Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

551results about How to "To achieve the purpose of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance epoxy resin asphalt warm mixing agent and preparation method thereof

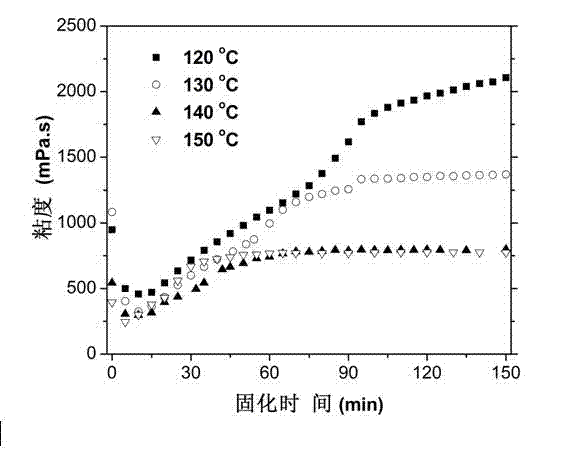

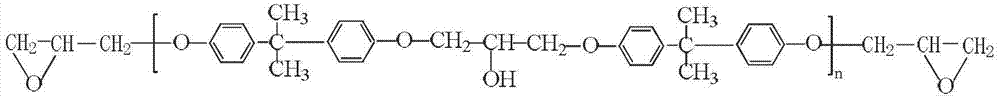

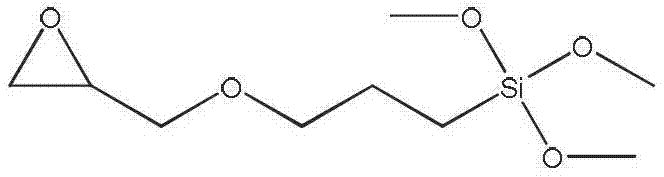

InactiveCN103113752ALow viscositySlow reaction speedClimate change adaptationBuilding insulationsDuctilityDefoaming Agents

The invention discloses a high-performance epoxy resin asphalt warm mixing agent comprising a component A and a component B, wherein the component A is composed of epoxy resin, a reinforcing agent and a coupling agent; the component B mainly comprises a flexible curing agent, an accelerant, a reinforcing agent, a toughening agent and a defoaming agent; and the mass proportion of the component A to the component B is equal to (100:250)-(100:300). High-performance warm mixing epoxy resin asphalt prepared by using the high-performance epoxy resin asphalt warm mixing agent provided by the invention has the characteristics of lower mixing temperature, high strength, better high-temperature ductility resistance and low-temperature fracture resistance, longer construction time, simple construction process, low-carbon and environment friendliness and the like and is suitable for paving pavements of roads, bridges, tunnels, airfield runways and the like. The invention discloses a preparation method of the high-performance epoxy resin asphalt warm mixing agent.

Owner:NANJING UNIV

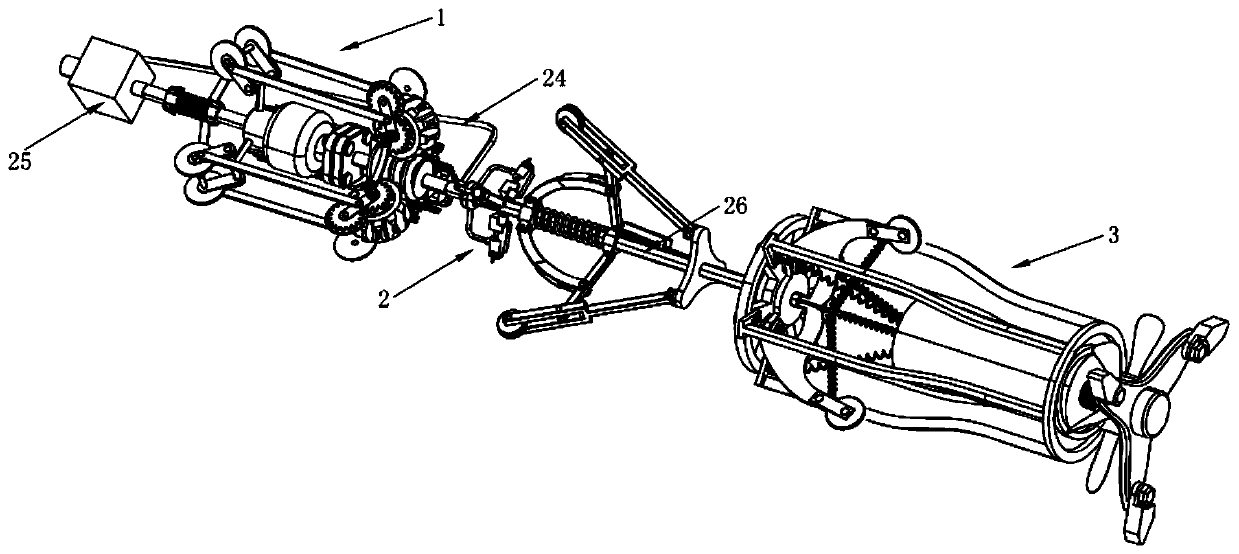

Combined pipeline washing and spraying robot

PendingCN110296294AAvoid influenceTo achieve the purpose of environmental protectionHollow article cleaningSpraying apparatusFlexible MechanismsEngineering

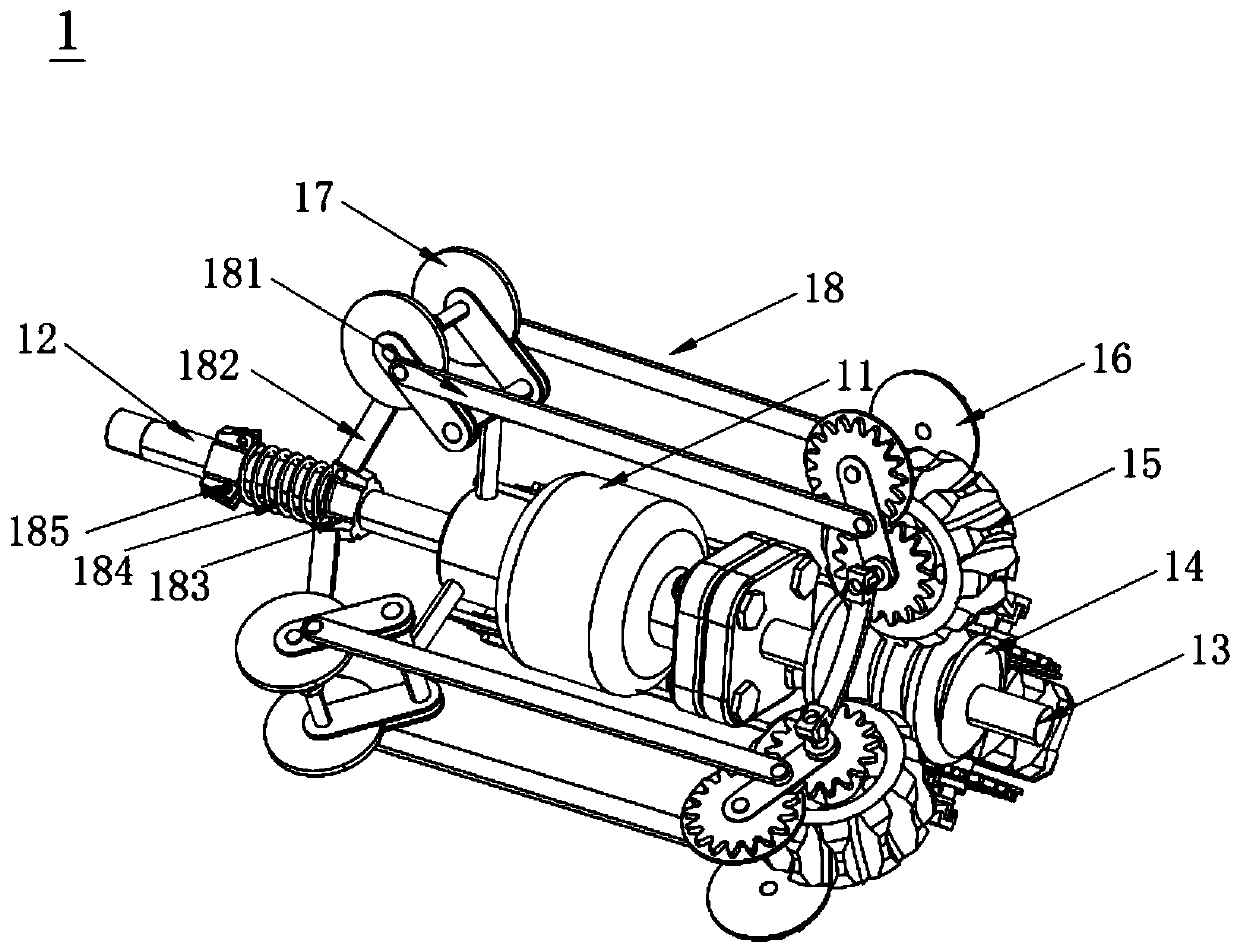

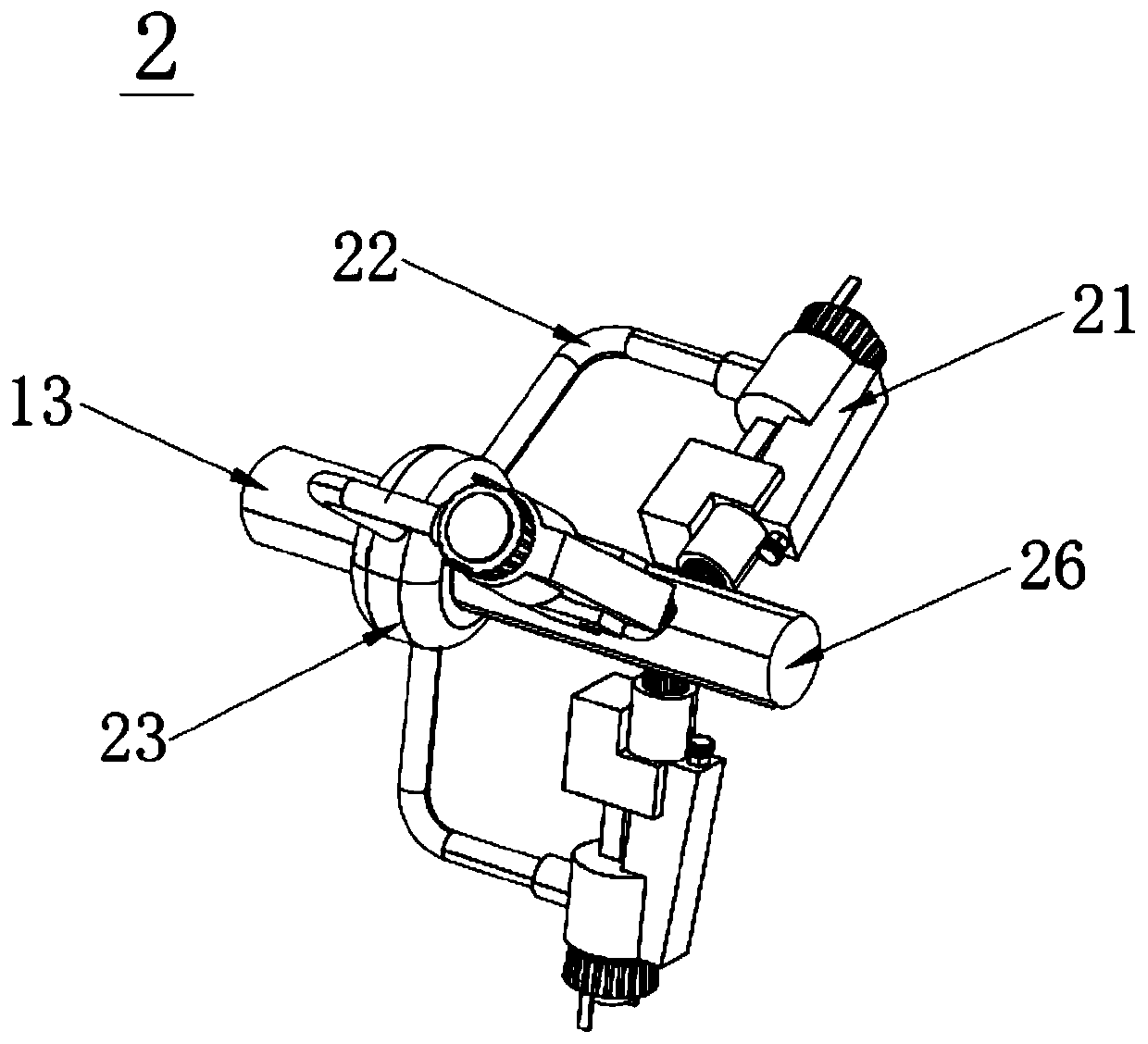

The invention discloses a combined pipeline washing and spraying robot. The combined pipeline washing and spraying robot comprises a moving mechanism, a spraying mechanism and a milling mechanism, wherein the moving mechanism is arranged at the rear end of the whole device, wherein the moving mechanism comprises a driving motor, a worm and a worm gear; one end of the driving motor is fixedly connected to an intermediate shaft at the left side; the spraying mechanism comprises spraying guns which are arranged at equal intervals around the intermediate shaft and are rotated synchronous with theintermediate shaft; the milling mechanism is arranged at the right end of the whole device; the motor is arranged in a flexible mechanism; and one end of the motor is connected to the flexible mechanism through a spring. According to the combined pipeline washing and spraying robot, the moving mechanism mainly composed of the worm gear and the worm is capable of driving the whole device to move ina pipeline; and meanwhile, the milling mechanism is arranged at the front part of the whole device, and dirt on the inner wall of the pipeline can be removed by milling through a cutter; and moreover, a novel cutter coating is adopted, and the process of passivating processing can be avoided, so that the influence of toxic passivating liquid on surrounding environment is avoided, and as a result,the purpose of environmental protection is achieved.

Owner:BENGBU COLLEGE

Large energy accumulation type air source heat pump hot water units

InactiveCN101464058ASave electricityTo achieve the purpose of environmental protectionFluid heatersHeat pumpsWater circulationEngineering

