Barium titanate-based Y5V nano-powder and preparation method for ceramic material thereof

A technology of nano-powder and barium titanate, which is applied in the field of barium titanate-based nano-powder and its preparation, can solve the problems of easy segregation of components in the precipitation method, high sintering temperature, and high electrode cost, and achieves the titanium-barium ratio and the doping ratio. The effect of easy control of impurities, high purity, and high reliability of dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to the composition formula:

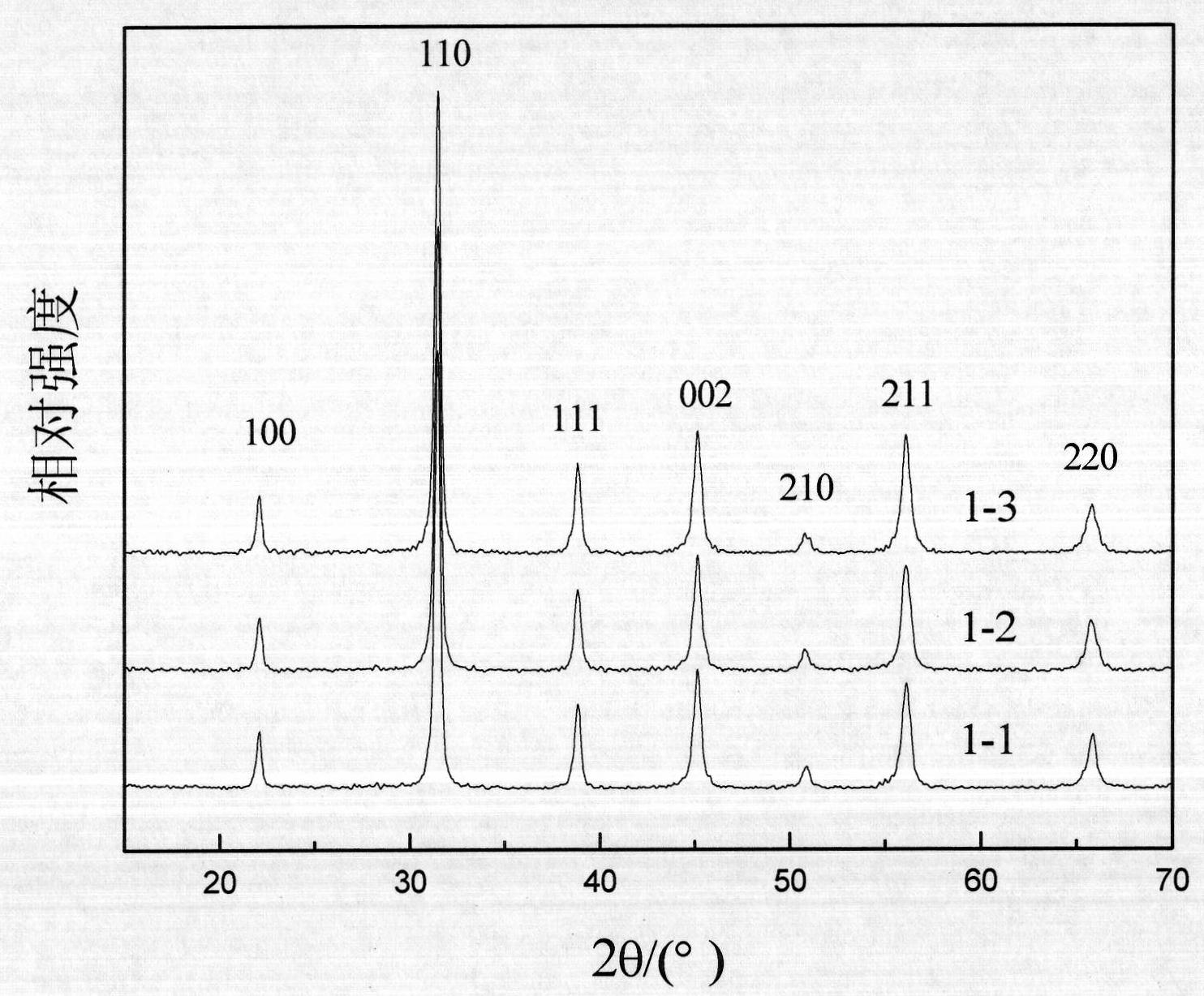

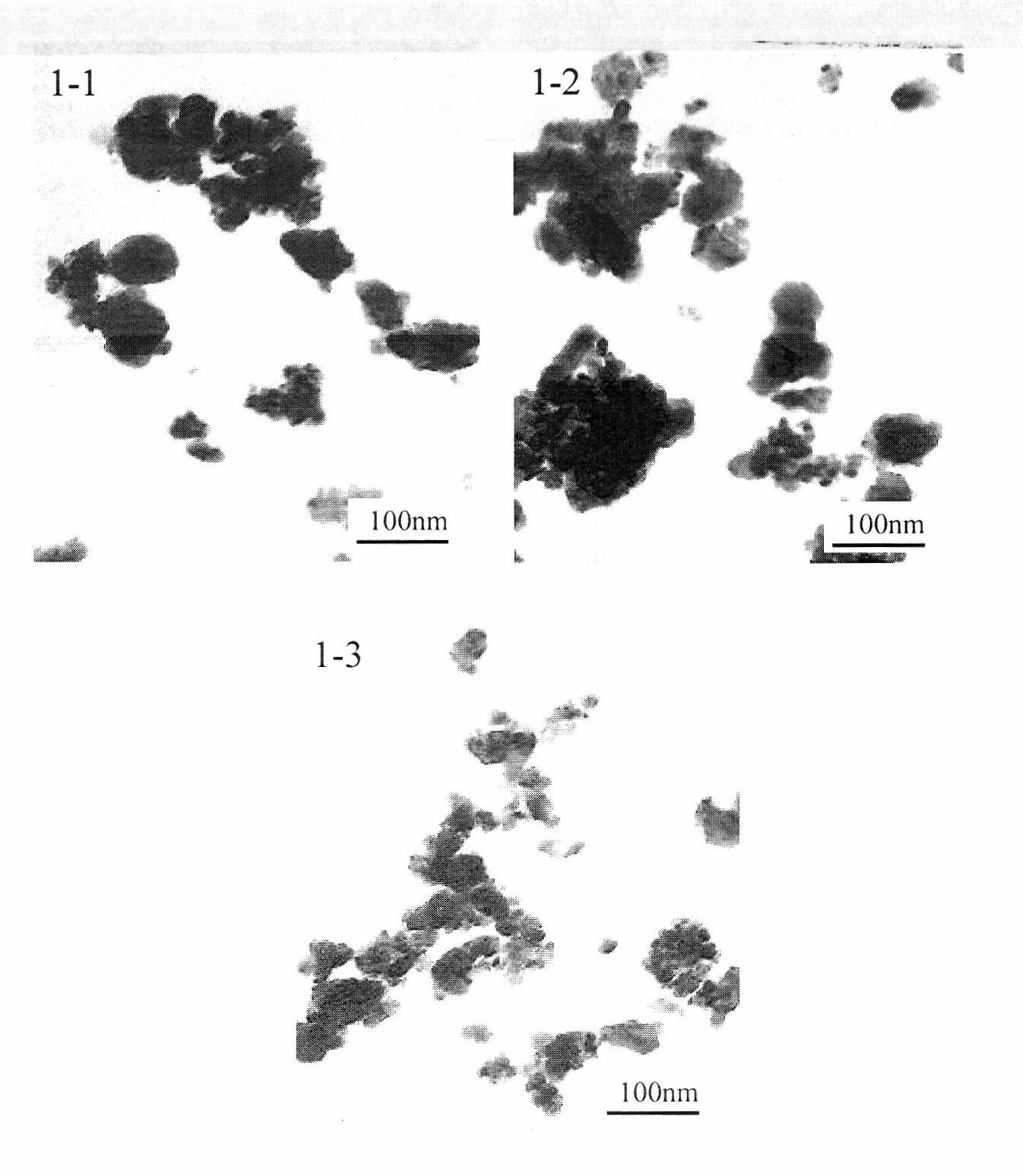

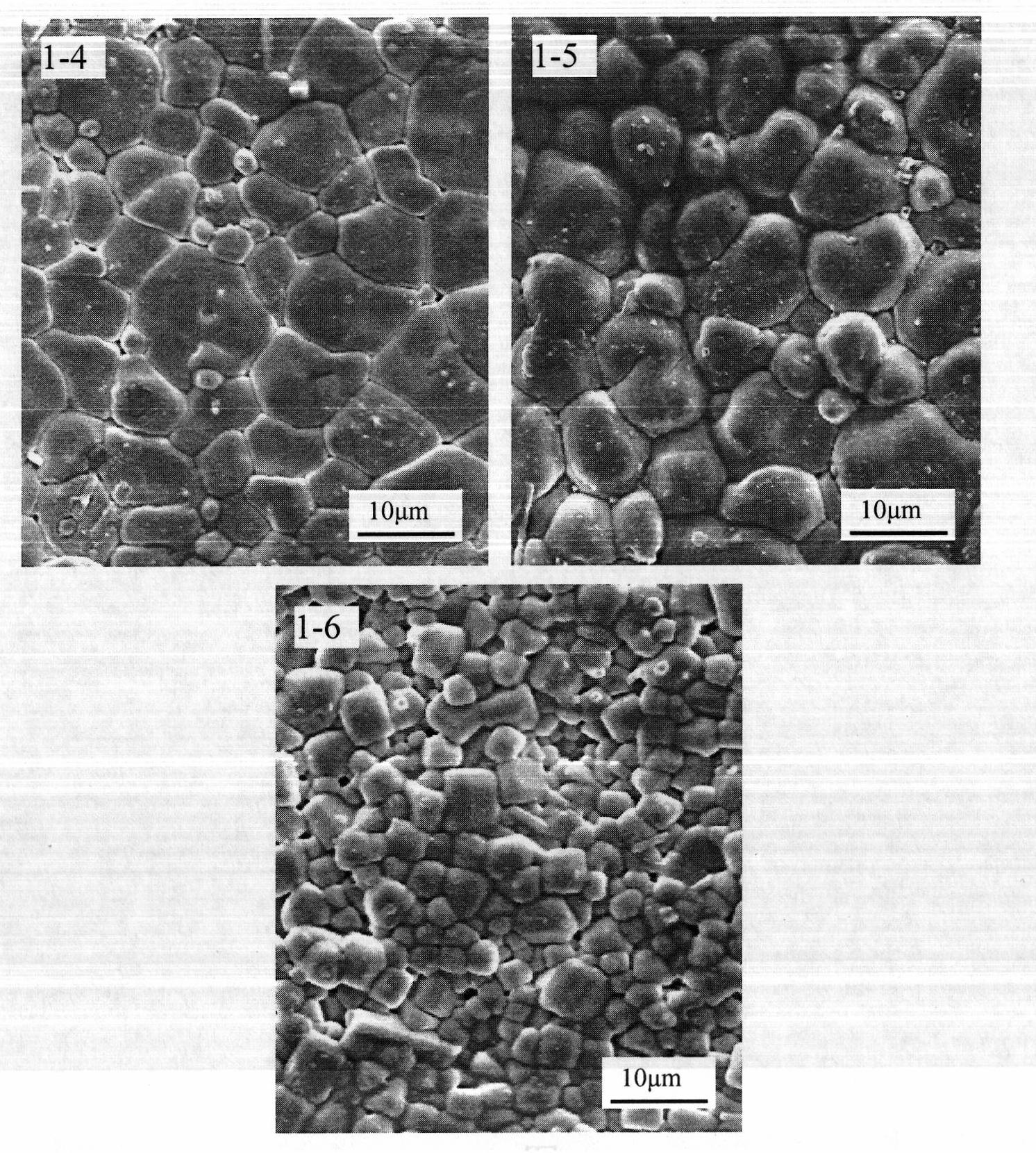

[0042] (Ba 0.87 Ca 0.09 Sr 0.04 )(Ti 0.86 Zr 0.08 sn 0.06 )O 3 +0.0137molZnO+0.0111molSiO 2 +0.0029molMnO 2 +0.0001molCeO 2 +0.0004molWO 3 +xmolNb 2 o 5 , fixed the content of Zn, Si, Mn, Ce, W, Ca, Sr, Zr, Sn