Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Solve the problem of low yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

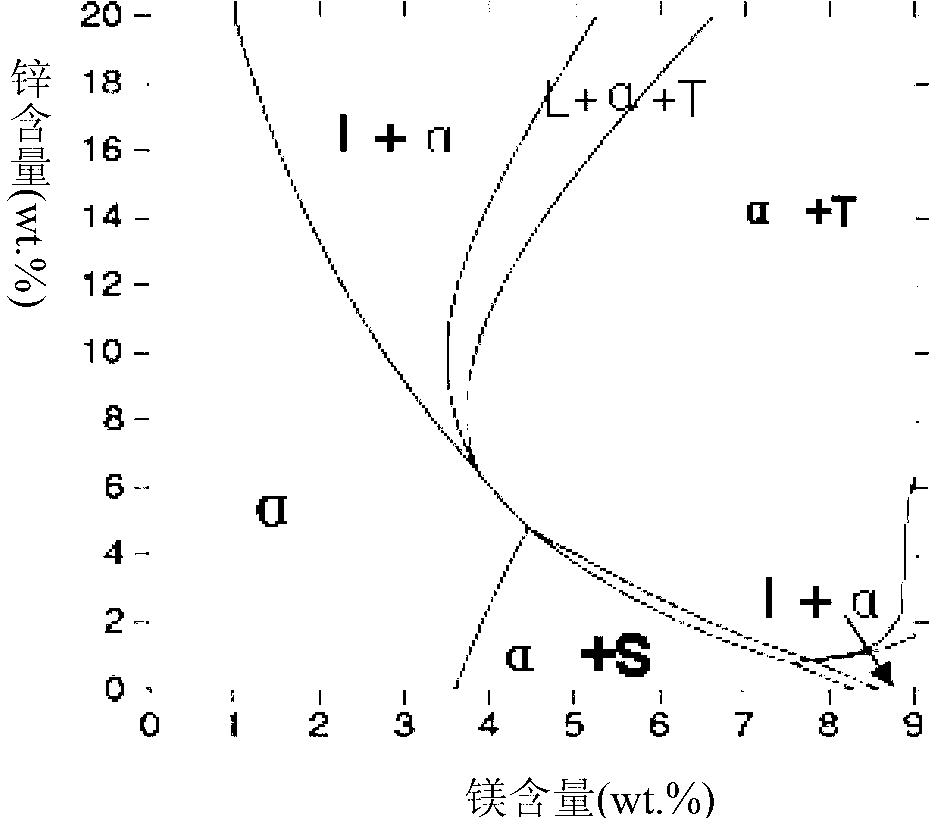

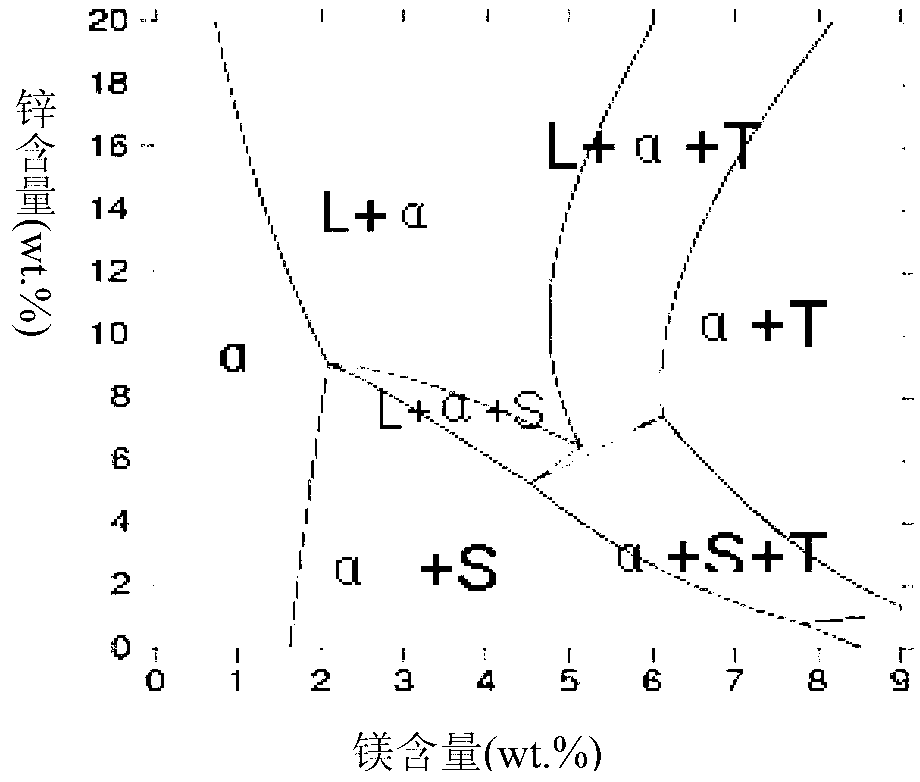

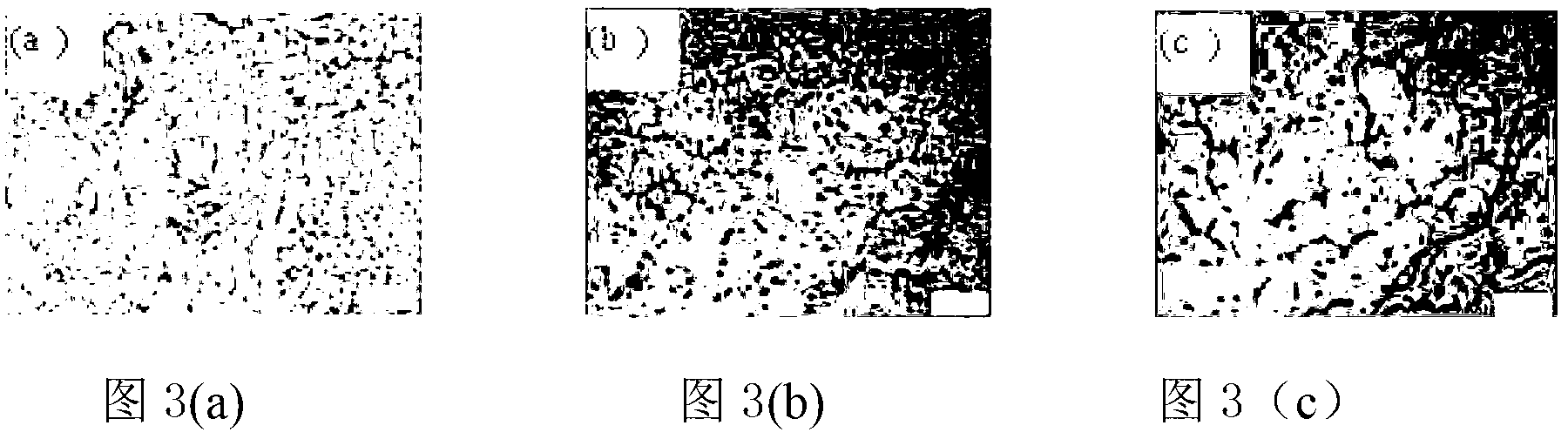

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

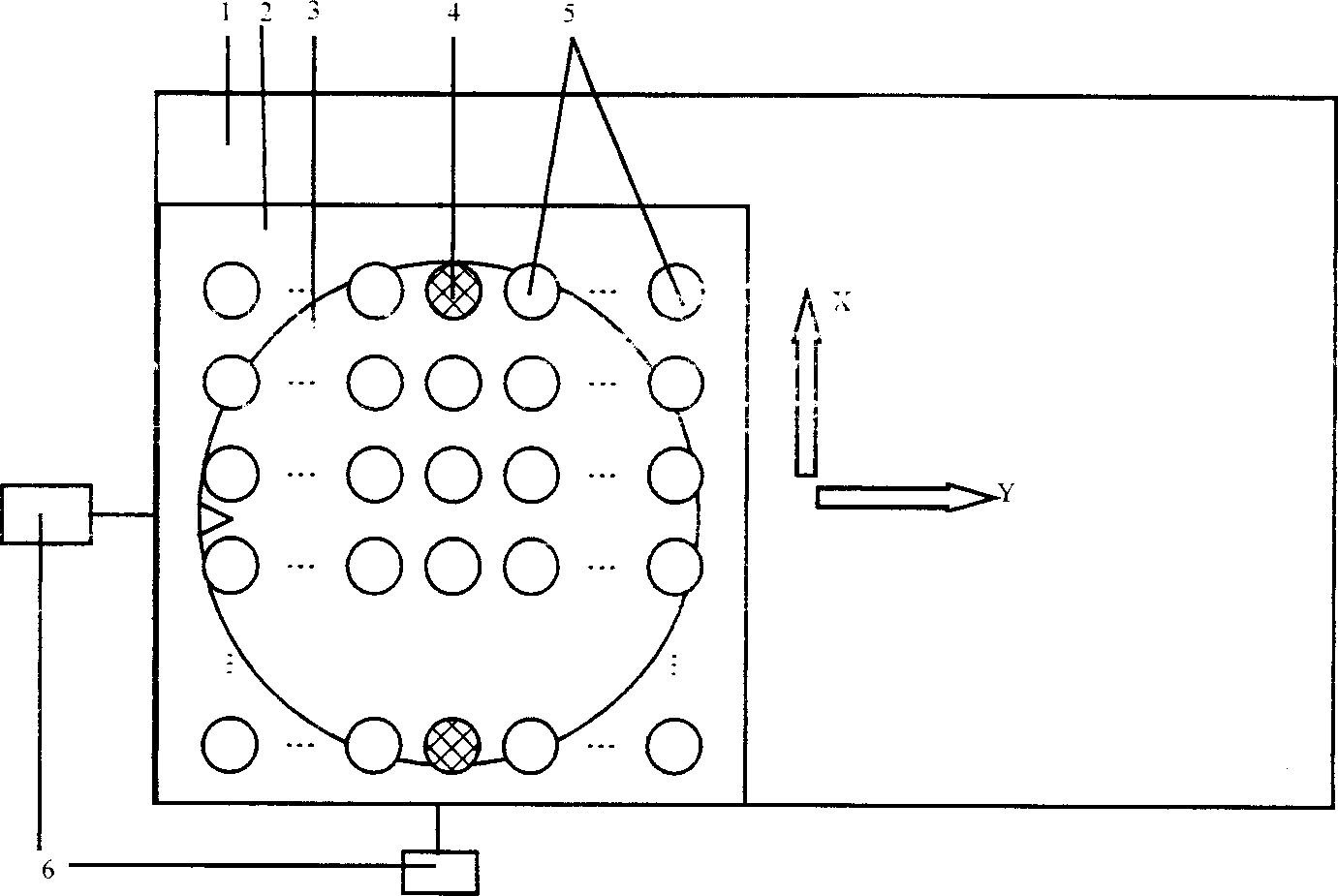

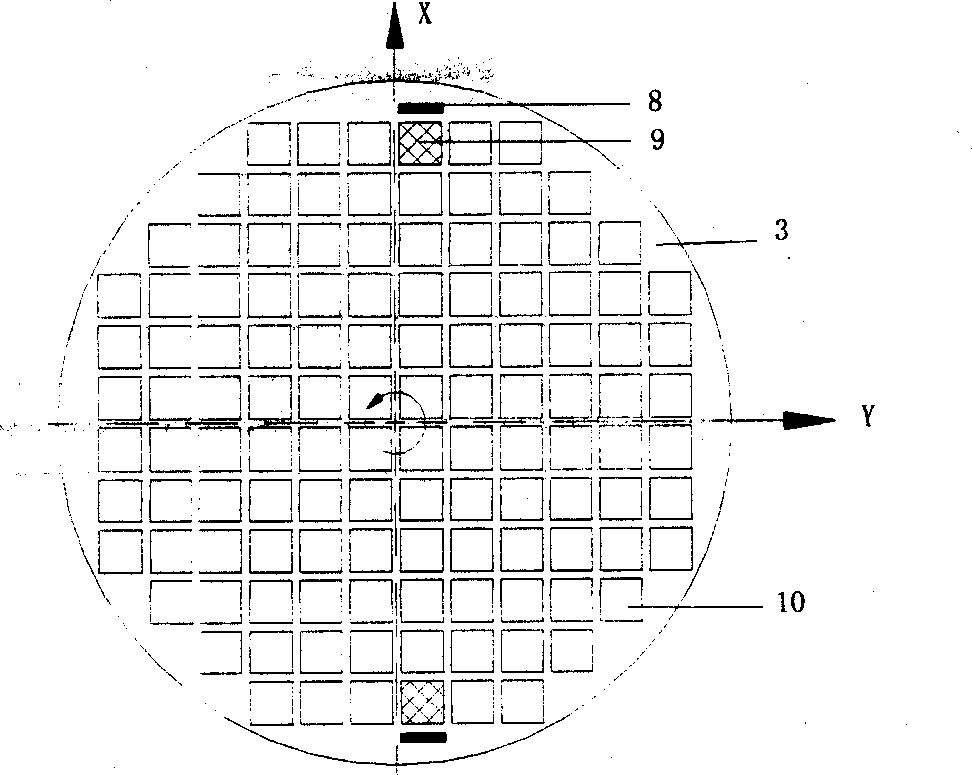

Alignment method and apparatus for array type optical probe scanning IC photoetching system