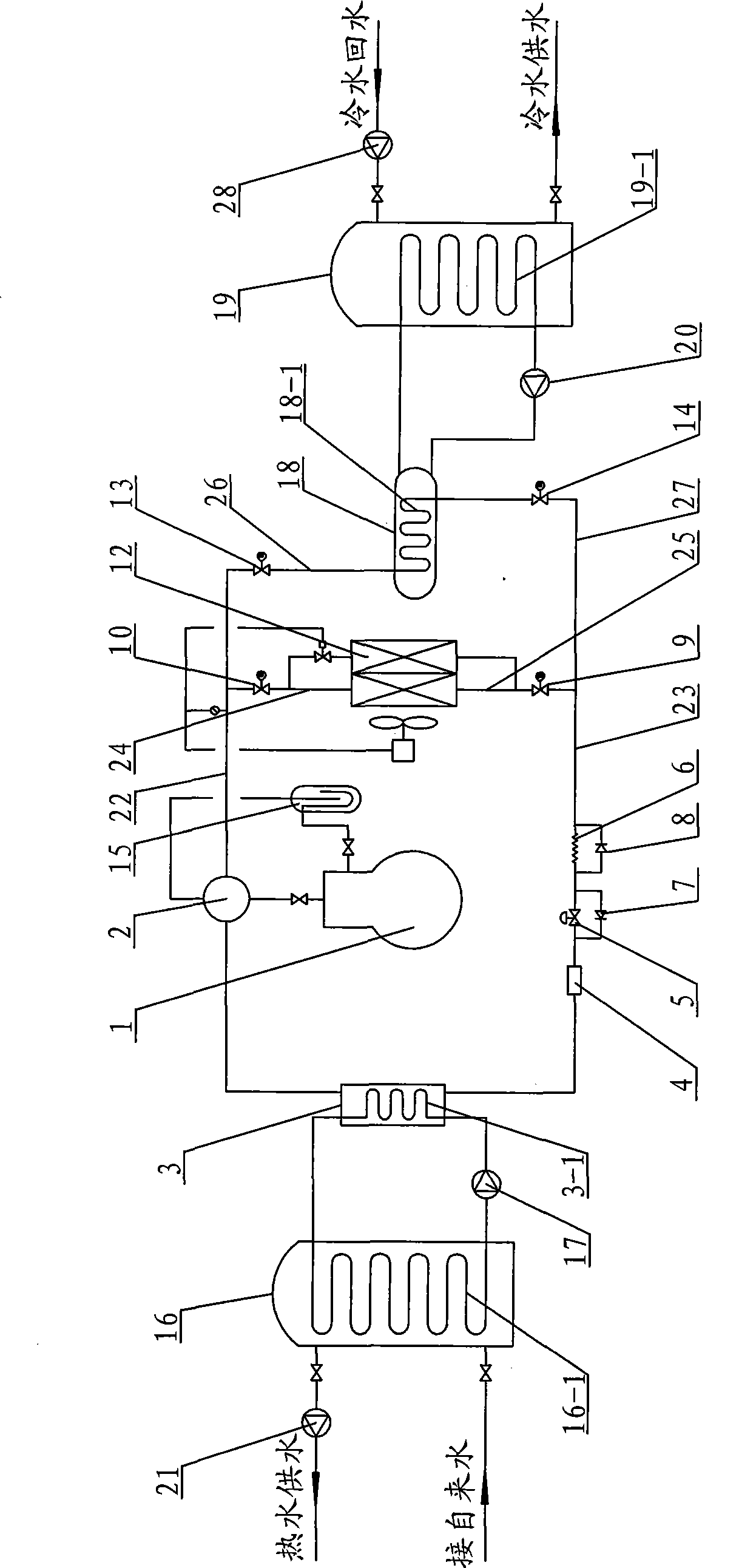

A large energy-storage type air source heat pump hot water unit relates to a heat pump hot water unit. The invention is designed to solve the problems that the existing heat pump system for supplying hot water completely realizes the supply of hot water by electric heating when an air-conditioner stops running and does not have the energy storage function simultaneously. Four valves of a four-way reversing valve are connected with a compressor, a plate heat exchanger, a gas-liquid separator and an outdoor heat exchanger, the outdoor heat exchanger is connected with a capillary, the capillary is connected with a dry filter through an electronic expansion valve, the dry filter is connected with the plate heat exchanger, the gas-liquid separator is connected with the compressor, two ends of a heat-exchange coil in a heat storage tank are respectively connected with two ends of a heat-exchange pipe in the plate heat exchanger, a hot water circulation pump is arranged on a pipeline between the heat storage tank and the plate heat exchanger, and a hot water supply pump is arranged on an output end of the heat storage tank. The large energy-storage type air source heat pump hot water unit can realize the direct water supply, the heat storage at night, the heat storage in winter, the defrosting and other operations and save electric energy by 70 percent compared with an electric water heater and an electric boiler.

Owner:HARBIN INST OF TECH

Method for inducing color changing of wood by grafting metal ions

InactiveCN106584624AGood dimensional stabilityAccelerated corrosionWood treatment detailsWood impregnation detailsSulfateColor changes

The present invention relates to a wood treatment technology, and provides a method for inducing the color changing of a wood. The method comprises: immersing a selected wood in a previously prepared metal ion sulfate solution for 1 h at a temperature of 80 DEG C, carrying out water washing, and drying under a certain condition, wherein the metal ion sulfate solution is any one selected from the sulfate solution of metal ions such as Na<+>, Fe<2+>, Cu<2+> and Mn<2+>, the concentration of the solution is 10%, the heat treatment temperature of the heat treatment process is 80-130 DEG C, preferably 120 DEG C, and the heat treatment time is 8-20 h. With the application of the method of the present invention to treat the wood, the chromatic value of the treated wood is high, the treated wood is dark red or dark yellow, the color is uniform, stable and comfortable, and the use value of the low color quality wood is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Solar greenhouse muskmelon organic ecological soilless culture technology

InactiveCN103598076AIncreased growth cycleIncrease productionAgriculture gas emission reductionCultivating equipmentsPest controlSeed treatment

A solar greenhouse muskmelon organic ecological soilless culture technology is characterized by including substrate preparation, culturing tank placing, variety selection, seed processing, sowing and seedling raising, scientific planting, moisture management, nutrition management, plant regulation, greenhouse environment regulation and control, and pest control. By the technology suitable for vegetable farmers to grow muskmelon in solar greenhouses, the problems of labor consuming, water and fertilizer waste, severe soil-borne diseases, and the like in the existing muskmelon culturing methods are solved.

Owner:QINGDAO DONGYI JINHE AGRI TECH

Preparation method for environment-friendly starch-based binder

InactiveCN102367367AImprove stabilityImprove adhesionProtein adhesivesStarch derivtive adhesivesPolyvinyl alcoholCitric acid

The invention discloses a preparation method for an environment-friendly starch-based binder. According to the method, oxidized starch and modified protein are mixed according to a mass ratio of 2:1 to 5:1; polyvinyl alcohol is added according to a mass ratio of oxidized starch to polyvinyl alcohol of 2:1 to 5:1 and uniformly mixed with oxidized starch and modified protein, and an obtained mixture is subjected to a reaction for 2 to 5 hours at a temperature of 50 to 80 DEG C; first liquid of the binder is prepared; the first liquid of the binder is taken out, an auxiliary agent is added, and the environment-friendly starch-based binder is prepared by uniformly mixing the first liquid of the binder and the auxiliary agent; the auxiliary agent is borax and / or citric acid, and the amount of the auxiliary agent accounts for 2 to 5% of the amount of dry starch base. The oxidation starch is prepared by using sodium periodate as an oxidizing agent and mixing the oxidizing agent with starch at a temperature of 20 to 50 DEG C; the raw material in the invention, starch, undergoes a chemical reaction with protein and produces firm chemical bonds, which enables a net structure of the binder to be formed; the net structure and the action of cross-linking agents allow the binder to have improved stability and enhanced water resistance; the invention enables cost to be saved and the goal of environmental protection to be realized.

Owner:SOUTH CHINA UNIV OF TECH

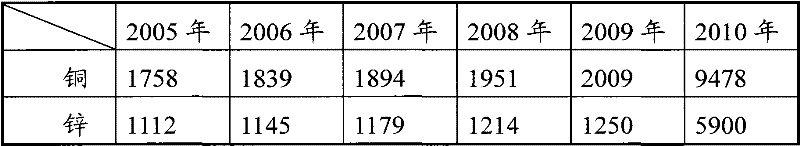

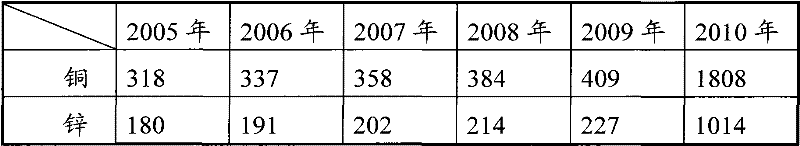

High elasticity and high conductivity beryllium-free copper alloy material and processing technique

ActiveCN101423906AAchieve performanceTo achieve the purpose of environmental protectionMachining processImpurity

The invention provides a high-elasticity high-conductivity beryllium-free copper alloy material and a machining process thereof. The alloying components in weight percentage of the material are divided into two groups as follows: (1) determined components: 90 to 97 percent of Cu, 1.8 to 7.0 percent of Ni, 0.20 to 1.8 percent of Si, 0.20 to 0.40 percent of Zn, and the balance being inevitable impurities, wherein the sum of the weight percentages of the alloying components is 100 percent; and (2) mutually replaceable components: 0.05 to 0.30 percent of Mg or 0.05 to 0.20 percent of Al, 0.05 to 2 percent of Cr or 0.05 to 2 percent of Ti or less than or equal to 0.5 percent of B or 0.05 to 0.2 percent of P or less than or equal to 0.3 percent of one or more than one among La, Ce and Nd, and the balance being inevitable impurities, wherein the sum of the weight percentages of the alloying components is 100 percent. A process flow adopts the following working procedures of proportioning, melting, casting, heating, hot-rolling, dissolving solids, milling surface, blooming, thermally treating deformation, finishing, checking and packaging. The machine process is characterized in the working procedures of proportioning, melting-casting, heating, dissolving solids and thermally treating deformation.

