Pollution-free gas drying agent and drying method thereof

A technology of gas drying and drying methods, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve problems such as polluting the environment, failing to discharge, and affecting the air quality of exported products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of pollution-free gas desiccant is made of the NaCL of 82-90%, the KCL of 6-12%, the MgCl of 2.5-4.5% by weight percentage 2 , 1.0-2.0% CaCl 2 Composition, its 82-90% refers to 82%, 83%, 84%, ... 88%, 89%, 90%, the unit is an integer change and includes decimals; 6-12% refers to 6%, 7%, 8 %, ... 9%, 10%, the unit is an integer change and includes decimals; 2.5-4.5% refers to 2.5%, 2.6%, 2.5%, ... 4.4%, 4.5%, the unit is a decimal change; 1-2% Refers to 1.0%, 1.1%, ... 1.9%, 2.0%, and the unit system changes in decimals.

Embodiment 2

[0022] Embodiment 2: on the basis of embodiment 1, when described NaCL is 85.5%, KCL is 9%, MgCL 2 3.8%, CaCl 2 When it is 1.7%, it constitutes the best embodiment of the present application.

Embodiment 3

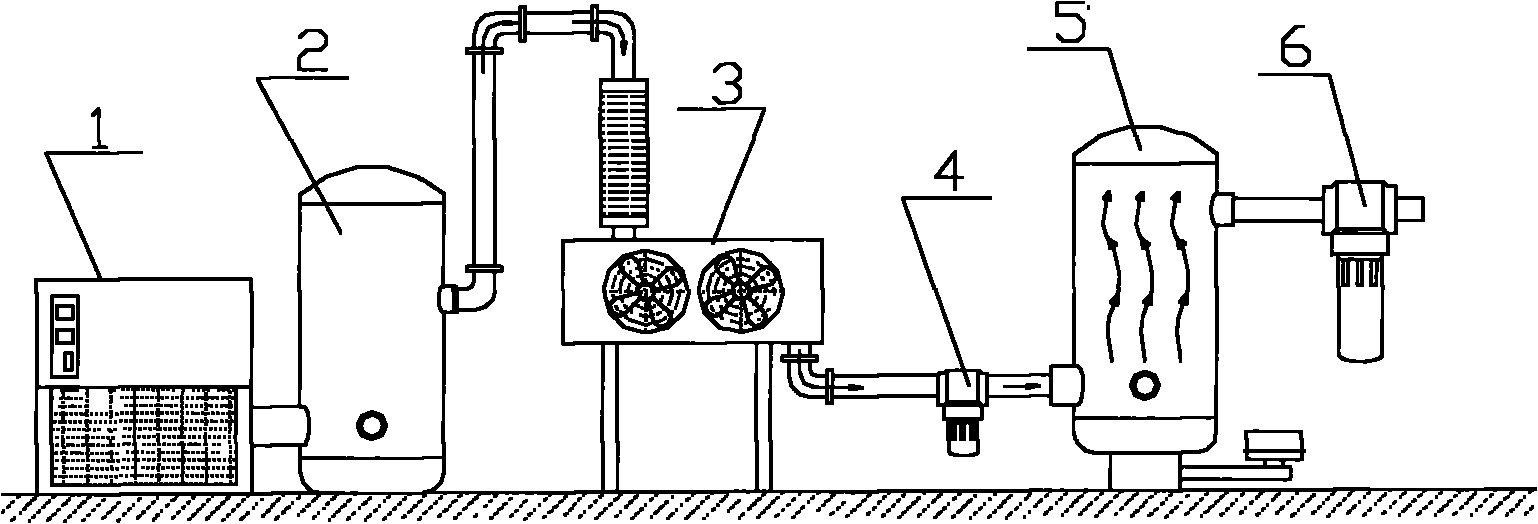

