Manufacturing method of integrally-formed inductor

A manufacturing method and inductance technology, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of reducing product yield, weight and performance deviation, poor uniformity, etc., to reduce costs and material waste, product Excellent performance and improved magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

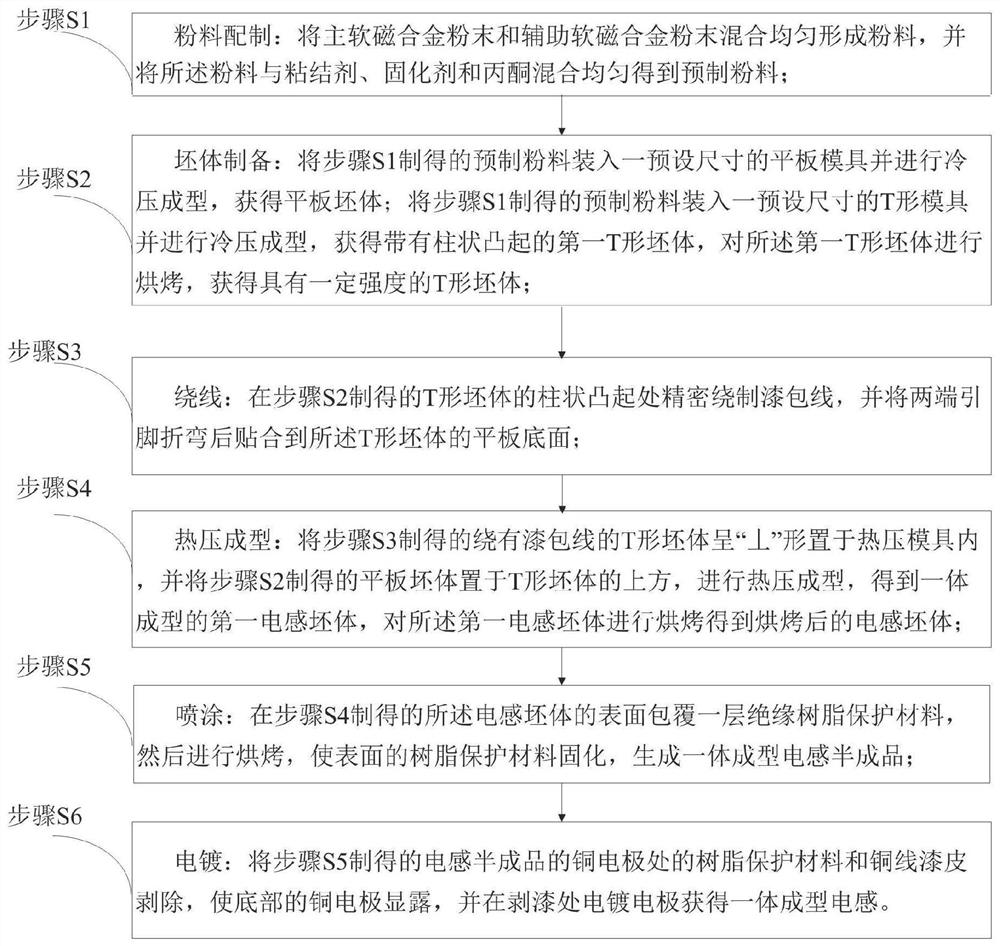

[0039] figure 1 The flow chart of the integrated molding inductor manufacturing process adopted by the specific embodiment of the present invention includes the following steps:

[0040] Step S1, powder preparation: uniformly mix the main soft magnetic alloy powder and auxiliary soft magnetic alloy powder to form a powder, and uniformly mix the powder with a binder, a curing agent and acetone to obtain a prefabricated powder;

[0041] Among them, the main soft magnetic alloy powder is selected from Fe-Si-B-C-Cr amorphous soft magnetic alloy powder, and its particle size is D50=10 μm, and the auxiliary soft magnetic alloy powder is selected from carbonyl iron powder, and its particle size is below 5 μm. The magnetic alloy powder and the auxiliary soft magnetic alloy powder are uniformly mixed according to the preset first mass ratio of 5:5 to form a powder, and the powder is mixed with the binder, curing agent and acetone according to the preset second mass ratio of 100:2: 0.5:1...