Owner:中铝洛阳铜加工有限公司

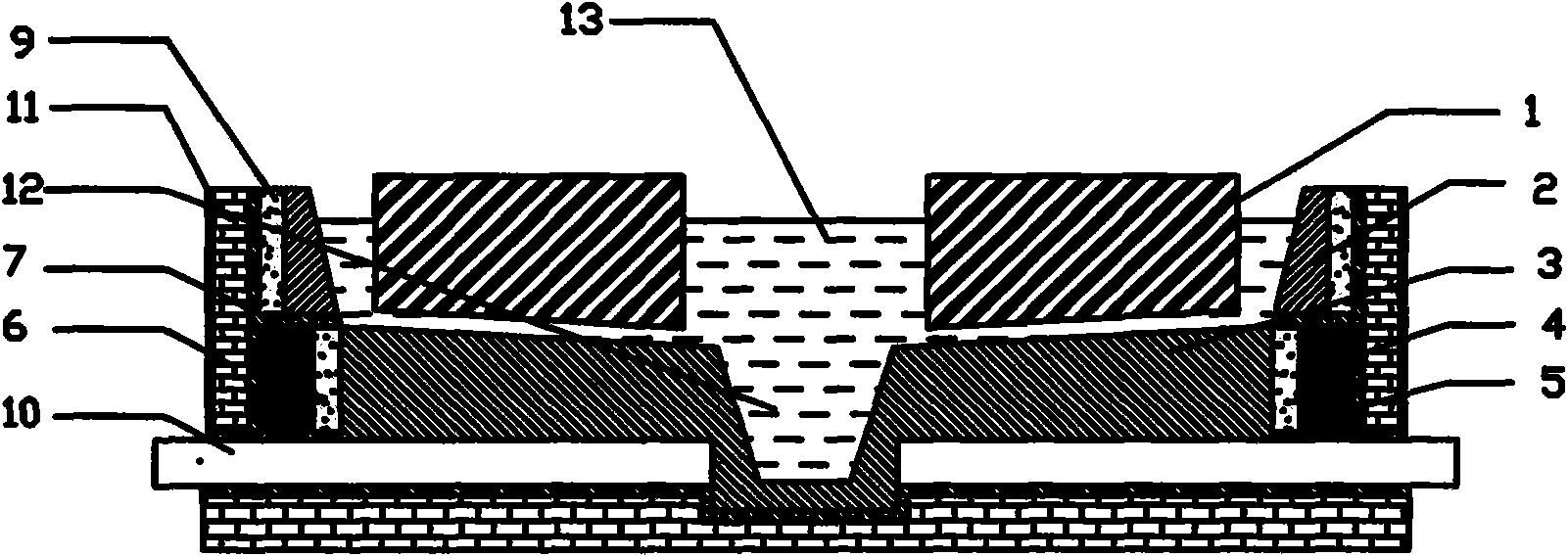

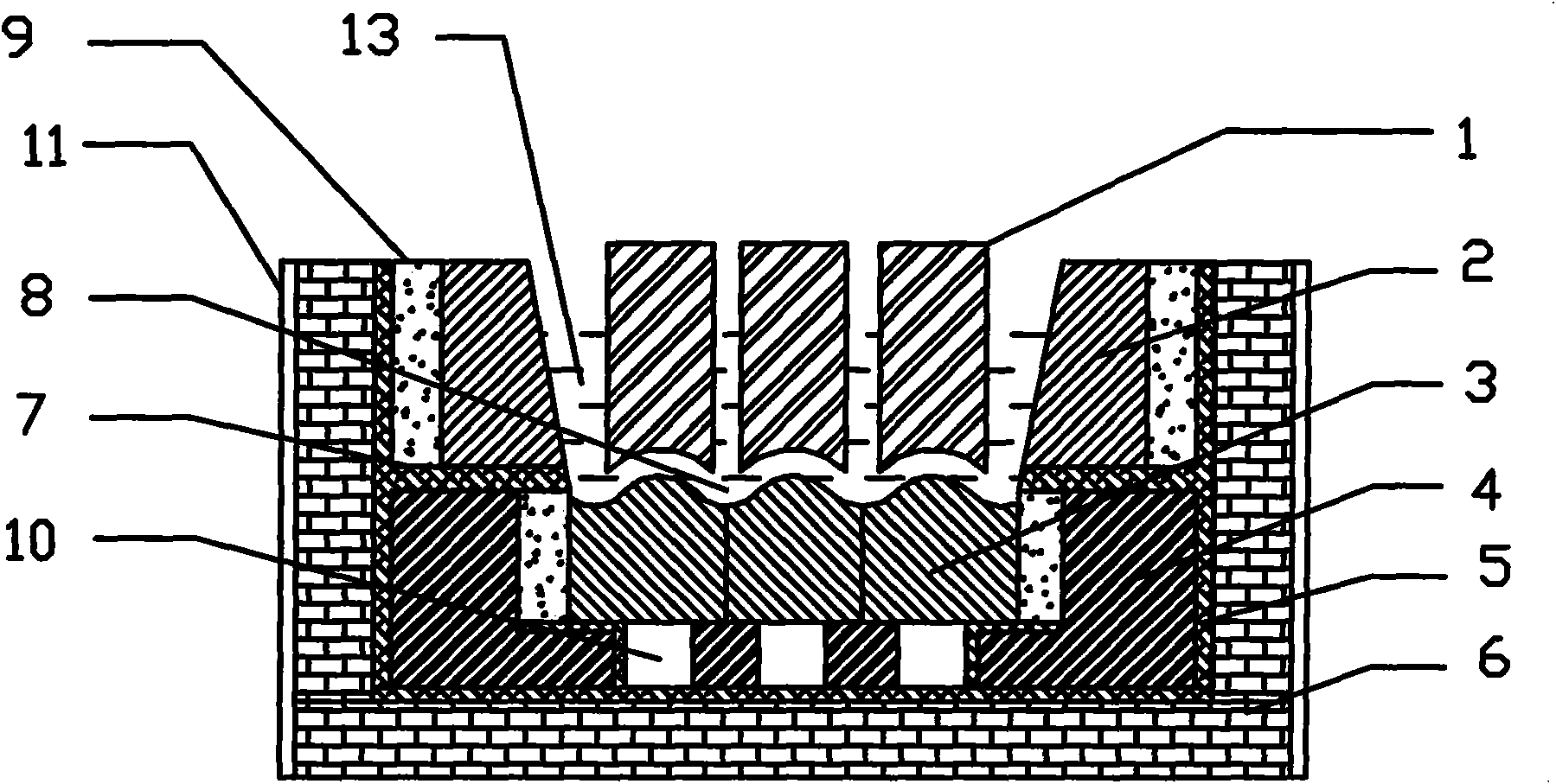

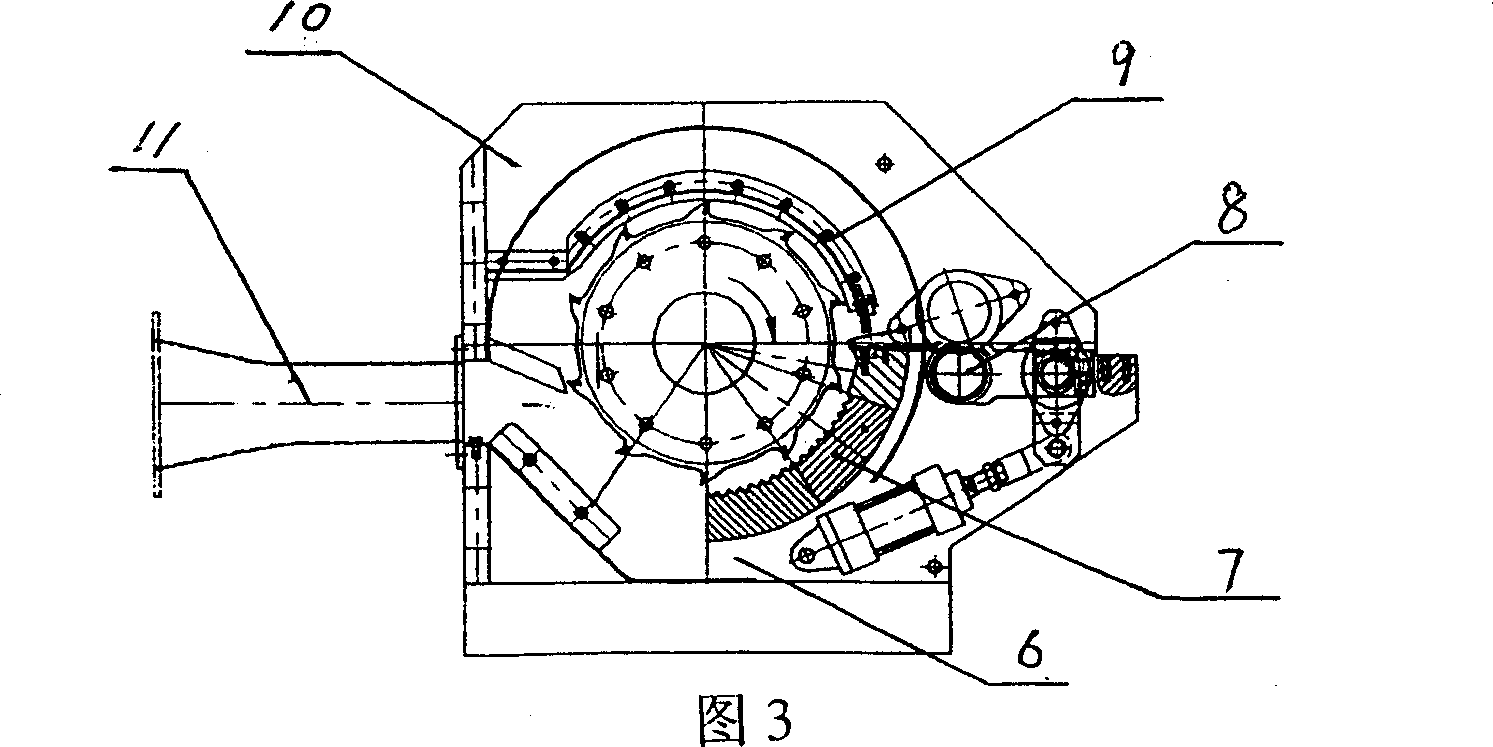

Bottom cathode diversion type rare earth electrolysis cell

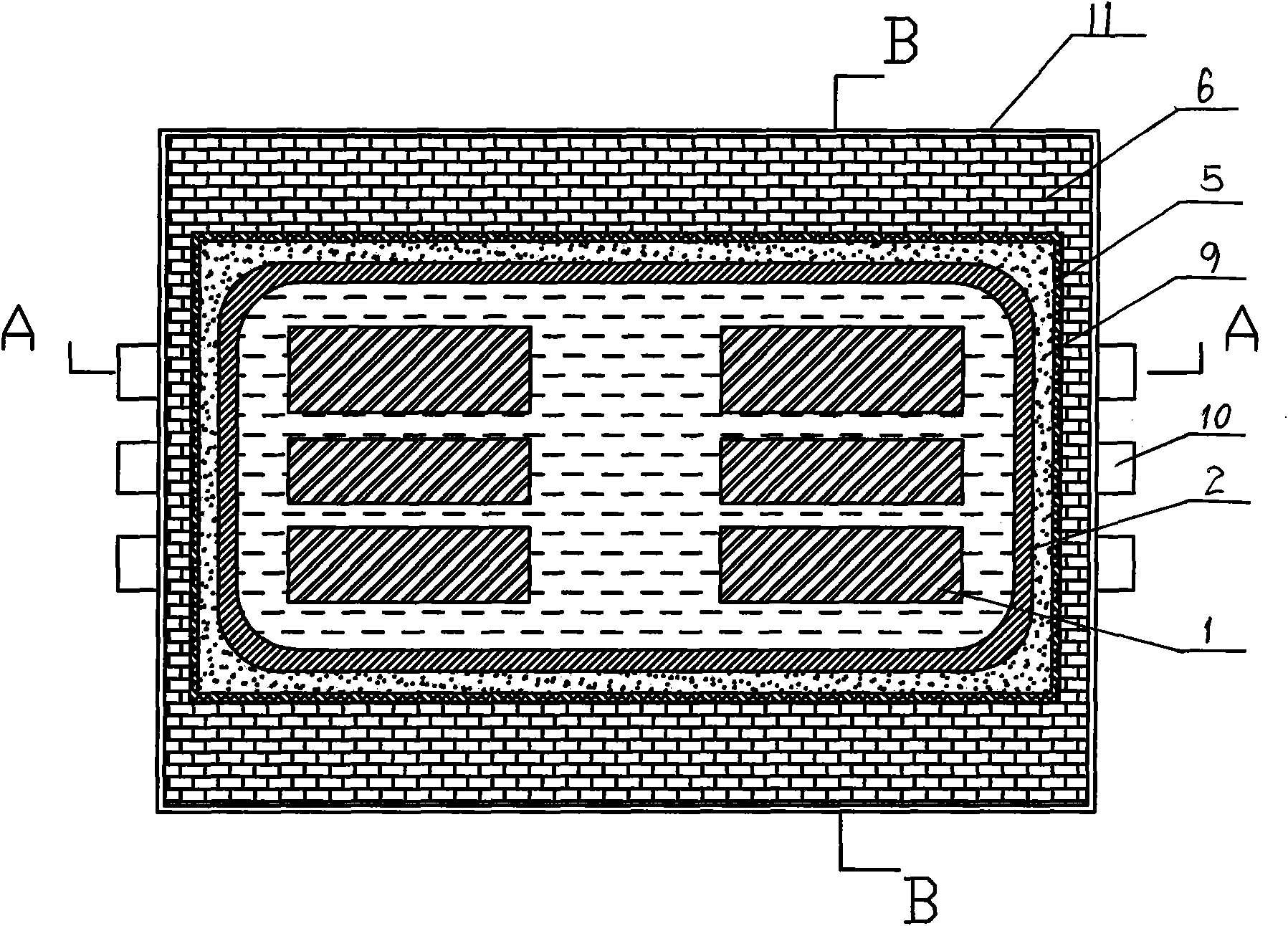

The invention relates to an electrolysis cell in the metallurgy field, in particular to a bottom cathode diversion type rare earth electrolysis cell which is suitable for improvement and development of a rare earth electrolysis cell. In the invention, cathodes are arranged just below anodes, the bottom of each anode is an arc concave surface, the top part of each cathode is an arc convex surface, the arc concave surface of each anode is arranged corresponding to the arc convex surface of each cathode, the cathodes are arranged in parallel, a diversion cell is formed at the connecting part of the cathodes, a high temperature insulating layer is arranged between the cathodes and a graphite crucible, and a cathode conductive bar is arranged below the cathodes. In the invention, a novel cathode and anode structure is designed, the requirement of high current density of the cathode and low current density of the anode in the electrolysis process because rare metals are all lively is met, the residence time of electrolysis metal drops in an electrolysis region is reduced by adopting a diversion type cathode structure, the secondary oxidation of the metals can be effectively reduced, the metal yield is improved, mature wiring mode and technology of the traditional electrolysis cell are effectively utilized by adopting the bottom cathode arrangement mode, and the generalization and macro-scale of the cell type are facilitated.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

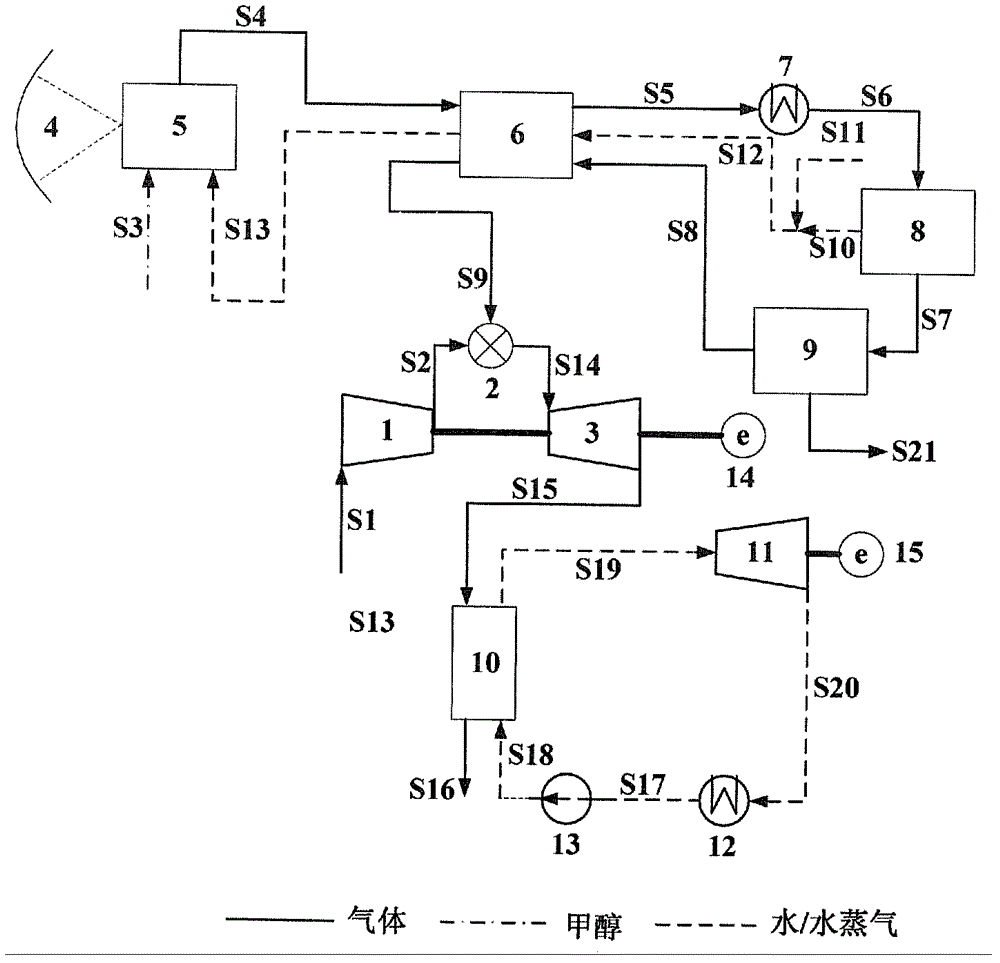

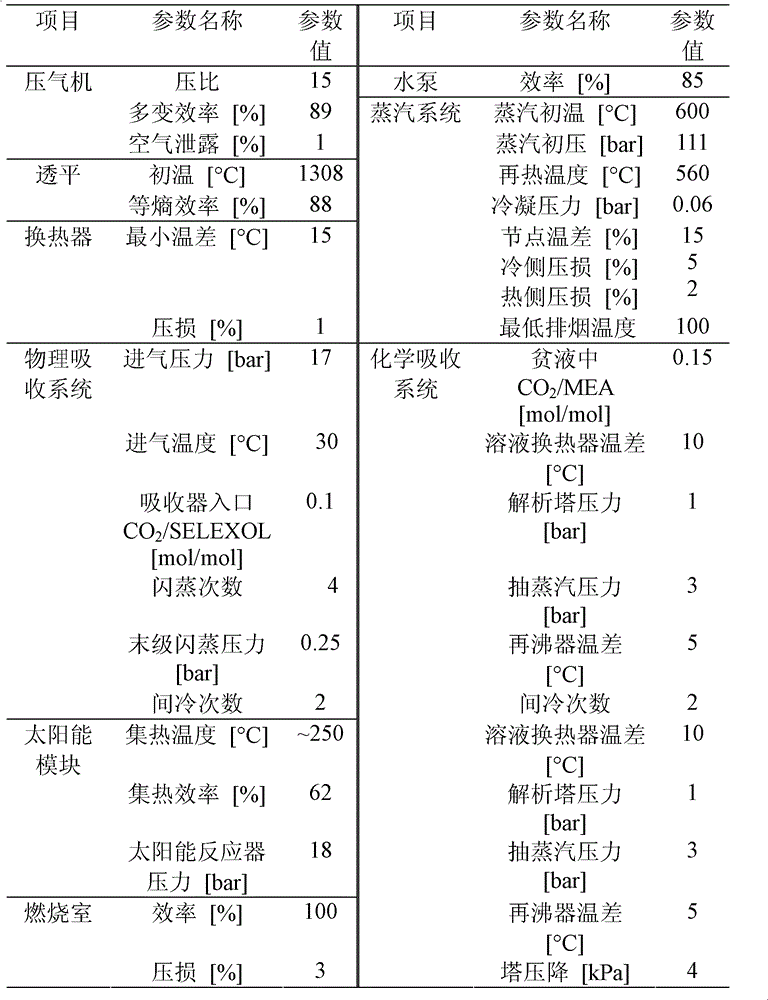

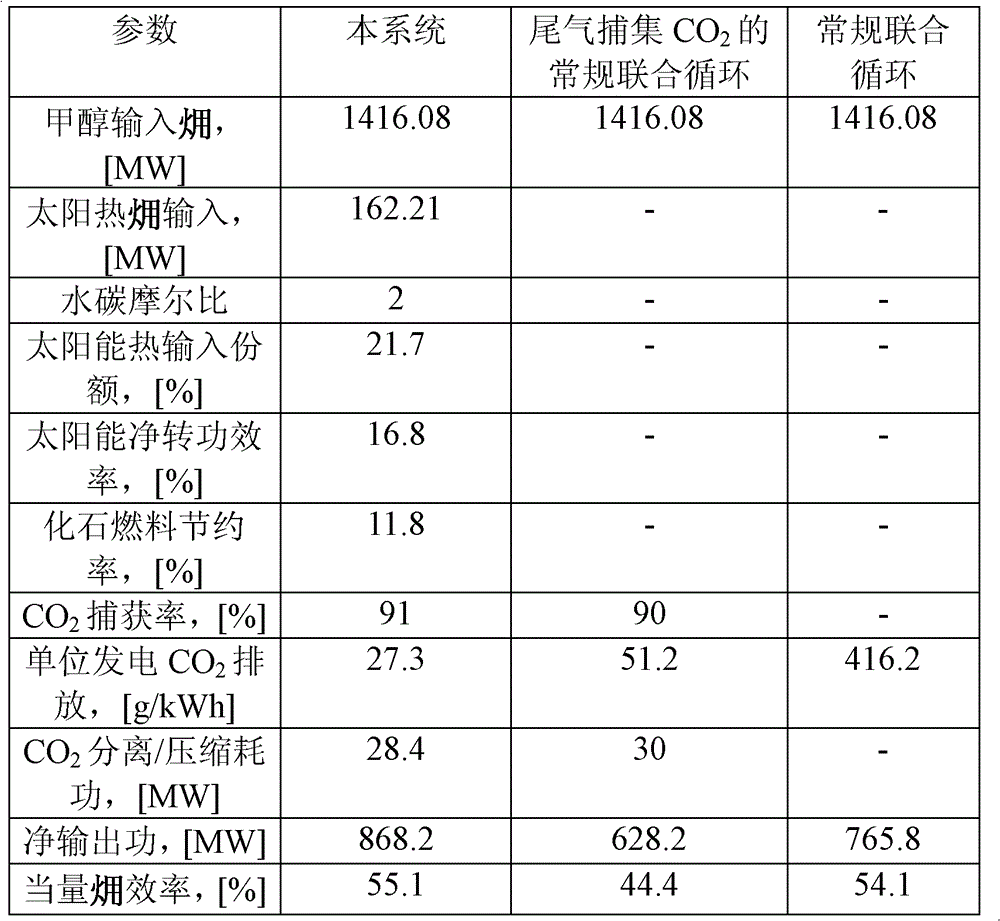

Low-CO2-emisison solar energy and methanol complementary thermodynamic cycle system and method

InactiveCN102797650AEfficient thermal power conversionSave energyHydrogenFrom solar energySteam reformingSyngas

The invention discloses a low-CO2-emisison solar energy and methanol complementary thermodynamic cycle system and a low-CO2-emisison solar energy and methanol complementary thermodynamic cycle method. A solar energy grade is improved in combination with an efficient combined cycle system. The method comprises the following steps of: providing methanol / steam reforming reaction heat by using intermediate-and-low temperature solar energy, and converting a fuel into synthesis gas in which H2 and CO2 with the approximate molar ratio of 3:1 are used as main ingredients, so that low-grade solar energy is converted into synthesis gas chemical energy; separating the CO2 by using an absorption unit; and performing heat-into-power conversion on the decarburized clean fuel in an efficient combined cycle process. The introduction of the solar energy is combined with the separation of the CO2, so that the consumption of fossil energy is reduced, and the fuel can be utilized cleanly. By the method, the clean conversion efficiency of the solar energy is 16.8 percent, the equivalent efficiency of the system is 55.1 percent which is 1 percent higher than that of the conventional combined cycle process, and the conservation rate of a fossil fuel can reach 11.8 percent; and the discharge capacity of the CO2 can be reduced at low energy consumption, so that the fossil fuel is saved, and the intermediate-and-low temperature solar energy can be subjected to efficient heat-into-power conversion and can be complemented with the fossil fuel.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Preparation method of teabag

The invention discloses a preparation method of a teabag, comprising the following steps of: 1. adopting refined tea leaves as materials, eliminating the coarse leaves, stems and pinaculum, removing tea dust of below 60 meshes by a tea sifting and grading machine and crushing the material of more than 20 meshes; 2. crushing the tea leaves by a tea leaf crushing machine to be more than 60 meshes, and screening out tea powder of more than 20 meshes and smaller than 60 meshes by a sizing screen; 3. selecting corresponding tea powder according to different flavor requirements, stirring for 20 to 40 minutes in a stirrer so as to lead the tea powder to be mixed evenly; 4. carrying out processing of impurity removing and processing of drying, sterilizing and increasing incense to the tea leaves meeting bag-packaged materials so as to lead the tea to achieve standard of food level materials; and 5. conveying the materials into a teabag machine special for tea to be packed into a food-level permeable strip bag and carrying out package to the finished product. As the tea is packed into the food-level permeable strip bag, the tea is applicable to be made by a bottled container with a slim outlet and has convenient package, drink and carry.