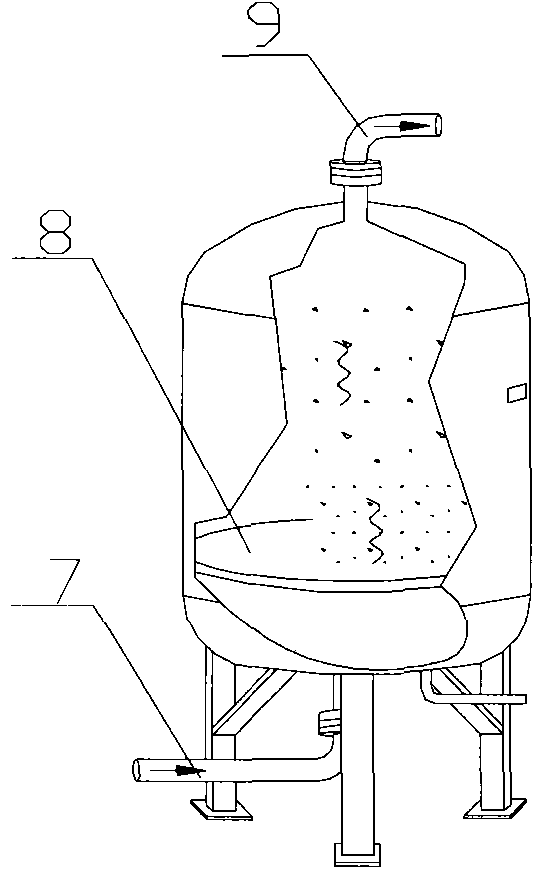

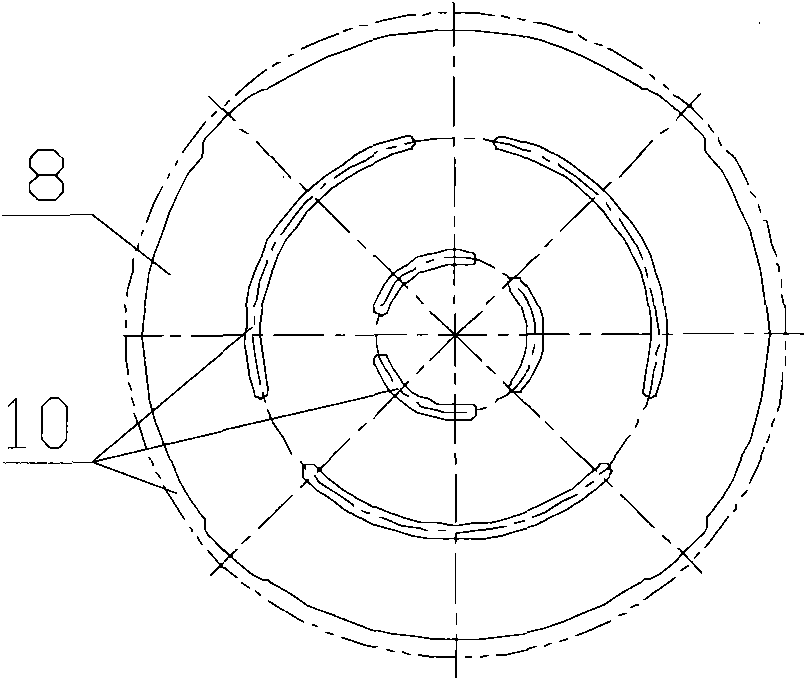

[0023] Embodiment 3: with reference to attached Figure 1-3 . A drying method for a dryer composed of a non-pollution gas desiccant. The humid air enters from the inlet 7 located at the bottom center of the container of the dryer 5, and is evenly divided by the splitter plate 8, so that the compressed air is evenly distributed in the tower and flows upward. , in full contact with the hygroscopic agent layer; the humid air first contacts the hygroscopic agent layer in the reaction zone, and the hygroscopic agent absorbs a large amount of water in the humid air, causing the hygroscopic agent to produce a chemical reaction; then enters the hygroscopic agent layer In the drying area, the hygroscopic agent further dries the humid air to make its dew point reach the required dew point; finally, through the preparation area of the hygroscopic agent, the fully dried compressed air is discharged from the air outlet 9 at the upper end of the container. That is to say, the hot and hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com