Fluorosilicone resin and preparation method thereof

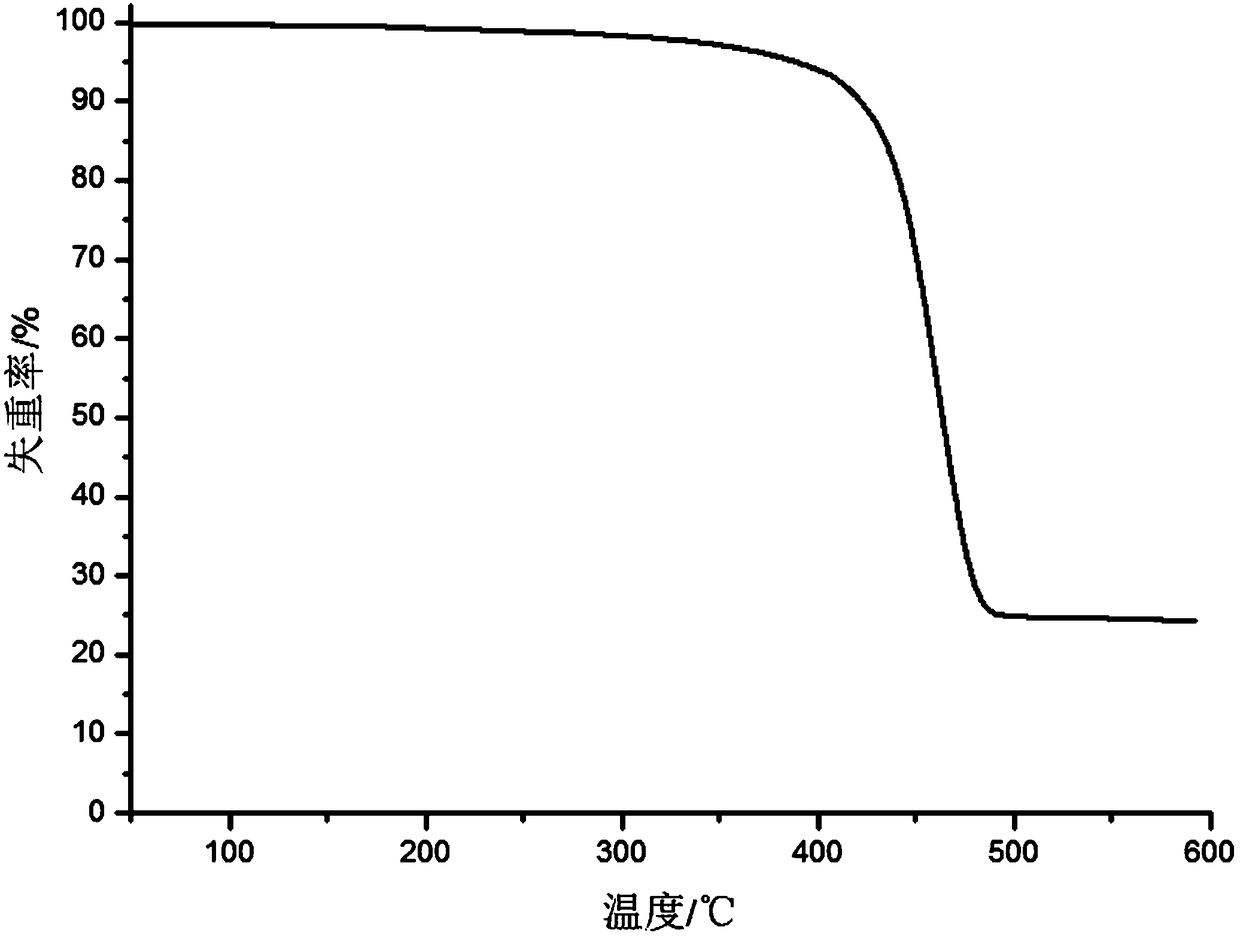

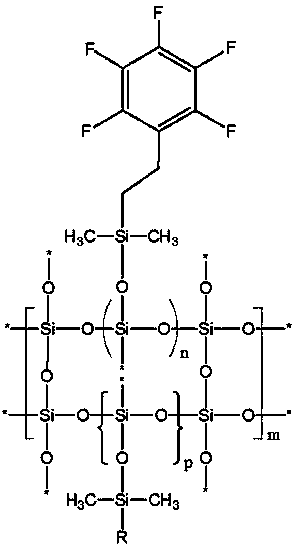

A technology of fluorosilicone resin and pentafluorophenylethyl dimethyl chlorosilane, which is applied in the field of high-temperature resistant fluorosilicone resin and its preparation, can solve problems such as insufficient heat resistance, achieve superior heat resistance, and avoid excessive exchange Combined, the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Synthesis of pentafluorophenethyldimethylchlorosilane

[0042]500mL three-neck flask, equipped with thermometer, reflux condenser and constant pressure dropping funnel, heated by oil bath. Add 80 g of toluene and 65 g of pentafluorostyrene in sequence, stir and dissolve, and add 0.26 g of chloroplatinic acid catalyst under nitrogen protection. Turn on the heating, and after the temperature rises to 80° C., 51 g of methyldichlorohydrosilane is added dropwise, and the dropping time is controlled at about 1 hour. After the dropwise addition, the insulation reaction was continued for 2 hours. After the reaction, the solvent and unreacted methyldichlorosilane were distilled off, and the 132°C fraction (3.75kPa) was collected by distillation under reduced pressure to obtain 95g of pentafluorophenethyldimethylchlorosilane. The purity of the product measured by gas chromatography was 96.6 %, yield 90.9%.

[0043] (2) Condensation to synthesize fluorosilicone resin

[00...

Embodiment 2

[0053] (1) The synthesis process of pentafluorophenethyldimethylchlorosilane is the same as in Example 1.

[0054] (2) Condensation to synthesize fluorosilicone resin