Owner:浙江茶乾坤食品股份有限公司

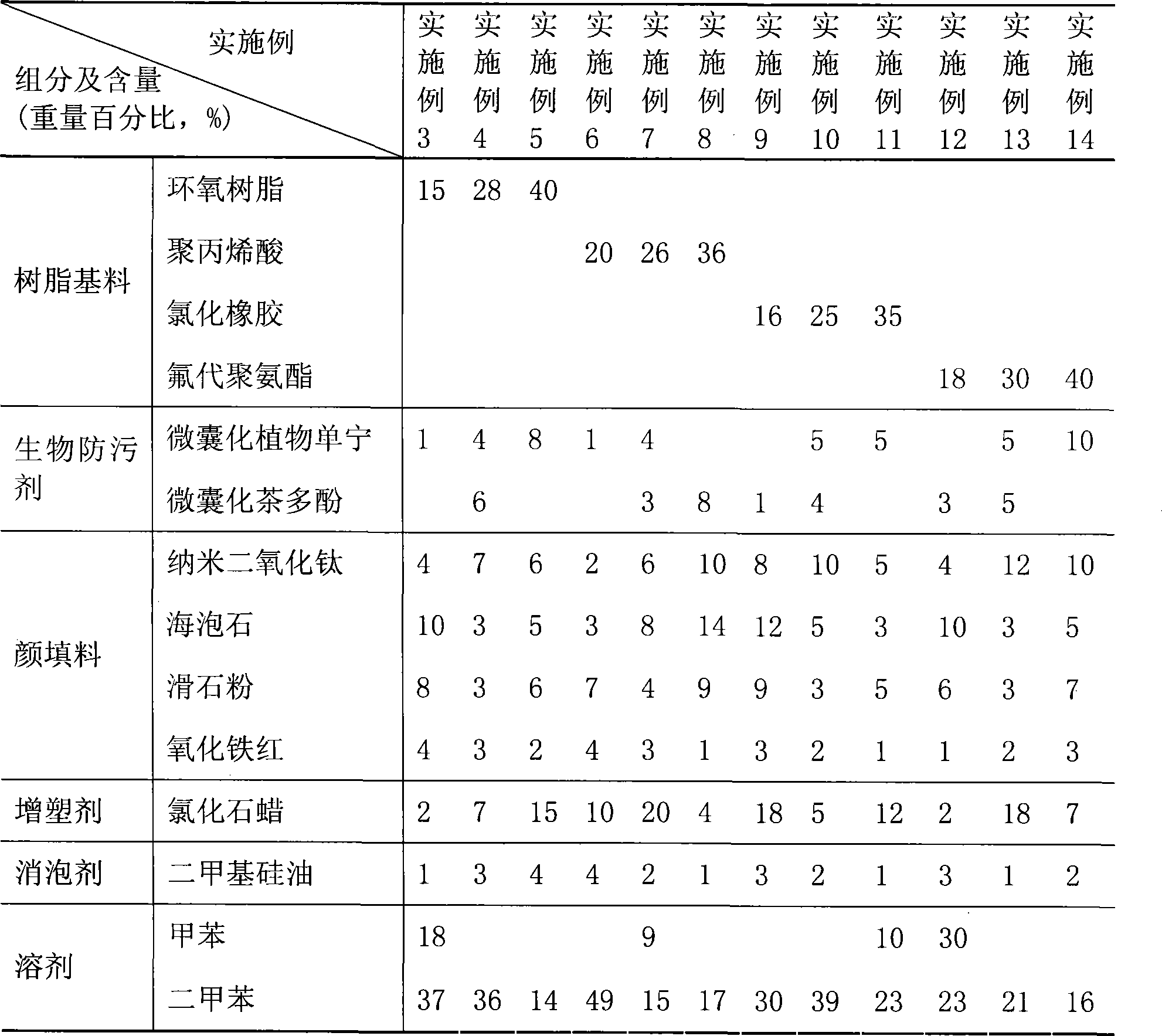

Slow release type biological anti-fouling paint

InactiveCN101186767ALow priceOvercome the disadvantage of high costRubber derivative coatingsAntifouling/underwater paintsTanninSolvent

The invention discloses a slow-soluble biological antifouling paint, which comprises binder resin, biological antifouling compositions, pigments, fillers, additives and solvents, wherein the biological antifouling compositions are vegetable tannin and tea polyphenols of biological extracts of plants. The vegetable tannin and the tea polyphenols are then encapsulated by employing the encapsulization technology, the encapsulated vegetable tannin and tea polyphenols are taken as the antifouling compositions, the antifouling paint of the invention is further composed by combining the binder resin, the pigments, the fillers, the additives and the solvent together with the vegetable tannin and the tea polyphenols, and the antifouling effect is achieved by the slow releasing of the vegetable tannin and the tea polyphenols from micro-capsules. The invention has the advantages that the invention coming from the biological extracts of plants is environment-friendly, the cost is low, the encapsulization technology is simple, the price of capsule materials is low and the large-scale production is easy to be achieved. Further, the invention is characterized by low surface energy, biological antifouling, long term slow releasing and environment protection, and is capable of being employed in antifouling treatment of ocean ships, ocean fixture and fittings, sewers, cable ducts, optical cable ducts and the like.

Owner:重庆丰博科技发展有限公司 +1

A photosensitive-thermosensitive microcapsule and photosensitive-thermosensitive recording material containing same

ActiveCN1731276AExcellent pollution problemImprove qualityPhotosensitive materialsPhotosensitive materials for photomechanical apparatusSolventPhotoinitiator

The invention relates to a light temperature-sensing recording material of the light temperature-sensing microcapsule which comprises a capsule wall and a capsule core, wherein the material of the capsule wall is polyurea or polyurethane; the capsule core comprises a dry head body, a light burster, a light incorporation or cross bonding component and solution.

Owner:HEBEI UNIVERSITY +1

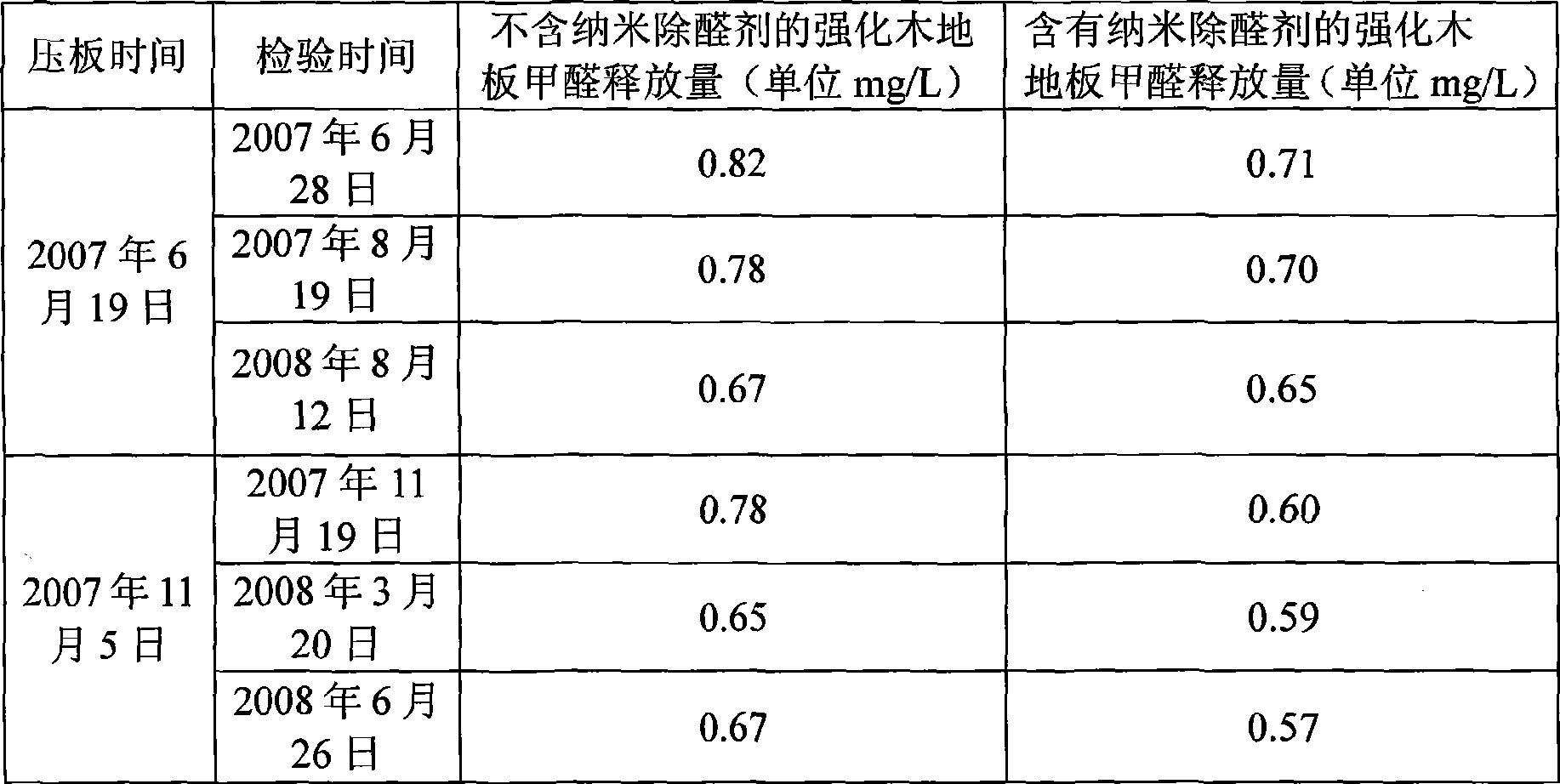

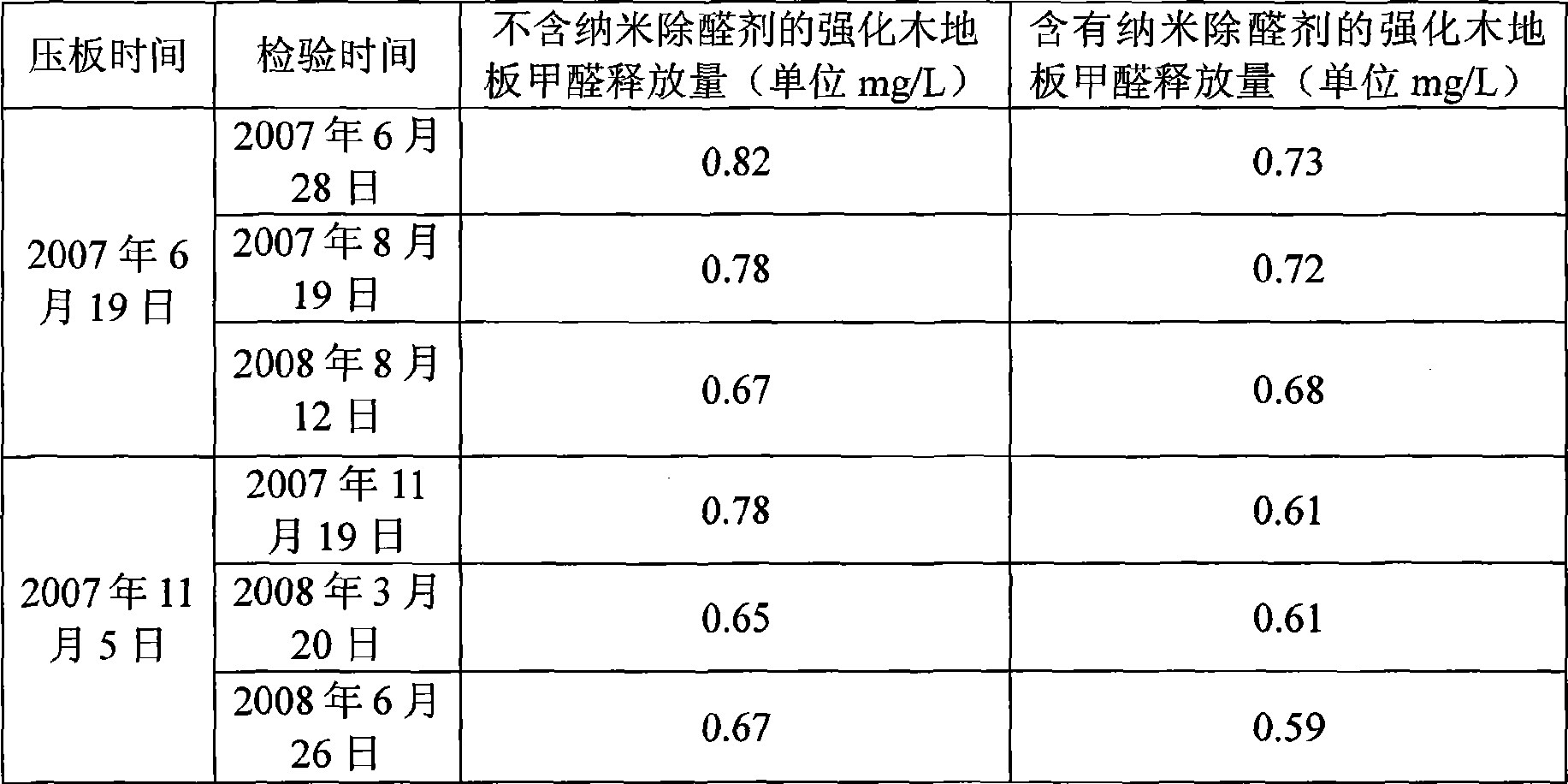

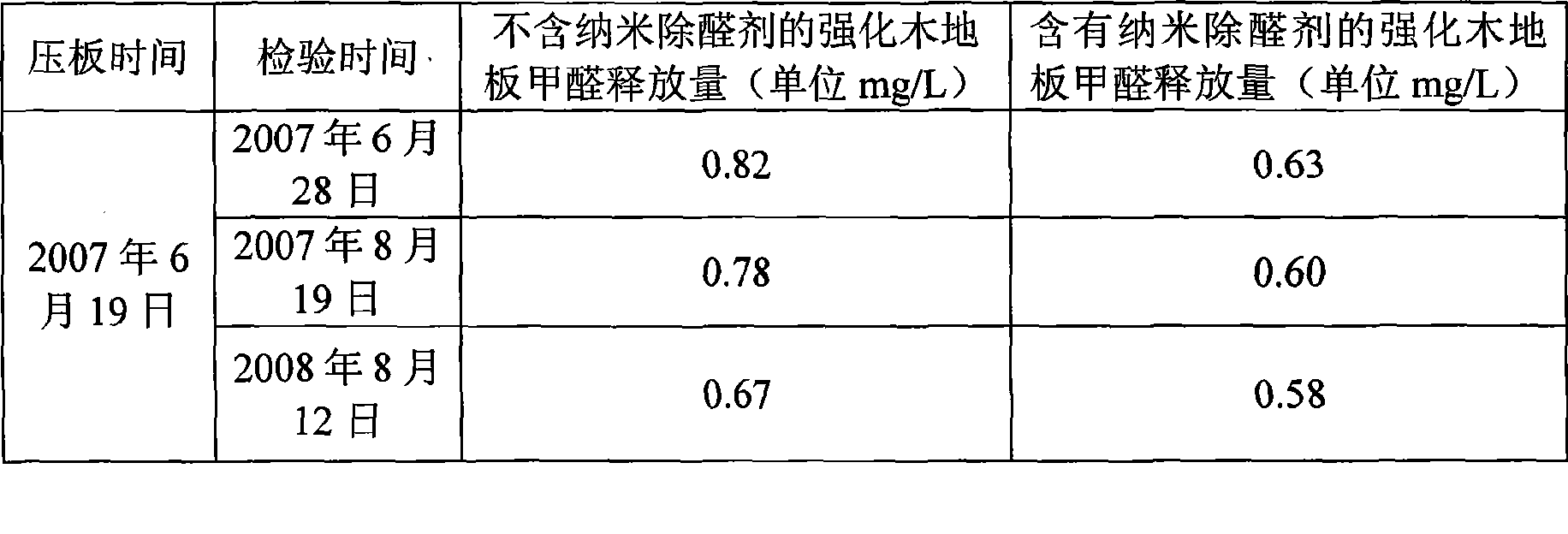

Intensified wooden floor capable of reaching EO grade standard

ActiveCN101418636AReduce formaldehyde emissionSimple processing technologyPaper/cardboard layered productsWood layered productsMedium density fiberboardPulp and paper industry

The invention discloses a laminate flooring which can reach the EO standard. The laminate flooring is formed by hot pressing dipped abrasion resistant paper, decoration paper, balance paper, and medium density fiberboard, wherein the abrasion resistant paper is made by dipping melamine resin added with nano aldehyde removing agent, the weight percent of the nano aldehyde removing agent in the composition is 1% to 20%, and the other is melamine resin. The formaldehyde releasing amount of the laminate flooring is very low and can reach EO standard, which reduces the harm of formaldehyde to the human health and achieves the purpose of environmental protection. The processing technology of the laminate flooring is simple, only need adding prepared nano aldehyde removing agent to the melamine resin for dipping abrasion resistant paper, and then processing the abrasion resistant paper, decoration paper, balance paper, and medium density fiberboard into the laminate flooring by conventional processes.

