigments different in molecular weight, 1-2% of at least one type of acrylic resin, 2-4% of at least one type of polyvinyl alcohol, 1-3% of at least one type of latex, 0.1-0.3% of at least one functional additive, 0.01-0.03% of at least one viscosity modifier and the balance water. After addition of the viscosity modifier, coating viscosity is controlled within a range of 500-600mPa.S. Glassine which adopts the glassine coating material has advantages of freeness of repellence to silicon oil coating, uniformity in silicon oil coating, low consumption and the like.

Owner:MINFENG SPECIAL PAPER

Surface coating device for automobile body pillar machining

InactiveCN110355046AIncrease frictionEasy to fixPretreated surfacesCoatingsEngineeringCentrifugal force

The invention discloses a surface coating device for automobile body pillar machining. The surface coating device comprises a fixing seat, wherein an electric telescopic rod is fixed on one side of the outer wall of the top of the fixing seat, a supporting plate is fixed on the outer wall of the top of the electric telescopic rod, a rotating rod is rotationally connected to one side of the outer wall of the bottom of the supporting plate through a bearing, a fixing plate is fixed on the outer wall of the bottom of the rotating rod, a U-shaped frame is fixed on the outer wall of the bottom of the fixing plate, a threaded hole is formed in the outer wall of one side of the U-shaped frame, the inner wall of the threaded hole is in threaded connection with a fixing bolt, the fixing bolt is connected with a clamping plate through a nut, and a protective pad is glued on the outer wall of one side of the clamping plate. According to the device, the phenomenon that a pillar falls off from theU-shaped frame due to centrifugal force generated during rotation so as to affect coating of the pillar is prevented, the influence on pillar machining due to the fact that the surface of the pillar is not coated uniformly is avoided, and the problem that the device is inconvenient to clean due to the fact that coating liquid drips on the device can be prevented.

Owner:十堰市寅云实业有限公司

Chemical copper plating solution and method for plating copper substrate by using chemical copper plating solution

PendingCN113388829AImprove stabilityReduce porosityLiquid/solution decomposition chemical coatingPrinted element electric connection formationChemical platingCopper plating

The invention discloses a chemical copper plating solution and a method for chemical copper plating. The chemical copper plating solution comprises the components including, by mass concentration, a main salt, a reducing agent, a complexing agent, a stabilizer, an accelerator, a surfactant and the balance ultrapure water. The chemical copper plating solution further comprises a pH value regulator and an additive, wherein the additive is polyvinylpyrrolidone and sodium diphenylaminesulfonate. The chemical copper plating method comprises the steps of alkaline oil removal, micro-etching, preimpregnation, activation, peptization and copper deposition. Alkaline oil removal, micro-etching, preimpregnation, activation and peptization are pretreatment procedures to adsorb colloidal palladium particles to a PCB to be plated with copper. In the copper deposition process, copper ions are catalytically reduced to the PCB to be plated with copper through the chemical copper plating solution. In the chemical copper plating solution, the polyvinylpyrrolidone and the sodium diphenylaminesulfonate are used as the combined additive, so that the chemical copper plating solution has the characteristics of being environmentally friendly, low in price and easy to obtain, and the copper plating effect can be effectively improved while the copper plating rate is ensured.

Owner:惠州金晟新电子科技有限公司

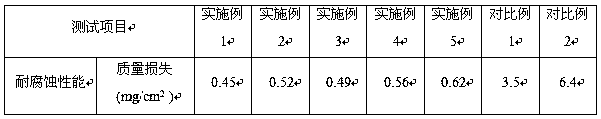

A wear-resistant Nd-Fe-B permanent magnet material for new energy vehicles and a preparation method thereof

InactiveCN109192427AMeet wear resistance requirementsImprove corrosion resistanceMagnetic materialsPermanent magnet manufactureOrganosiliconCorrosion

The invention belongs to the technical field of preparation of permanent magnet materials, in particular to a wear-resistant NdFeB permanent magnet material for new energy vehicles and a preparation method thereof. The invention is composed of composite material mixed with polyurethane resin, organosilicon modified epoxy resin and modified kaolin powder, which is coated on the outer surface of Nd-Fe-B magnetic material. The composite coating can not only have high corrosion resistance and heat resistance, but also can be prepared by supersonic plasma spraying technology. The coating is compact, uniform, good bonding strength between coating and workpiece, and has enough hardness, which can meet the requirements of wear resistance in the environment of new energy vehicles.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

