Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Solve easy pulverization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

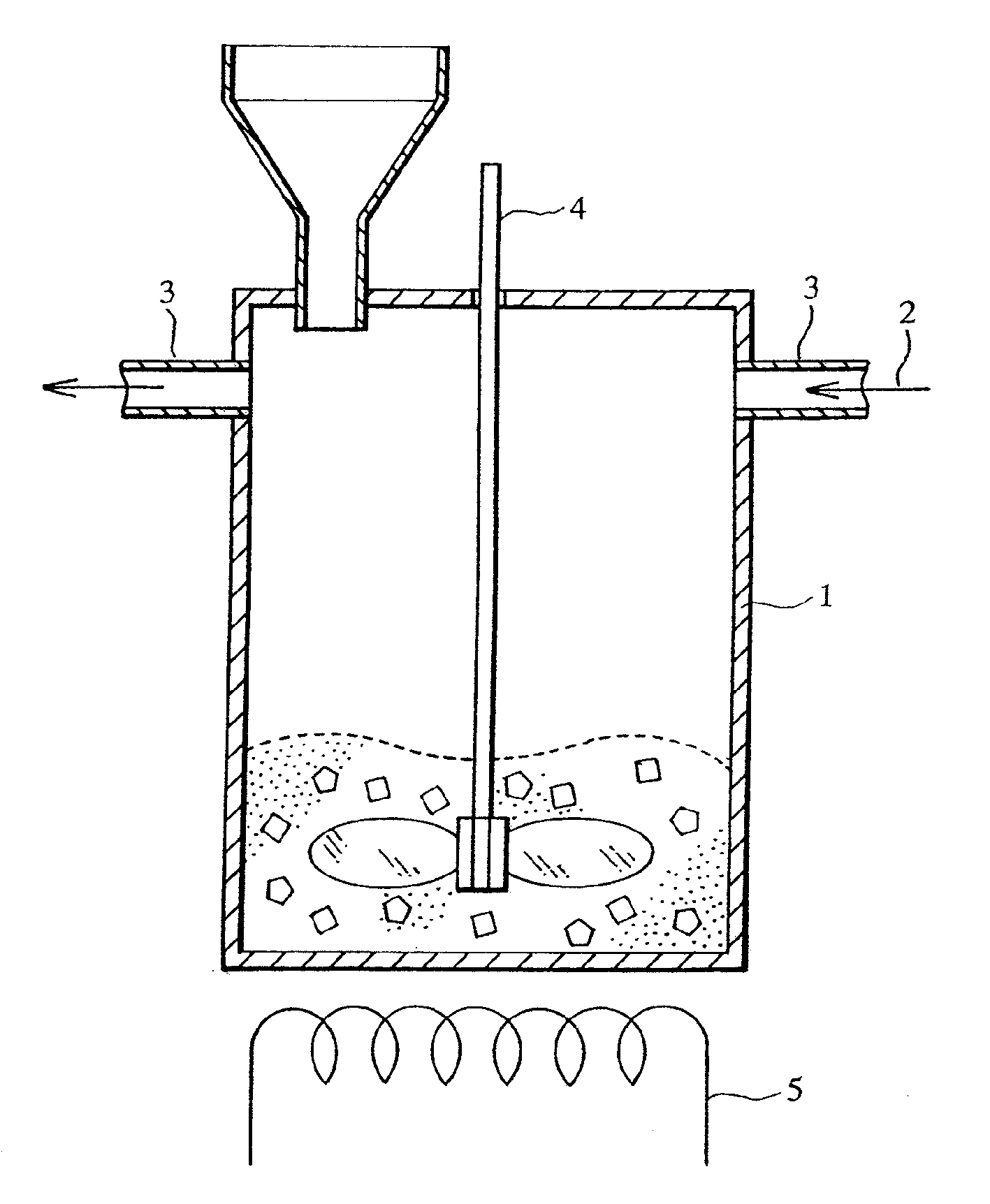

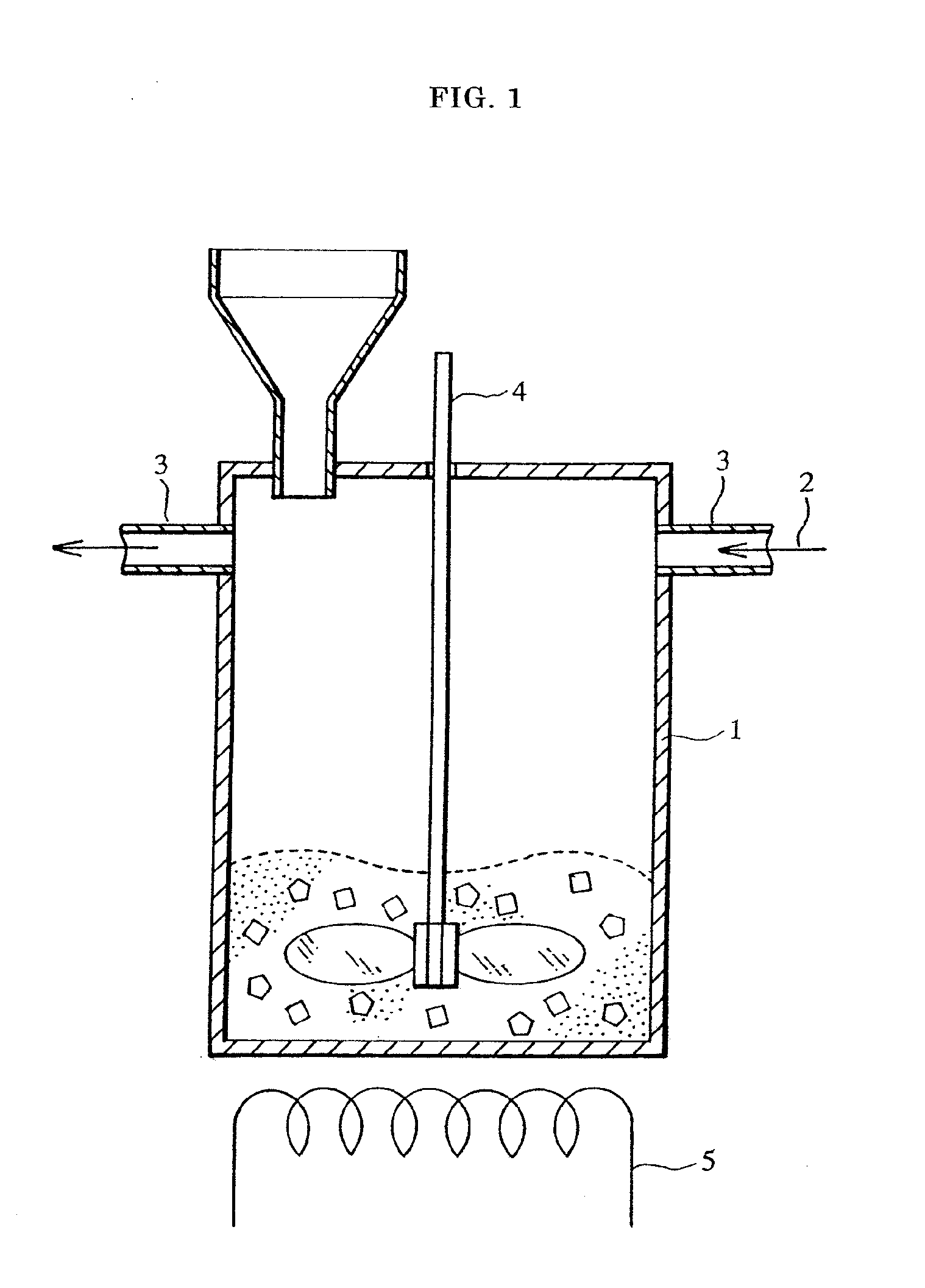

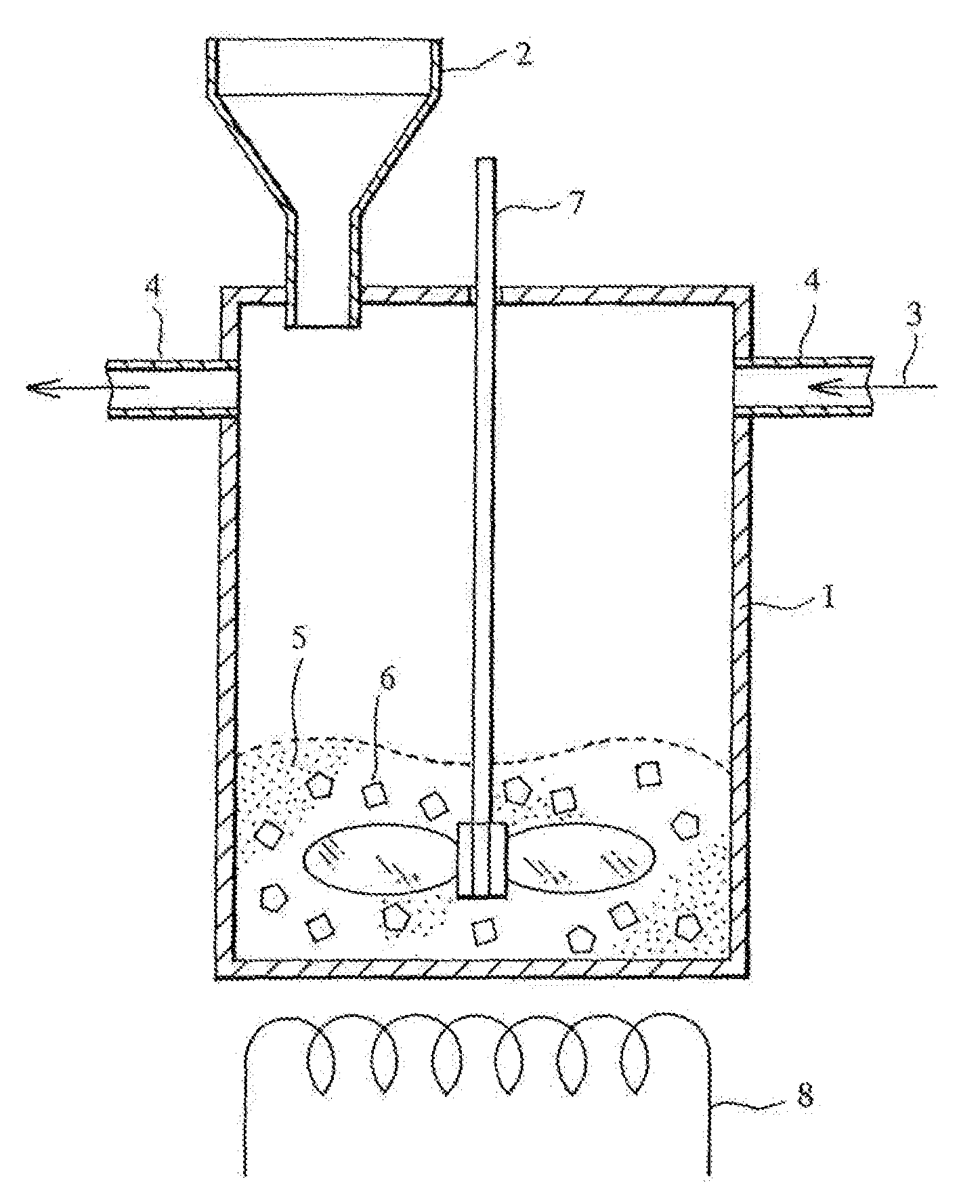

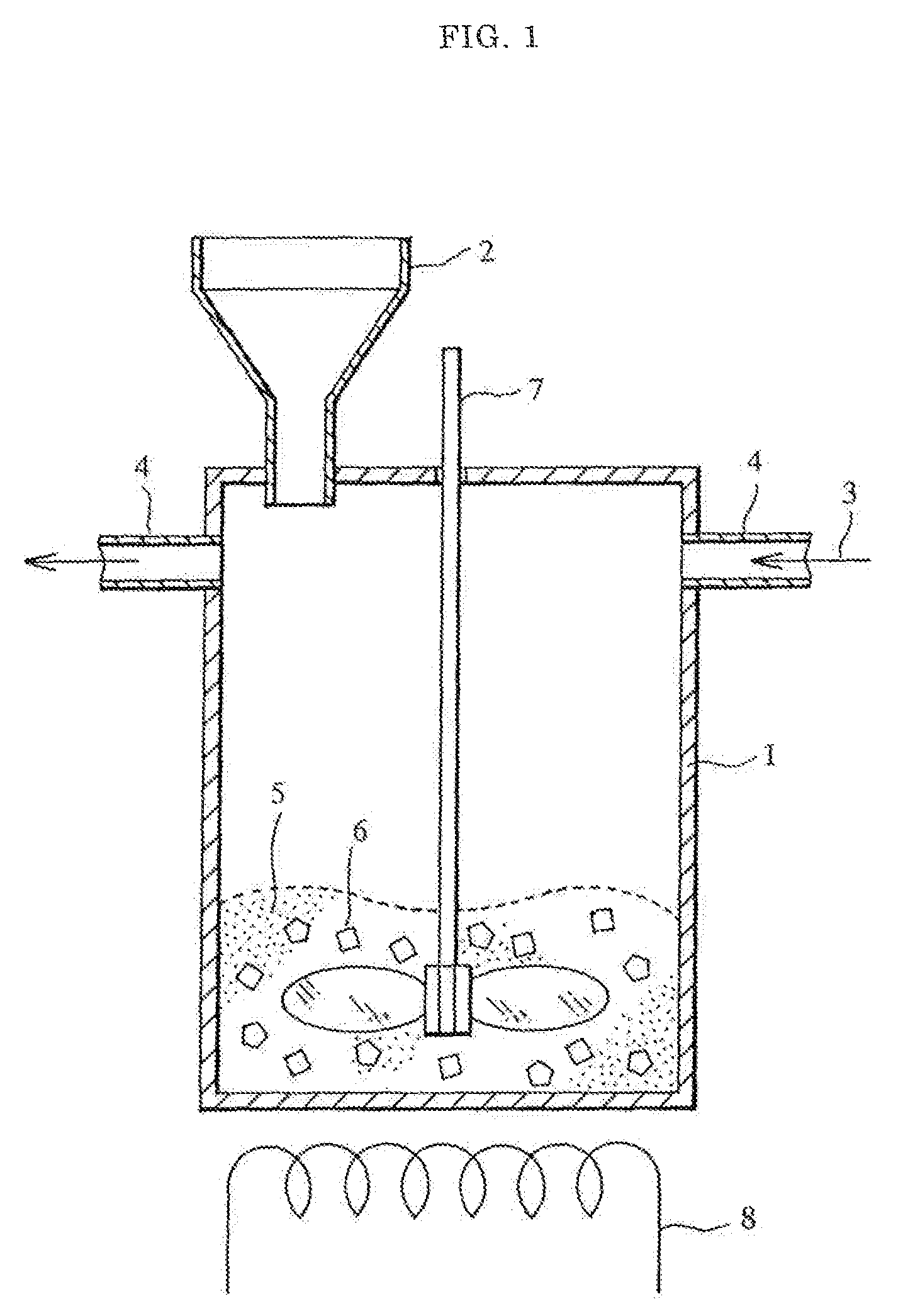

Catalyst and method for thermal decomposition of organic substance and method for producing such catalyst

InactiveUS20110144406A1Improve liquiditySubstance longLiquid hydrocarbon mixture productionCombustion using catalytic materialOrganic matterSilicon dioxide

