Intensified wooden floor capable of reaching EO grade standard

A standard technology for laminate flooring, applied in the direction of wood laminate products, chemical instruments and methods, paper/cardboard laminate products, etc., which can solve the problem that the floor cannot be mass-produced on a large scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

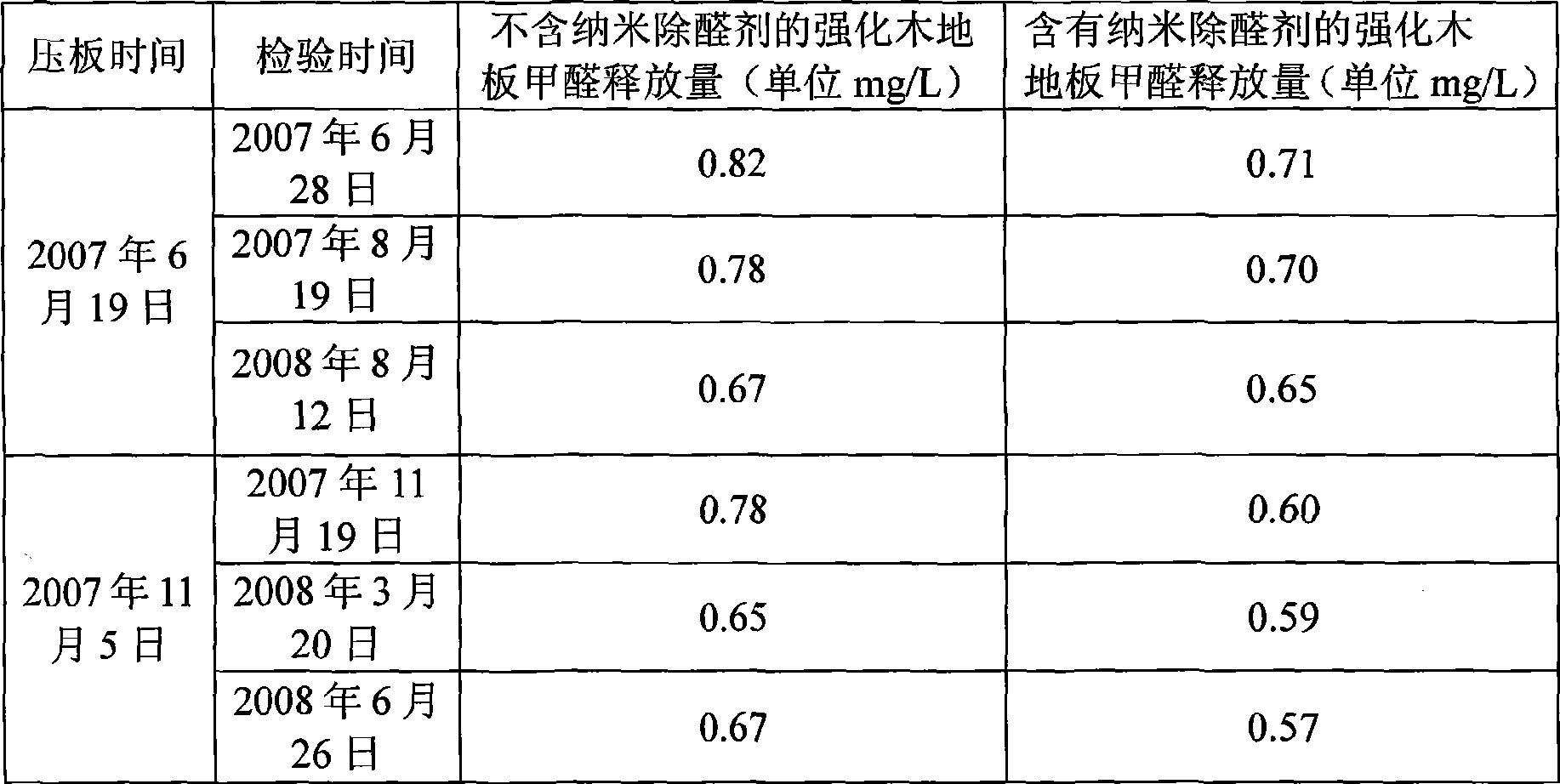

[0016] When the melamine resin impregnated wear-resistant paper was added the nano formaldehyde removal agent that the percentage by weight is 1%, obtained result is as follows:

[0017]

[0018] The formaldehyde emission of the laminate flooring containing nano-formaldehyde scavenger is lower than that of the laminate floor without nano-formaldehyde scavenger, but it has not yet reached the E0 standard.