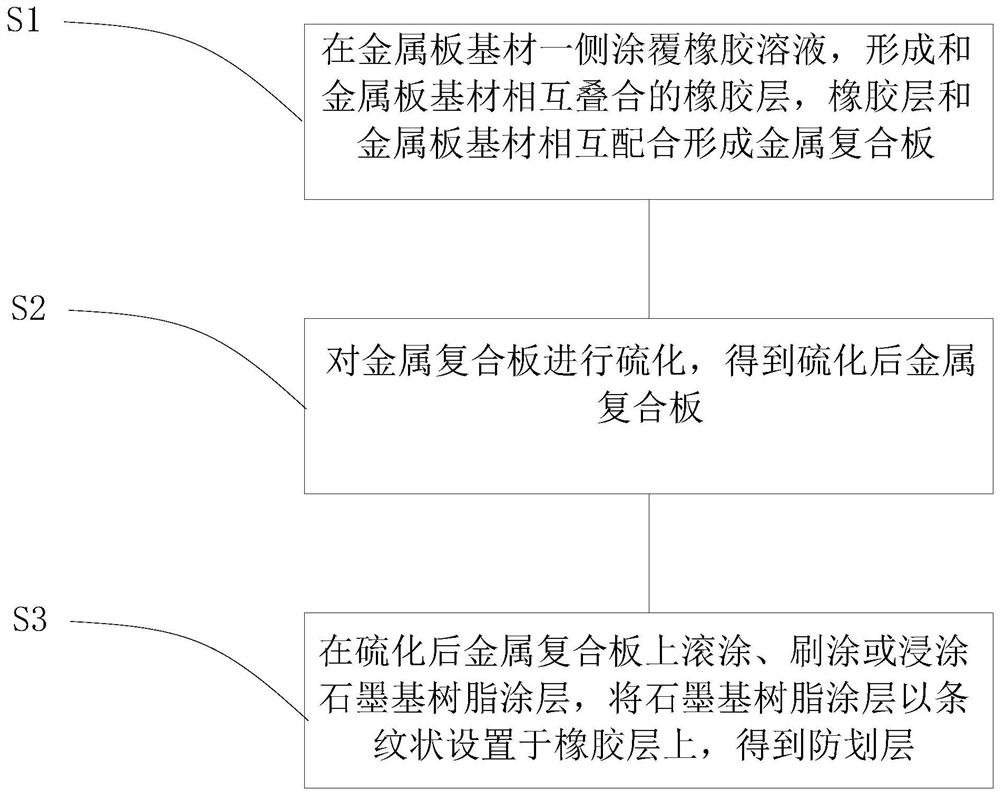

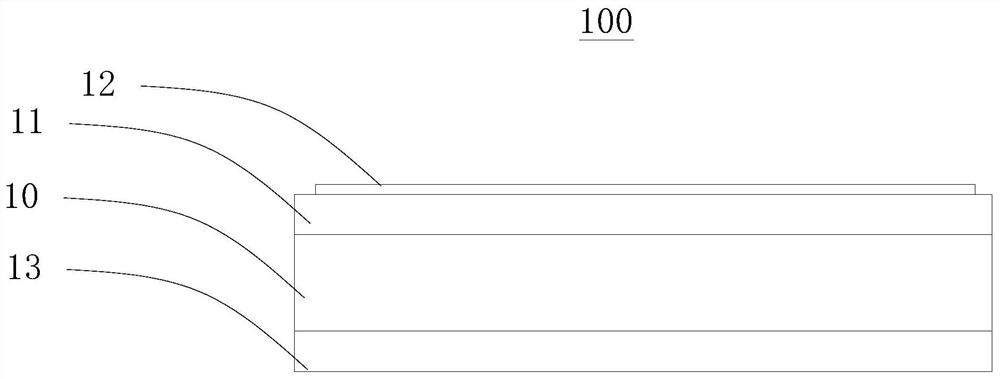

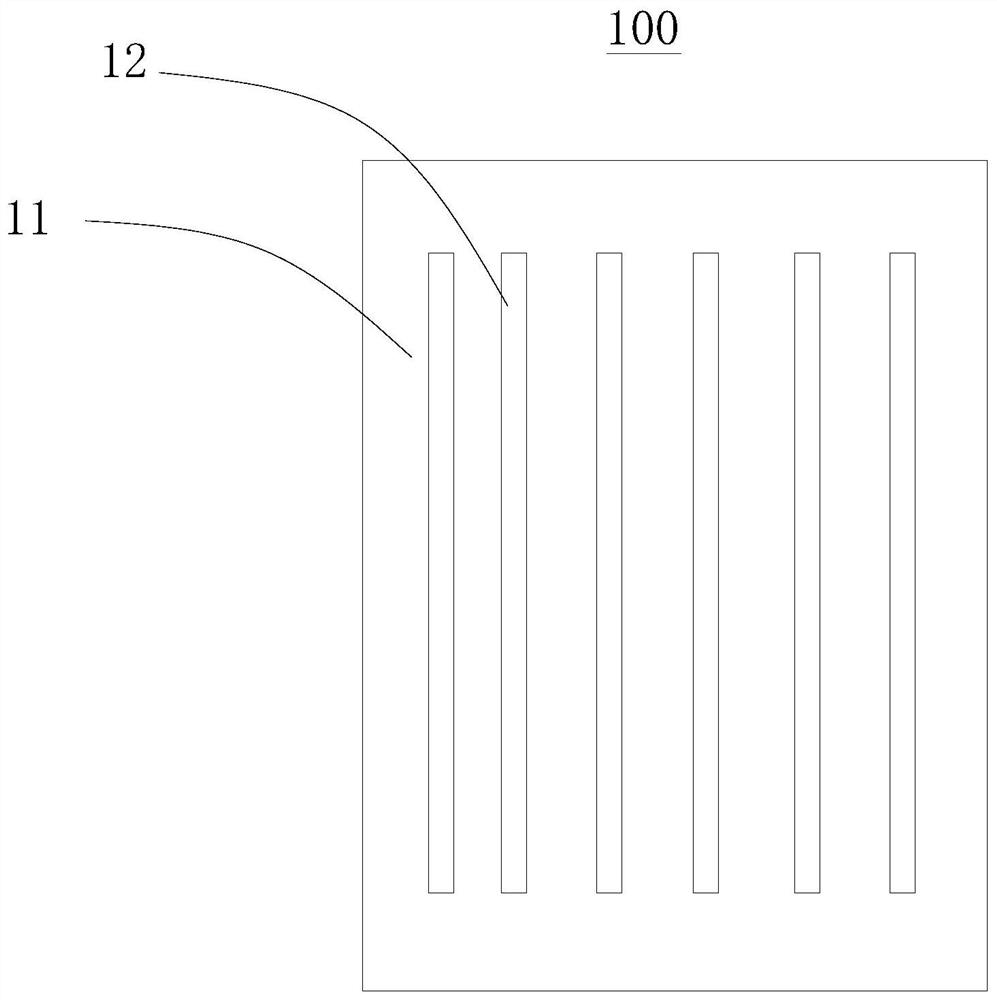

Automobile stripe silencing sheet and preparation process

ActiveCN112622858AOne-time brushing area is largeLarge brushing areaNoise/vibration controlFilm/foil adhesivesVulcanizationResin coating

The invention provides an automobile stripe silencing sheet and a preparation process, and relates to the technical field of silencing sheet production. The preparation process comprises the following steps: S1, coating one side of a metal plate base material with a rubber solution, and forming a rubber layer overlapped with the metal plate base material, wherein the rubber layer and the metal plate base material are matched with each other to form a metal composite plate; s2, vulcanizing the metal composite plate to obtain a vulcanized metal composite plate; and S3, roll coating, brush coating or dip-coating a graphite-based resin coating on the vulcanized metal composite plate, and arranging the graphite-based resin coating on the rubber layer in a striped manner to obtain the anti-scratching layer. According to the preparation process, the striped graphite-based resin coating can be processed on the rubber layer,so that the prepared silencing sheet has an anti-scratching effect, the metal composite plates are prevented from being stacked together in the product stamping process, burrs on the edges of a friction product are prevented from scratching the surface of the product in the packaging process, and the final forming quality of the product is improved. The silencing sheet is prepared by the process and has all the beneficial effects.

Owner:庄浩楠

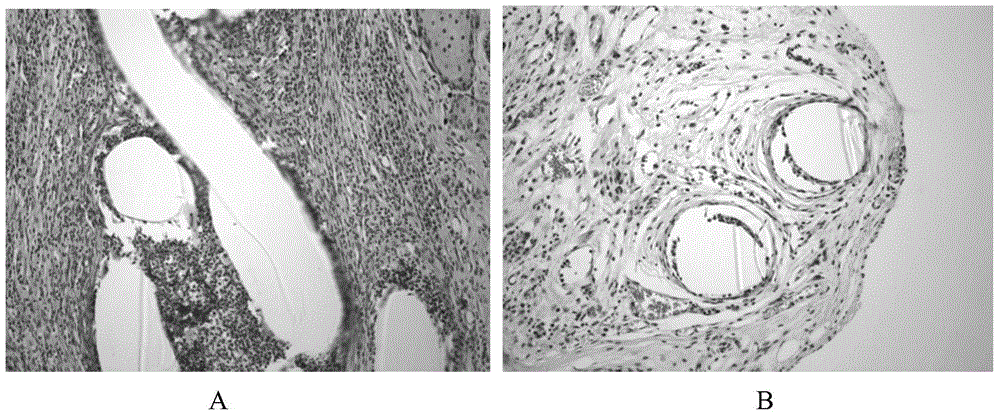

Preparation method of organic-inorganic core sheath structure compound biological material and product

InactiveCN104984396AUniform coating on the surfaceHave mechanical propertiesProsthesisTissue CompatibilityAcellular matrix

The invention discloses a preparation method of an organic-inorganic core sheath structure compound biological material and the product. The method particularly comprises the following steps: immersing a dopamine activated polypropylene mesh piece into an acellular matrix solution, then adding an MES buffer solution dissolved with EDC and NHS, and conducting light resistant reaction to obtain the organic-inorganic core sheath structure compound biological material, wherein the acellular matrix solution is an MES buffer solution containing acellular matrix. The preparation method is simple, needs no special equipment and easy for scale production, and the prepared organic-inorganic core sheath structure compound biological material not only has the mechanical property of polypropylene material, but also has the good tissue compatibility of the acellular matrix, has no obvious inflammatory reaction after being implanted, and is expected to be developed and applied to the fields of regeneration medicine and the like.

Owner:CHONGQING ACAD OF ANIMAL SCI

Palladium activating solution for nickel plating of magnesium alloy and nickel plating method of magnesium alloy

InactiveCN105779977AGood electrical conductivityGood brightnessLiquid/solution decomposition chemical coatingIonUrea

The invention provides a palladium activating solution for nickel plating of a magnesium alloy and a nickel plating method of the magnesium alloy. The palladium activating solution for nickel plating of the magnesium alloy comprises 0.25 to 0.45 g / L of palladium oxide, 10 to 30 g / L of stannous oxide, 10 to 15 g / L of citric acid, 150 to 200 g / L of sodium oxide, 0.1 to 0.5 g / L of sodium stannate, 30 to 80 g / L of urea, and deionized water. The nickel plating method of the magnesium alloy comprises the steps of 1) activation pre-treatment: carrying out alkaline degreasing, water washing, acid etching, water washing, alkaline etching and water washing on a magnesium alloy sample; 2) activation treatment: soaking the magnesium alloy sample subjected to alkaline etching in the step 1) in the palladium activating solution for activation treatment; and 3) chemical nickel plating treatment: carrying out water washing on the magnesium alloy sample activated in the step 2), and soaking the magnesium alloy sample subjected to water washing in a chemical nickel plating solution for chemical nickel plating treatment. According to the nickel-plated magnesium alloy obtained through the method, the abrasion resistance and electrical conductivity are good, the brightness of a nickel-plated layer of the magnesium alloy is good, the surface is uniform and free of pits, the binding force is good, and the application value is high.

Owner:SHENZHEN RUN SUN CHEM TECH

Size grading controllable preparation method for nano vanadium nitride powder

ActiveCN111632682AHigh puritySimple processMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsVanadium nitrideVanadium atom

The invention discloses a size grading controllable preparation method for nano vanadium nitride powder, and relates to the technical field of high-melting-point nitride powder preparation. The size grading controllable preparation method comprises the following steps: firstly, performing surface treatment on metal vanadium powder through dispersing grinding equipment; then, preparing vanadium nitride aggregates through a chemical vapor deposition method; and finally, performing grinding treatment through dispersing grinding equipment to obtain a nano vanadium nitride powder finished product.Metal vanadium powder is modified in the dispersing grinding equipment, so that modifying effect can be remarkably improved, surface coating is uniform, and follow-up chemical vapor deposition reaction is facilitated better. After the vanadium nitride aggregates are prepared, the dispersing grinding equipment is utilized to re-treat; and the grinding equipment with a reasonable structural design can prepare the nano vanadium nitride product with uniform product grain size distribution, and the product quality is high.

Owner:安徽中航纳米技术发展有限公司

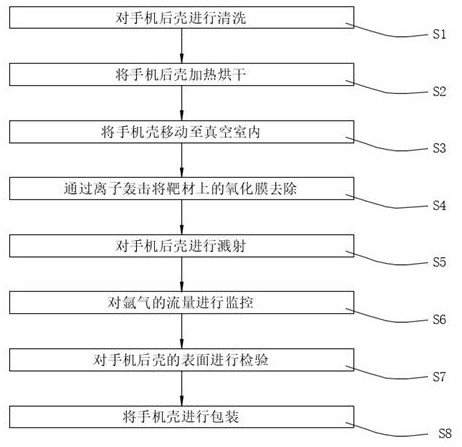

Vacuum magnetic control mobile phone rear shell coating process

InactiveCN112593197AEasy to control in real timeGood coating effectVacuum evaporation coatingSputtering coatingIon bombardmentMass spectrometry

The invention discloses a vacuum magnetic control mobile phone rear shell coating process. The process comprises the following steps of S1, cleaning a mobile phone rear shell; S2, heating and drying the mobile phone rear shell; S3, moving the mobile phone rear shell into a vacuum chamber; S4, removing an oxide film on a target material through ion bombardment; S5, performing sputter coating on themobile phone rear shell; S6, monitoring the flow of argon; S7, inspecting the surface of the mobile phone rear shell; and S8, packaging the mobile phone rear shell. According to the vacuum magnetic control mobile phone rear shell coating process, the gas environment in the vacuum chamber is detected through mass spectrometry equipment, so that the flow of the argon in the vacuum chamber is conveniently controlled in real time, the coating effect on the mobile phone rear shell is improved, meanwhile, ion bombardment is conducted on the target material, and oxide and impurities on the surface of the target material are removed, so that the magnetron sputtering coating quality of the mobile phone rear shell is improved, and the coating use of the mobile phone rear shell is facilitated.