The invention provides a catalyst for thermal decomposition of an organic substance having the form of spherical granule having a particle diameter of 0.1 to 1.2 mm, a pore volume of 0.1 to 0.3 mL / g, a tap density of 1.05 to 1.4 g / mL, and a wear rate of 2% by weight or less, the catalyst being obtained by mixing and granulating a pulverized product of an inorganic oxide exemplified by titanium oxide with at least one sol selected from a titania sol, a silica sol, an alumina sol, and a zirconia sol to make spherical granules, calcining the spherical granules at a temperature from 400 to 850° C., and sieving the calcined granules.

Owner:SAKAI CHEM IND CO LTD

Catalyst and method for thermal decomposition of organic substance and method for producing such catalyst

InactiveUS8956995B2Improve liquiditySubstance longLiquid hydrocarbon mixture productionCombustion using catalytic materialOrganic matterSilicon dioxide

The invention provides a catalyst for thermal decomposition of an organic substance having the form of spherical granule having a particle diameter of 0.1 to 1.2 mm, a pore volume of 0.1 to 0.3 mL / g, a tap density of 1.05 to 1.4 g / mL, and a wear rate of 2% by weight or less, the catalyst being obtained by mixing and granulating a pulverized product of an inorganic oxide exemplified by titanium oxide with at least one sol selected from a titania sol, a silica sol, an alumina sol, and a zirconia sol to make spherical granules, calcining the spherical granules at a temperature from 400 to 850° C., and sieving the calcined granules.