in the sample, changed the amount of Nb doped to 0.0011, 0.0019 and 0.0023, and synthesized barium titanate-based Y5V nanopowder by sol-gel method ( Recorded as #1-1, #1-2 and #1-3) and their ceramic materials (recorded as #1-4, #1-5 and #1-6 in sequence), the specific steps are as follows:

[0043] a) Weigh 44.7881 g of tetrabutyl titanate according to the stoichiometric ratio, add 30 ml of glacial acetic acid and 5 ml of absolute ethanol under stirring, and fully stir;

[0044] b) Add 33.3824g of barium acetate, 1.2762g of strontium nitrate, 2.4270g of calcium acetate, 3.8558g of zirconium oxynitrate, 0.1007g of cerium nitrate, 0.1509g of zinc acetate, 0.0782g of manganese nitrate and 0.4472g of ammonium metat...

Embodiment 2

[0053] According to the composition formula:

[0054] (Ba 0.90 Ca 0.07 Sr 0.03 )(Ti 0.96-x Zr x sn 0.04 )O 3 +0.0137molZnO+0.0111molSiO 2 +0.0029molMnO 2 +0.0001molCeO 2 , fixed the Zn, Si, Mn, Ce, Ca, Sr, Sn content in the sample, changed the Zr content to 0.07, 0.08 and 0.09, and synthesized barium titanate-based Y5V nanopowder by sol-gel method (recorded as #2 -1, #2-2 and #2-3) and ceramic materials thereof (recorded as #2-4, #2-5 and #2-6 successively), calculate the dosage of each substance according to the composition, and the specific steps are with reference to Example 1 .

[0055] Depend on Figure 5 It can be seen from the XRD pattern of the figure that the barium titanate-based nanopowder obtained by sintering at 900 ° C in the figure is composed of a single cubic phase of barium titanate without other impurity phases. from Image 6 The average particle size is estimated to be between 60nm and 80nm from the TEM photos. The SEM photos of ceramic sample...

Embodiment 3

[0059] According to the composition formula:

[0060] (Ba 0.87 Ca 0.09 Sr 0.04 )(Ti 0.90 Zr 0.04 sn 0.06 )O 3 +0.0137molZnO+0.0111molSiO 2 +0.0029molMnO 2 +xCeO 2 , fixed the Zn, Si, Mn, Ca, Sr, Sn, Zr content in the sample, changed the Ce content to 0.0010mol, 0.0015mol and 0.0020mol, and used the sol-gel method to synthesize the barium titanate-based Y5V nanopowder (recorded in turn are #3-1, #3-2, and #3-3) and their ceramic materials (recorded as #3-4, #3-5, and #3-6 in turn), and calculate the dosage of each substance according to the composition. For specific steps, refer to In Example 1, the difference is that the titanate is isopropyl titanate, the organotin is diethyldibutyltin, and the silicate is isopropyl titanate.

[0061] Depend on Figure 9 It can be seen from the XRD pattern of the figure that the barium titanate-based nanopowder obtained by sintering at 1150 ° C in the figure is composed of a single cubic perovskite phase of barium titanate without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com