Owner:苏州市三同电子科技有限公司

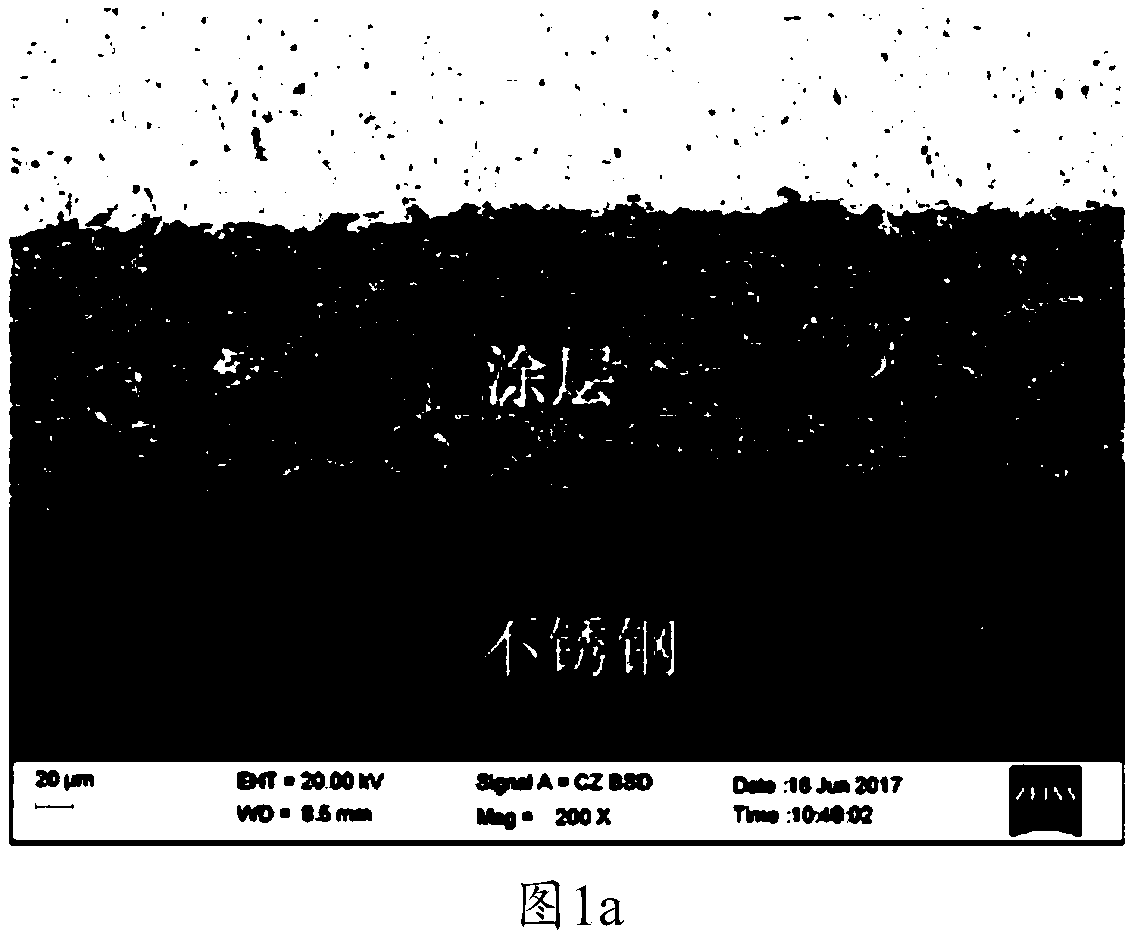

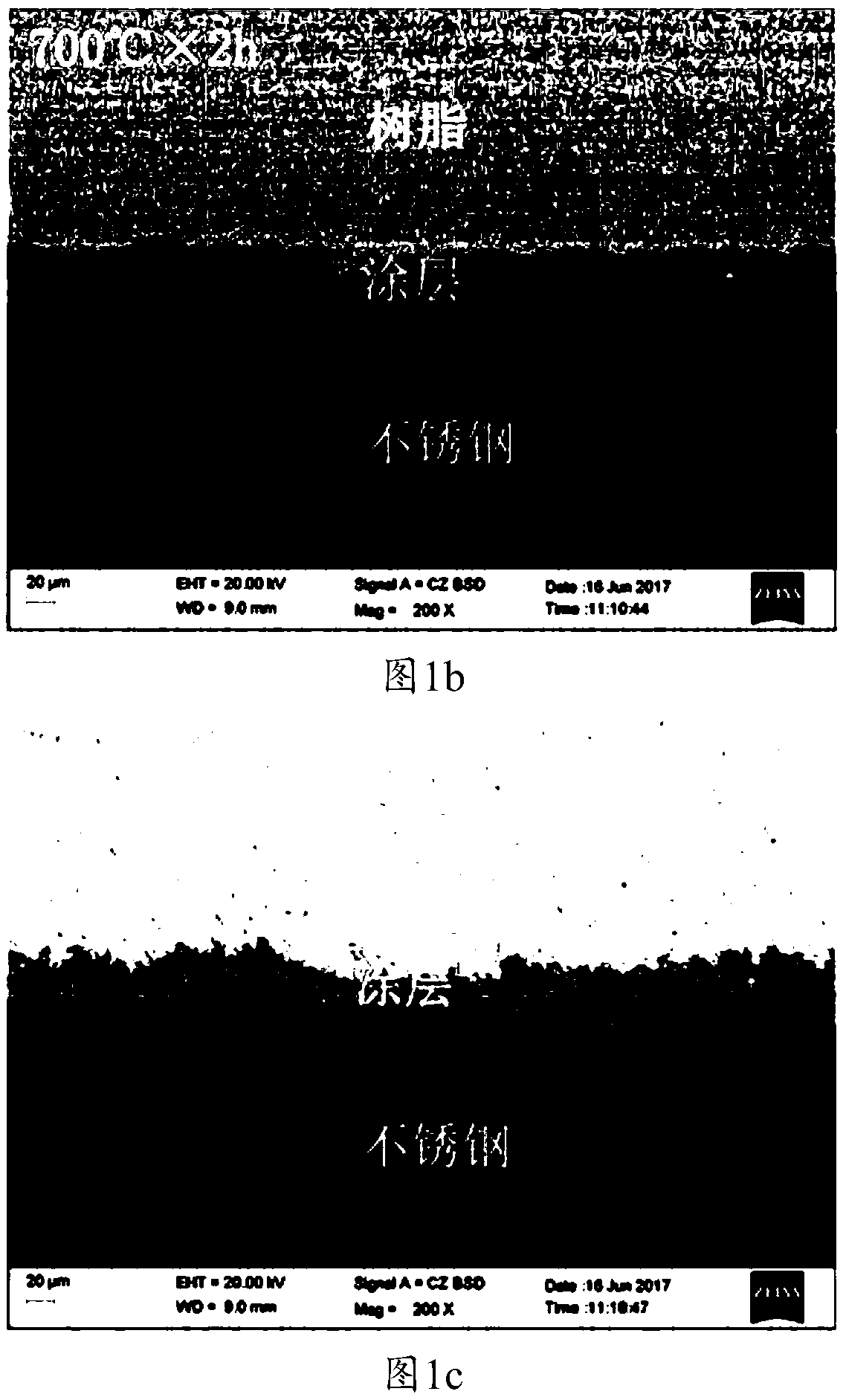

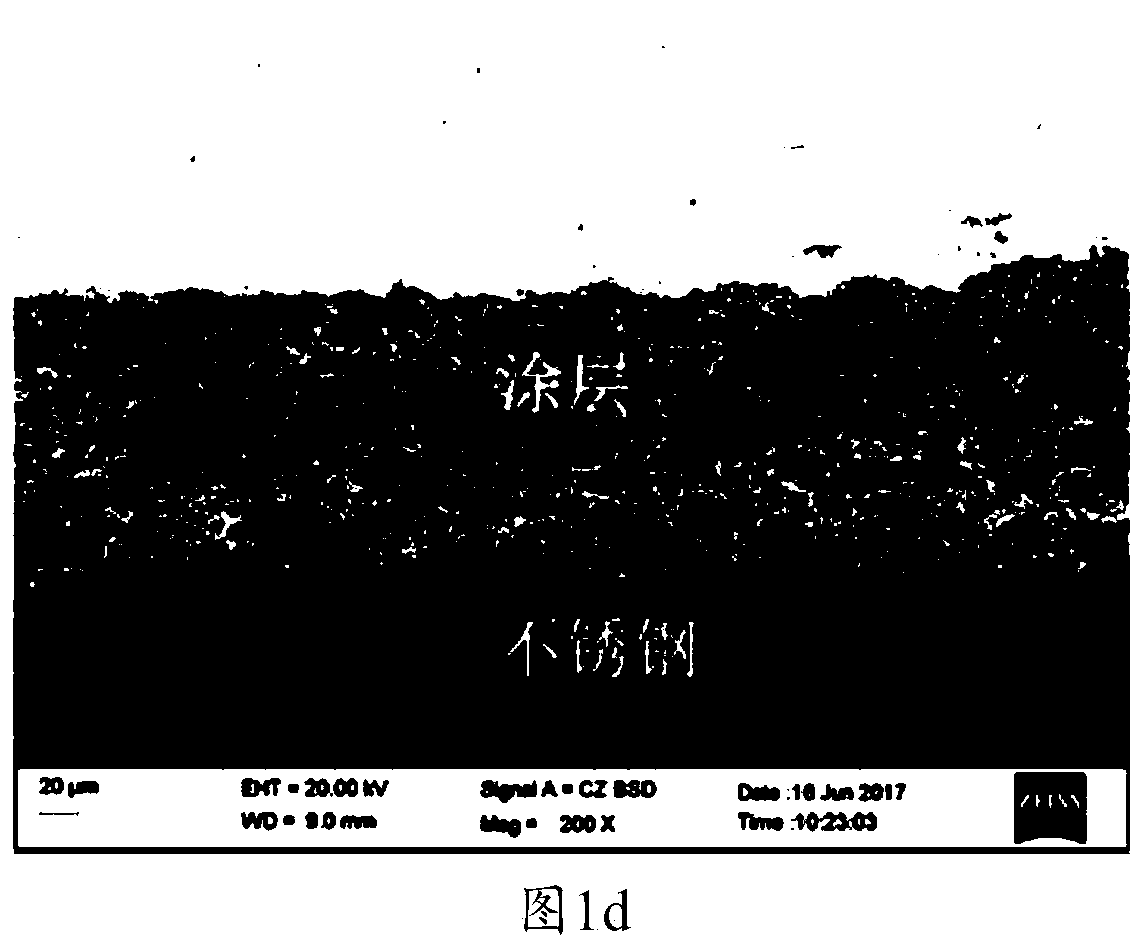

A kind of surface anti-corrosion method of metal substrate

ActiveCN107419213BImprove surface roughnessFacilitated DiffusionMolten spray coatingCeramic coatingSpray coating

The invention belongs to the technical field of corrosion prevention of stainless steel surfaces, and particularly relates to a surface anti-corrosion method of a metal substrate. According to the surface anti-corrosion method, a multicomponent alloy penetration technique is adopted on the basis of a plasma spraying technique, so that a zinc-titanium alloy carburizing layer is formed on the surface of the stainless steel substrate, and the binding force of a Zn-Ti-Al2O3 hot spray coating and the surface of the substrate is greatly increased; by adopting the zinc-titanium alloy carburizing layer, the corrosion effect caused by the existence of ceramic coating pores can be reduced, and the anti-corrosion capability of the spray coating is increased. Therefore, the binding force of the spray coating prepared by adopting the technical scheme and the surface of the stainless steel substrate is large, so that the spray coating is difficult to peel off, and the high-temperature oxidation and corrosion resistant performance of the metal substrate is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

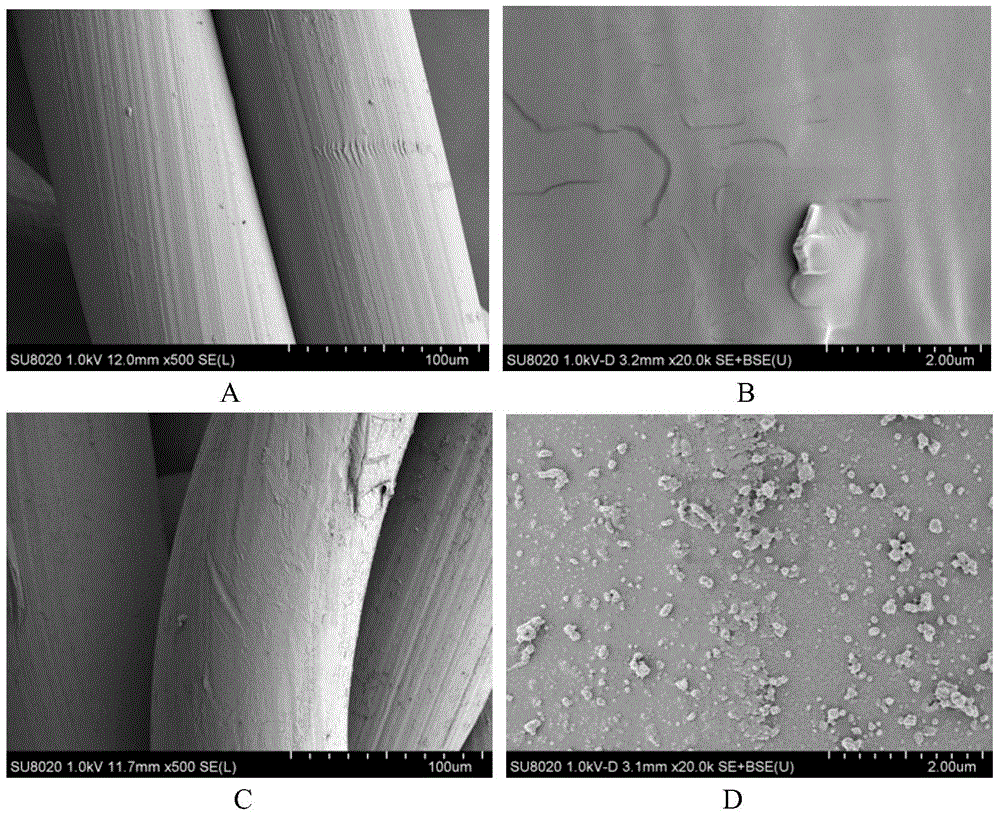

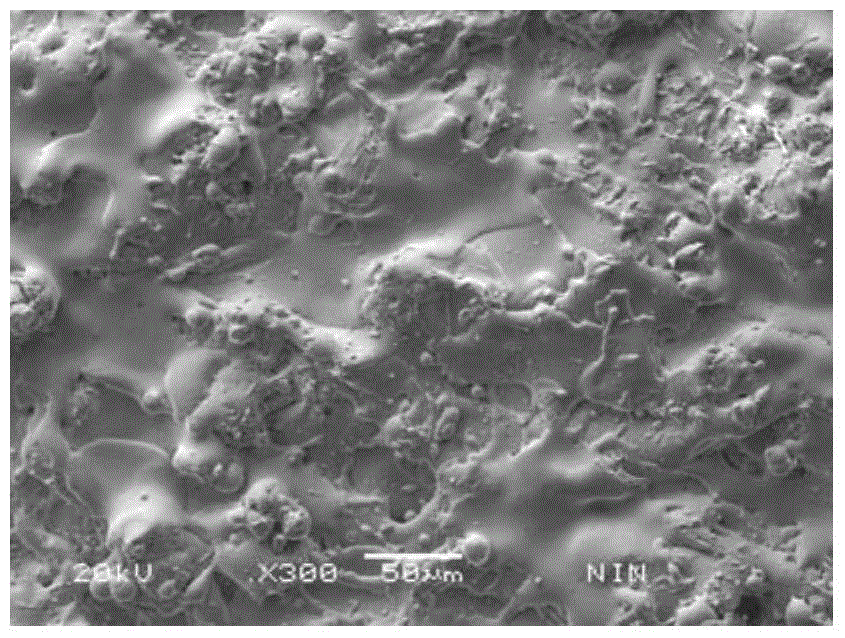

Preparation technology for irradiated nuclear fuel core electron microscope sample

ActiveCN102539200BUniform coating on the surfaceImprove conductivityPreparing sample for investigationScanning electron microscopeElectron microscope

The invention discloses a preparation technology for an irradiated nuclear fuel core electron microscope sample. The preparation technology comprises the following preparation processes, such as cutting sampling, sample splicing, sample grinding / polishing and the like, so that the irradiated nuclear fuel core electron sample is manufactured. The preparation technology disclosed by the invention meets use requirements on scanning electron microscopes, and the manufactured irradiated nuclear fuel core electron sample is suitable for observing number, size, form and distribution situations of air holes in fuel particles under the scanning electron microscopes.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for spraying composite coating on plunger of emulsification pump and plunger including same