Embodiment 2

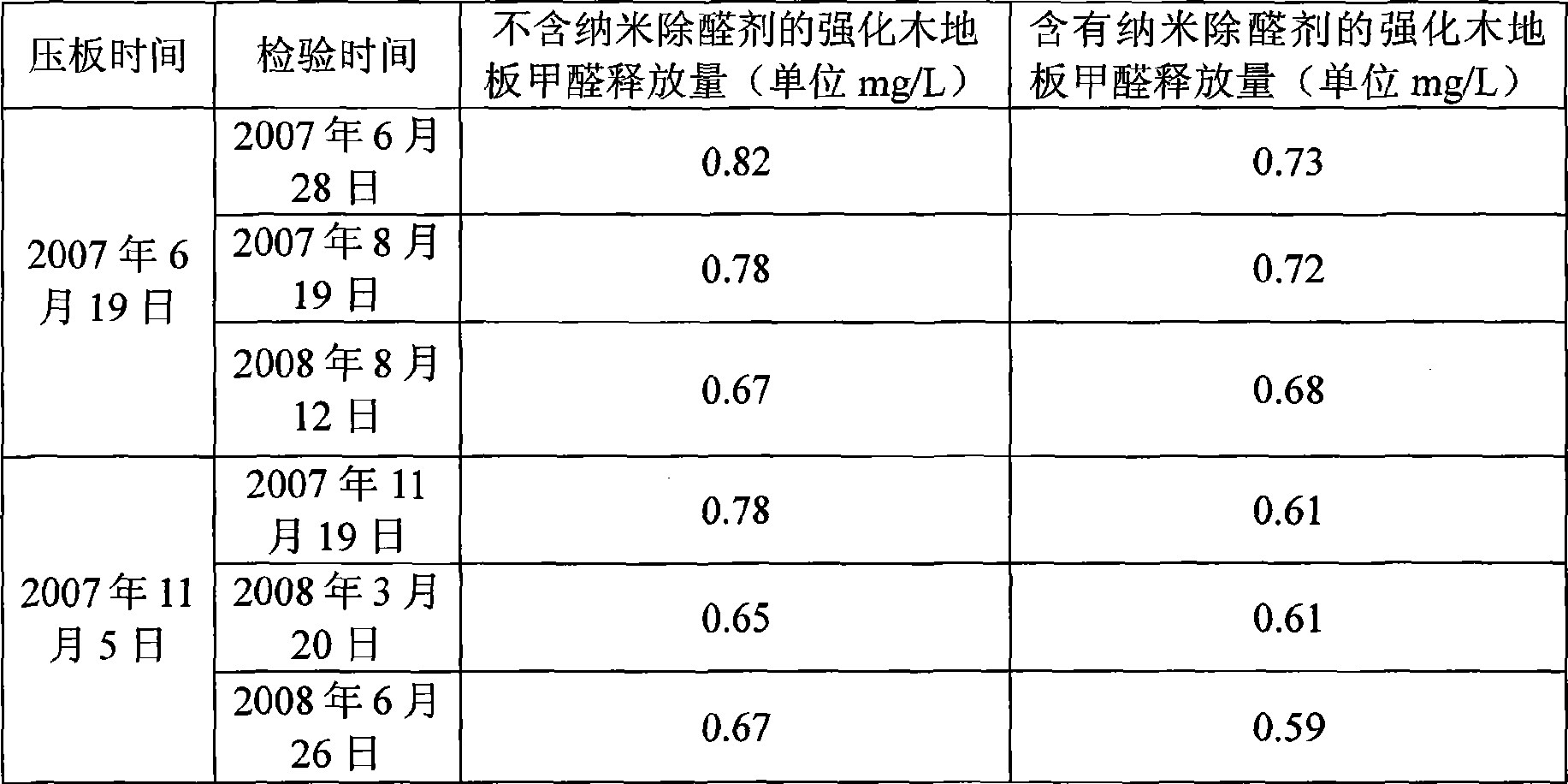

[0020] When the melamine resin impregnated with wear-resistant paper was added the nano formaldehyde removal agent of 1.5% by weight, the obtained results were as follows:

[0021]

[0022] The laminate flooring containing nano-formaldehyde scavenger has lower formaldehyde emission than the laminate floor without nano-formaldehyde scavenger, but it does not meet the E0 standard.