InactiveCN1333554AQuality assuranceSolve the problem of low yieldSemi-permeable membranesPhotomechanical apparatusGraphicsServo actuator

Firstly, according to the defined key points of circuit pattern, coding distinctive characteristics of circuit pattern, etching them on the silicon wafer, setting a pair a calibrating pattern, makingt he calibrating pattern position at circuit pattern place, and the calibrating pattern is formed from calibrating subpatterns. According to the key points of pattern, on the silicon wafer etching calibrating subpattern, when the alignment is made to key point of pattern, fetching calibrating subpattern coordinate and making comparison of said coordinate with recorded coordinate of calibrating subpattern. In the inveneted equipment the working table is placed on the base seat, and driven by precision servo-actuator, the silicon wafer to be worked can be fixed on the working table by means of suction cup, calibrating optical head and optical probe array are positioned over silicon wafer, a pair of calibrating optical heads is positioned in the middle of optical probe array are positioned over silicon wafer, a pair of calibrating optical heads is positioned in the middle of optical probes, the optcial probes array is arranged in the rectangular form. Said invention can save alignment time of pattern and can raise alignmant efficiency.

Owner:TSINGHUA UNIV

Continuous rheological extending forming method for preparing Al alloy tube

InactiveCN101224490ASignificant positive effectSolve process problemsMetal rolling arrangementsChemical compositionConductive materials

The invention relates to a continuous rheological extension forming method used for preparing an aluminium alloy pipe. The invention adopts a continuous extension forming device which mainly consists of a water cooling rotation roller, a fixed shoe plate, an extrusion forming die, a back pressing block and a base. The key point is that the invention is achieved by the steps that the chemical ingredients of the invention are 0.8% of an Mg, 0.7% of a Si, less than or equal to 0.1% of total impurity, and an Al with the residual quantity according to the mass percentage; a melting furnace is pre-heated to 700 DEG C when an aluminium ingot is added; an Al-Si master alloy is added when the temperature is 760 DEG C; the Mg is pressed into the melting body when the temperature is reduced to 720 DEG C; a refining is achieved by a hexachloroethane when the temperature is increased to 740 DEG C; after that, the melting body is covered and the temperature is increased and kept at 760-800 DEG C; finally, the aluminium alloy pipe is prepared by the continuous extension forming device of the melting body. The pipe tissue is uniform and fine; the tensile strength of T6 state is 300MPa, the elongation thereof is 10% and the equivalent conductivity is 54.38IACS. The invention has the advantages of high efficiency, saving energy, short process flow and fast effect. The product of the invention becomes the conductive material which is urgently required by power industry.

Owner:NORTHEASTERN UNIV

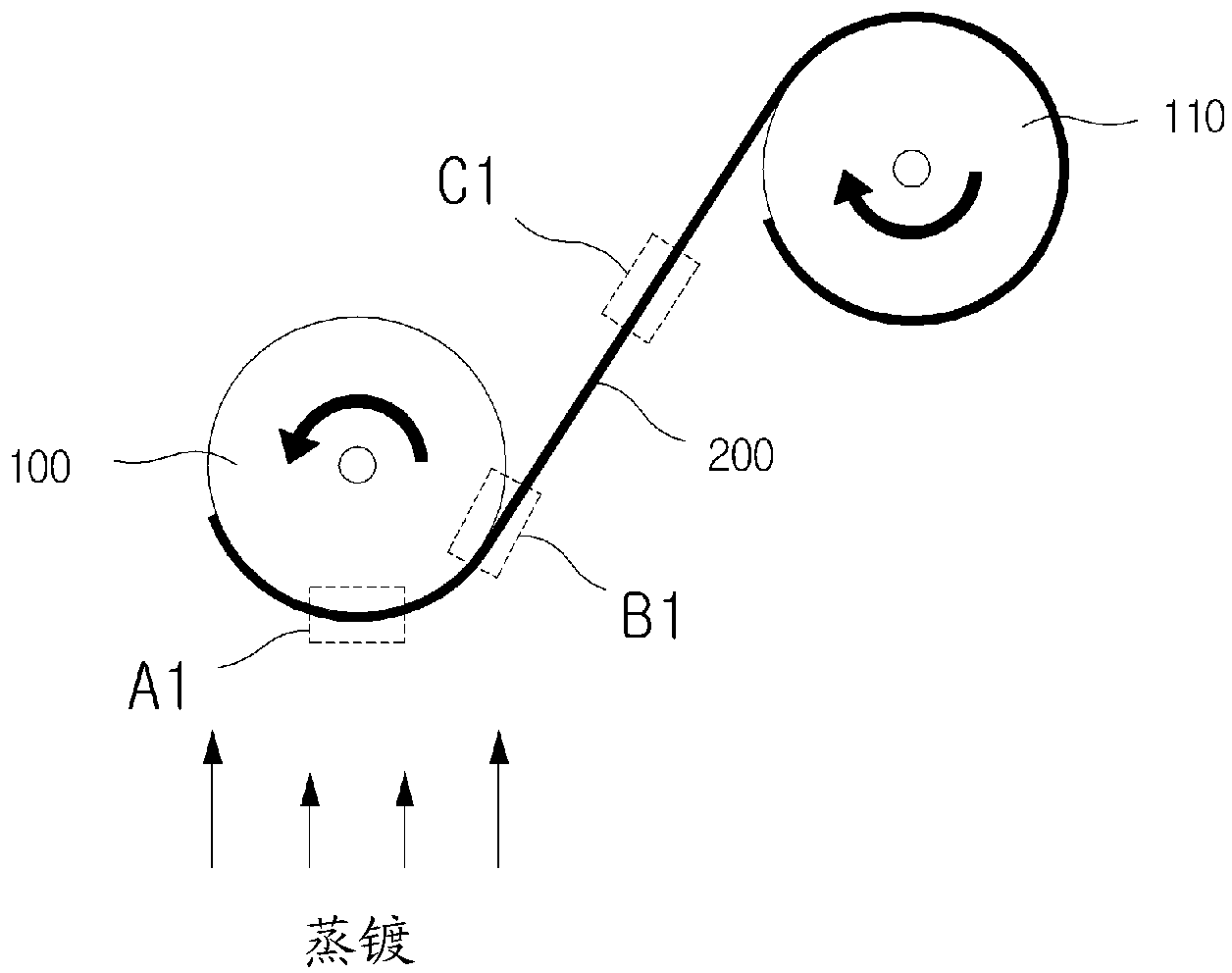

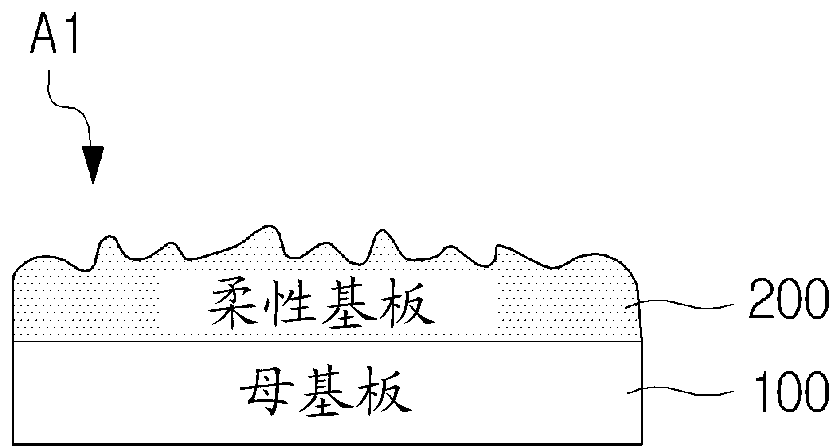

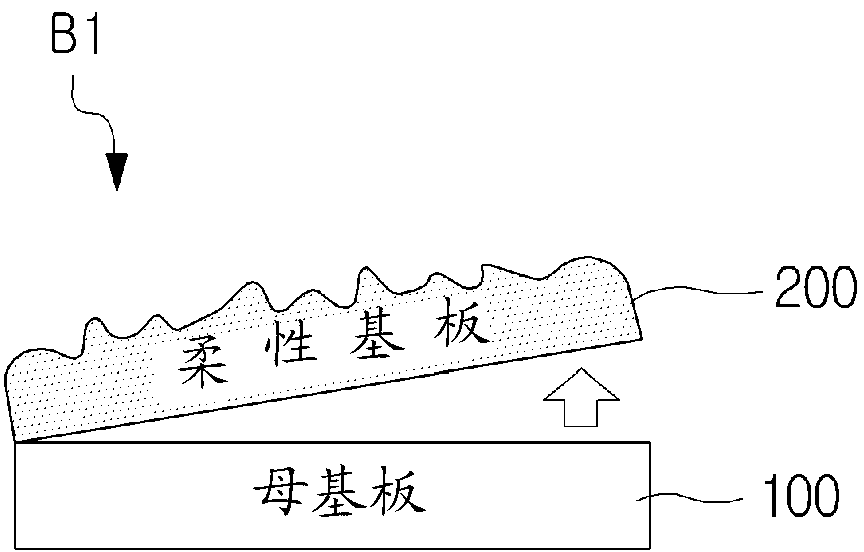

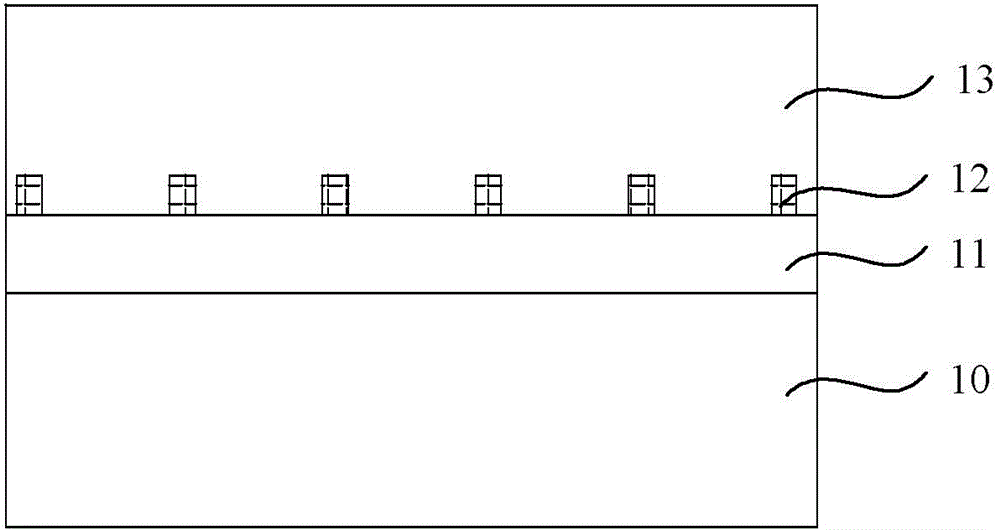

Method for manufacturing a flexible electronic device using a roll-shaped motherboard, flexible electronic device, and flexible substrate

InactiveCN103299448AReduce processing timeSave moneyTransistorCircuit bendability/stretchabilitySurface roughnessEngineering

The objective of the present invention is to solve the problems of degraded performance and yield of a flexible electronic device due to low processable temperature, high surface roughness, high thermal expansion coefficient, and poor handling characteristics of existing flexible substrates. The method for manufacturing a flexible electronic device according to the present invention comprises the steps of: forming a flexible substrate on a roll-shaped motherboard; separating the flexible substrate from the roll-shaped motherboard; and forming an electronic device on a separated surface of the flexible substrate that contacted the motherboard.