The invention discloses a method for spraying a composite coating onto an emulsification pump plunger. The method comprises the following steps that (1) a metal plunger matrix is subjected to oil removal treatment, and sand blasting is carried out after drying; (2) a metal plunger obtained after sand blasting is preheated, and a NiCrAl and Al2O3 containing composite transition layer is sprayed onto the metal plunger through supersonic plasma; (3) after the composite transition layer is sprayed, a Al2O3 and TiO2 composite ceramic face layer is sprayed onto the surface of the composite metal transition layer through supersonic plasma; and (4) the metal plunger with the ceramic face layer sprayed is subjected to rough grinding, accurate grinding and polishing treatment, and the composite coating is obtained. Through the adoption of the method, a supersonic plasma method is utilized, the contents of Al2O3 and TiO2 in the composite coating are controlled, and the obtained coating is high inbonding strength, even in coating surface and high in density and hardness; and compared with a full ceramic plunger, the plunger is not prone to being damaged, the binding force of the coating and the matrix is high, the plunger is repairable, and the application range of the plunger is widened.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Antistatic thermal control coating composition and its preparation method and application

ActiveCN104774510BUniform coating on the surfaceNo bubblesElectrically-conductive paintsOmegaThermal control

The invention discloses an antistatic thermal control coating composition, a preparation method and applications thereof. The coating composition comprises priming paint and finish paint. The priming paint is composed of a matrix namely organic fluorine resin and a filling material namely modified zinc oxide powder; wherein the zinc oxide is capable of forming vertical channels in the priming paint layer. The finish paint is composed of a matrix namely methyl silicone resin with multiple functional groups and a filling material namely modified zinc oxide powder; wherein part of the filling material penetrates the interface between the priming paint layer and the finish paint layer. The prepared antistatic thermal control coating has a white color, a thickness of 130 to 200 [mu]m, a solar absorption ratio of 0.20 to 0.25, a hemispherical emissivity of 0.85 to 0.91, a total mass loss (TML) not more than 1%, collectable volatile condensed mass (CVCM) not more than 0.1%, and a volume resistivity ([rho]v) not more than 107 [omega].m. The coating does not have the phenomenon of cracking, peeling, bubbling, and fading after 100 times of high-low temperature thermal cycle experiments in a temperature range of -100 to 100 DEG C, the optical properties of the coating is stable, and the adhesive force of the coating is high.