Owner:圣象实业(江苏)有限公司

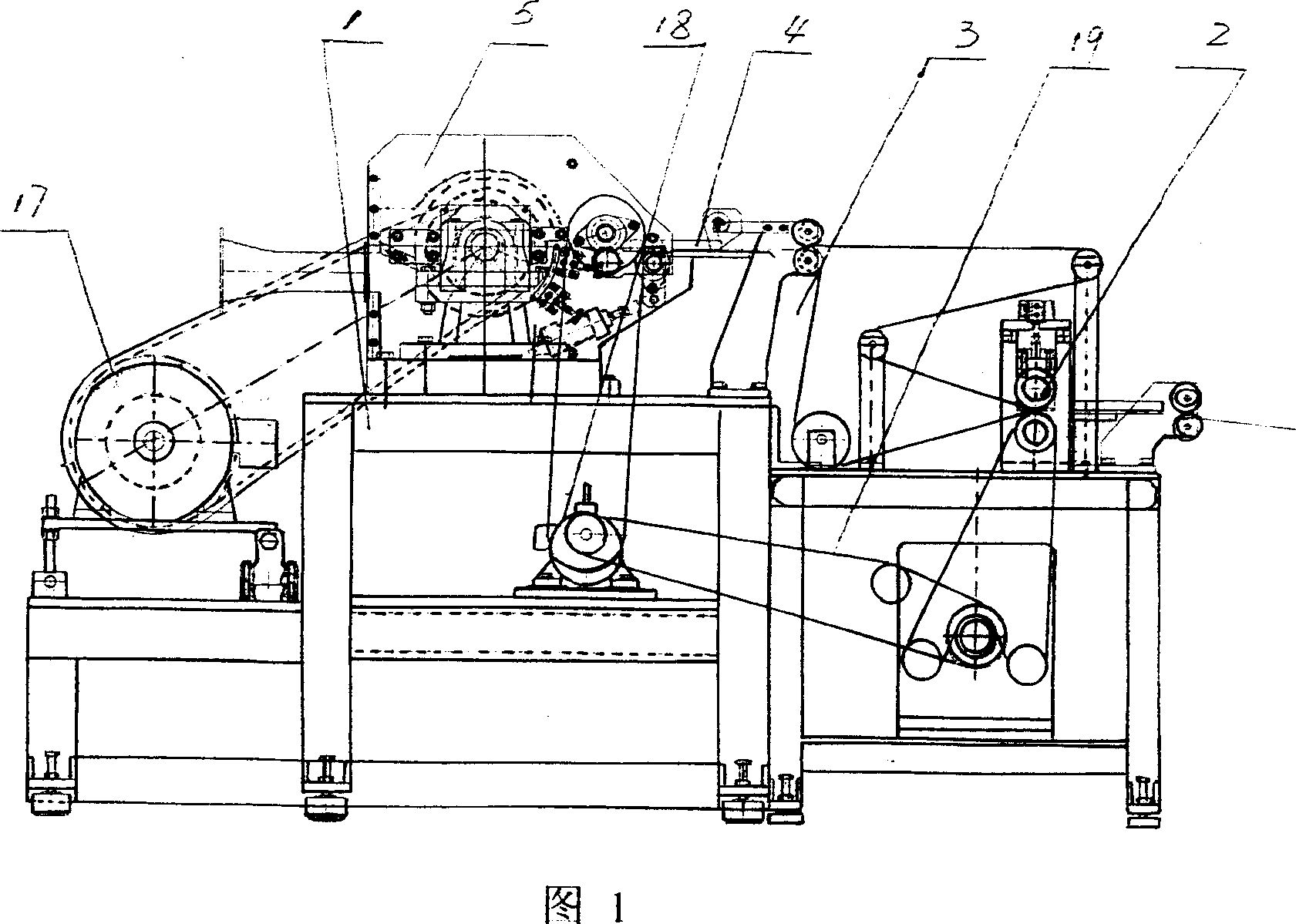

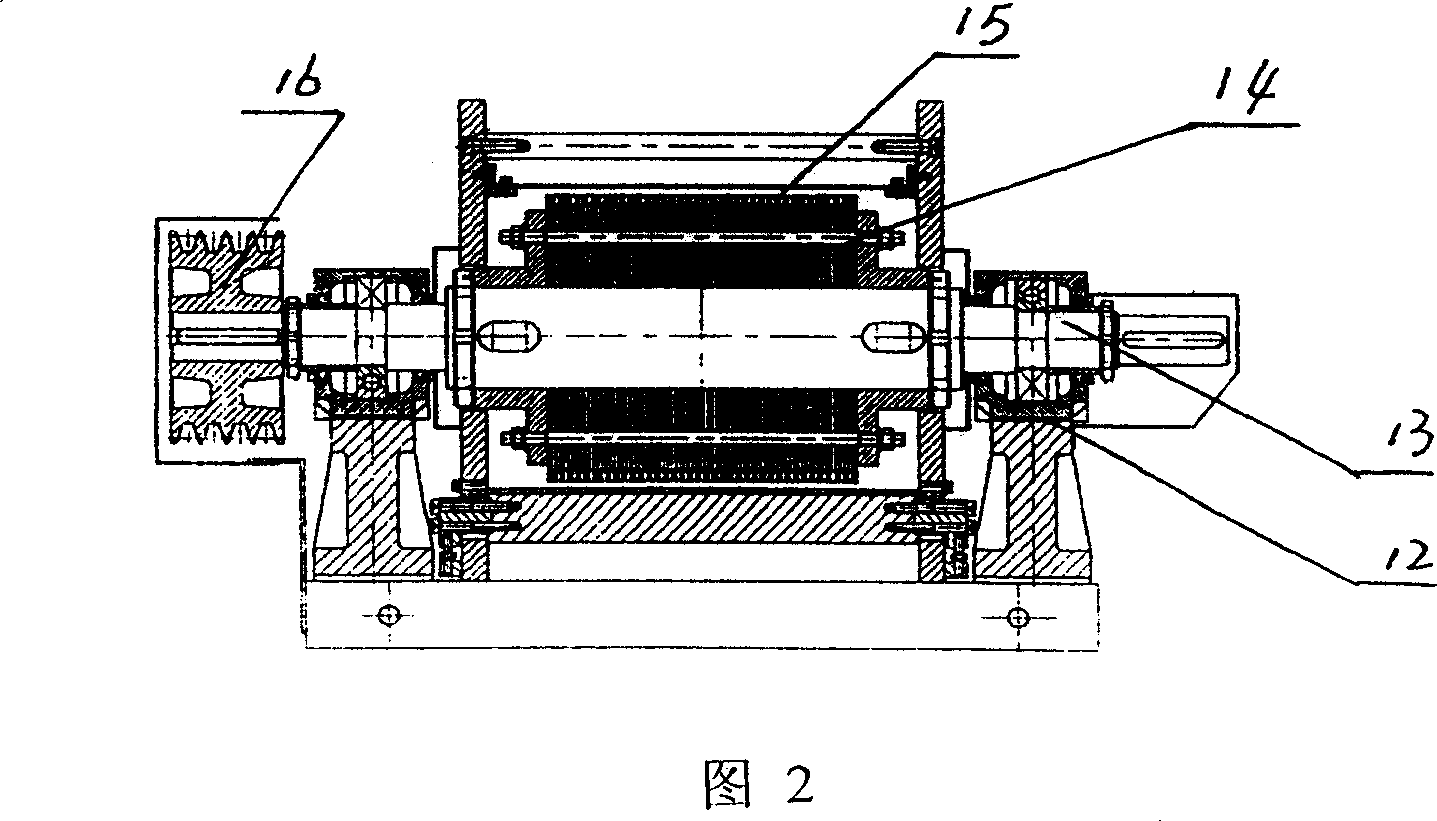

Fibre decomposite and fibre de-composition apparatus

This invention relates to fiber solute body and its machine for producing treatment, half treatment and un-treatment pulp slurry. The fiber solute body is on the materials shelf, pulpboard folding agencies is in the front of double feed month, slitting knife assembly is in the in the front of pulpboard folding agencies, both the slitting knife assembly and pulpboard folding agencies are on the materials shelf. The motor in slitting knife assembly is driven by transportation agency, the knife in slitting knife assembly is driven by Drive agency, the slitting plate is sent to pulpboard folding agencies by the transportation agencies, and then to be made into a double-decker by pulpboard folding agencies, finally be sent to the fiber solute body by feeding assembly to solute fiber. The advantages are as follows: Firstly, effectively reduce dust pollution to achieve the purpose of environmental protection; secondly, not only reduce the volume of fiber, and greatly reduced the consumption of electric power; thirdly, not only improve its crushing capacity, but also significantly reduces vibration noise, raise its forming rate.

Owner:HANGZHOU XINYUHONG INTELLIGENT EQUIP CO LTD

Calcium phosphate opaque glass and method for making same

InactiveCN101182117AThe process steps are simpleReduce manufacturing costCalcium biphosphateBoron oxide

The invention discloses a manufacturing method for calcium phosphate opaque glass, which includes following steps: firstly, 70-75 portions of silicon dioxide, 0.5-2.0 portions of alumina, 8.0-12.0 portions of calcium oxide, 2.0-5.0 portions of magnesium oxide, 9.8-15.0 portions of sodium oxide, 1-3 portions of phosphorus pentoxide, 0.1-0.2 portions of boron oxide and 0.1-0.5 portions of calcium nitrate are evenly mixed into raw material; secondly, the raw material is melted and clarified and is stretched into forming through squeezing to obtain raw glass; thirdly, the heat treatment of opacifying is implemented on the raw glass, whish is then cooled to be at the normal temperature, and the polishing and the cutting forming are implemented successively to obtain the calcium phosphate opaque glass. The invention also provides the calcium phosphate opaque glass, which is made according to the preparation method. The calcium phosphate opaque glass of the invention has the advantage of perfect opaque effect.

Owner:ZHEJIANG UNIV

Novel organic siloxane polymer material for electronic packaging

ActiveCN105348809AReduce environmental pollutionImprove mechanical propertiesSide chainOrganosilicon

The invention relates to an organic siloxane polymer material for electronic packaging. The organic siloxane polymer material comprises hydroxy-terminated polydimethylsiloxane, silane or siloxane containing at least two alkoxy groups, poly(methylphenylsiloxane) containing vinyl groups, hydrogen-containing silicone oil, a condensation catalyst, a platinum catalyst, a curing inhibitor and white carbon black, wherein the vinyl groups in poly(methylphenylsiloxane) are located at an end group and a side chain, and the mass content of the side-chain vinyl group is 3%-10% on the basis of the mass of the component. The organic siloxane polymer material can be applied to the field of electronic packaging and has the characteristics of good mechanical properties, high mechanical strength and excellent transparency.