Owner:POHANG IRON & STEEL CO LTD

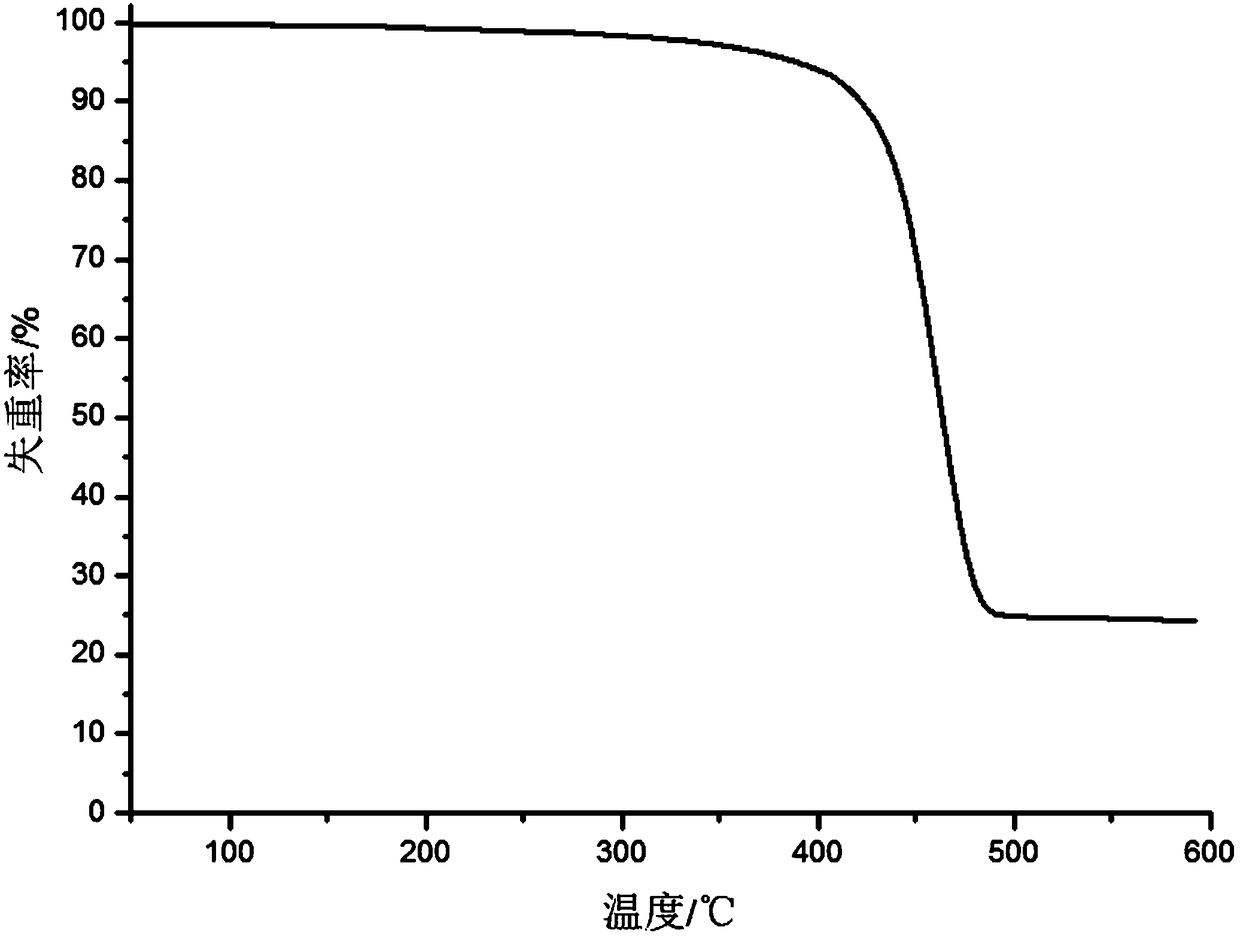

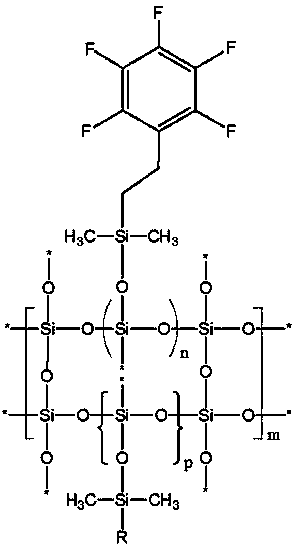

Fluorosilicone resin and preparation method thereof

ActiveCN108484914AImprove thermal stabilityHigh carbon-fluorine bond energyTrimethylsilyl chlorideAdhesive

The invention discloses fluorosilicone resin and a preparation method thereof. The method comprises the following steps: pentafluorostyrene is used as a raw material, and pentafluorophenethyldimethylchlorosilane is obtained by a hydrosilylation reaction; and the pentafluorophenethyldimethylchlorosilane, trimethylchlorosilane and ethyl orthosilicate are subjected to a polycondensation reaction to prepare the pentafluorophenyl silicon resin. When the resin disclosed by the invention is prepared, a secondary polycondensation process is adopted, so that the defect of a larger difference of hydrolysis reactivity of the pentafluorophenethyldimethylchlorosilane and copolymerized trialkylmonochlorosilane is overcome, and a preparation yield is high; the obtained pentafluorophenyl silicone resin has superior heat resistance; the method has the advantages of a simple preparation process, low requirements on equipment and raw materials easy to obtain, and is suitable for industrialized enlarged production; and the heat-resistant fluorosilicone resin can be applied to high-molecular materials such as heat-resistant adhesives.

Owner:SHENZHEN TAIKE TECH

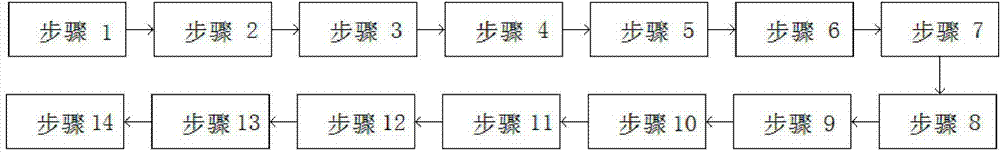

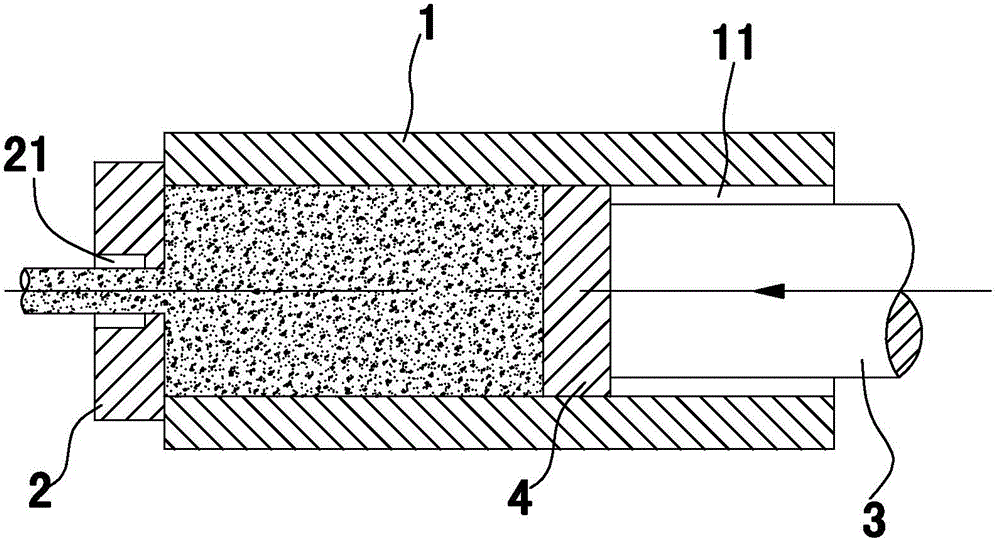

Manufacturing technique of pure nickel tube

The invention relates to the technical field of tubular material manufacture and particularly relates to a manufacturing technique of a pure nickel tube. The manufacturing technique of the pure nickel tube comprises the following production steps: (1) baking a nickel plate; (2) performing vacuum refining; (3) performing electroslag remelting; (4) forging; (5) performing ultrasonic flaw detection; (6) processing a round bar; (7) performing dye penetrant inspection; (8) perforating to tube blank; (9) cropping tube blank and coping; (10) performing cold rolling, deoiling and annealing; (11) performing surface treatment; (12) performing finish rolling to obtain the product; (13) annealing; (14) shaping. By adopting the technical solution, the low finished product rate of the traditional manufacture process is solved, the finished product rate is increased, the production cost is reduced, the shaped product is easy to process, the intensity and the elongation property are greatly increased, the impurities are reduced, the degree of purity is increased and the service life of the processing device is prolonged.

Owner:上海宏慧镍合金材料科技股份有限公司

Low-lead extruded brass bar and production method thereof

The invention provides a low-lead extruded brass bar and a production method thereof. The production method comprises the steps of carrying out fusion casting on raw materials, and then extruding to obtain a solid brass ingot, wherein the raw materials include 45-50% of electrolytic copper raw materials, 19-29% of low-lead environment-friendly foundry returns, 0.8-1.0% of bismuth, 25-30% of zinc ingots, 0.01-0.02% of magnesium and 0.01-0.02% of tin; extruding the brass ingot to form the brass bar. By using the formula and method provided by the invention, the low-lead environment-friendly extruded brass bar with excellent polishing and electroplating, machining and impact molding performances can be prepared.

Owner:龙岩市鸿航金属科技有限公司

Method and system for optimizing analogue integrated circuit

ActiveCN105303008ASolve the problem of low yieldSpecial data processing applicationsEngineeringMetapopulation

The embodiment of the invention discloses a method and system for optimizing an analogue integrated circuit. According to the method, a circuit-stage analogue program is adopted for simulating a new-generation population, the circuit performance indexes of all individuals in the new-generation population are obtained, and meanwhile an SPICE simulator is utilized for carrying out Monte Carlo analytical estimating on the new-generation population to obtain a yield estimated value through an SPICE model and Gaussian process regression. The circuit performance indexes and the yield participate in an evolution algorithm as constraint conditions at the same time in the population evolution process, and therefore the problem that in the prior art, the yield is low in the final decision making process is solved.