Owner:SHANGHAI INST OF SATELLITE EQUIP

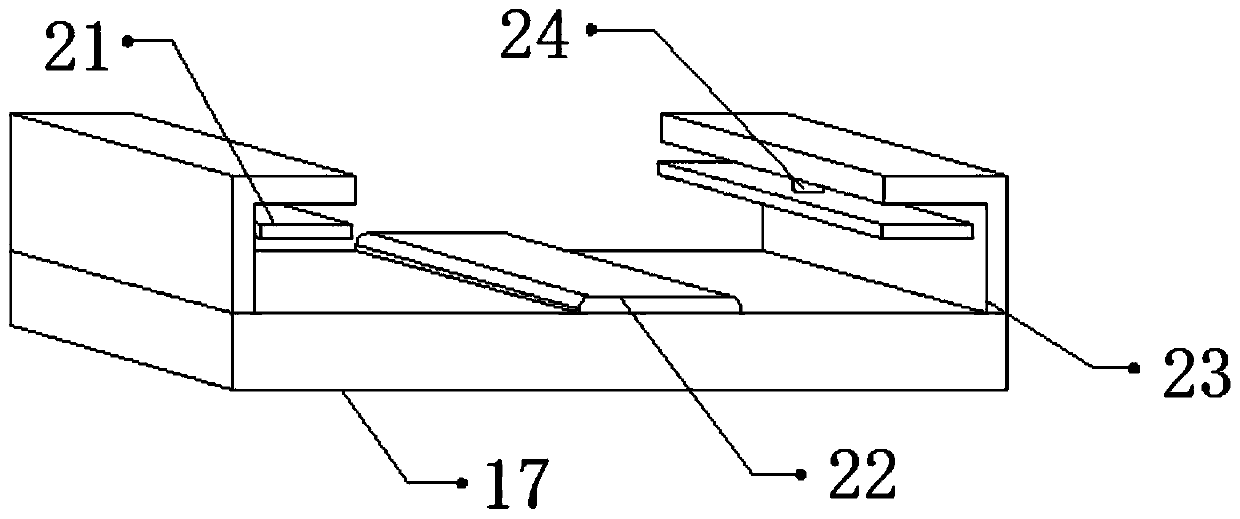

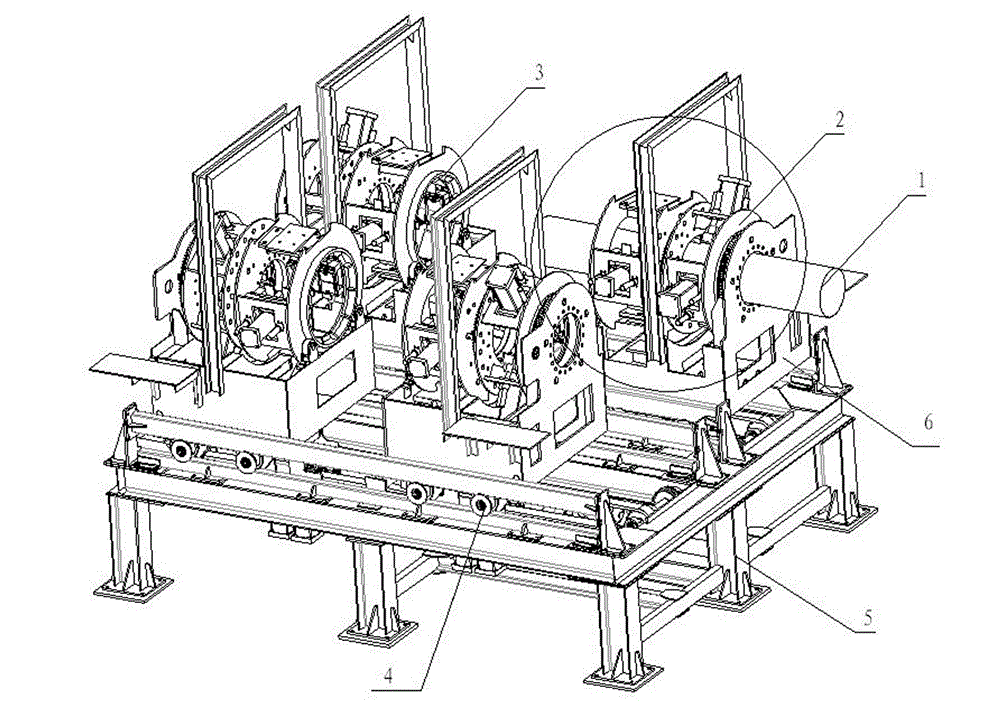

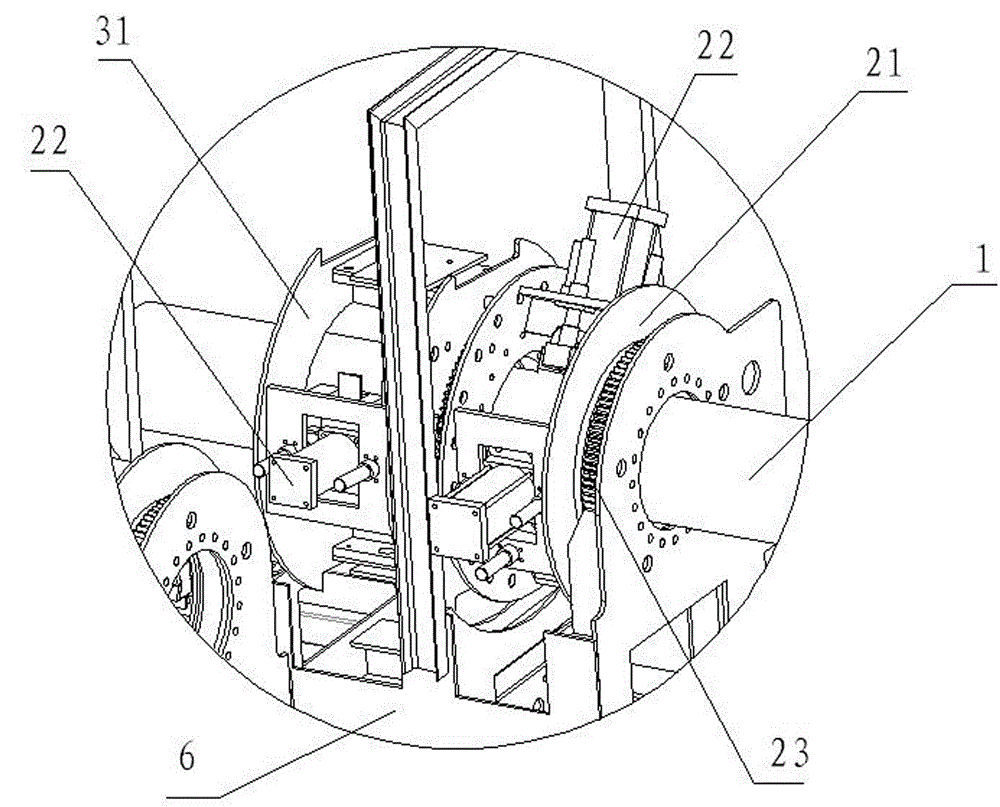

Rotary conduction mechanism

InactiveCN102747407ARealize follow-up conductionTo achieve the purpose of rotating conductionElectrolysis componentsElectricitySpring steel

The invention provides a rotary conduction mechanism. The rotary conduction mechanism comprises a rotating device, a conducting device and a conveying device, wherein the rotating device consists of a servo motor, a compaction cylinder and the like, and the servo motor can regulate the rotation speed of a mechanism according to the self-rotation speed of a mandril during traveling. The conducting device is used for conducting by utilizing a carbon brush, and a spring steel sheet is arranged at the tail part of the carbon brush so as to automatically regulate the abrasion loss; and the whole conducting device is compacted on the mandril through the compaction cylinder and is connected with the rotating device through a rotary support to synchronously work. A conveying device is used for conveying the rotating device and the conducting device forwards, and the conveying motor of the conveying device is a variable frequency motor and can freely set the conveying speed. According to the rotary conduction mechanism, the rotating device, the conducting device and the conveying device work together so as to reach a purpose of rotary electricity conduction, a follow-up patch type electricity conduction operation is realized, and the rotary electricity conduction of the mandril can be realized in an electroplating process, thus the surface plating layer is more uniform.