[0055] In a 250mL Erlenmeyer flask, 19.4g of pentafluorophenethyldimethylchlorosilane, 5.5g of trimethylmonochlorosilane and 63g of ethyl orthosilicate were uniformly mixed to obtain a mixed silane, which was set aside.

[0056] 500mL three-neck flask, equipped with thermometer, reflux condenser and constant pressure dropping funnel, heated by oil bath. First carefully and slowly pour 8g of water and 5g of concentrated sulfuric acid into 50g of tetrahydrofuran, heat the mixture to 70°C, then add the pre-prepared mixed silane dropwise, and the dropping time is controlled at about 42min. After the addition, the reaction was incubated for 6 hours.

[0057] The reaction was stopped, and the reaction solution was distilled under reduced pressure to remove the by-product ethanol and the solvent tetrahydrofuran. The...

Embodiment 3

[0062] (1) Synthesis of pentafluorophenethyldimethylchlorosilane

[0063] 500mL three-neck flask, equipped with thermometer, reflux condenser and constant pressure dropping funnel, heated by oil bath. Add 40 g of trifluoromethylbenzene and 32 g of pentafluorostyrene in sequence, stir and dissolve, and add 0.1 g of chloroplatinic acid catalyst under nitrogen protection. Turn on the heating, and after the temperature rises to 80°C, add 26g of methyldichlorohydrosilane dropwise, and the dropping time is controlled at about 1 hour. After the dropwise addition, the insulation reaction was continued for 1.5 hours. After the reaction, the solvent and unreacted methyldichlorosilane were distilled off, and the 132°C fraction (3.75kPa) was collected by distillation under reduced pressure to obtain 46g of pentafluorophenethyldimethylchlorosilane. The purity of the product measured by gas chromatography was 95.8 %, yield 84.6%.

[0064] (2) Polycondensation synthesis of pentafluorophen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com