Owner:中科芯云微电子科技有限公司

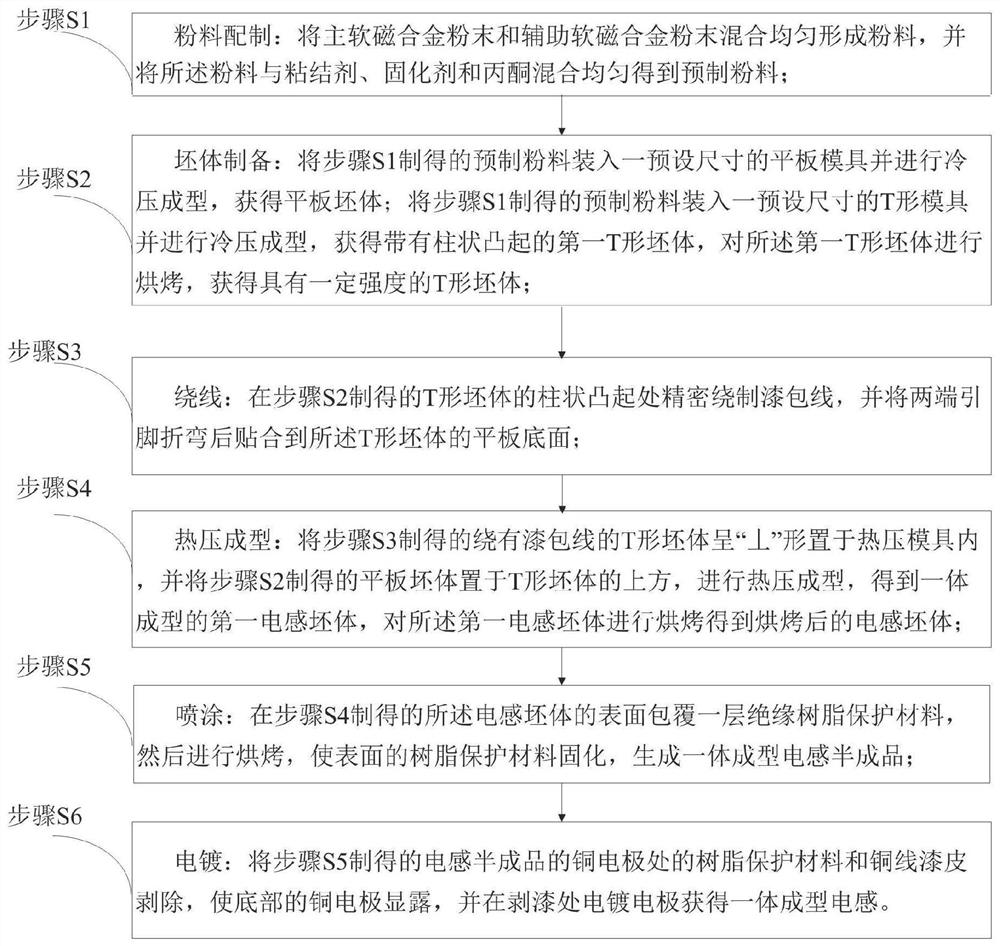

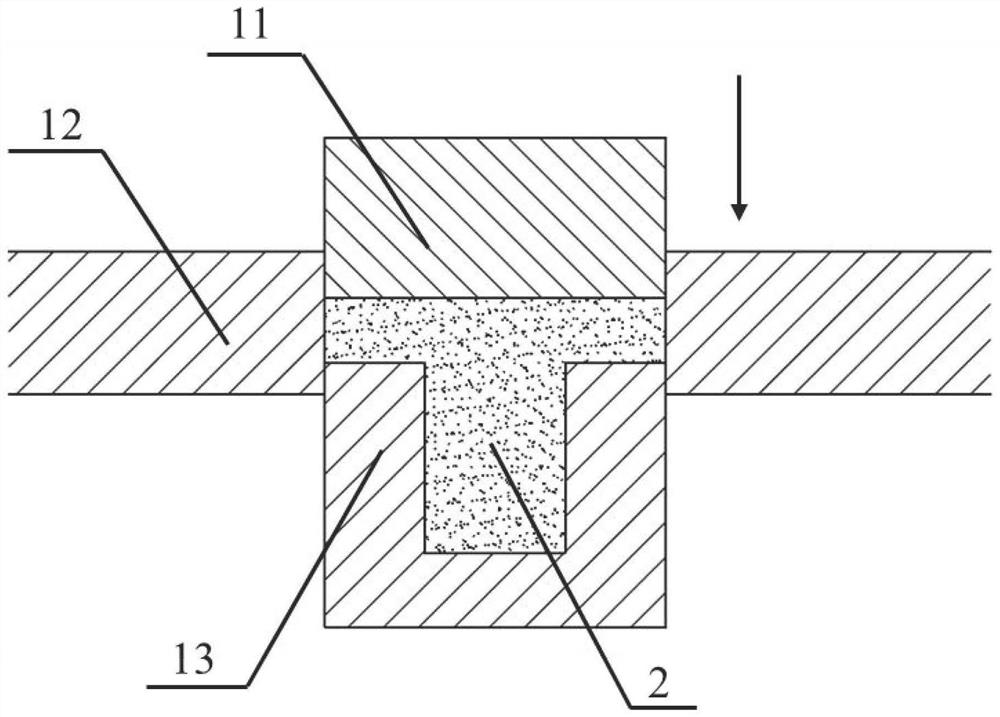

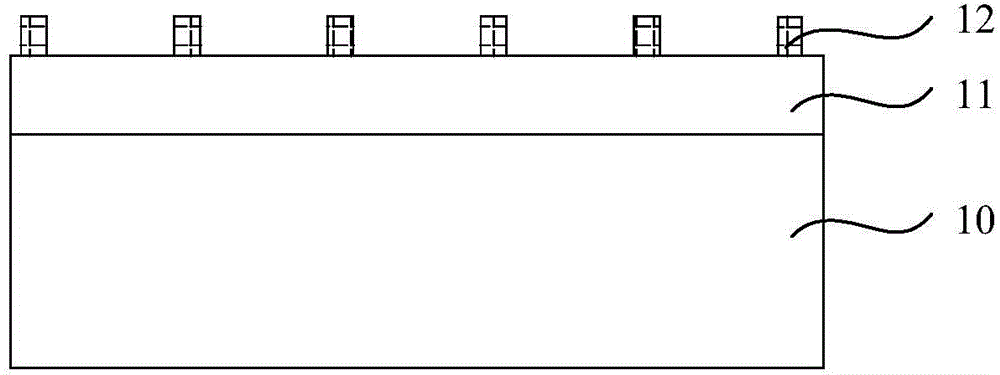

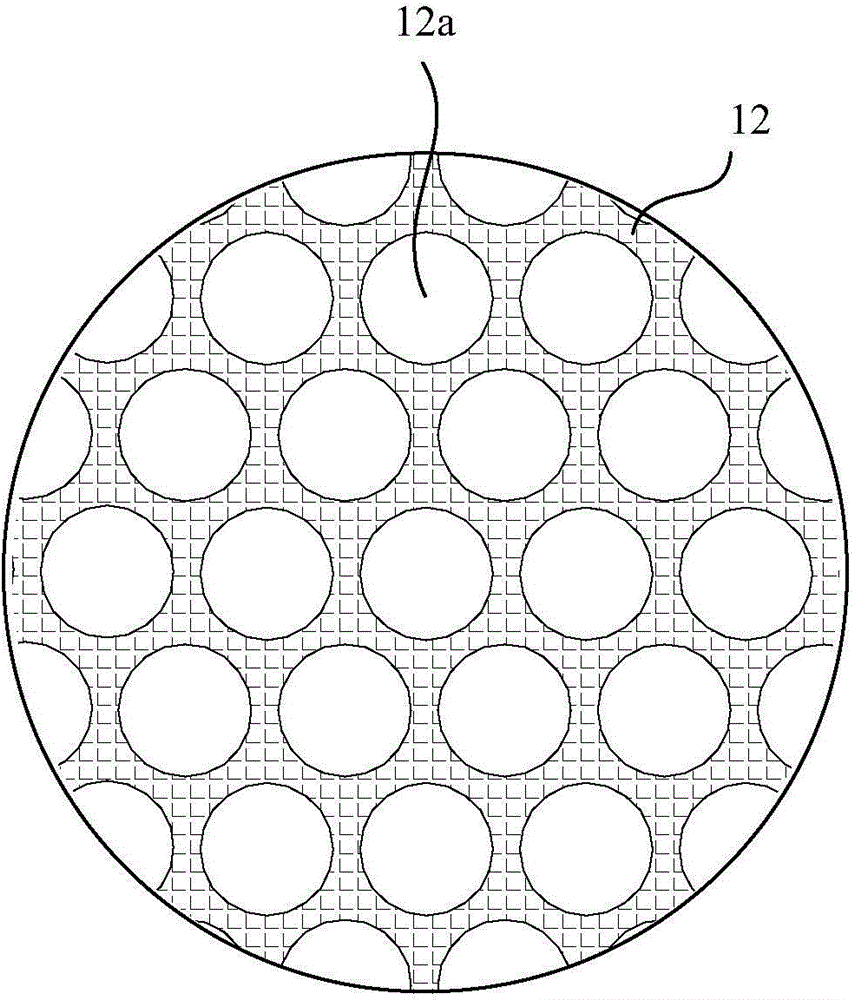

Manufacturing method of integrally-formed inductor

ActiveCN112397295ASolve the problem of low yieldImprove yieldIncreasing energy efficiencyInductances/transformers/magnets manufactureInductorFirming agent

The invention relates to the field of inductor manufacturing, and especially relates to a manufacturing method of an integrally-formed inductor. The method mainly comprises the following steps: S1, uniformly mixing main soft magnetic alloy powder and auxiliary soft magnetic alloy powder, and then mixing with a binder, a curing agent and acetone; S2, pressing a flat plate blank and a T-shaped blankwith preset sizes; S3, winding an enameled wire; S4, carrying out hot press molding and baking on the flat plate blank and the T-shaped blank wound with the enameled wire; S5, spraying and coating aninsulating resin protective material, and then baking; and S6, stripping the resin and the patent leather at the copper electrode, and electroplating the electrode to generate the integrally formed inductor. The technical scheme has the beneficial effects that by controlling the weight and the size of the prefabricated flat plate blank, the yield of a hot pressing link can be improved, and the cost and material waste in inductor manufacturing are reduced; and in addition, ultrasonic vibration is applied to the cold and hot pressing process, so that particles can be fully filled, inductance density is improved, and magnetic conductivity is remarkably improved.

Owner:NINGBO ZHONGKE BIPULASI NEW MATERIAL TECH CO LTD

Substrate and epitaxial wafer for flip LED chips and making methods thereof

ActiveCN104835890AEliminate dislocation defectsAvoid reflectionsSemiconductor devicesQuantum efficiencyGallium nitride

The invention provides a substrate and an epitaxial wafer for flip LED chips and making methods thereof. The substrate comprises a gallium nitride substrate material and a dielectric layer with a graphical structure, and the dielectric layer is embedded into the gallium nitride substrate material. The substrate making method comprises the following steps: forming a lattice matching layer on a sapphire substrate; forming a dielectric layer with a graphical structure on the lattice matching layer, wherein the dielectric layer exposes part of the lattice matching layer; growing a gallium nitride substrate material on the lattice matching layer and the dielectric layer until the lattice matching layer and the dielectric layer are completely separated due to the stress of the gallium nitride substrate material; and removing at least part of the lattice matching layer. Both the gallium nitride substrate material and the dielectric layer embedded in the gallium nitride substrate material adopted by the substrate for flip LED chips provided by the invention have double functions of internal quantum efficiency increasing and external quantum efficiency increasing.

Owner:HANGZHOU SILAN AZURE

Device and method suitable for improving yield of welding leading tape of double-stander cold rolling mill

The invention relates to a device and a method suitable for improving yield of a welding leading tape of a double-stander cold rolling mill. The method comprises the steps of rotating ground rollers to uncoil a qualified coil; conveying the end part of a steel coil to a welding position after uncoiling the qualified coil; coiling a leading tape coil upwards to a leading tape uncoiler, conveying the leading tape coil to a transverse cutting shear after centering the leading tape coil by using centering vertical rollers and straightening the leading tape coil by using a straightening machine, and shearing off an unqualified leading tape head; conveying the leading tape head to the welding position; welding the leading tape head with the end part of the steel coil by using a welding machine; reversely rotating the ground rollers to carry out recoiling; bundling a recoiled big coil, and conveying the recoiled big coil to a double-stander rolling device through an double-stander; uncoiling the steel coil by using a steel coil uncoiler, wherein an uncoiled steel belt penetrates the space between mill rolls of a double-stander reversable mill, and two upper mill rolls of the double-stander reversable mill are both lifted; and coiling two ends of the steel belt by using a steel belt coiling machine, and starting rolling after the mill rolls of the double-stander reversable mill fall. According to the device and the method, the cold rolling efficiency of an iron and steel enterprise can be increased, a narrow leading tape can be used, and the production cost is relatively low.

Owner:JIGANG INT ENG & TECH CO LTD

Producing technique for steel pipe cool sizing

InactiveCN101085452ASolve the problem of low yieldSimple processMetal rolling arrangementsThermal expansionEngineering

The steel tube cold radius fixing comprises the procedures of selecting material with the outer radius of the material bigger than the upper limit of the standard, composed of the design, adjustment and radius calibration of the rolling hole, inspection, cutting and final product delivery. It completely solves the difficulty of low yield rate of oil sleeve tube. It is simple, high in productivity, adjusted by corresponding roller, relying on the hydraulic pushing force to form the rolling hole, to get to the shrink of radius, calibrating circle, and rectifying the tube with quick operation. It is energy economical. It requires small investment and land occupation, free from heating furnace and cold bed. The yield rate is high, precise in adjustment dimension, free from influence of thermal expansion.