Owner:SAKAI CHEM IND CO LTD

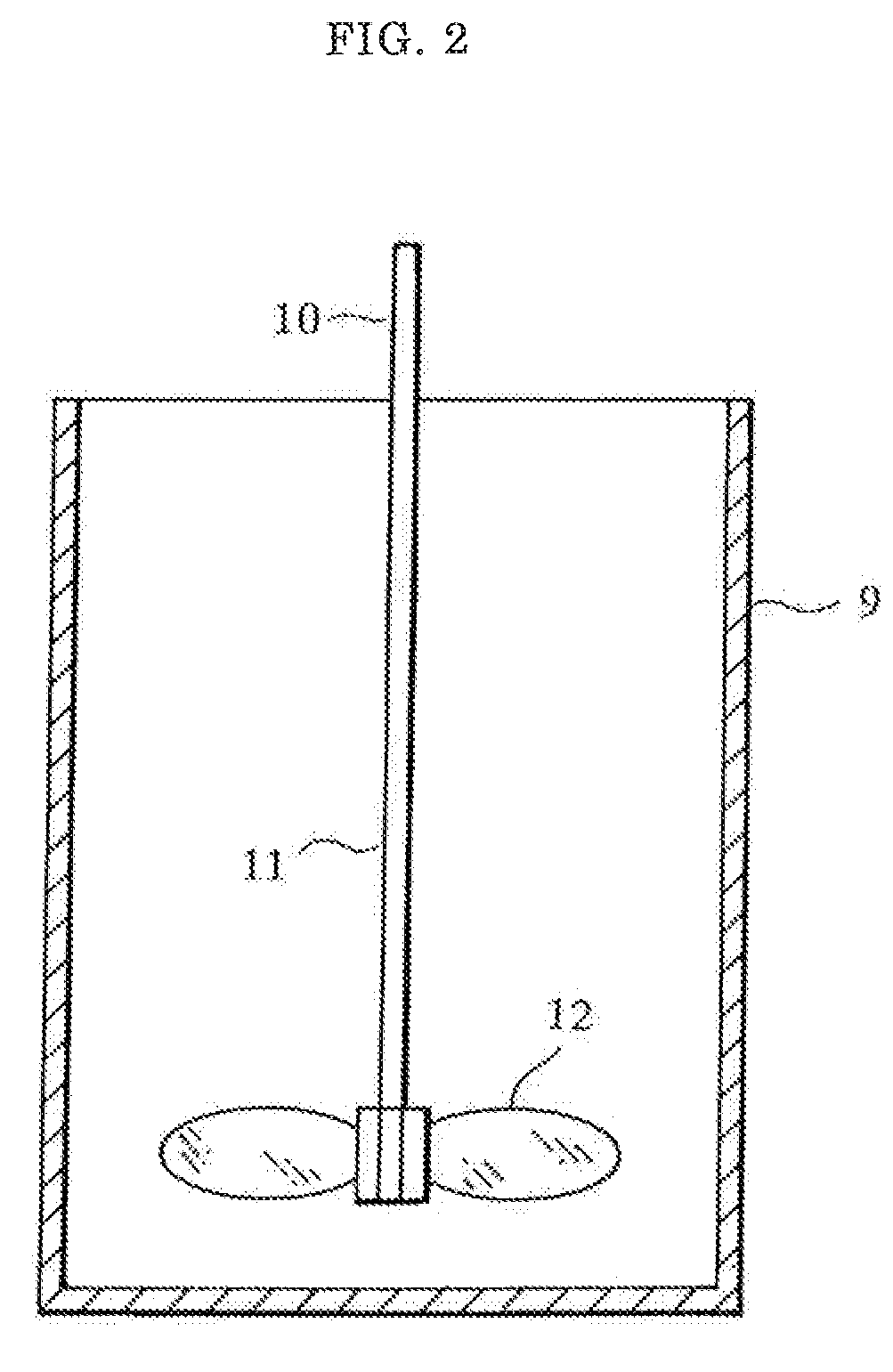

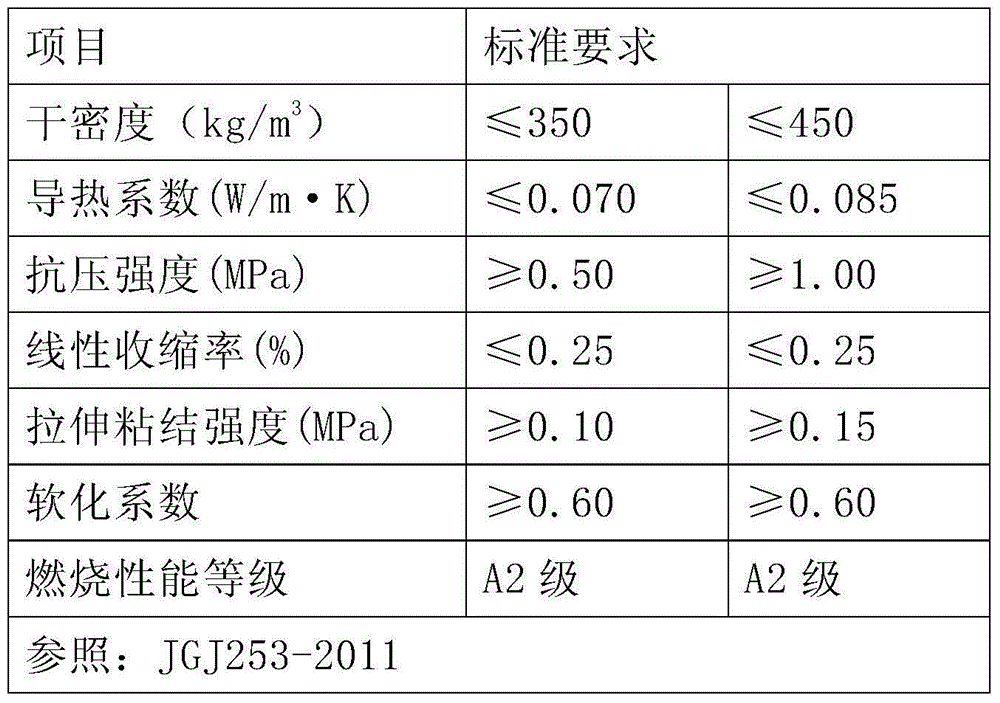