Embodiment 2

[0051] Select the same main soft magnetic alloy powder, auxiliary soft magnetic alloy powder and proportioning thereof as in Example 1, select the same binding agent and curing agent as in Example 1, the same powder, binding agent, curing agent and The ratio of acetone, but in this embodiment 2, no ultrasonic vibration is applied during the preparation of the green body and the hot pressing molding process. The rest of the methods, steps, and process parameters are the same as in the embodiment 1, and the integrated molded inductor is obtained. The corresponding performance parameters are shown in the table shown in 1.

Embodiment 3

[0053] Step S1, powder preparation: uniformly mix the main soft magnetic alloy powder and auxiliary soft magnetic alloy powder to form a powder, and uniformly mix the powder with a binder, a curing agent and acetone to obtain a prefabricated powder;

[0054] Among them, the main soft magnetic alloy powder is selected from Fe-Si-B-Nb-Cu nanocrystalline soft magnetic alloy powder, and its particle size is D50=10 μm, and the auxiliary soft magnetic alloy powder is selected from carbonyl iron powder, and its particle size is below 5 μm. The main soft magnetic alloy powder and the auxiliary soft magnetic alloy powder are uniformly mixed according to the preset first mass ratio of 5:5 to form a powder, and the powder is mixed with the binder, curing agent and acetone according to the preset second mass ratio of 100: 2:0.5:12 Mix evenly to obtain prefabricated powder 7, and use epoxy resin as the binder.

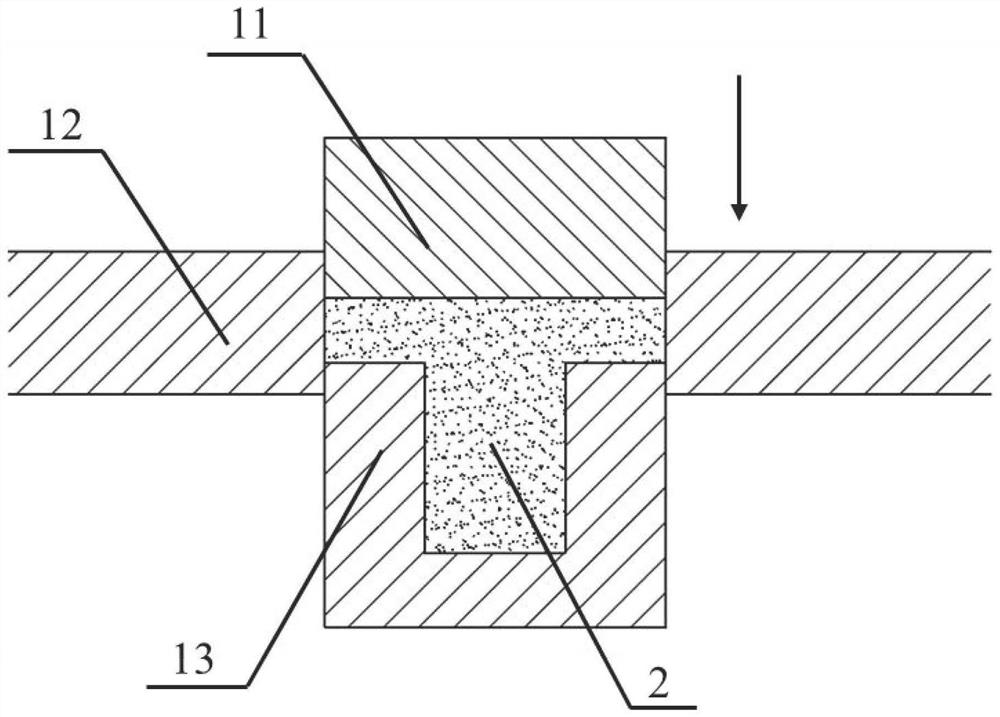

[0055] Step S2, green body preparation: put the prefabricated powder 7 prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com