Embodiment 3

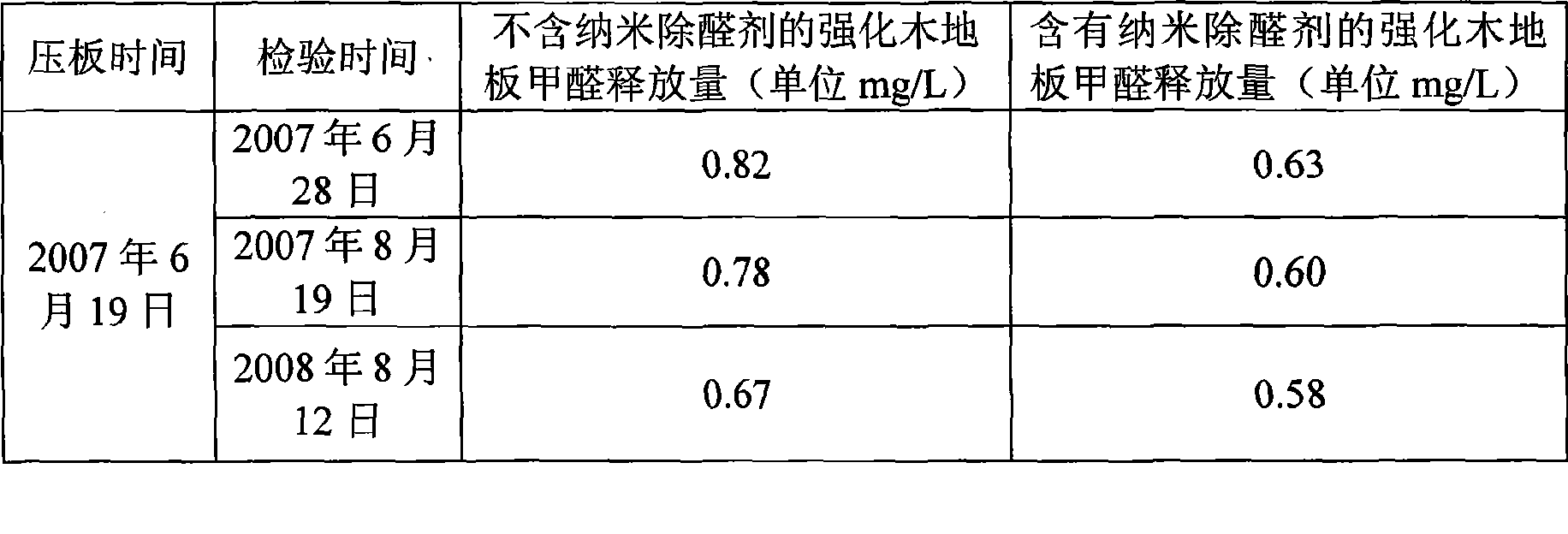

[0024] When the melamine resin impregnated with wear-resistant paper was added the nano formaldehyde remover of 2.5% by weight percentage, the obtained results are as follows:

[0025]

[0026]

[0027] The formaldehyde emission of laminate flooring containing nano-formaldehyde scavenger has partially reached the E0 standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com