Owner:TIANJIN PIPE GROUP CORP

Preparation method of silver metal oxide electrical contact material

The invention discloses a preparation method of a silver metal oxide electrical contact material and belongs to the technical field of electrical contact materials for low-voltage apparatuses. The preparation method comprises the following steps: carrying out oxygen positive pressure oxidizing reaction on silver metal alloy (AgMe) powder with nano and micron particle sizes to produce silver metal oxide (AgMeO) powder, and then adopting a near-net forming technology to produce a finial silver metal oxide electrical contact material. The preparation method has the advantages of short production period, simpleness in process, no raw material waste, and no needs for powder mixing and processes of extrusion, draw forming and the like; further, the technology is easy in establishing a full-automatic production line and is suitable for the requirements for industry 4.0; and in addition, the obtained silver metal oxide electrical contact material is uniform in tissue, high in density and good in wear and arc erosion resistances.

Owner:KUNMING UNIV OF SCI & TECH

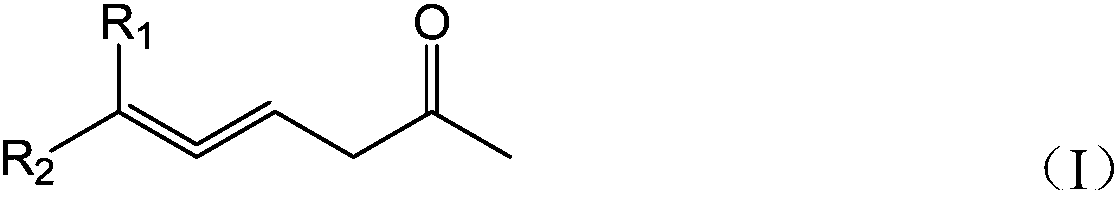

Method for preparing unsaturated ketone

ActiveCN109503342ASolve the impact of subsequent hydrogenation qualitySolve the problem of low yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholSynthesis methods

The invention discloses a method for preparing unsaturated ketone. According to the method, an unsaturated alcohol and 2-alkoxy propylene are adopted as raw materials, an acid resin in a fixed bed aremodified, a Saucy-Marbet reaction is carried out, and unsaturated ketone is synthesized with high selectivity and high yields. According to the method, the modified acid resin is adopted as a catalyst, the problem that a common acid resin is poor in catalysis effect is solved; in addition, a fixed bed reactor is adopted to catalyze reactions, separation of the catalyst from reaction products before and after reactions can be achieved, equipment corrosion and adverse influence of a great amount of acids upon later industrial aftertreatment can be avoided, and the method is an economic and efficient synthesis method.

Owner:SHANDONG NHU VITAMIN CO LTD +1

Aluminum alloy composite skin material flat ingot and manufacturing method thereof

The invention discloses an aluminum alloy composite skin material flat ingot and a manufacturing method thereof, and belongs to the field of alloy ingot manufacturing. The problem that the yield of cast ingots is low due to the defects of air holes, slag inclusion and coarse grains of the aluminum alloy composite material skin flat cast ingots manufactured by the existing method is solved. The materials of the aluminum alloy composite skin material flat ingot consist of Si, Mg, Na, B, impurities and the balance of Al; and the impurities are Fe, Cu, Mn, Ni, Zn and Ti. The method comprises the following steps of preparing materials; obtaining an alloy melt after smelting; and refining the modified alloy melt and casting. By controlling the change of the ingot specification, the scientific proportion of the raw material components, the improvement of the modification process and the improvement of the casting process, the defects of pores, slag inclusion, coarse grains and the like of theingot are reduced, then the yield of the alloy ingot is improved, the yield reaches more than 91%, and the problem of low ingot yield prepared through the existing method is solved. The manufacturingmethod disclosed by the invention is suitable for manufacturing the aluminum alloy composite skin material flat ingot.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Shaping process for light alloy proximate matter

The invention mainly discloses a shaping process for light alloy proximate matter. According to the technical scheme, the shaping process includes the steps that (1) burdening is carried out; (2) raw materials are mixed; (3) the raw materials are transported; (4) continuous extrusion molding is carried out; (5) a straightening machine is used for conducting straightening treatment on the left side face and the right side face of the proximate matter, and conducting smoothness correction on the upper side face and the lower side face of the proximate matter; (6) cooling sizing is carried out; (7) an ion fan is used for conducting destaticization on the proximate matter; (8) a machined product is cut to be at the height meeting the requirement; (9) surface treatment is carried out, wherein a spraying device is used for coloring, and a film plating machine is used for film plating; and (10) a finished product is inspected. According to the shaping process, the problems that existing proximate matter is simple in structure, the cross section performance is limited, and the yield is low are solved, the automation performance is high, the stability is good, the strength of the proximate matter is improved, the production number of the proximate matter is increased, the material of the product is uniform, the quality is high, and the yield is high.

Owner:浙江日佳铜业科技有限公司

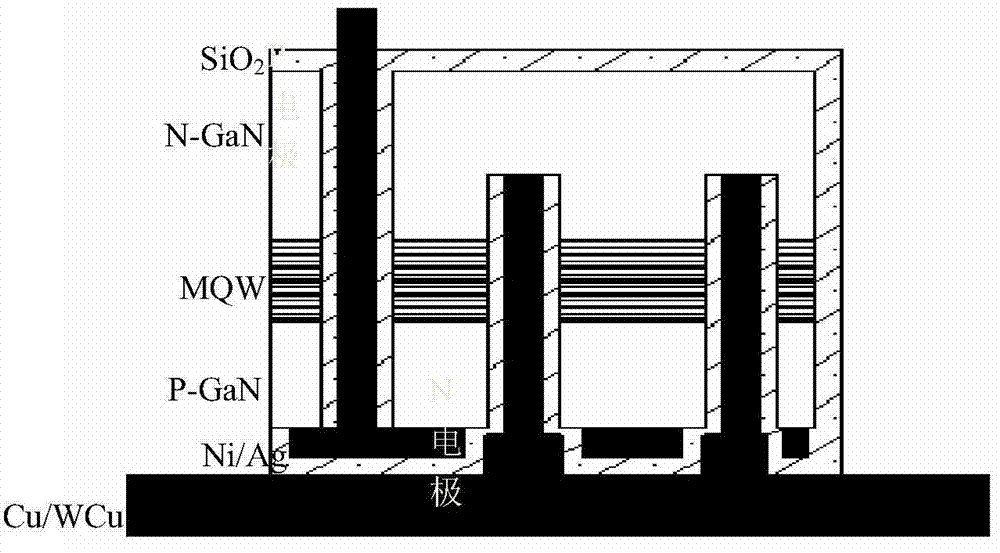

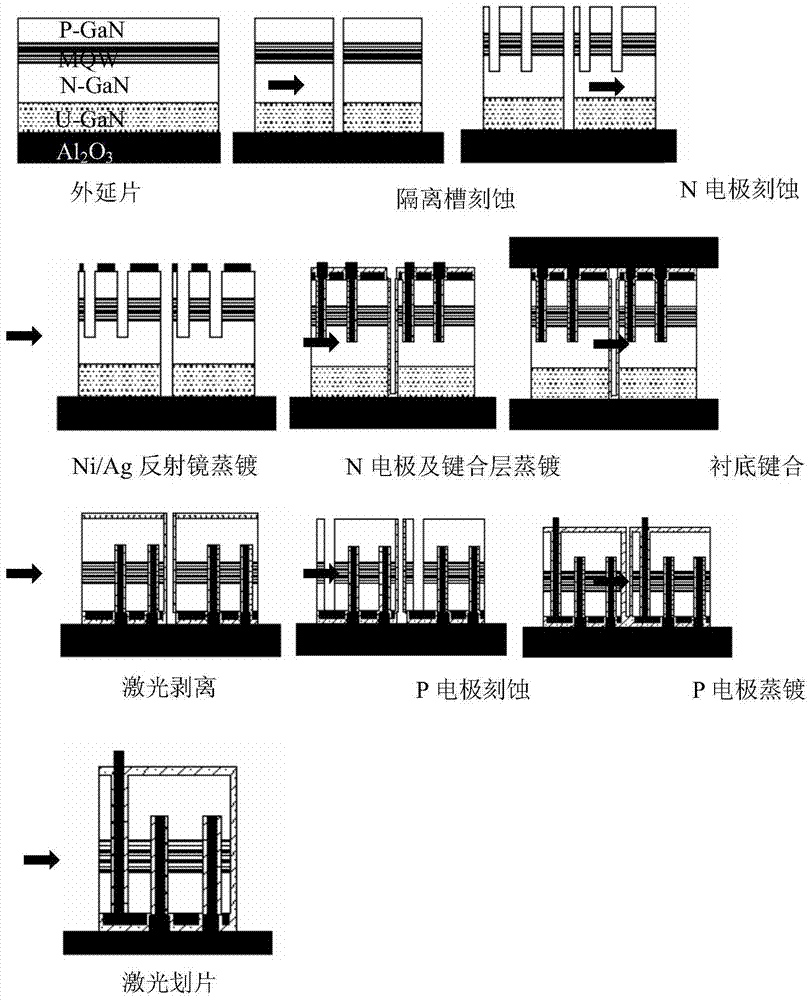

Vertical-structure LED chip manufacturing method

InactiveCN104851945ASolve the problem of uneven etching depthAvoid high voltage and leakageSemiconductor devicesTungstenCopper alloy

In order to raise the processing yield of vertical-structure LED chips, the present invention provides a novel method for manufacturing the-vertical structure LED chips, which can notably reduce electric leakage of the chips and raise the chip production yield. A P electrode of the chip is formed on the surface of the chip, an N electrode of the chip is bonded with a silicon / copper / tungsten copper alloy substrate, and the P electrode is welded with a support during packaging of the chip. Combination of the ICP etching technique and the hot acid corrosion technology is adopted to form chip isolation channels. A laser spot is adjusted during laser stripping so as to be matched in size with the chip after the isolating channels are formed. An epitaxial wafer is bonded on the silicon / copper / tungsten copper alloy substrate through a high-temperature bonding technique, the ultrasonic technology is then used, and by using internal stress produced in the bonding process and the ultrasonic vibration technology, separation of gallium nitride and the substrate is further raised.

Owner:西安利科光电科技有限公司

Wavelength selective radiator coating applied to thermophotovoltaic power generation device and preparation method

The invention discloses a wavelength selective radiator coating applied to a thermophotovoltaic power generation device and a preparation method of the wavelength selective radiator coating. Firstly, erbium oxide powder and aluminum oxide powder are uniformly mixed, then mixed powder is obtained, grinding balls, a ball-milling liquid, the mixed powder and a dispersing agent are added to a ball-milling tank for ball milling, and uniformly dispersed slurry is obtained; the grinding balls in the slurry are filtered out, the ball-milling liquid in the slurry is dried, and dry powder is obtained; the dry powder is put in a high-temperature atmosphere furnace and heated, so that the erbium oxide powder and the aluminum oxide powder in the dry powder are sintered to form composite powder, the grinding balls, a binding agent and a diluent are added to the composite powder, the mixture is subjected to ball milling, the uniformly mixed slurry after ball-milling is dried, and then a die can be used for coating a substrate material; after the coated substrate material is dried and sintered at a high temperature, the wavelength selective radiator coating is formed and obtained. The mechanical performance and the surface strength of the coating are improved, the thermal stability of a coating radiator is improved, and the defect that the coating cannot be bonded to a ceramic substrate easily is overcome.

