High-performance epoxy resin asphalt warm mixing agent and preparation method thereof

A technology of epoxy resin and warm mix agent, which is applied in building insulation materials, building components, climate change adaptation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

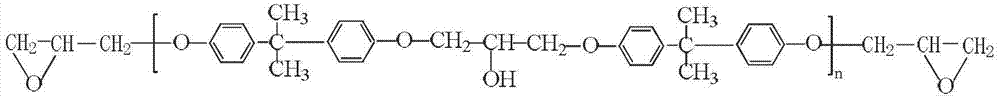

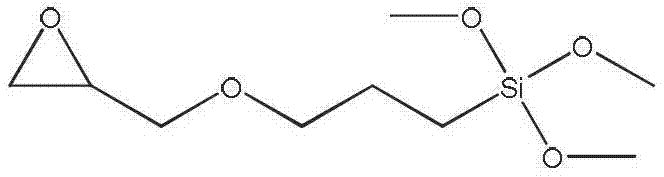

[0054]Example 1: Weigh 100 parts (parts by mass, the same below) of epoxy resin bisphenol A glycidyl ether epoxy resin (E51) (provided by Wuxi Bluestar Petrochemical Co., Ltd.), and add 0.1 part of carbon black (N660) (provided by Cabot Corporation of the United States) and 0.2 parts of γ-(2,3 glycidoxy) propyltrimethoxysilane (KH-560) (provided by Nanjing Yudeheng Fine Chemical Co., Ltd.), heated to 80 ° C, Stir mechanically for 30 minutes, cool to room temperature, and obtain component A of high-performance warm-mix epoxy resin asphalt warm mix agent.

Embodiment 2

[0055] Example 2: Weigh 100 parts of epoxy resin bisphenol A glycidyl ether epoxy resin (E51), add 0.3 parts of carbon black (N660) and 0.5 parts of γ-(3,4 epoxycyclohexane) ethyl Trimethoxysilane (KH-530) (provided by Nanjing Wanda Silicon Industry Co., Ltd.), heated to 80°C, mechanically stirred for 30 minutes, and cooled to room temperature to obtain component A of high-performance warm-mix epoxy resin asphalt warm mix agent.

[0056] The preparation method of component B of high-performance warm-mix epoxy resin asphalt warm-mix agent is as follows:

Embodiment 3

[0057] Example 3: 119 parts of hexadecenyl succinic anhydride (HDSA) (provided by Dixie Chemical Company of the United States), 1 part of mixed fatty acid amide (Licomont BS 100) (provided by Klein Company of Switzerland), 3 parts of nonylphenol (provided by U.S. provided by Huntsman), 5 parts of titanium dioxide (provided by Shanghai Jianghu Titanium White Chemical Products Co., Ltd.), 20 parts of liquid polysulfide rubber (provided by Japan Toray) and 0.1 part of polysiloxane defoamer (BYK-A530 ) (provided by Xiamen Kangdilong Trading Co., Ltd.), heated to 100 ° C, mixed with a colloid mill for 30 minutes, and cooled to room temperature to obtain component B of high-performance epoxy resin asphalt warm mix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com