Owner:江苏矽时代材料科技有限公司

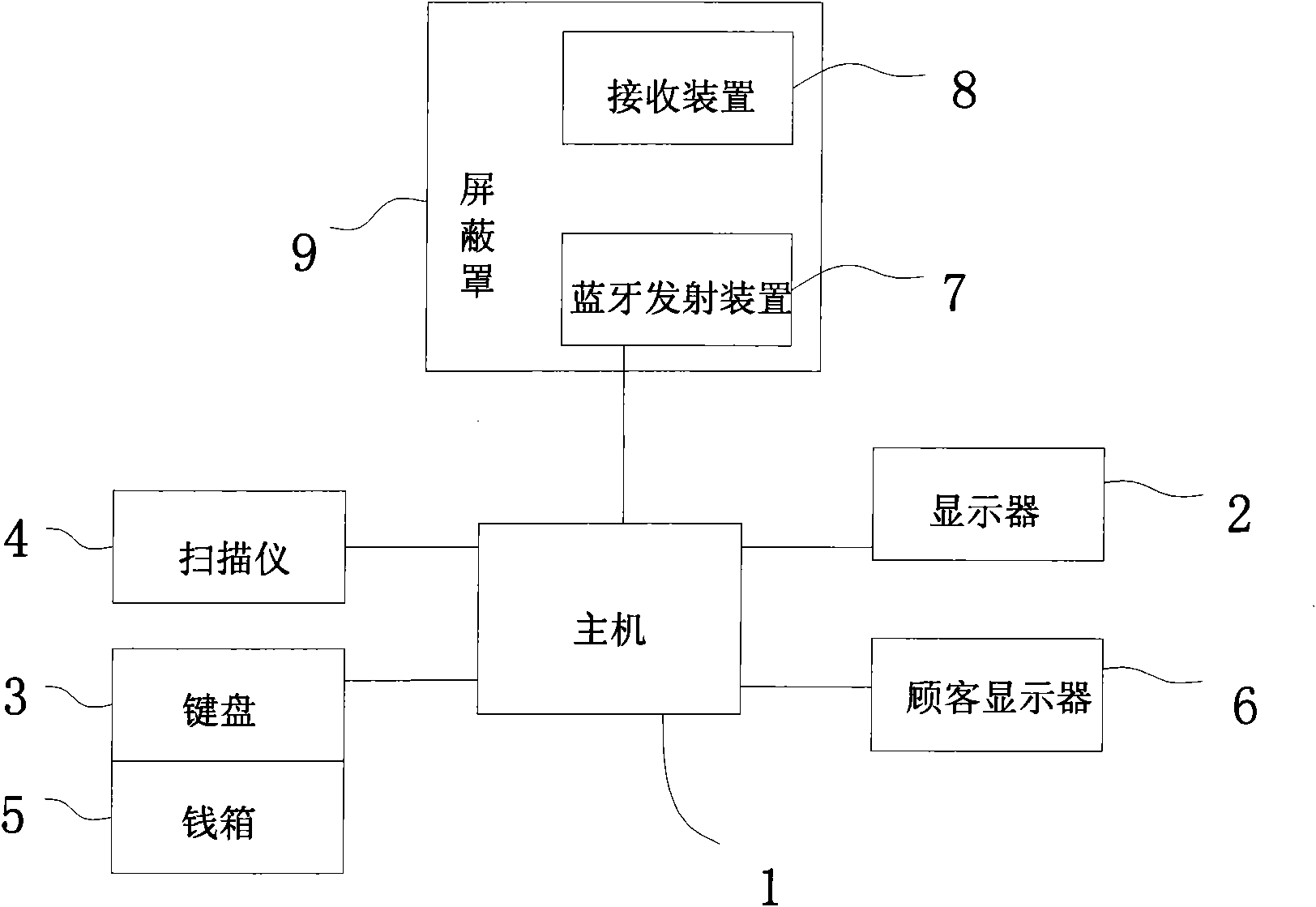

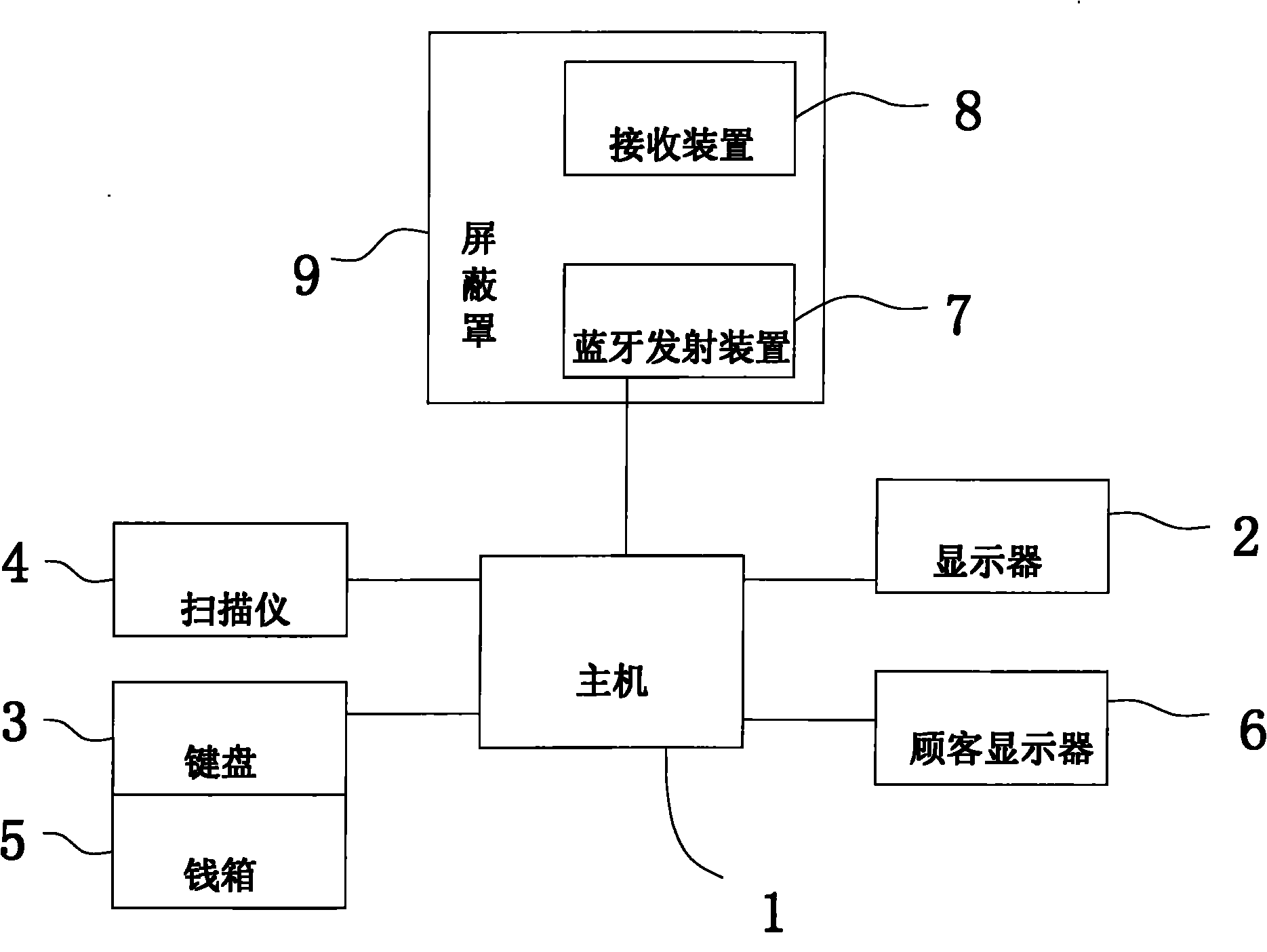

System and method for transmitting shopping receipt through Bluetooth

InactiveCN102402826AReduce usageSend quicklyNear-field transmissionCash registersRelevant informationInvoice

The invention relates to a system and a method for transmitting shopping receipt through Bluetooth. The system comprises a cash register, and is characterized in that: the cash register is connected with a Bluetooth transmitting device; a receiving device is also provided; and a screening cover is disposed out of the transmitting device. The method comprises the following steps of: acquiring shopping information; editing the shopping information to be information to be sent; placing the receiving device in the screening cover by a receiving party; searching and finding the receiving device and sending the information to the receiving device by the transmitting device; and storing the information in a host. The shopping receipt instead of paper receipt is sent by Bluetooth, so that paper can be saved and environment protection can be realized; and electronic information is quickly sent without waiting for receipt printing. For the same receiving device, the cash register also can make statistics on the shopping information, and the customer can regularly make out an invoice but not collect paper receipt of every time, so that statistical time in making invoices is saved; in addition, the sent contexts of the information can produce more contexts, including related information such as preferential information of businessmen, advertisements and the like.

Owner:胡华敏

Biodegradable stone paper and preparation method thereof

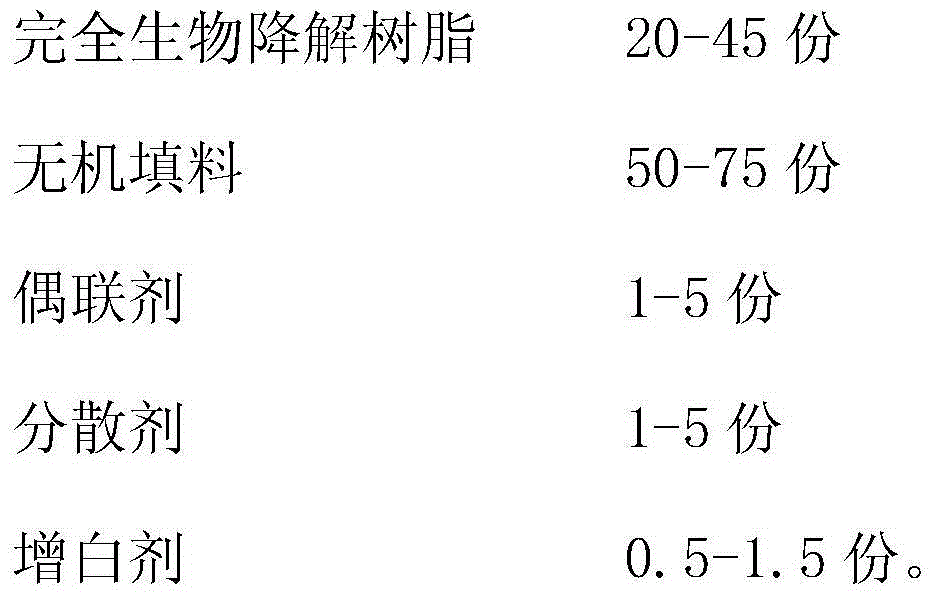

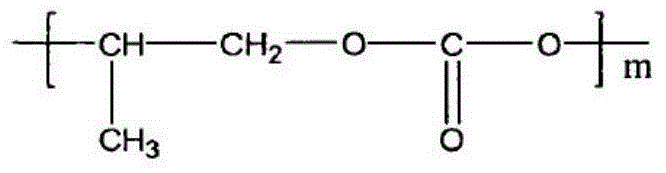

InactiveCN104693710ASolve the problem of non-biodegradableTo achieve the purpose of environmental protectionFolding endurancePapermaking

The invention discloses biodegradable stone paper and a preparation method thereof, and belongs to the technical field of light industrial papermaking. Main ingredients of the stone paper comprise, 50-75 parts of inorganic filler, 20-45 parts of full biodegradable resin, 1-5 parts of coupling agent, 1-5 parts of dispersing agent and 0.5-1.5 parts of brightening agent, wherein the full biodegradable resin is a mixture of carbon-dioxide-based full-degradable plastic and biodegradable polyester. The stone paper prepared by the preparation method is a full-degradable material, and the problem that existing stone paper regards polyethylene as a base body, and resin is not degradable is solved. The stone paper has a series of advantages that the strength is higher, the folding endurance is high, and the whiteness is high.

Owner:SUN YAT SEN UNIV +1

Production method of ceramic wafer art picture

InactiveCN101508224AQuality assuranceReduce manufacturing costSpecial ornamental structuresInksPrinting inkChemical substance

The invention provides a method for manufacturing a ceramic plate art picture, which comprises the following steps: 1, cutting a baked ceramic plate of which the thickness is less than 7 mm into a size in accordance with the size of the picture, performing laser carving on the surface of the ceramic plate and polishing the surface to honed flatness; 2, storing an artistic work or a photo into a computer, applying printing ink onto the surface of the ceramic plate through spray printing of a computer spray printing machine or flat screen printing, and baking the ceramic plate in a kiln at a temperature of between 150 and 400 DEG C to form a product; 3, performing anti-ultraviolet treatment on the surface of the baked product; and 4, arranging a decorative frame. The printing ink used in step 2 is UV printing ink of which the components are light polymerization resin, a light polymerization initiator, a coloring matter and accessory ingredients. The ceramic plate art picture manufactured by the method can resist corrosion of chemical substances such as strong base, strong acid, and methylbenzene, and is waterproof, dampproof, not fading, environment-friendly and scratch resistant.

Owner:萧华

Method for preparing fluorine phosphorus composite opacifying glass

The invention discloses a method for preparing a fluorophosphate composite opaque glass, which comprises the following steps: 1) raw material preparation: 50 to 65 portions of silica, 0.5 to 6.5 portions boron oxide, 2 to 5 portions alumina, 10 to 17.5 portions calcium oxide, 0.5 to 6 portions of magnesium oxide, 0.5 to 2 portions of zinc oxide, 5 to 10 portions of sodium oxide, 5 to 8 portions of phosphorus pentoxide, 0.5 to 2 portions of sodium fluosilicate and 1 portion of calcium nitrate. The materials form the raw material after evenly mixing; 2) the raw material is melted under the temperature ranging from 1,300 DEG C to 1,480 DEG C and a clarification; the material then is extruded and pulled for shaping; an annealing is followed and the material is then cooled to a normal temperature. After a polishing and a cutting, the fluorophosphate composite opaque glass is obtained. The method for preparing the fluorophosphate composite opaque glass in the invention has the advantages of not only preventing the environment pollution by fluoride, but also saving energy.

Owner:ZHEJIANG UNIV

Flotation separation method for refractory sulfide ore and high-sulfur copper-zinc ore

The invention discloses a flotation separation method for refractory sulfide ore and high-sulfur copper-zinc ore. The method comprises the following steps: performing first-stage ore grinding on a raw ore and then performing first-stage flotation on the raw ore, wherein the raw ore after being subjected to the first-stage ore grinding meets the demand that more than 90% of ore fineness is less than 200 meshes; adopting the processes of once rough flotation, once fine flotation and once scavenging; performing second-stage ore grinding on the ore after being subjected to the first-stage flotation, wherein tailings of the first-stage flotation are sulfur concentrates; performing second-stage flotation on the ore which is subject to the second-stage ore grinding and meets the demand that more than 90% of ore fineness is less than 400 meshes; performing copper-zinc separation flotation; adopting the processes of once rough flotation, triple fine flotation and once scavenging; adding C6MT sodium phosphate as a modifier and separating copper concentrates from the tailings; performing third-stage flotation on the tailings; and adopting the processes of once rough flotation, triple fine flotation and twice scavenging, thereby separating zinc concentrates from the sulfur concentrates. The method provided by the invention has the advantages of reasonable process, saved investment and low cost. By using the method, the flotation precision of copper-zinc ore is increased, the recovery rate of copper and zinc concentrates is increased, the national mine resource is furthest recovered, utilized and protected, and the national technical level of separating copper-zinc ore is promoted.

Owner:TURPAN XUEYIN METAL MINING

Method for extracting fucoidan through biological enzymolysis process

InactiveCN106832041AHigh extraction rateThe extraction process is safe and environmentally friendlyAntinoxious agentsAntiviralsSolid phasesChemistry

The invention belongs to the technical field of fucoidan extraction and provides a method for extracting fucoidan through a biological enzymolysis process. The method comprises the following steps: grinding kelp into slurry; soaking; adding acidic cellulase and hemicellulase; adding alkaline pectinase; adding protease; adding sodium chloride and water and reacting, thereby acquiring sodium alginate jelly; adding modified attapulgite; centrifuging by using a centrifugal machine; and adding ethyl alcohol and dewatering, thereby acquiring solid-phase fucoidan. According to the method for extracting fucoidan provided by the invention, the biological enzymolysis process is adopted; on the basis of the structure and ingredients of kelp cytoderm, a defined amount of related enzyme is added in stages, so that the cytoderm is thoroughly split; the fucoidan therein is fully released, so that the extraction rate of the fucoidan is increased; the modified attapulgite is added for decolorizing and removing fishy smell in an extraction process, so that the appearance of the product is cleaner; and besides, the extraction steps are simplified, the use of the chemical raw materials is reduced and the purpose of environmental protection is achieved.

Owner:安徽天安生物科技股份有限公司

Manufacturing method of packaging box plates

InactiveCN103786230AReduce weightGood elasticityNon-macromolecular adhesive additivesWood working apparatusSteel platesAgricultural crops

The invention discloses a manufacturing method of packaging box plates. The manufacturing method includes the steps of preparing materials, including the main material crop offcut; pouring wood chips, glue, and the crop offcut into a glue blender, and mixing well; laying, namely coating a veneer with a glue layer prior to laying the veneer on a steel plate, and making sure the glue side faces upside; placing the steel plate on a conveyor belt; evenly laying mixture on the veneer of the steel plate by a spreader; laying another veneer with the lower surface glued, on the mixture; pressurizing and solidifying, namely heating and pressurizing a laid plate blank in a hot press, at the temperature of 140-170 DEG C, holding the pressure for 6-10 minutes for solidification and forming; stripping and trimming, namely stripping the solidified plate and trimming the plate. Specifically, the materials include, by weight, 30-40% of the wood chips, 8-10% of the glue, and the balance of the crop offcut. The glue is dicyclopentadiene modified unsaturated polyester resin glue. Therefore, environment protection is achieved.

Owner:孟可星

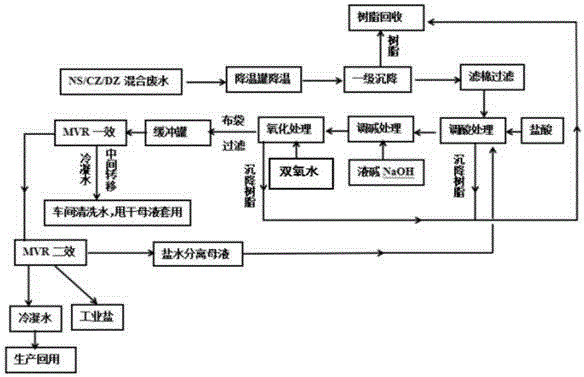

Method for treatment of mixed wastewater produced during production of rubber accelerator NS\CZ\DZ

InactiveCN106587476ASolve processing problemsTo achieve the purpose of environmental protectionTreatment involving filtrationMultistage water/sewage treatmentDistillationEvaporation

The present invention provides a method for treatment of mixed wastewater produced during production of a rubber accelerator NS\CZ\DZ. The mixed waste water is cooled to 50 to 70 DEG C, resin is precipitated by primary precipitation, so that 20-30 percents of resin is removed, and unprecipitated resin is filtered by filter cotton; hydrochloride is added to filtered water for acid-adjusting treatment, and pH of the water is adjusted to 3-5; stirring and precipitating are conducted, the obtained sediment is released from the bottom of a tank, then a liquid alkali is added to the water for alkali-adjusting treatment, and pH of the water is adjusted to 8-9; hydrogen peroxide with the usage amount being 0.3-0.8 percent of the water is added for oxidation treatment; and stirring is performed, a supernatant is filtered by a close bag, and an obtained filtrate is subjected to one-effect and two-effect evaporation in MVR distillation equipment. Simple methods of acid-base regulation and oxidation are used to recycle organic components in the waste water and the purposes of consumption reduction, waste reduction and environmental protection are achieved by evaporating to separate inorganic salts from the waste water. COD of the wastewater is reduced to 700 or below, mechanical application of return water is fully achieved, and the method is easily-operated, economical and environmentally friendly.

