Low-lead extruded brass bar and production method thereof

A brass rod and brass technology, which is applied in the field of copper alloys for plumbing bathroom parts and equipment, can solve the problems of difficult polishing, difficult processing, and good movement, achieve good physical properties and surface quality, and improve cutting Processing performance, the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

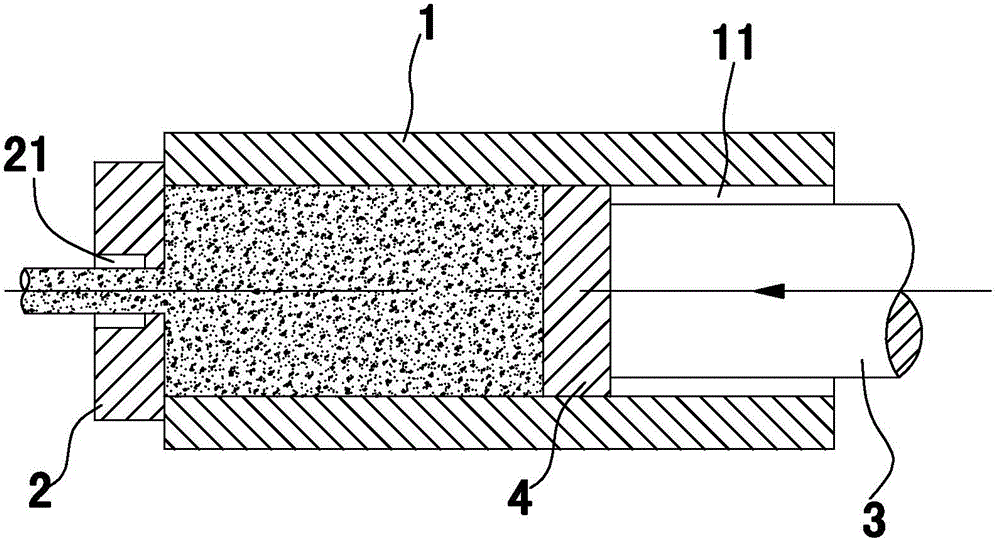

Image

Examples

Embodiment 1

[0028] The invention discloses a low-lead extruded brass rod, which comprises the following raw materials in percentage by weight: 45% of electrolytic copper raw material, 19% of low-lead environmental protection recycled material, 0.8% of bismuth, 25% of zinc ingot, 0.01% of magnesium, tin 0.01%. Each of the above-mentioned raw materials is a dry raw material.

[0029] The production method for producing low-lead extruded brass rods with the above-mentioned ratio of raw materials: including the steps of melting, casting and extruding solid brass ingots and extruding the brass ingots into copper rods:

[0030] The step of said melting and extruding solid brass ingot comprises:

[0031] 1) Put the electrolytic copper raw material accounting for 45% of the brass raw material into the power frequency copper melting furnace, start the industrial voltage high voltage 380V, and then add 0.1% environmental protection refining slag removal agent (the environmental protection cleaning...

Embodiment 2

[0051] Embodiment 2 of the present invention discloses a low-lead extruded brass rod, comprising the following raw material composition in weight percentage: 48% of electrolytic copper raw material, 25% of low-lead environmental protection recycle material, 0.9% of bismuth, 28% of zinc ingot, and 0.02% of magnesium. %, tin 0.02%. Each of the above-mentioned raw materials is a dry raw material.

[0052] A production method for producing low-lead extruded brass rods by using the above raw material ratio, including the steps of melting, casting and extruding solid brass ingots and extruding the brass ingots into copper rods:

[0053] The step of said melting and extruding solid brass ingot comprises:

[0054] 1) Put the electrolytic copper raw material accounting for 48% of the brass raw material into the power frequency copper melting furnace, start the industrial voltage high voltage 380V, and then add 0.1% environmental protection refining slag removal agent (the environmenta...

Embodiment 3

[0067] Embodiment 2 of the present invention discloses a low-lead extruded brass rod, comprising the following raw material composition in weight percentage: 50% of electrolytic copper raw material, 29% of low-lead environmental protection recycle material, 1.0% of bismuth, 30% of zinc ingot, 0.02% of magnesium %, tin 0.02%. Each of the above-mentioned raw materials is a dry raw material.

[0068] The production method for producing low-lead extruded brass rods with the above raw material ratio includes the steps of melting, casting and extruding solid brass ingots and extruding the brass ingots into copper rods:

[0069] The step of said melting and extruding solid brass ingot comprises:

[0070] 1) Put the electrolytic copper raw material accounting for 50% of the brass raw material into the power frequency copper melting furnace, start the industrial voltage with a high voltage of 380V, and then add 0.1% environmental protection refining slag removal agent (the environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com