Low-CO2-emisison solar energy and methanol complementary thermodynamic cycle system and method

A technology of thermal cycle system and solar energy, which is applied in the field of thermal cycle system where solar energy and methanol are complementary, can solve the problems of great impact on system performance, decrease in system efficiency, and large amount of exhaust gas to achieve clean utilization, low energy consumption cost, Effect of Conservation of Fossil Energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

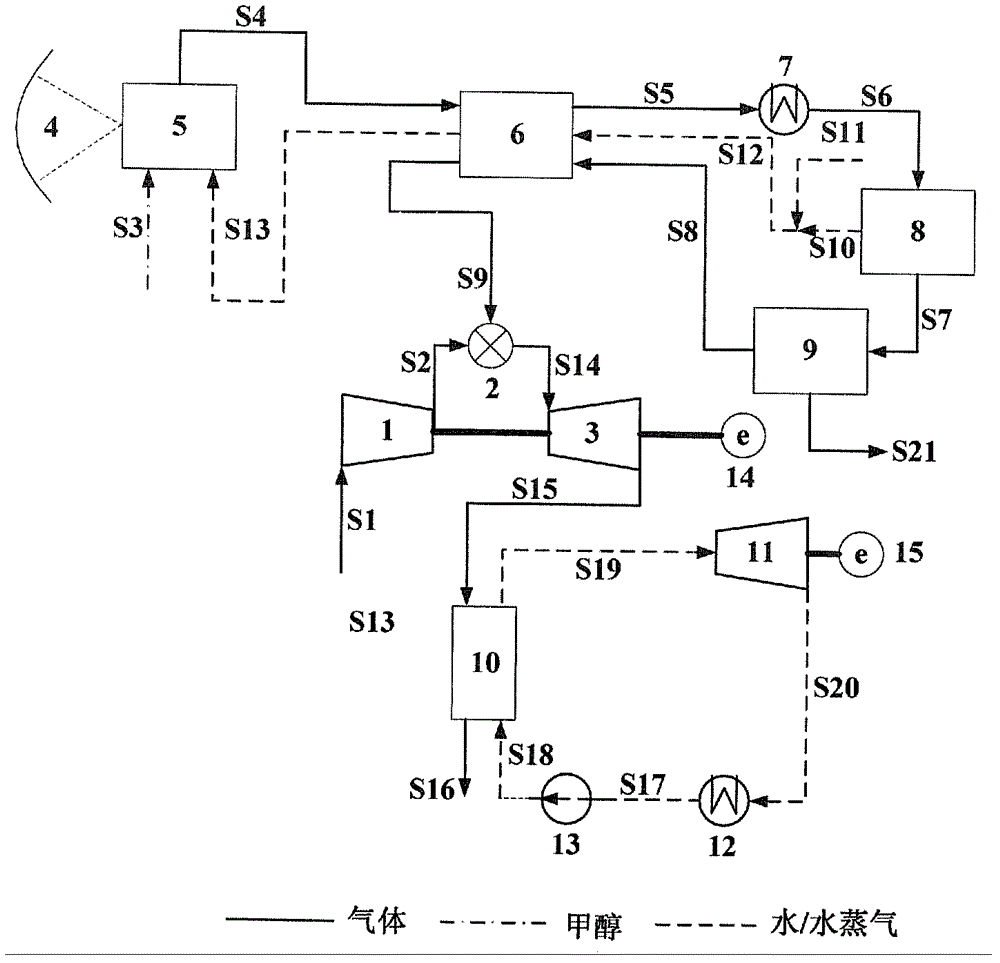

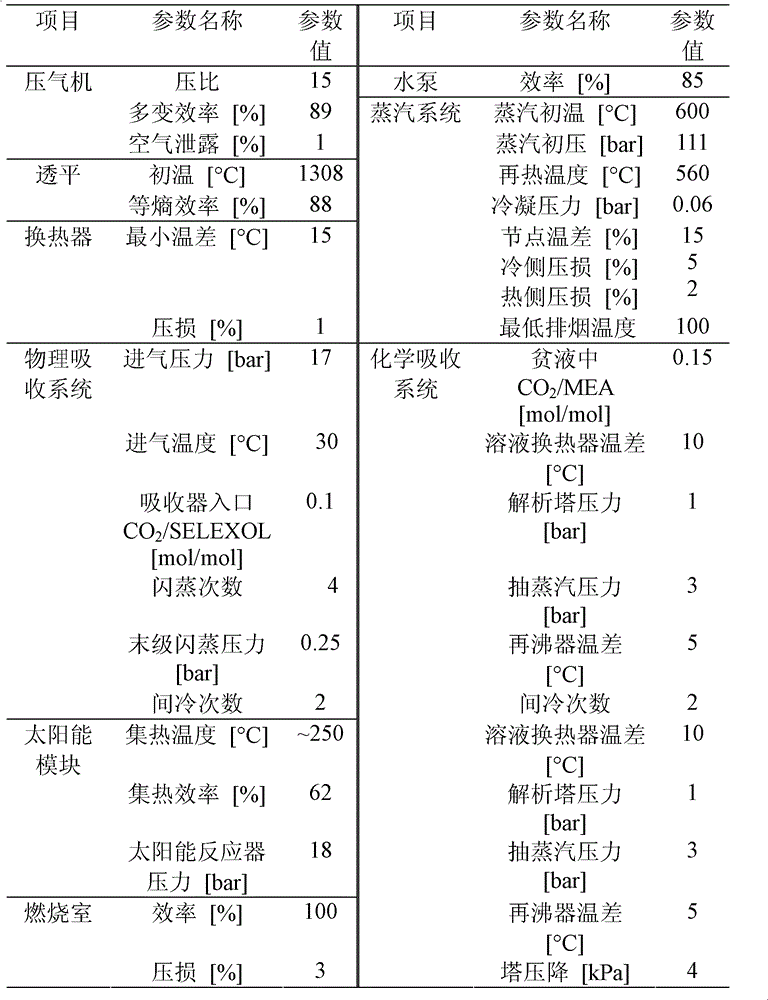

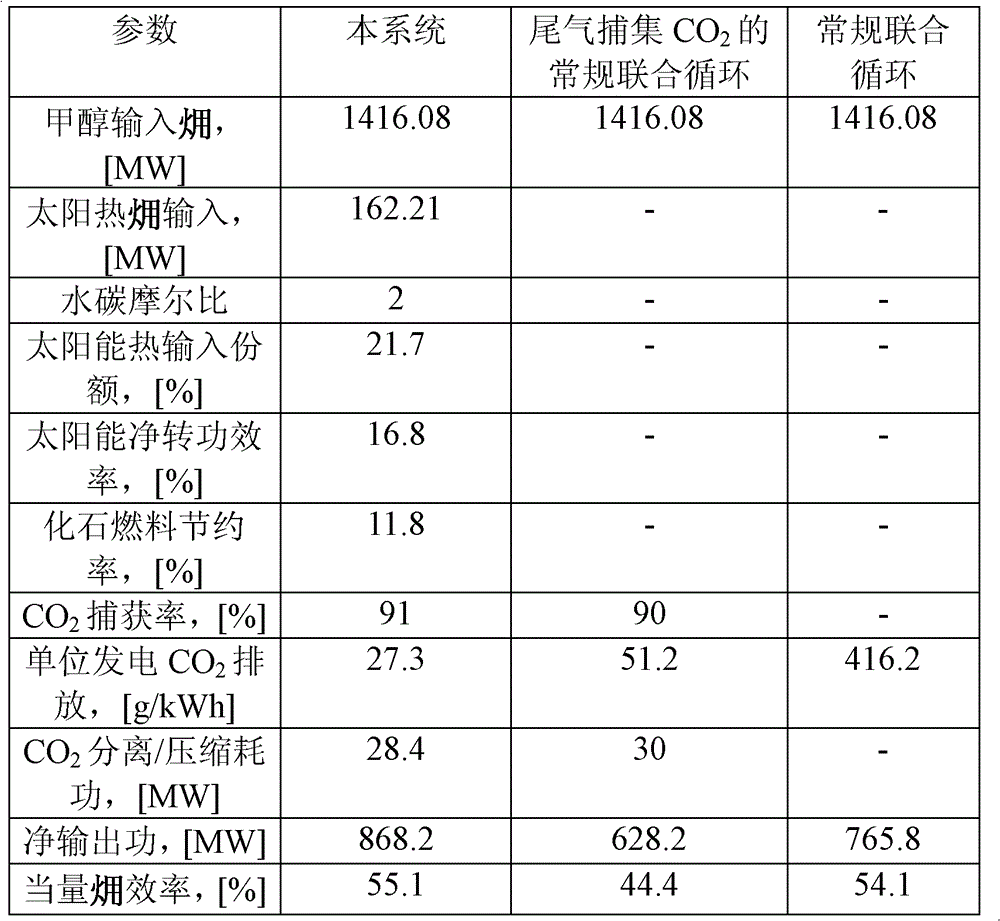

[0048] The invention provides a low CO 2 The discharged solar energy and methanol complement the thermodynamic cycle system and method, which combine the solar energy upgrade with the high-efficiency combined cycle system. The medium and low temperature solar energy first provides the reaction heat of methanol / steam reforming, and converts the fuel into H 2 And CO 2 (H 2 With CO 2 The molar ratio is close to 3:1) as the main component of synthesis gas, so that low-grade solar energy is converted into synthesis gas chemical energy; and CO is realized by the absorption unit 2 The decarbonized clean fuel will finally achieve thermal power conversion in the high-efficiency combined cycle.

[0049] Such as figure 1 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com