Owner:KEMAI CHEM

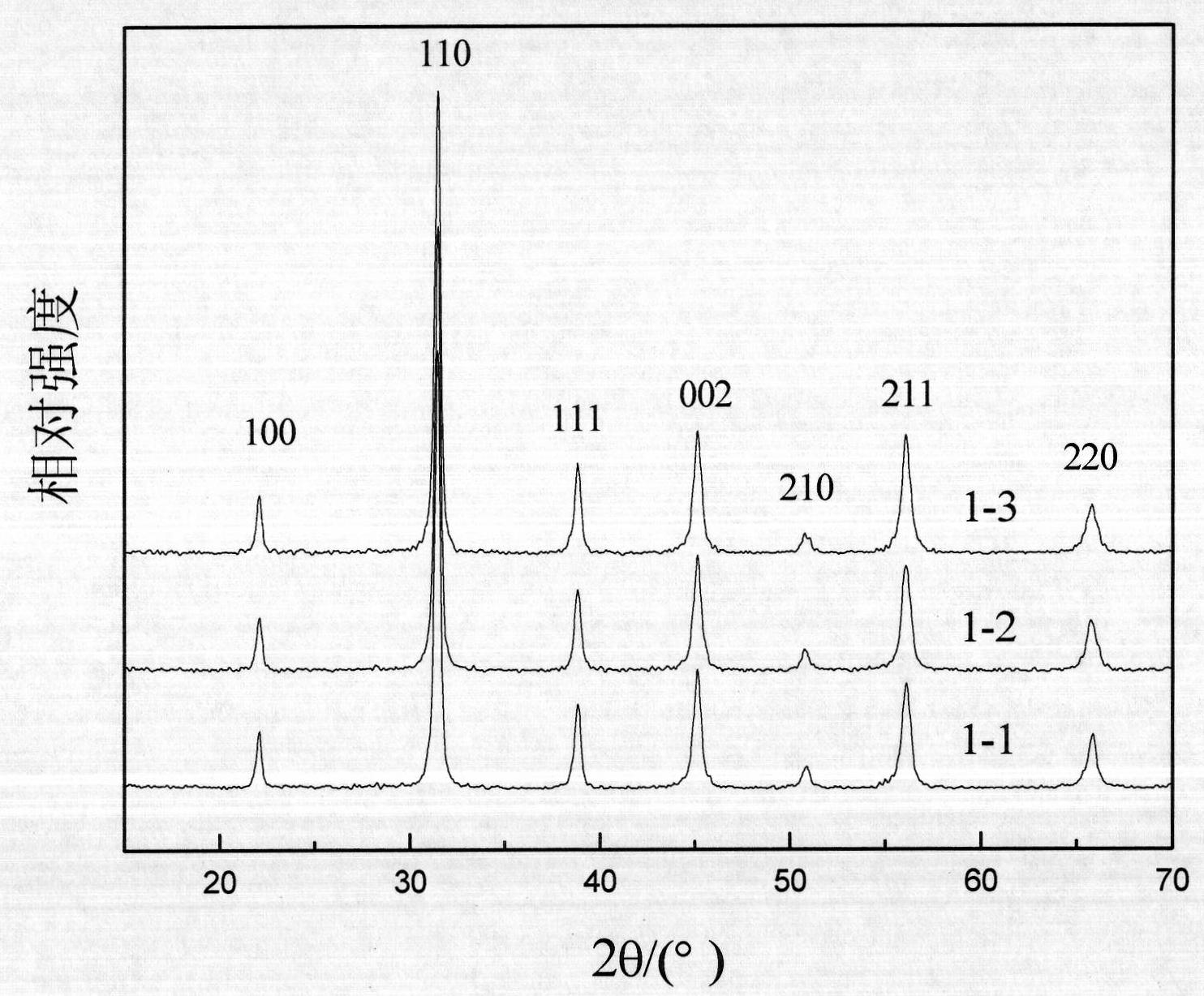

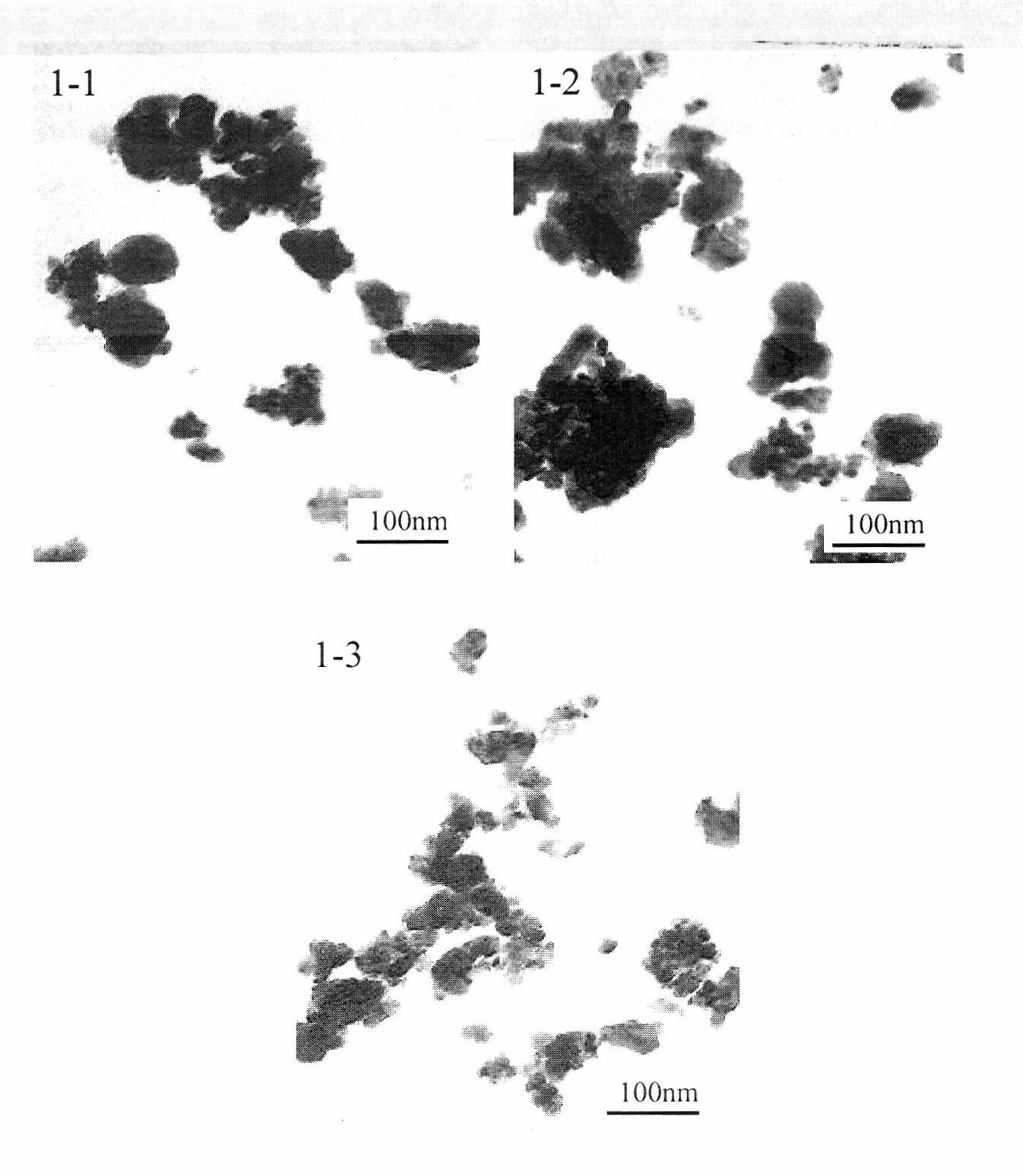

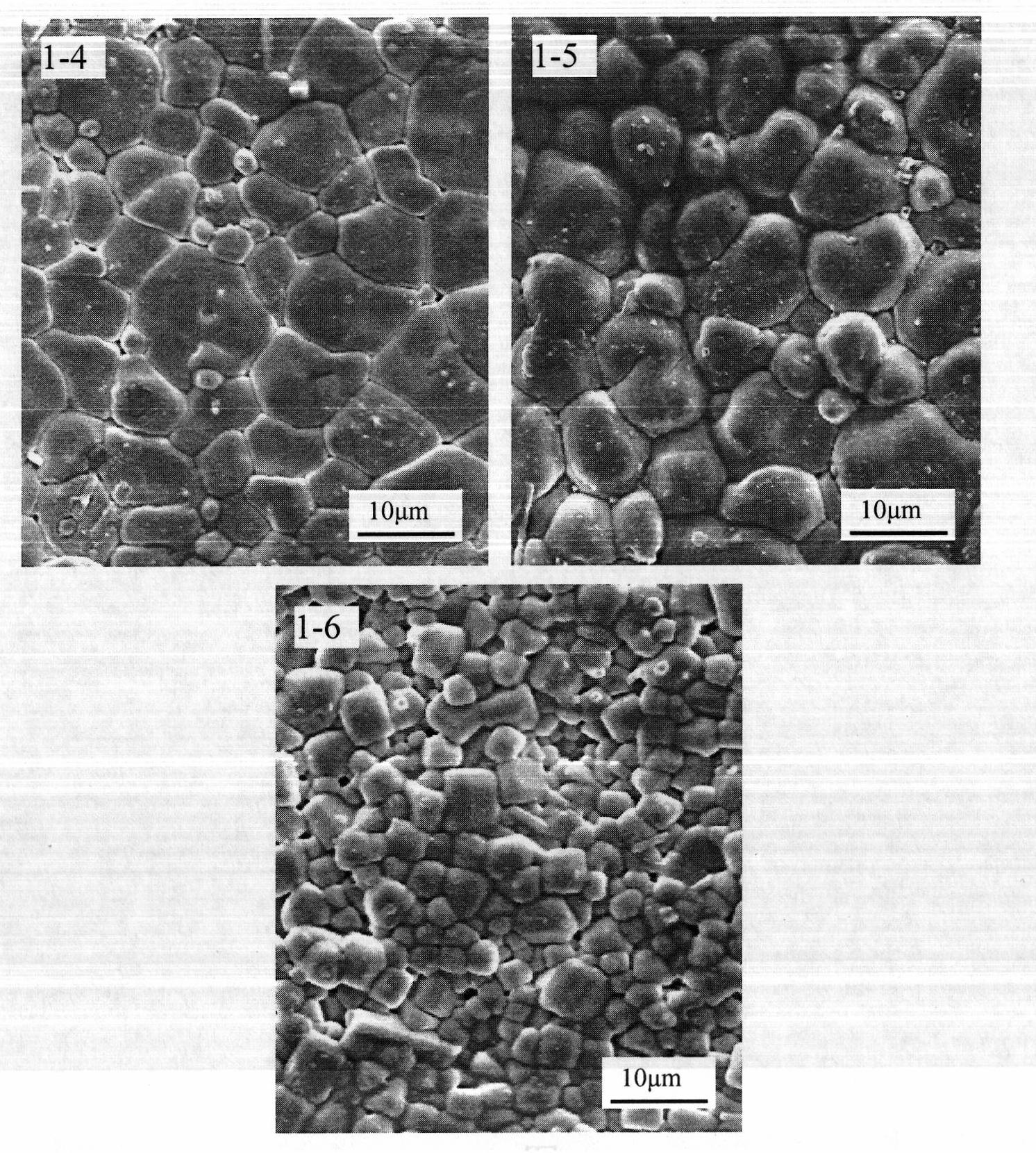

Barium titanate-based Y5V nano-powder and preparation method for ceramic material thereof

The invention discloses barium titanate-based Y5V nano-powder, which is characterized in that: the chemical composition of the powder is represented by a general formula: (Ba1-x-ySrxCay)(Ti1-m-nZrmSnn)O3+A, in which x is more than or equal to 0.01 and less than or equal to 0.05; y is more than or equal to 0.06 and less than or equal to 0.10; m is more than or equal to 0.04 and less than or equal to 0.12; n is more than or equal to 0.01 and less than or equal to 0.06; A may be CeO2, ZnO and SiO2; and dielectric ceramic powder comprises 1 to 4 percent of the A in molar percentage. The powder can be sintered into a barium titanate-based Y5V ceramic material with high dielectric property by sintering at the temperature of between 1,250 and 1,300 DEG C and preserving the heat for 0.5 to 8.0 hours. The preparation method has the advantages of homogeneous components, easy control prescription, and good sintering activity of nano-powder and the powder, and can meet the development requirements on the miniaturization, the base metal and the environmental protection of Y5V ceramic capacitors.

Owner:NORTHWEST UNIV(CN)

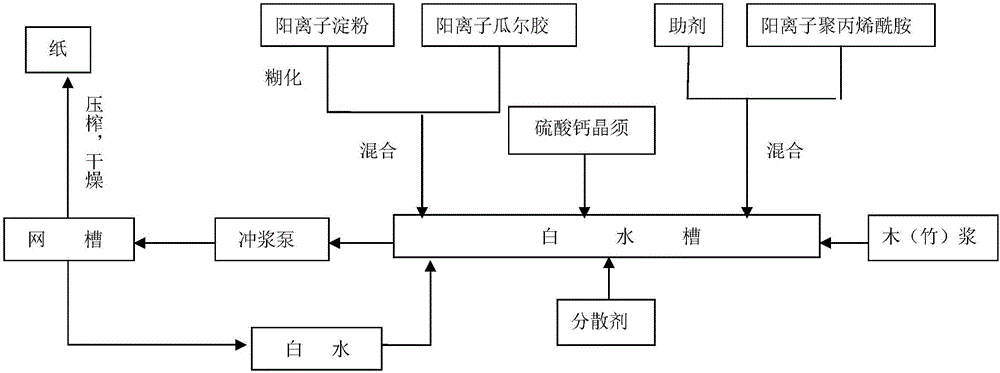

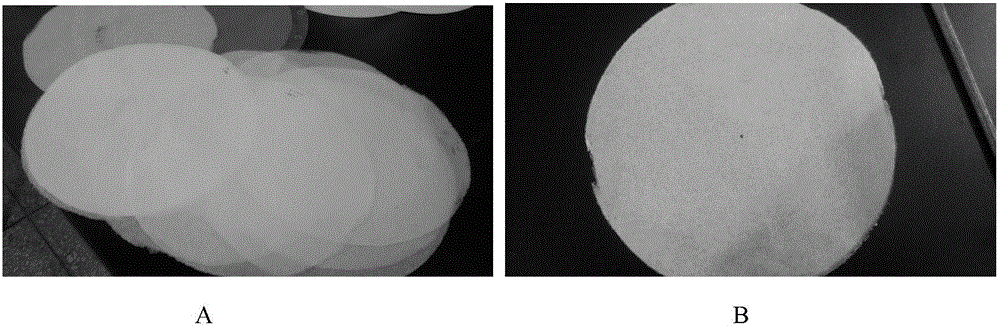

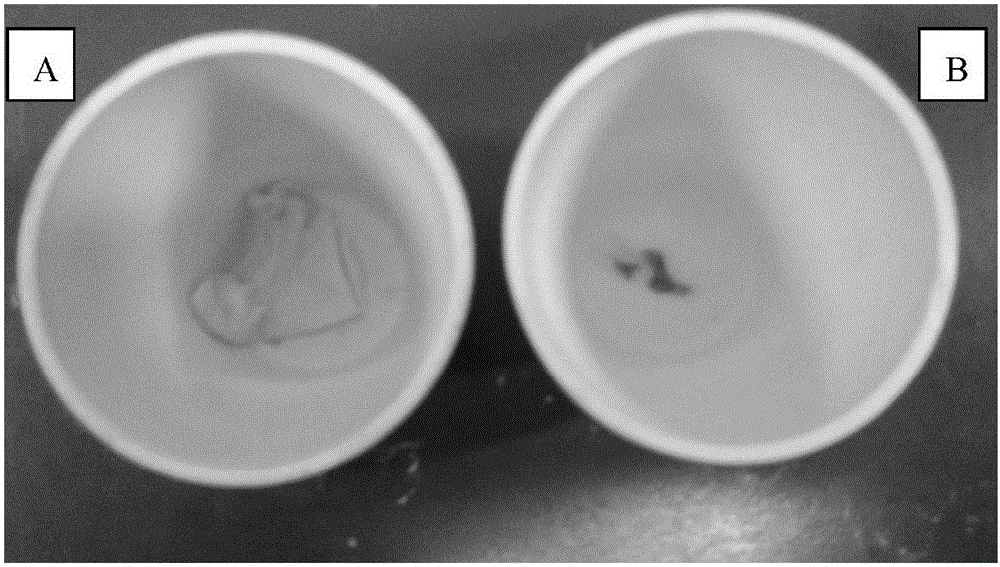

Papermaking raw material prepared from modified calcium sulfate whiskers and application

