Preparation method and application of spherical nano bismuth oxide photocatalyst

A photocatalyst, bismuth oxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low solar energy utilization, low quantum efficiency, and catalytic activity. Low and other problems, to achieve the effect of high solar energy utilization, high quantum efficiency and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

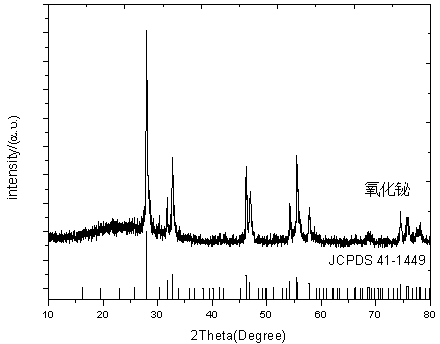

[0016] Under stirring conditions, add 1.5 mmol of bismuth nitrate pentahydrate to 35 mL of water, then add 4.5 mmol of sodium gluconate, stir well, adjust the pH of the solution to 10 with sodium hydroxide, and obtain a mixed solution. The mixed solution was put into an autoclave, sealed, and kept at 120° C. for 18 hours to carry out hydrothermal reaction. After the reaction, the autoclave was cooled to room temperature, the solution in the autoclave was centrifuged to collect the precipitate, washed with distilled water, dried at 50°C for 6 hours, and calcined at 400°C for 5h to obtain material 1. X-ray electron diffraction image from material 1 ( figure 1 ) It can be seen that material 1 is a pure phase of bismuth oxide. From the electron microscope topography of material 1 ( figure 2 ) It can be seen that bismuth oxide is nano-spherical with an average diameter of about 200nm.

Embodiment 2

[0018] Under stirring conditions, 1.5 mmol of bismuth nitrate pentahydrate was added to 35 mL of water, and then 6 mmol of sodium gluconate was added, stirred thoroughly, and the pH of the solution was adjusted to 11 with sodium hydroxide to obtain a mixed solution. Put the mixed solution into an autoclave, seal it, and keep it at 180°C for 24 hours to carry out hydrothermal reaction. After the reaction, the autoclave was cooled to room temperature, the solution in the autoclave was centrifuged to collect the precipitate, washed with distilled water, dried at 60°C for 4 hours, and then calcined at 500°C for 3h to obtain material 2. From the X-ray electron diffraction image of material 2, it can be seen that material 2 is a pure phase of bismuth oxide. From the electron microscope topography of material 2, it can be seen that bismuth oxide is in the shape of nanospheres with an average diameter of about 200 nm.

Embodiment 3

[0020] Under stirring conditions, 1.5 mmol of bismuth nitrate pentahydrate was added to 35 mL of water, and then 7.5 mmol of sodium gluconate was added, fully stirred, and the pH of the solution was adjusted to 13 with sodium hydroxide to obtain a mixed solution. Put the mixed solution into an autoclave, seal it, and keep it at 150°C for 22 hours to carry out hydrothermal reaction. After the reaction, the autoclave was cooled to room temperature, the solution in the autoclave was centrifuged to collect the precipitate, washed with distilled water, dried at 70°C for 3 hours, and then calcined at 600°C for 1 hour to obtain material 3. From the X-ray electron diffraction image of material 3, it can be seen that material 3 is a pure phase of bismuth oxide. From the electron microscope topography of material 3, it can be seen that bismuth oxide is in the shape of nanospheres with an average diameter of about 200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com