Owner:NANJING UNIV OF SCI & TECH +1

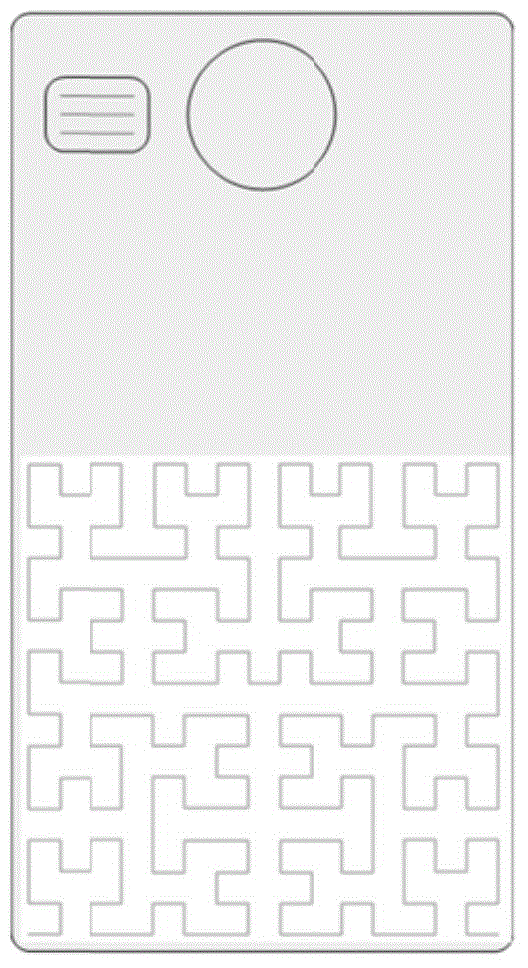

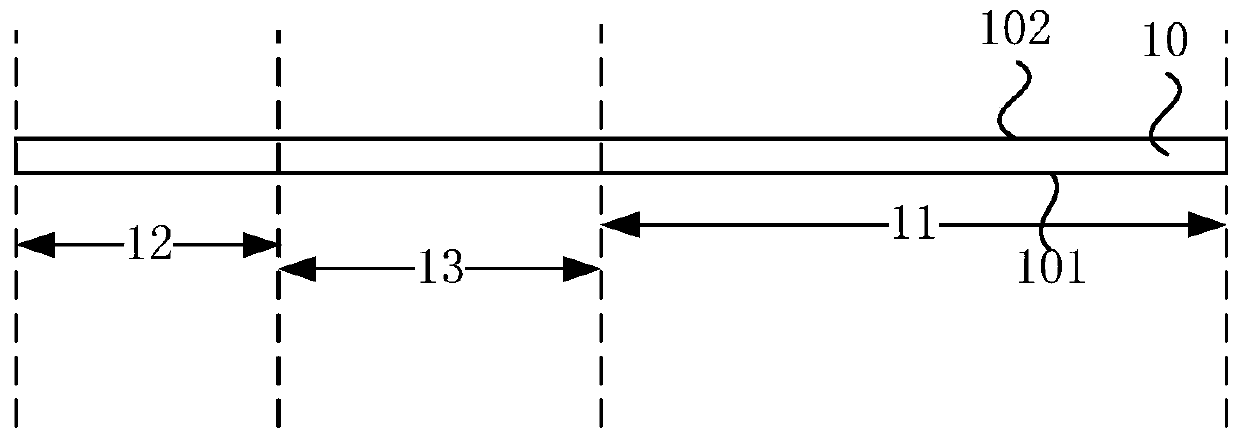

LDS antenna, LDS antenna manufacturing method and LDS antenna manufacturing apparatus

InactiveCN105322274ASolve the problem of low yieldPossess the production technology to meet the requirementsAntenna supports/mountingsAntennas earthing switches associationMulti bandMiniaturization

The present invention discloses an LDS antenna, an LDS antenna manufacturing method and an LDS antenna manufacturing apparatus. The method includes the step of structuring a fractal antenna on a terminal housing through the laser direct structuring LDS technique. According to the invention, the fractal antenna is manufactured through the LDS technique, and the combination of the two solves the problem of a low yield rate of the fractal antenna in the correlative technique so that the fractal antenna mass manufacturing is possible. The LDS antenna can realize miniaturization and support multi-band frequency, and is characterized in that the manufacturing technique of the antenna meets requirements.

Owner:ZTE CORP

Bending structure manufacturing method, bending structure and display panel

The embodiment of the invention discloses a bending structure manufacturing method, a bending structure and a display panel. The bending structure manufacturing method comprises the steps of providinga flexible substrate, wherein the flexible substrate comprises a first non-bending area, a second non-bending area, and a bendable area for connecting the first non-bending area and the second non-bending area; forming a metal routing layer on the second surface of the flexible substrate, wherein at least part of metal routing layer is located in the bendable area; forming a first auxiliary bending layer on the metal routing layer, wherein at least part of the first auxiliary bending layer covers the metal routing layer located in the bendable area, and the first auxiliary bending layer is made of a contractile memory material; bending the flexible substrate in the bendable area, so that the second non-bending area is located on one side, far away from the second surface, of the first surface of the first non-bending area; and keeping the flexible substrate to be at a bending state, and controlling the first auxiliary bending layer to contract, so that the area of the first auxiliarybending layer is reduced, and the manufacturing yield of the bending structure is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

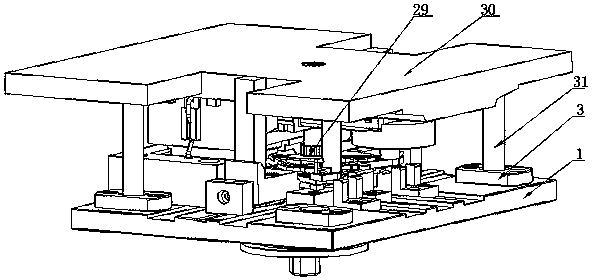

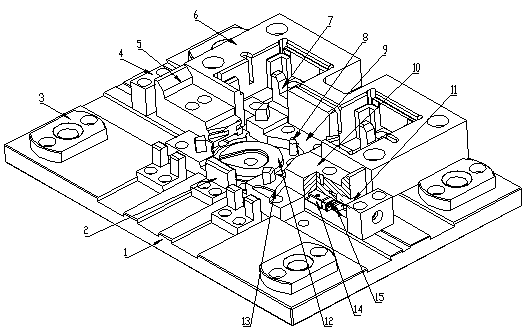

Pointer five-in-one assembly mold for assembly of gas meter

InactiveCN109719653AEasy to assembleImprove assembly efficiencyAssembly machinesWork holdersEngineeringCam

The invention relates to a pointer five-in-one assembly mold for assembly of a gas meter. At present, a method of automatic assembling a machine core is not occurred in the market, the pointer, the transmission parts of a pointer disc, a front control rod, a rear control rod, a cam shaft, a guide rod frame, a valve cover and the like are irregularly in shape in the assembly process of the machinecore of the gas meter after investigation is carried out, the assembling is troublesome, at present, an auxiliary assembling mold of the transmission parts of the pointer, the pointer disc and the like of the gas meter is not existed. The invention relates to a pointer five-in-one assembly mold for assembly of the gas meter. A plurality of positioning grooves, threaded holes, round holes and pinholes are formed in a bottom plate of the mold of a lower mold, and fixing blocks are fixed in limiting grooves in the bottom plate of the mold of the lower mold through screws; and the mold solves the problems that due to the fact that the transmission parts of the pointer, the pointer disc, the front control rod, the rear control rod, the cam shaft, the guide rod frame, the valve cover and the like are irregular in shapes, the difficult assembling is caused.

Owner:江西宝群电子科技有限公司

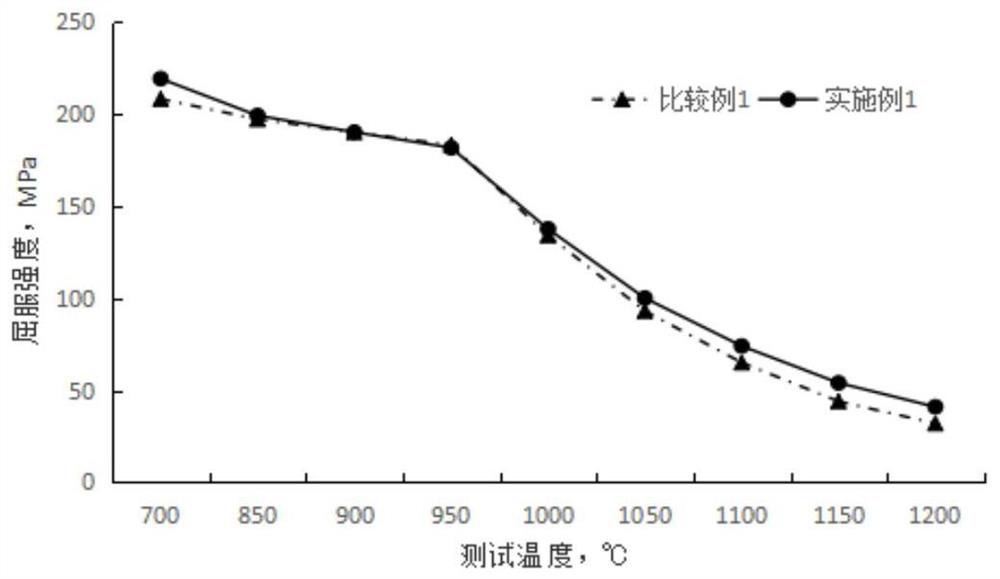

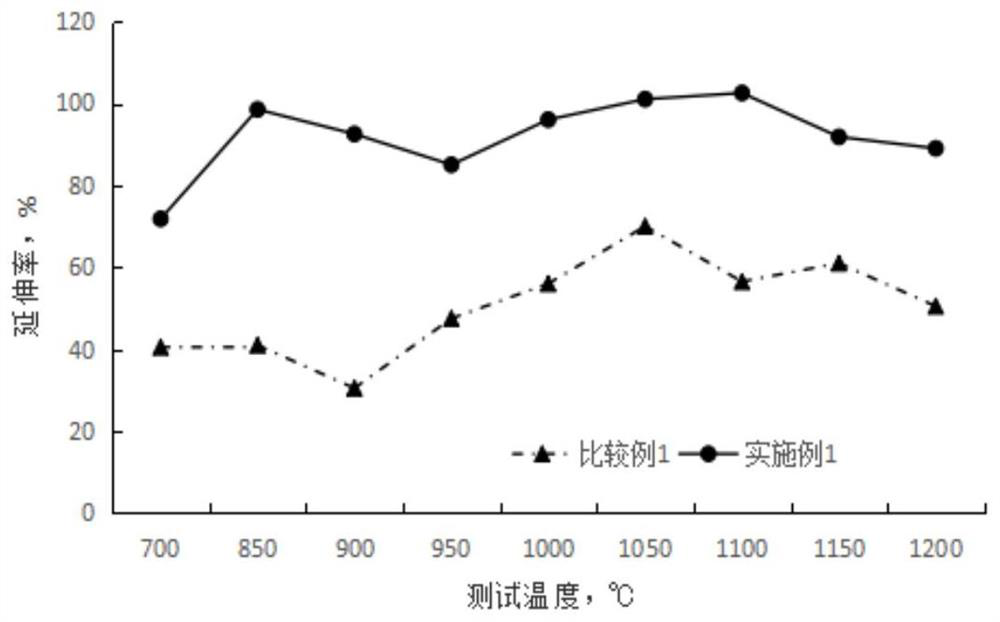

High-plasticity easy-to-process cobalt-based deformation high-temperature alloy and preparation method thereof

PendingCN111961923AImprove hot and cold processing performanceImprove plasticityIncreasing energy efficiencySuperalloyElectro-slag remelting

The invention discloses a high-plasticity easy-to-process cobalt-based deformation high-temperature alloy and a preparation method thereof, and belongs to the technical field of deformation high-temperature alloy materials. Components of the alloy comprise, by weight percent, 0.08%-0.13% of C, not larger than 0.4% of Si, 1.0%-2.0% of Mn, 9.0%-11.0% of Ni, 19.0%-21.0% of Cr, 14.0%-16.0% of W, 0.3%-1.0% of Al, not larger than 3.0% of Fe and the balance Co and inevitable impurities and other elements. The preparation method of the alloy comprises the steps that after being blended, materials aremolten in a vacuum induction furnace; cast electrode bars are used for electroslag remelting; after a steel ingot is subjected to homogenizing annealing, air cooling is carried out; the forging temperature ranges from 910 DEG C to 1230 DEG C, heat treatment is carried out at the temperature ranging from 1180 DEG C to 1240 DEG C, and air cooling is carried out after heat preservation; and cold drawing deformation ranges from 48% to 60%. The alloy and the preparation method have the advantages that through adding of elements Al and Y, on the premise that strength is not reduced, the cold and heat processing performance of the alloy is improved, and plasticity, the technological process and the yield of the alloy are improved

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Injection mold for embedding of automobile sealing strip insert

PendingCN107160630AImprove securityNo personal injuryDomestic articlesComposite materialSafety coefficient

The invention discloses an injection mold for embedding of an automobile sealing strip insert. The injection mold comprises an upper mold plate (1), a lower mold plate (2), an ejection plate (3), a base plate (4) and a sealing strip (7). The ejection plate (3) is located on the base plate (4). The lower mold plate (2) is located between the upper mold plate (1) and the ejection plate (3). An upper mold plate (5) is arranged below the upper mold plate (1). A lower mold plate (6) is arranged above the lower mold plate (2). The lower mold plate (2) is provided with an oblique slide block (8) used for forming the rubber coating part of the front end face of the sealing strip (7), a slide block (22) used for forming the rubber coating part of the inner side face of the sealing strip (7) and a mobile slide block (36) positioning the outer side face of the front end of the sealing strip (7). The upper mold plate (1) is provided with an oblique guide column (33) slidably matched with the oblique slide block (8). By adoption of the injection mold for embedding of the automobile sealing strip insert, personal injury cannot be caused, so that the safety coefficient is high.

