Surface coating device for automobile body pillar machining

A technology of surface coating and automobile body, which is applied in the direction of surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of column processing influence, column falling off, etc., achieve uniform coating, prevent inconvenience, increase The effect of high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

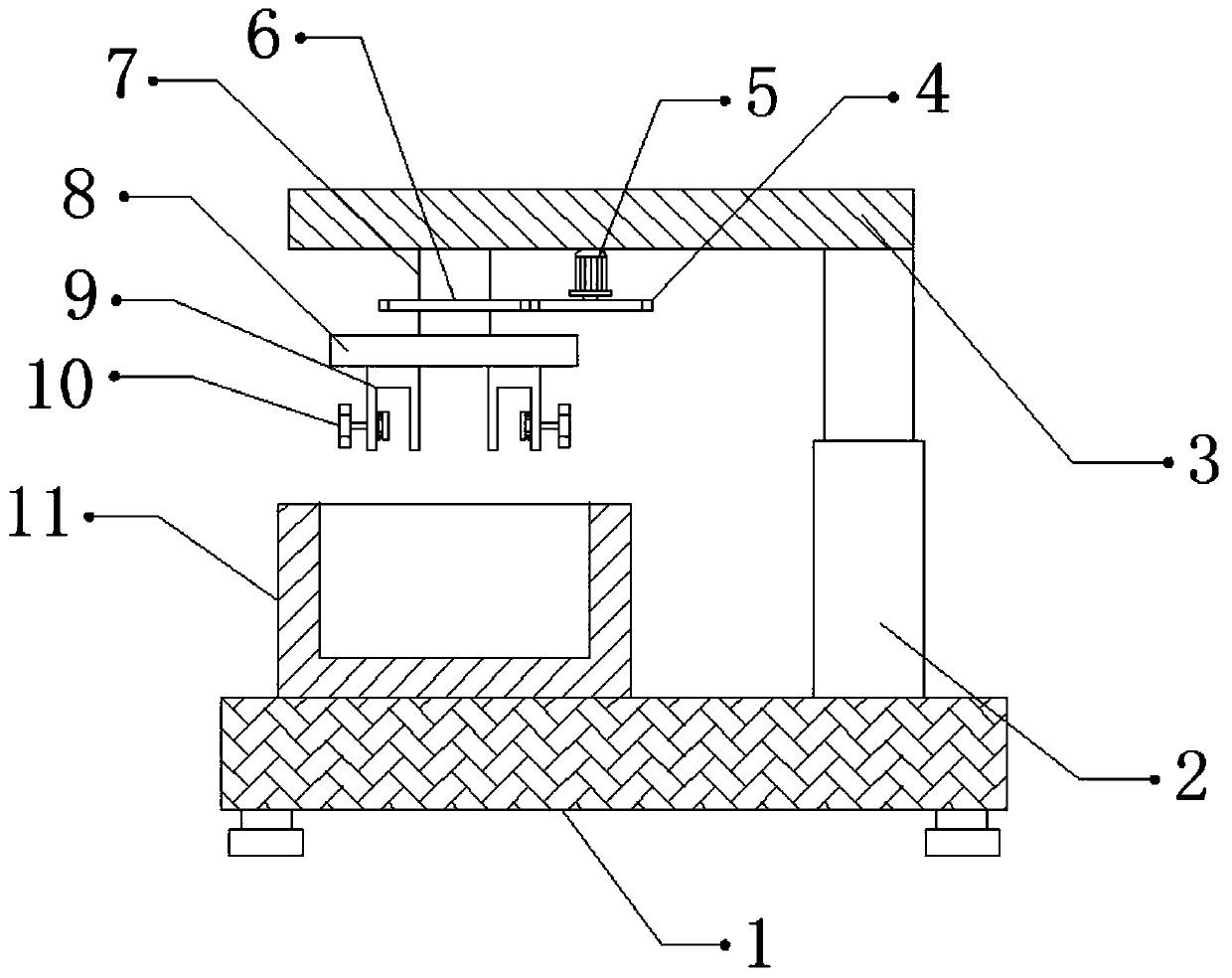

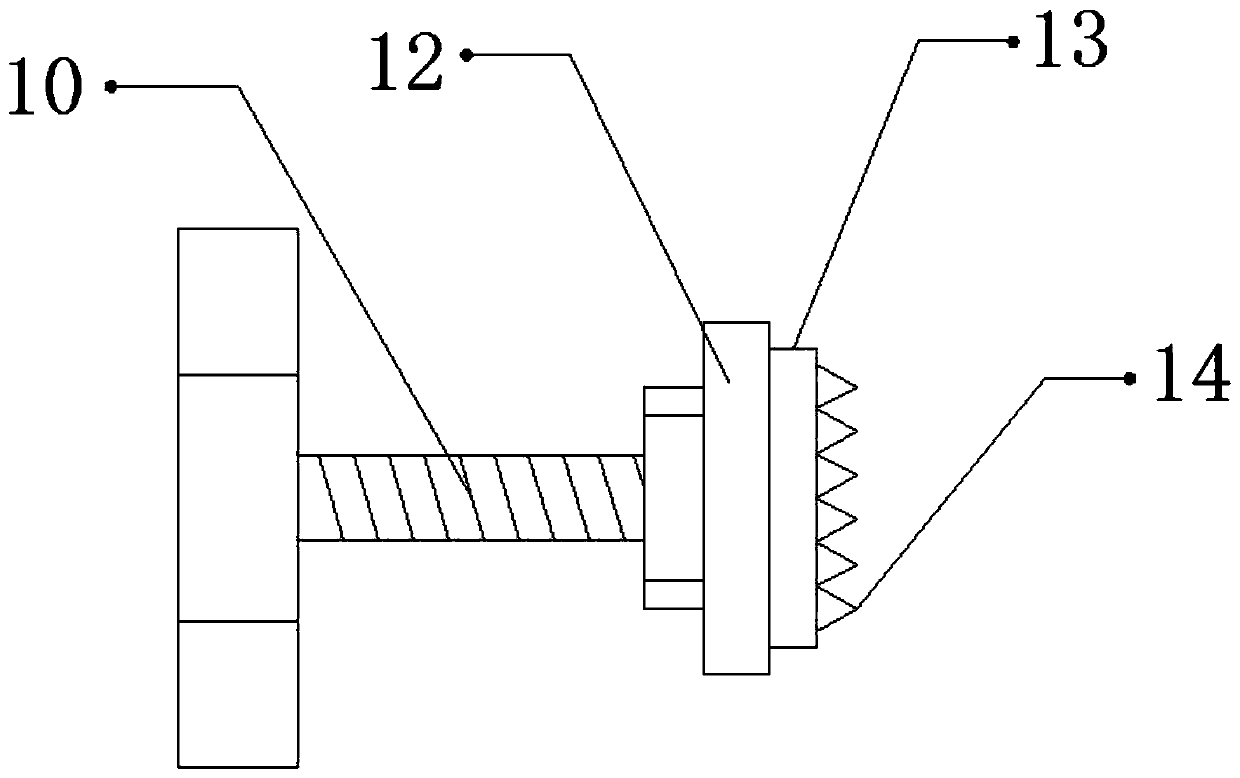

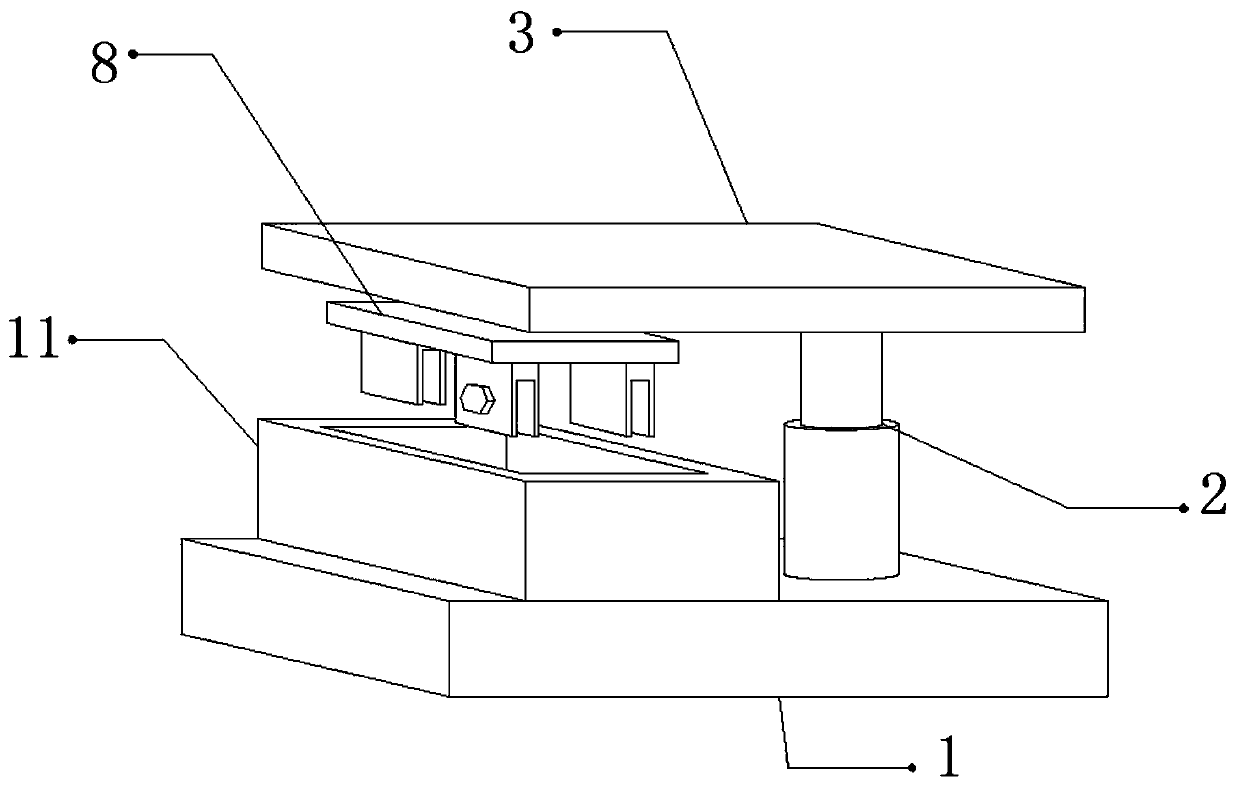

[0026] refer to Figure 1-3 , a surface coating device for automobile body column processing, including a fixed seat 1, one side of the top outer wall of the fixed seat 1 is connected with an electric telescopic rod 2 by bolts, and the top outer wall of the electric telescopic rod 2 is connected with a support plate 3 by bolts , one