Owner:WUXI PENTE ENVIRONMENTAL PROTECTION ENG

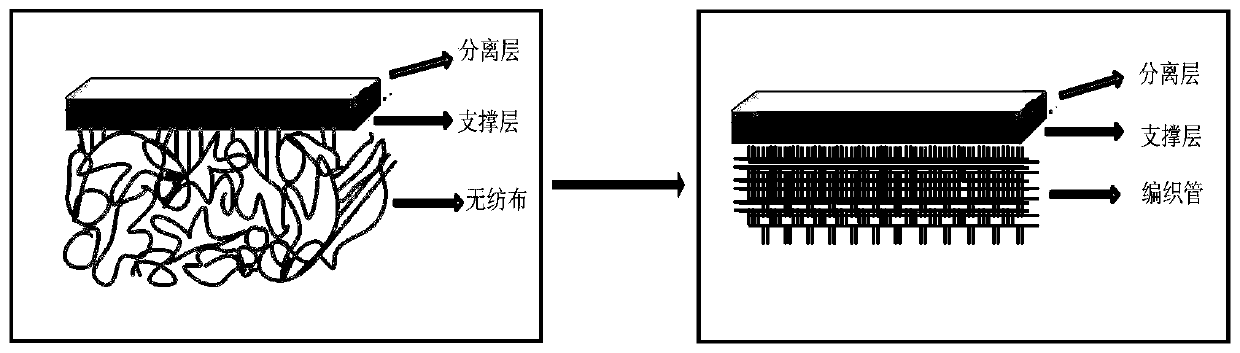

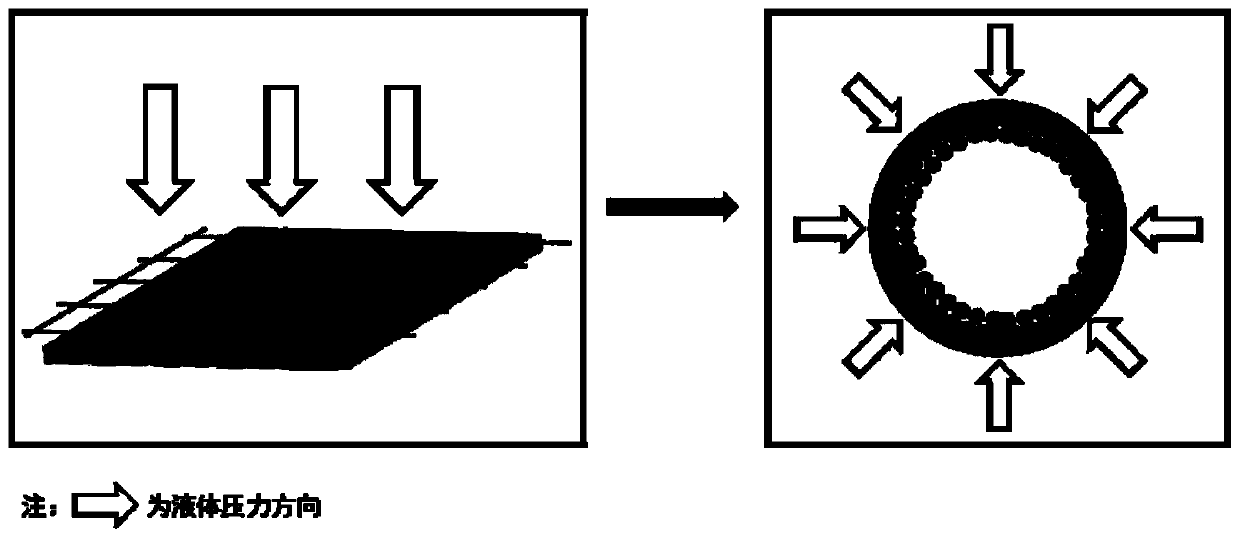

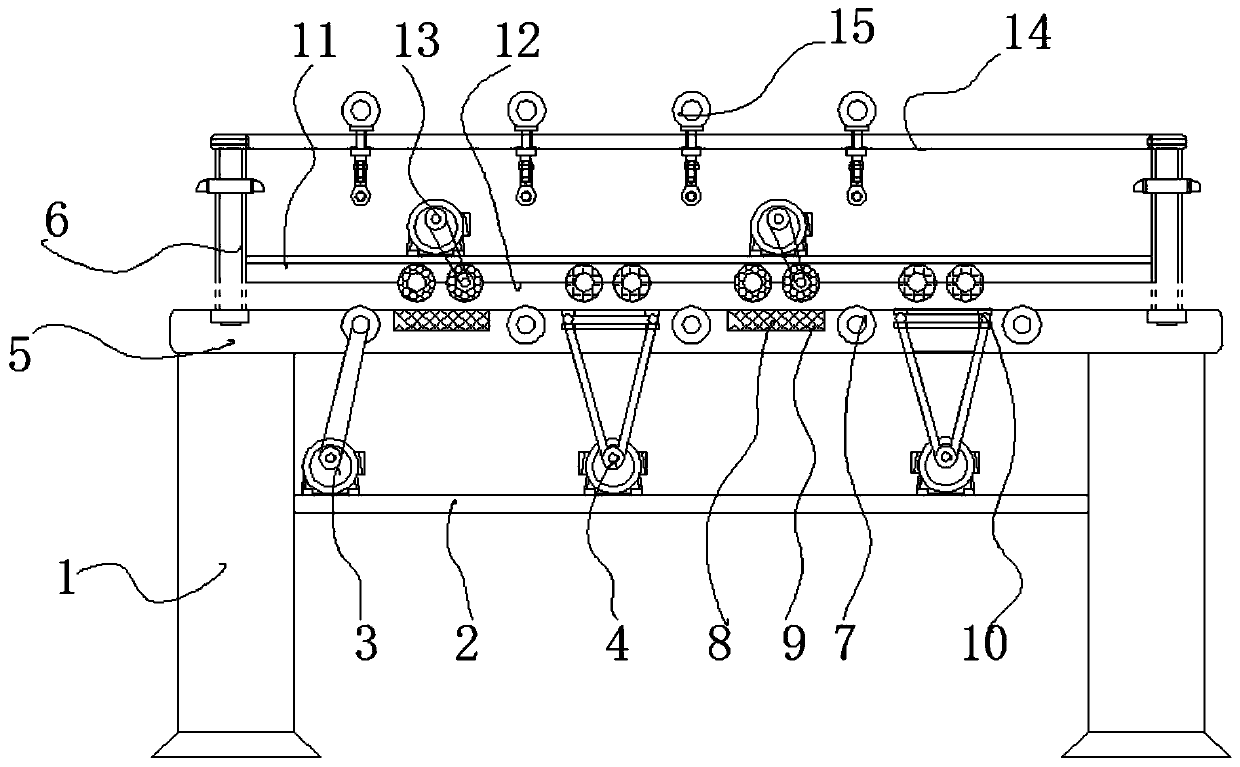

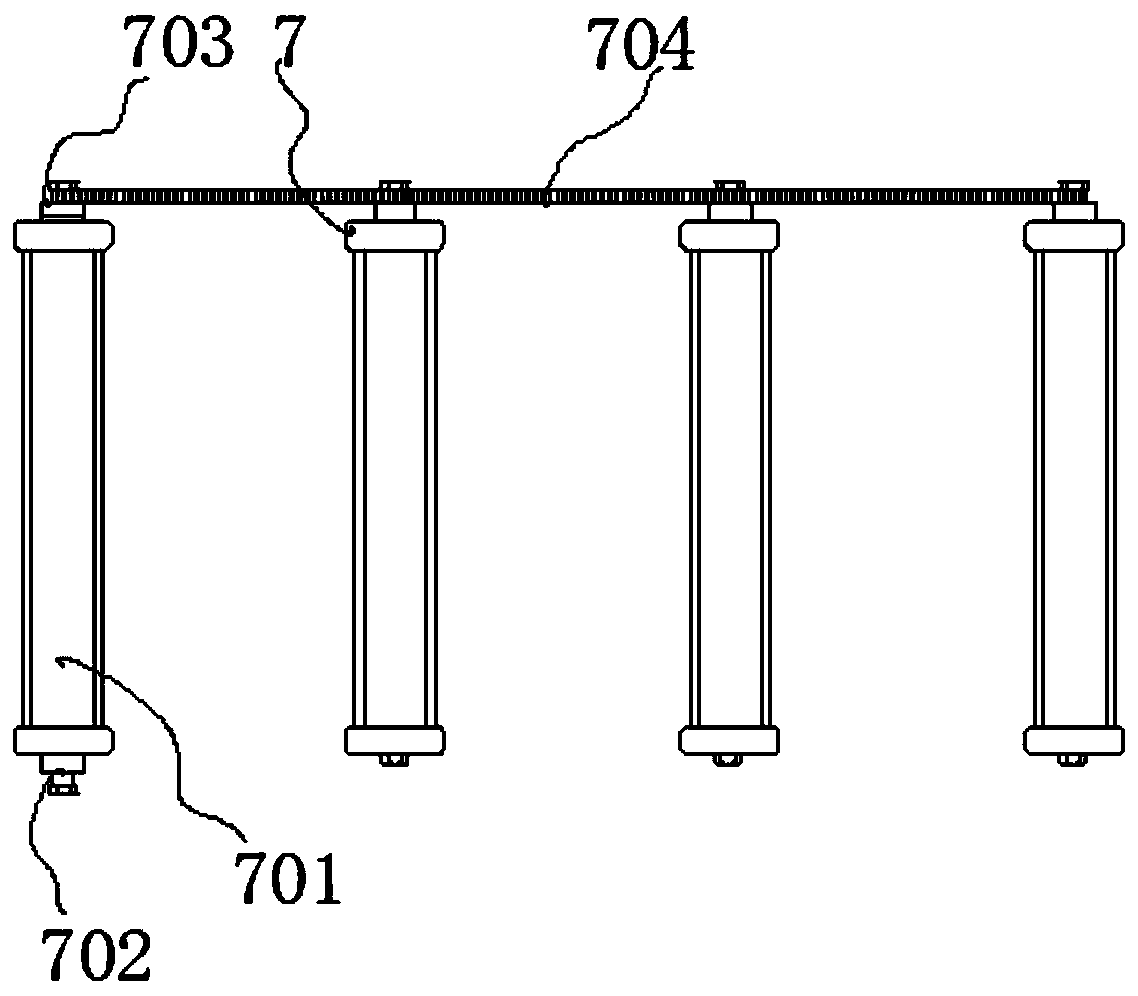

Application of hollow fiber braided tube, hollow fiber desalination membrane and preparation method thereof