Owner:NINGHAI HESHI PLASTIC CO LTD

Preparation dedicated binder of microbeam analysis standard sample and blending method thereof

ActiveCN103131335AEliminate surrounding holesNot easy to fall offNon-macromolecular adhesive additivesPreparing sample for investigationEmbedding rateEthyl-2-cyanoacrylate

The invention provides a preparation dedicated binder of a microbeam analysis standard sample. The preparation dedicated binder of a microbeam analysis standard sample comprises components with the following volume fraction: alpha-ethyl cyanoacrylate, the volume fraction of the alpha-ethyl cyanoacrylate is more than 50%, tackifier, the volume fraction of the tackifier is 1-5%; stabilizer, the volume fraction of the stabilizer is 1-5%, flexibilizer, the volume fraction of the flexibilizer is 1-5%, and polymerization inhibitor, the volume fraction of the polymerization inhibitor is 1-5%. Simultaneously, the invention further provides a blending method of the preparation dedicated binder of a microbeam analysis standard sample, a throwing sequence is as following: the alpha- ethyl cyanoacrylate, the polymerization inhibitor, the stabilizer, the flexibilizer, and the tackifier, blended using time is controlled within one tenth of a binder solidification time. The preparation dedicated binder of the microbeam analysis standard sample possesses appropriate liquidity, solidification speed, and good electroconductibility in the meantime, solves an embedding problem of the microbeam analysis standard sample in the preparation process, so that an embedding rate of finished products is effectively improved.

Owner:BAOSHAN IRON & STEEL CO LTD

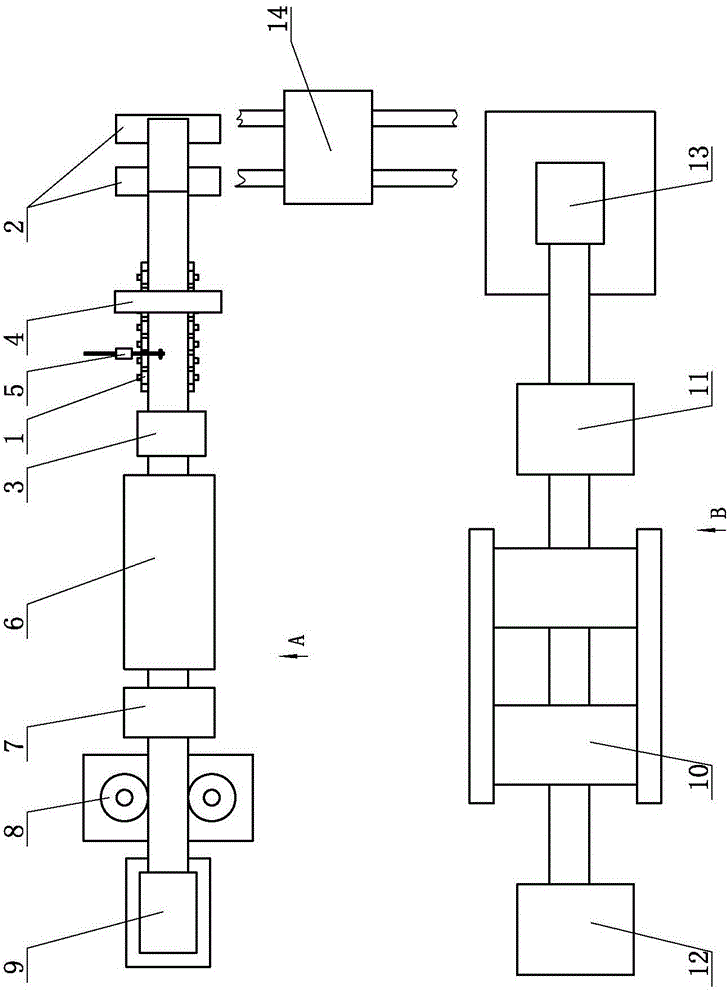

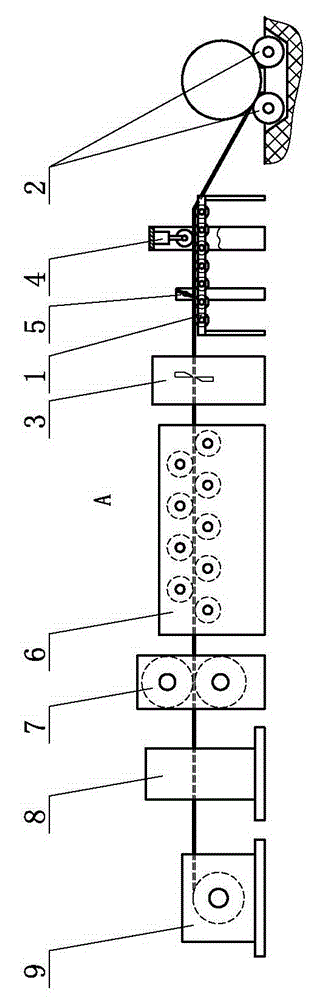

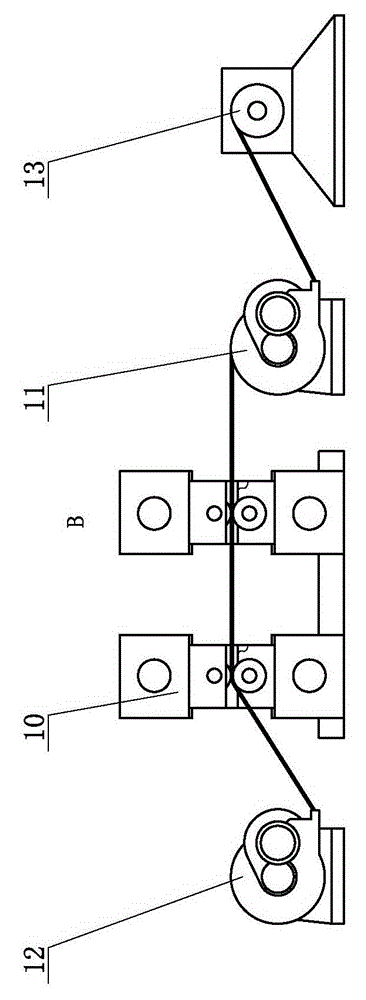

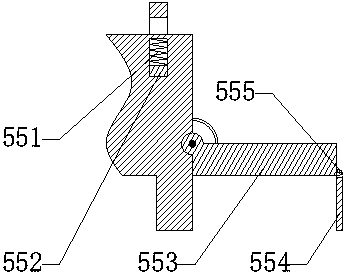

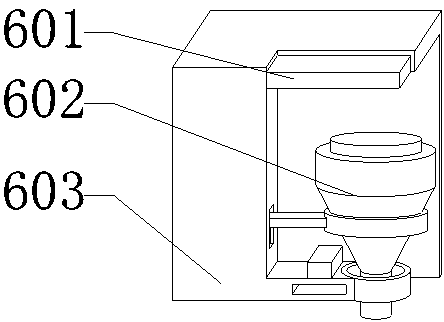

Sweet potato vermicelli processing system

InactiveCN108887662ARealize automatic processingReasonable designFood scienceEngineeringAseptic processing

The invention relates to the field of sweet potato vermicelli processing, in particular to a sweet potato vermicelli processing system. The processing system comprises an additive preparation device,a sterile treatment device, a clean treatment device, smashing and packaging equipment, a grinding device, adjusting and gelatinizing equipment, a mixing device, battening and drying equipment and sterile treatment and storage device. According to the sweet potato vermicelli processing system, the processes are reasonably set, responsibility coordination and distribution are achieved, sweet potatovermicelli is processed, and the sweet potato vermicelli is made.

Owner:长沙光宙科技有限公司

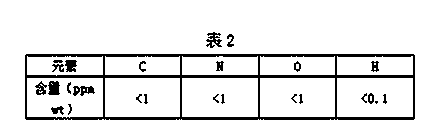

High-strength and high-elasticity copper-titanium alloy and manufacturing method thereof

ActiveCN113278844AHigh strengthHigh elongationFurnace typesMetal rolling arrangementsTitanium metalNon-metallic inclusions

The invention discloses a high-strength high-elasticity copper-titanium alloy and a manufacturing method thereof. The copper-titanium alloy comprises the following components in percentage by mass: 2.3%-3.8% of Ti, less than or equal to 0.3% of Ni, less than or equal to 0.3% of Fe, less than or equal to 0.1% of Y, less than or equal to 0.1% of La and the balance of Cu and inevitable impurity elements, wherein the sum of Cu and Ti is greater than or equal to 99.3%. The manufacturing method comprises the steps of vacuum smelting, plate blank casting, hot rolling for a strip, cold rolling, solid solution treatment, aging, finish rolling and the like. The high-strength high-elasticity copper-titanium alloy and the manufacturing method thereof have the following beneficial effects: through the vacuum smelting, a vacuum high-temperature smelting environment is provided, so that active titanium element in the alloy is strictly controlled, the contents of hydrogen, oxygen, nitrogen, inclusions and the like in the prepared copper-titanium alloy are low, the purity of the copper-titanium alloy is high, and gas, impurities and non-metallic inclusions are removed in a refining process for copper and titanium metal, so that the quality of the prepared copper-titanium alloy is improved; and the problems of long production process for the copper-titanium alloy strip and low yield are solved, and shorter process for producing the copper-titanium alloy strip and higher efficiency are achieved, so that large-scale production is facilitated.