InactiveCN106368050AImprove retentionHigh strengthInorganic fibres/flakesNon-macromolecular organic additionChemical LinkageFiber

The invention relates to a papermaking raw material prepared from modified calcium sulfate whiskers, and belongs to the technical field of papermaking. The modified calcium sulfate whiskers are adopted to replace 20%-35% of wood (bamboo) pulp of the raw material. The modified calcium sulfate whiskers are obtained through the steps that calcium sulfate whisker raw materials are dispersed into water added with a modifying agent, the mixture is fully stirred at certain temperature, and then filtering is conducted. The invention further relates to application of the modified calcium sulfate whiskers in papermaking. According to the papermaking raw material, by modifying the calcium sulfate whiskers, the retention rate of the whiskers can be significantly increased, and the strength of paper is enhanced; part of wood (bamboo) pulp is replaced with the modified calcium sulfate whiskers, therefore, the using amount of the papermaking raw material-wood (bamboo) pulp is decreased, and the purposes of reducing the production cost and achieving environmental friendliness are achieved. Dissolution of modified calcium sulfate and interaction between the whiskers and chemical bonds the plant fiber surfaces are fully taken into account by the papermaking raw material technology and the auxiliary using amount, and therefore the retention rate and the strength of the paper are guaranteed.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

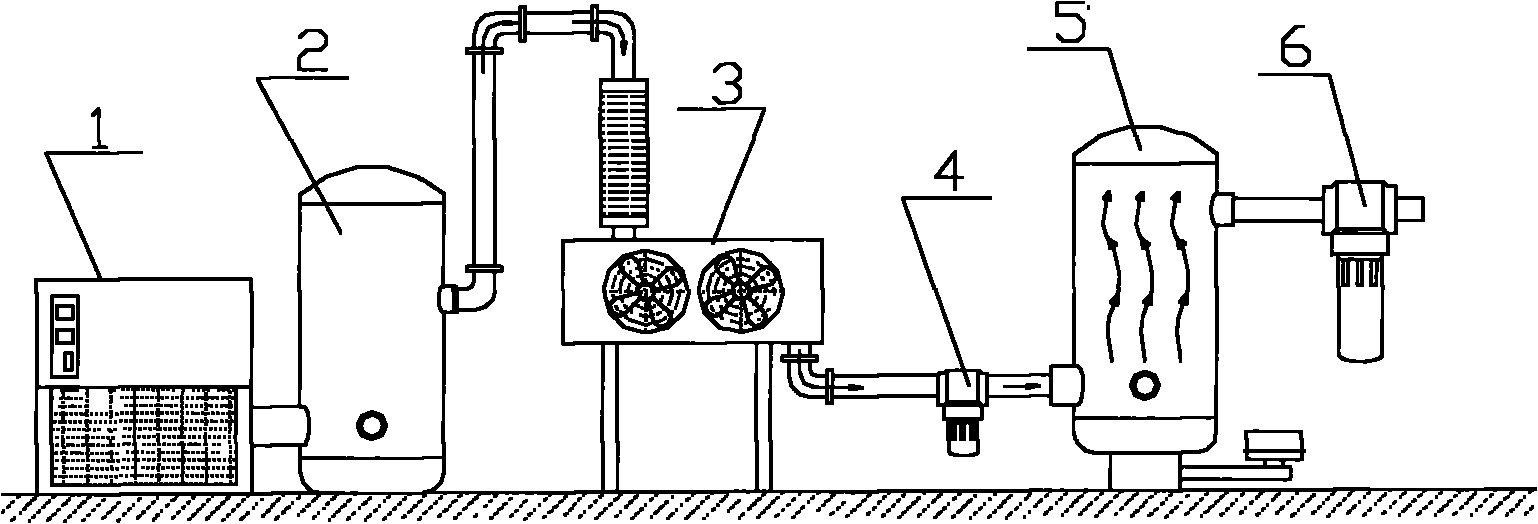

Pollution-free gas drying agent and drying method thereof

ActiveCN101829478AGuaranteed pressure dew point effectWill not polluteDispersed particle separationChemical reactionHigh energy

The invention relates to a pollution-free gas drying agent which has high dehumidifying efficiency, slow dissolving speed and no pollution after dissolution, and can be directly dissolved in water to be exhausted to the environment, and a drying method thereof. The method comprises the steps that: wet air enters through an inlet which is positioned in the center of the bottom of a dryer container, so that the compressed air is uniformly distributed and flows upwards through the uniform diversion of a splitter plate, and the air is fully contacted with a moisture-absorbing agent layer; the wetair is firstly contacted with the moisture-absorbing agent layer in a reaction zone, and the moisture-absorbing agent absorbs plenty of water in the wet air, so that the moisture-absorbing agent undergoes chemical reaction; the wet air enters a drying zone of the moisture-absorbing agent layer, and the moisture-absorbing agent further dries the wet air, so that the dew point of the wet air reaches the required dew point; and finally, the fully dried compressed air is exhausted through an air outlet at the upper end of the container by passing through a preparation area of the moisture-absorbing agent. The dryer of the invention overcomes the defect that the conventional dryer has complex structure, high energy consumption, and environmental pollution, and has the advantages of stable performance, low energy consumption, low cost, no pollution, and low requirement on the working environment.

Owner:杭州科林爱尔气源设备有限公司

Cationic polymer for papermaking and preparing method thereof

ActiveCN101130938AIncrease profitLow costNon-fibrous pulp additionPaper/cardboardMethacrylateCationic polymerization

The present invention provides a cationic polymer for making paper and its preparation method. The described cationic polymer for making paper is one of acrylamide, ammonium methylacrylyloxyethyltrimethyl chloride, dimethylaminoethyl methacrylate chlorinated benzyl quaternary ammonium, dimethylaminoethyl acrylate chlorinated benzyl quaternary ammonium or ammonium dimethyl diallyl chloride or mixture of more than two kinds of them, under the initiation of initiating agent they are polymerized so as to obtain the invented cationic polymer. Its cationic charge density is 80%-95%, viscosity is 50-200 centripoise and its solid content is 50-70%.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

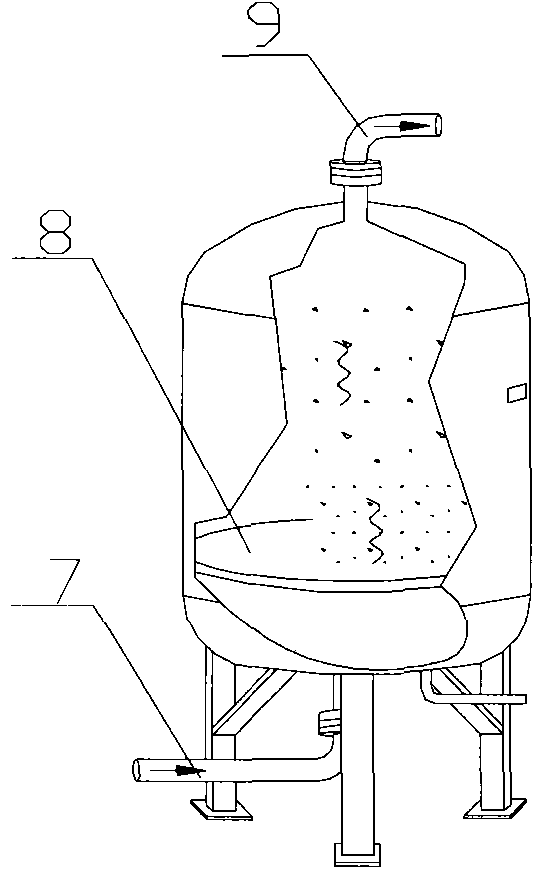

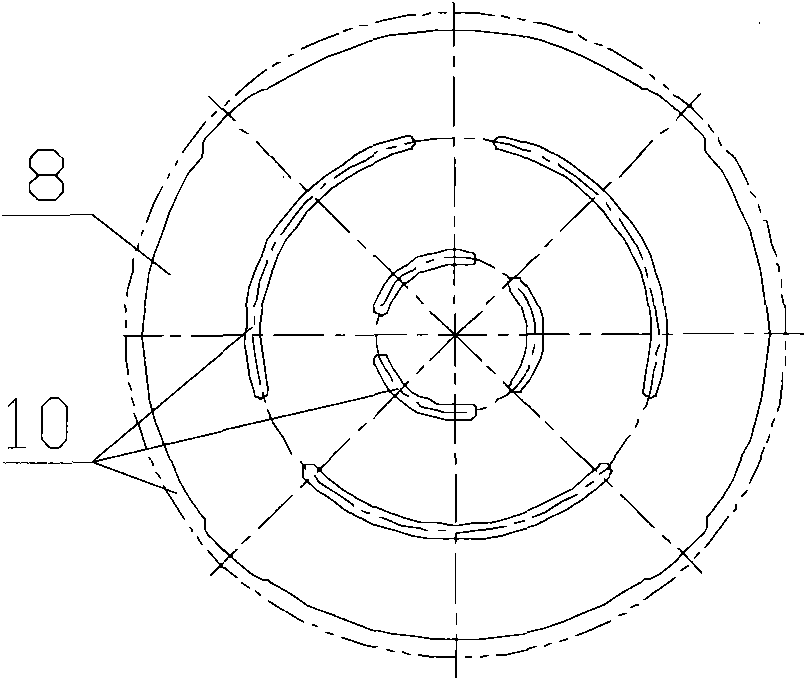

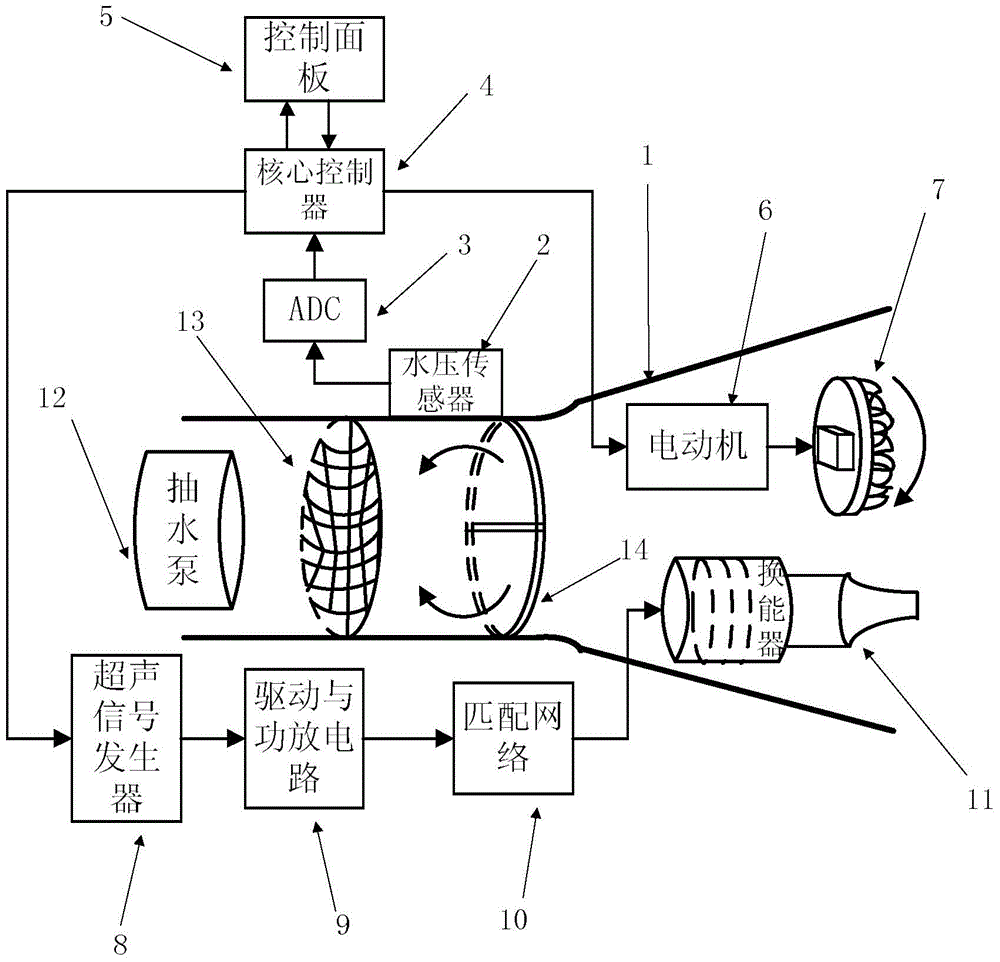

Environment-friendly surface inspection cleaning device for underwater construction

The invention discloses an environment-friendly surface inspection cleaning device for an underwater construction. The environment-friendly surface inspection cleaning device comprises a device shell, a hydraulic pressure sensor, an analog-digital converter, a core processor, a control panel, an electromotor, a cleaning brush, an ultrasonic power supply and an energy converter, wherein a signal output end of the hydraulic pressure sensor is connected with the core processor through the analog-digital converter; the hydraulic pressure sensor is fixedly mounted on the device shell and is used for sensing a hydraulic pressure signal capable of reflecting the water depth of the device shell and transmitting to the analog-digital converter; after the hydraulic pressure signal is converted by the analog-digital converter, the hydraulic pressure signal is transmitted to the core processor; depth information for the device shell is generated by the core processor according to the received hydraulic pressure signal and is outputted to the control panel; and a corresponding signal for controlling the electromotor or the ultrasonic power supply is outputted by the core processor. According to the invention, the physical brush cleaning is combined with the ultrasonic cleaning, so that the underwater construction can be thoroughly cleaned and a better cleaning effect is achieved.

Owner:HOHAI UNIV CHANGZHOU

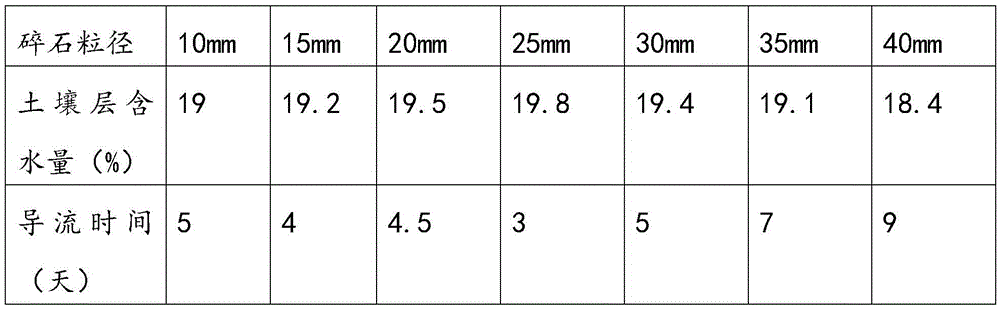

Water seepage structure and method

InactiveCN105569159ASpeed up penetrationAvoid Waterlogging ProblemsSewerage structuresSewage drainingSurface layerWater level

The invention relates to a water seepage structure and method. The water seepage structure comprises a water seepage well and a water permeation layer, wherein the water seepage well is vertically arranged in a soil layer of the ground; the water seepage well is filled with a flow guide object; the water seepage well infiltrates received water into an underground water layer through the flow guide object; the water permeation layer is arranged on the soil layer and covers a well mouth of the water seepage well; and the water permeation layer directly infiltrates surface water into the soil layer or guides the surface water into the water seepage well. The water seepage well is arranged on the ground, so that water in a ground surface layer can be quickly infiltrated into the underground water layer to quickly recover the underground water level, the cost is low, and the efficiency is high; the water seepage well is filled with the flow guide object, so that the seepage velocity of the water can be increased by utilizing a capillary tube principle; and the water permeation layer is arranged on the surface layer of the water seepage well, so that accumulated water can be prevented from being generated on the surface of the soil layer between water seepage wells.

Owner:路金铭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com