The invention provides uses of a hollow fiber braiding pipe, and a hollow fiber desalination film and a preparation method thereof, particularly a hollow fiber braiding pipe reinforcing type desalination film obtained by using the hollow fiber braiding pipe. The preparation method comprises: (1) adopting a hollow fiber braiding pipe as a base lining, carrying out high temperature singeing treatment, removing disordered fibers from the braiding pipe surface, and preparing a hollow fiber ultra-filtration film by coating a polymer on the surface; and (2) forming an ultra-thin desalination layer (interface polymerization function layer) on the surface of the hollow fiber ultra-filtration film by using an interface polymerization method through a polyamine aqueous solution and a polyacyl chloride organic solution. According to the present invention, the obtained hollow fiber desalination film is a low-defect film, wherein the utilization rate of the film can be effectively improved, the additional economic cost caused by the film defect can be reduced, a certain positive role is provided in the film preparation and the film application promotion, and the film fiber generates the self-compacting during the use process due to the influence of the high operation pressure, and it is ensured that no defect is generated during the running process.

Owner:TIANJIN MOTIMO MEMBRANE TECH

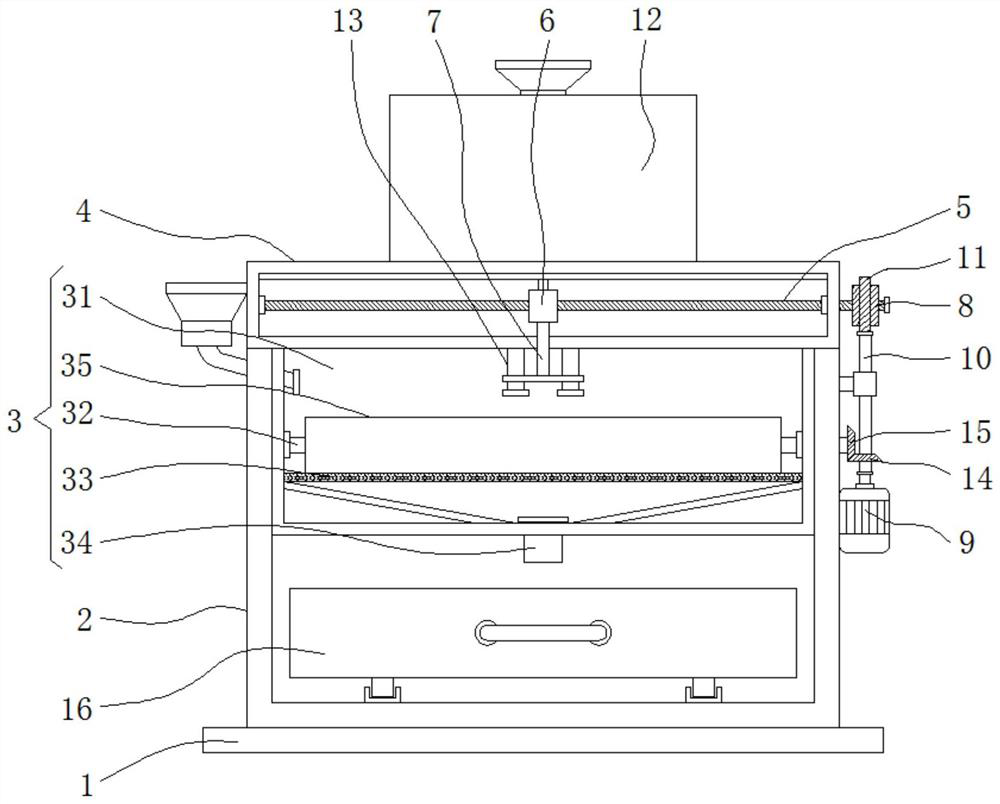

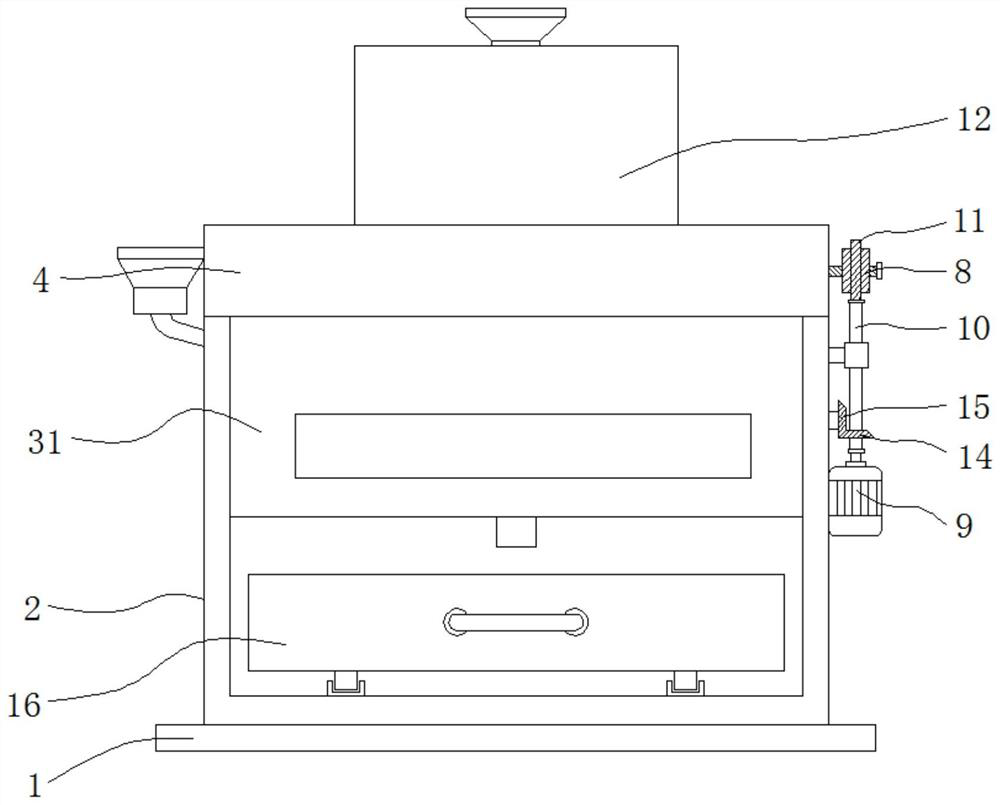

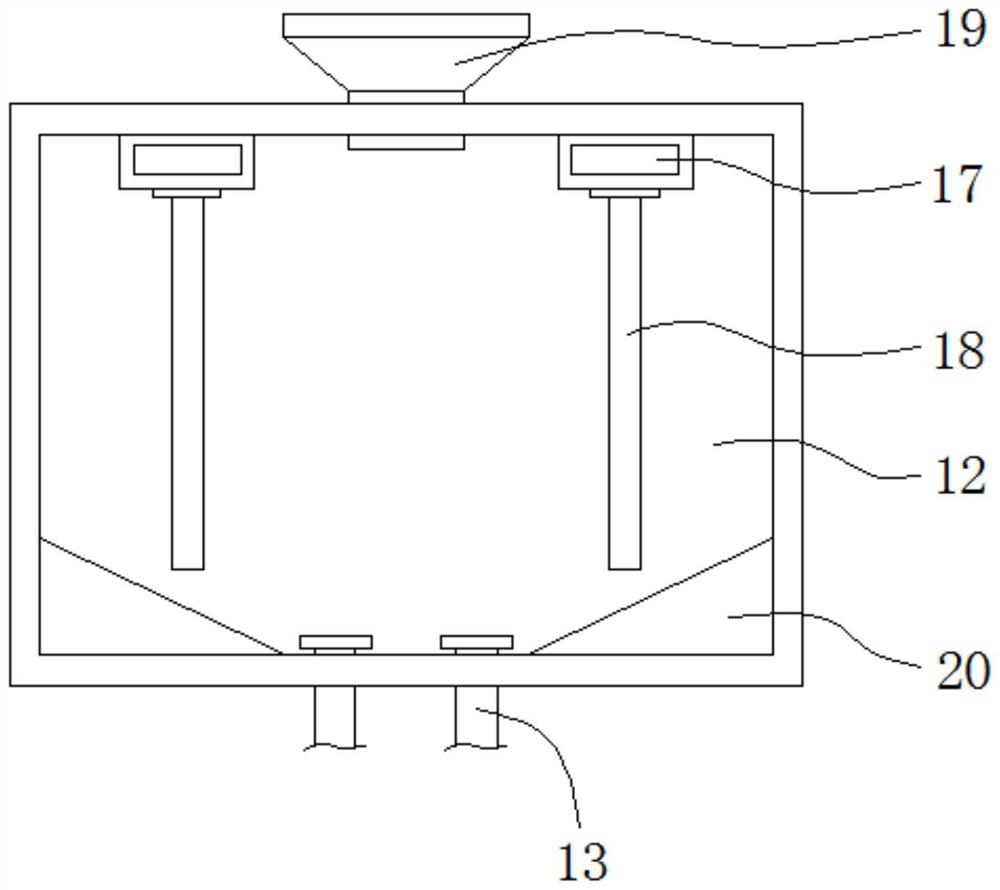

Coating device for warp knitting coated cloth

InactiveCN111036500AUniform coating on the surfaceGood coating efficiencyLiquid surface applicatorsCoatingsElectric machineCotton material

The invention discloses a coating device for warp knitting coated cloth. The coating device comprises supporting columns and a top plate. A bottom plate is fixed between the supporting columns; a vibration motor is mounted on the right side of a first motor; a workbench is fixed to the upper portion of the supporting columns. An auxiliary heating plate and a vibration mechanism are installed on the surface of the workbench, an electric heating wire is installed in the auxiliary heating plate, an installation groove is arranged in the workbench, a fixing plate is fixed between hydraulic telescopic columns, an upper coating mechanism is installed on the lower surface of the fixing plate, and a feeding mechanism is installed in the middle of the top plate. Two different materials can be coated on the cloth simultaneously in the coating process of the cloth, the coating efficiency is greatly improved, the surface of the cloth can be coated more uniformly through different upper and lower coating means in the coating process, the material can be cooled after the temperature of the material on the surface of the cloth is kept consistent and the phenomenon that the coating material is caked on the surface of the cloth is avoided.