Owner:国工恒昌新材料沧州有限公司

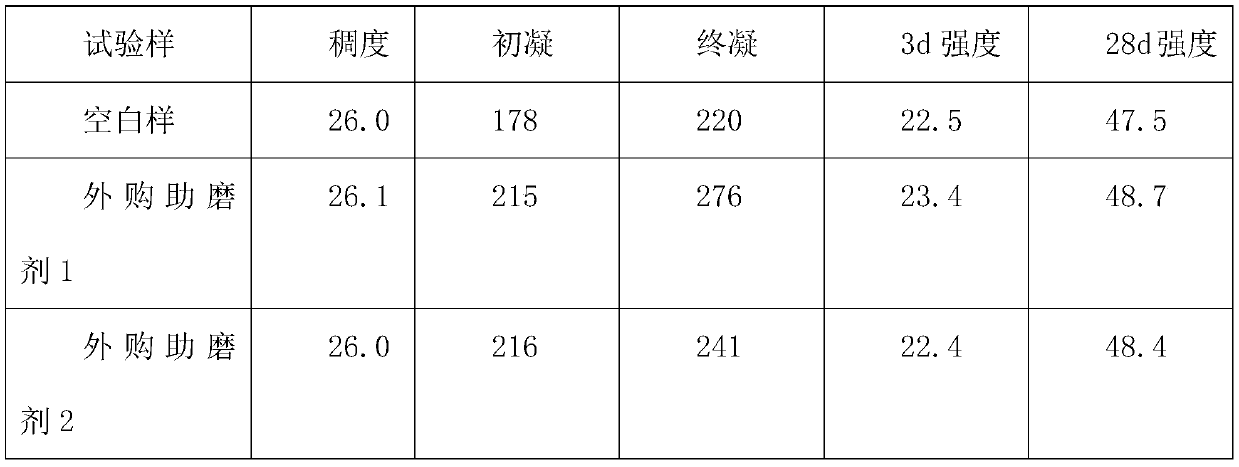

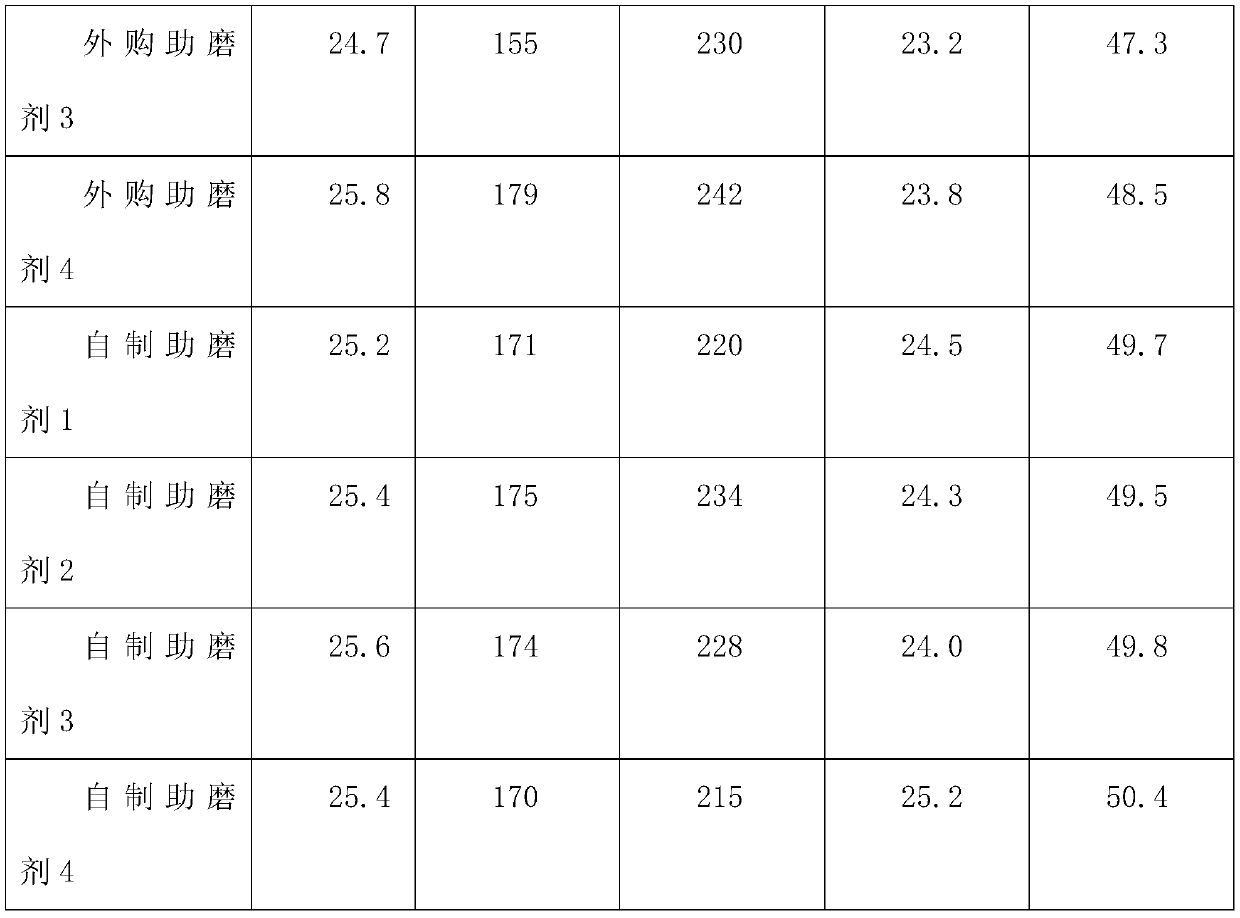

Self-made grinding aid

PendingCN111253106ASolve the problem of low yieldImprove the grinding processTriethanolamineGlycerol

The invention discloses a self-made grinding aid. The raw material components are as follows: 10-15% of ethylene glycol, 20-35% of triethanolamine, 20-30% of glycerol residues, 1-5% of sodium acetate,1-2% of industrial salt, 1-3% of lignin and the balance water (totaling 100%). The preparation method comprises the following steps: step 1, during preparation, controlling the temperature of water to be 40-45 DEG C, adding the glycerol residues and the triethanolamine, and then uniformly mixing the glycerol residues and the triethanolamine; and step 2, adding glycerol residues and triethanolamine into water, and uniformly mixing, and sequentially adding ethylene glycol, sodium acetate, lignin and industrial salt. The self-made grinding aid can solve the problem of low yield of a mill in thecement production process, the clinker ratio is high, static electricity in the mill is eliminated, a cement grinding process is improved, the grinding efficiency is improved, and the production costof the cement grinding aid is reduced; the cement grinding table yield can be effectively increased by 5-7 tons / hour, the clinker ratio is reduced by 2.0%, the power consumption is reduced by 1.5-2 kilowatts / ton, and meanwhile, various chemical and physical inspection results of cement meet the national standard.

Owner:XINJIANG TIANSHAN CEMENT CO LTD

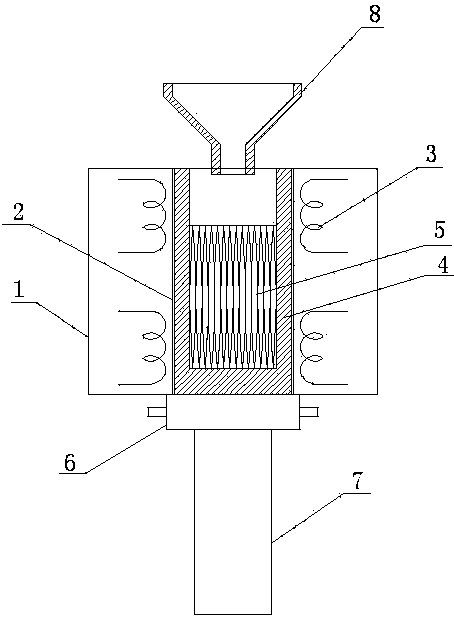

Device and method for preparing high-purity copper and copper alloy ingot

The invention provides a device and a method for preparing high-purity copper and a copper alloy ingot. The device comprises a heating furnace, wherein a casting mould channel is arranged in the heating furnace, a plurality of heating elements are uniformly arranged in the furnace wall of the heating furnace, a cooling support is arranged at the bottom of the heating furnace, a casting mould is arranged in the casting mould channel, the bottom of the casting mould is connected with the cooling support, and the bottom of cooling support is connected with a traction device. The method mainly comprises the following steps of: (1) melting electrolytic copper or a copper alloy of which the weight purity is more than 99.9999% in a crucible under the condition of being vacuum or filling inert gases, (2) using the heating elements in the furnace wall of the heating furnace to heat the side wall of the casting mould uniformly, and (3) injecting molten metal in the crucible into the casting mould of which the side wall is heated through a tundish, and then carrying out traction on the cooling support downwards through the traction device, so that the casting mould forms a temperature gradient that the temperature is increased from the bottom up.

Owner:JINCHUAN GROUP LIMITED

Method for fractionating and crystallizing palm oil

InactiveCN104293485ARaise the crystallization temperature pointImprove crystallization efficiencyFatty-oils/fats separationOil and greaseFiltration

The invention discloses a method for fractionating and crystallizing palm oil. Through the adoption of the method, not only is the crystallizing efficiency of the palm oil with the lower content of stearic acids improved, but also the yield of liquid palm oil is improved. The method comprises five steps of oil feeding, heating and crystal destruction, cooling and crystallization, crystal maintenance and filtration, wherein the step of the oil feeding comprises the steps of adding palm oil fat of which the melting point is 26-30 DEG C to palm oil fat to be fractionated, and mixing the two kinds of palm oil fat.

Owner:TIANJIN LONGWIT OILS & GRAINS IND CO LTD

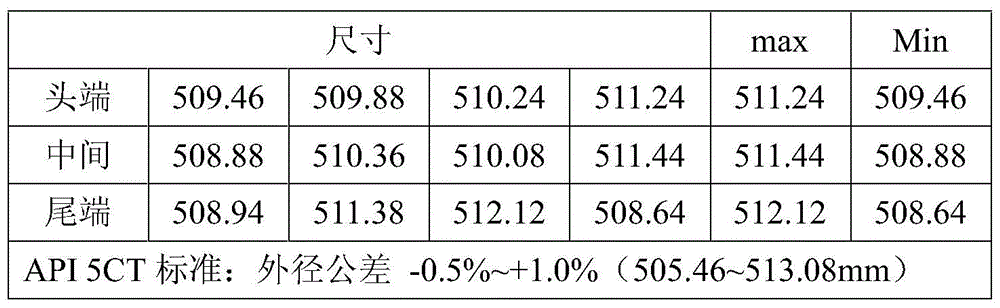

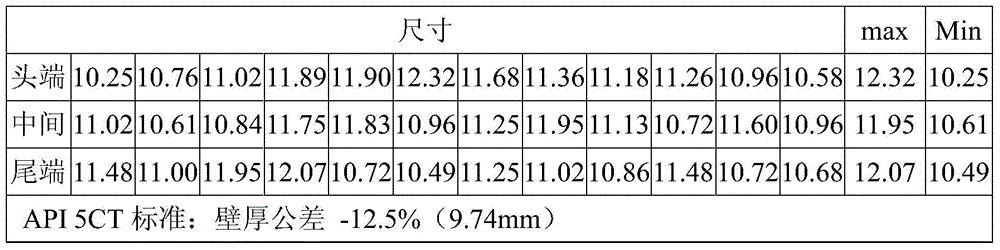

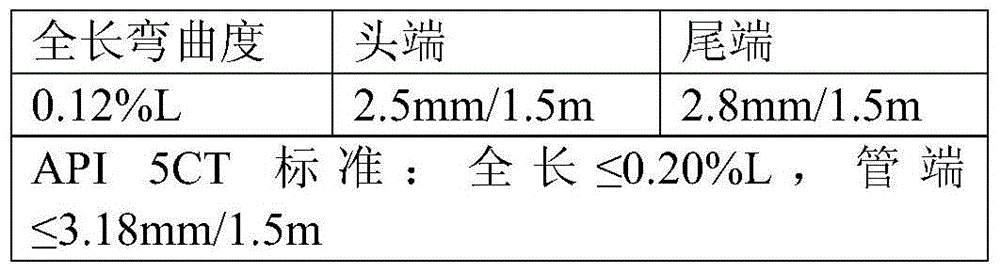

Production method for drawing type expanded extra-large-caliber J55 casing pipes

ActiveCN105710147ASolve the accuracy problemSolve quality problemsMechanical propertyMaterials science

The invention relates to the technical field of seamless steel pipe production and provides a production method for drawing type expanded extra-large-caliber J55 casing pipes. The method includes the steps that pipe blanks with the diameter being 356*15.5 mm are produced; each pipe end is heated and expanded to form a horn-shaped opening; primary heating expansion is conducted and comprises three passes of heating expansion; and secondary heating expansion is conducted and comprises three passes of heating expansion. By the adoption of the technical scheme, the problems that a drawing type pipe expanding unit is low in geometric dimension accuracy, poor in surface quality and low in yield are solved, the curvature, the outer diameter, the wall thickness size and the mechanical performance of the produced J55 casing pipes with the diameter being 508 mm can meet the API 5CT standard, the J55 casing pipes with the diameter being 508 mm can be produced through the drawing type pipe expanding unit in batches, and the expanding yield reaches 89%.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com