side of the outer wall at the bottom of the support plate 3 is rotatably connected with a rotating rod 7 through a bearing, and the outer wall at the bottom of the rotating rod 7 is connected with a fixed plate 8 by bolts, and the outer wall at the bottom of the fixed plate 8 is connected with a U-shaped frame 9 by bolts, and the U A side outer wall of the frame 9 has a threaded hole, and the inner wall of the threaded hole is threadedly connected with a fixed bolt 10, and the fixed bolt 10 is connected with a splint 12 through a nut, and the outer wall of the side of the splint 12 is glued with a protective pad 13, and the protective pad One side ...

Embodiment 2

[0030] refer to Figure 4 , a surface coating device for automobile body column processing. Compared with Embodiment 1, one side of the outer wall of the bottom of the support plate 3 is connected with a connecting plate 15 by bolts, and the outer wall of one side of the connecting plate 15 is connected by bolts. There is a dryer 16, and the dryer 16 is electrically connected to the switch.

[0031] Working principle: when in use, put the coating liquid into the collection box 11, and clamp and fix the splint 12 to the column to be coated by twisting the fixing bolt 10, and the protection pad 13 and the fixing teeth 14 can increase the The friction between the large column and the U-shaped frame 9 is convenient for fixing the column, preventing the column from falling off from the U-shaped frame 9 due to the centrifugal force generated during rotation. After the fixing is completed, turn on the switch, and the electric telescopic rod 2 will drive The column moves downward, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com