Owner:浙江亦阳新材料有限公司

A kind of preparation method of wear-resistant and corrosion-resistant nickel-based alloy coating

ActiveCN104032256BImprove corrosion resistanceImprove work efficiencyMolten spray coatingWear resistantAlloy coating

The invention discloses a method for preparing a wear-resisting corrosion-resisting nickel-based alloy coating. The method comprises the following steps: cleaning the surface of a workpiece to be sprayed, subsequently performing abrasive blasting to coarsen, further washing, spraying a nickel alloy coating of which the thickness is 40-60mu m onto the washed surface by using a supersonic speed plasma spraying system and a plasma spray gun, after the spraying, naturally cooling in air so as to obtain the nickel-based alloy coating, wherein the spraying process parameters are as follows: the power is 30-40KW, the powder supply velocity is 20-30g.min<-1>, the main gas flow is 90-110L.min<-1>, and the spraying distance is 90-110mm. Due to adoption of the method that the wear-resisting corrosion-resisting nickel-based alloy coating is prepared by using a supersonic speed plasma spraying technique, the obtained nickel-based alloy coating is compact, the surface of the coating is uniform, the coating is good in adhesion strength with the workpiece, the hardness of the coating can meet the requirement, and the technique requirements of wear-resistance and corrosion-resistance at high temperature (300 DEG C) can be well met.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

A coating ingredient for glassine paper

ActiveCN106638150BReduce consumptionUniform coating on the surfaceCoatings with pigmentsPaper/cardboardAcrylic resinPVA - Polyvinyl alcohol

A glassine coating material is prepared from, by total coating formulation weight, 3-5% of at least one or two pigments different in molecular weight, 1-2% of at least one type of acrylic resin, 2-4% of at least one type of polyvinyl alcohol, 1-3% of at least one type of latex, 0.1-0.3% of at least one functional additive, 0.01-0.03% of at least one viscosity modifier and the balance water. After addition of the viscosity modifier, coating viscosity is controlled within a range of 500-600mPa.S. Glassine which adopts the glassine coating material has advantages of freeness of repellence to silicon oil coating, uniformity in silicon oil coating, low consumption and the like.

Owner:MINFENG SPECIAL PAPER

Motor shaft with insulating ceramic and preparation method thereof

InactiveCN111646781AHigh hardnessExcellent dielectric propertiesShaftsMechanical energy handlingPolyvinyl alcoholBasalt fiber

The invention discloses a motor shaft with an insulating ceramic, which comprises a shaft body, an annular groove is formed in the outer ring of the shaft body, and an annular insulating ceramic layerwith the thickness of 0.012-0.015 mm is covered in the groove. The invention discloses a preparation method of the motor shaft with the insulating ceramic, which comprises the following steps: ball-milling and mixing alumina powder, composite basalt fiber, zirconium dioxide, cerium dioxide, polyvinyl butyral, a flexibilizer, a densifier, a refiner and a tackifier until the particle size is less than or equal to 0.1 mu m, and drying at 105-112 DEG C to obtain a premix; derusting and descaling the surface of a shaft body through a grinding wheel to be smooth and clean, then polishing the shaftbody through abrasive paper, removing greasy dirt with acetone, pickling with hydrochloric acid, washing with ethanol, and drying to obtain a pretreated shaft body; and electroplating the premix to the surface of the pretreated shaft body, accurately grinding until the coating thickness is 0.012-0.015 mm, and polishing to obtain the motor shaft with the insulating ceramic.

Owner:中擎电机有限公司

A laser cladding process

ActiveCN109183029BReduce pollutionImprove bindingMetallic material coating processesLaser processingPhysical chemistry

The invention relates to the technical field of laser processing, in particular to a laser cladding process. Including the following steps: S1: cleaning the surface of the metal component, using a detergent to remove surface oil; S2: preheating the metal component in a heat treatment furnace; S3: using a laser and adding prefabricated alloy powder for laser cladding; S4: laser After the radiation leaves, it is cooled rapidly, and the surface of the metal component is ground and polished after cooling. The invention is suitable for industrial production, can replace the chrome-plating process, saves coating cost, and reduces environmental pollution; the obtained coating has high hardness, good wear resistance, and better combination of the coating and the workpiece surface.

Owner:佛山市南海区科琎精密机械有限公司

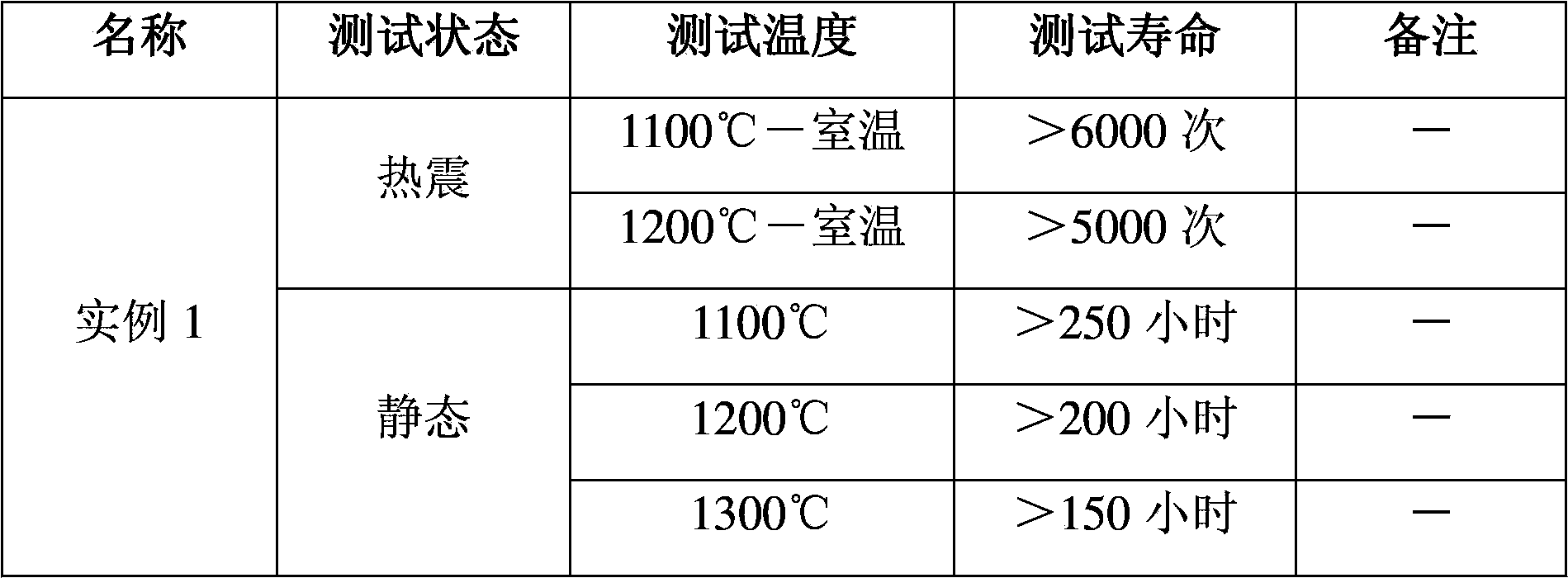

High temperature oxidation-resistant material for low-density niobium alloy and method for preparing high temperature oxidation-resistant coating from high temperature oxidation-resistant material

InactiveCN102719713BSolve the problem of severe oxidationExtended service lifeHeat inorganic powder coatingCoated surfaceOxidation resistant

The invention relates to a high temperature oxidation-resistant material for low-density niobium alloy and a method for preparing a high temperature oxidation-resistant coating from the high temperature oxidation-resistant material. The high temperature oxidation-resistant material is characterized by comprising the following components in weight percentage: 10-15wt% of Si, 2-3wt% of Ti, 1-2wt% of Mo, 0.8-1.2wt% of HfO2, 0.7- 0.9wt% of W and the balance of Al. The high temperature oxidation-resistant coating prepared from the high temperature oxidation-resistant material effectively solves the problem of severe oxidation of low-density niobium alloy in an atmospheric environment above 800-degree C, especially about 1100-degree C, keeps high-temperature mechanical properties of the low-density niobium alloy to the maximum extent, expands the application range of low-density niobium alloy and prolongs the service life of low-density niobium alloy; moreover, the high temperature oxidation-resistant coating prepared from the high temperature oxidation-resistant material has good high temperature oxidation resistance, a uniform coating surface and a dense microstructure.

Owner:NINGXIA ORIENT TANTALUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com