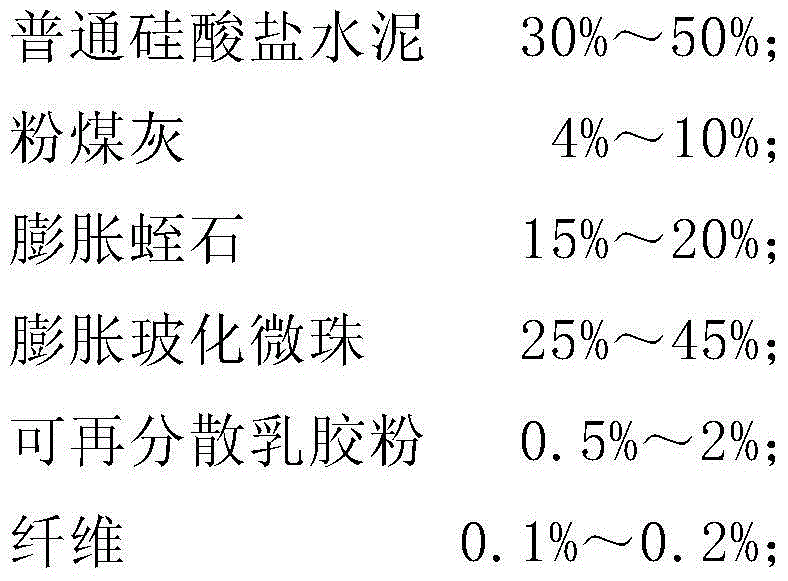

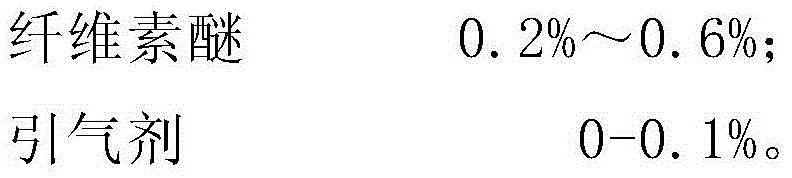

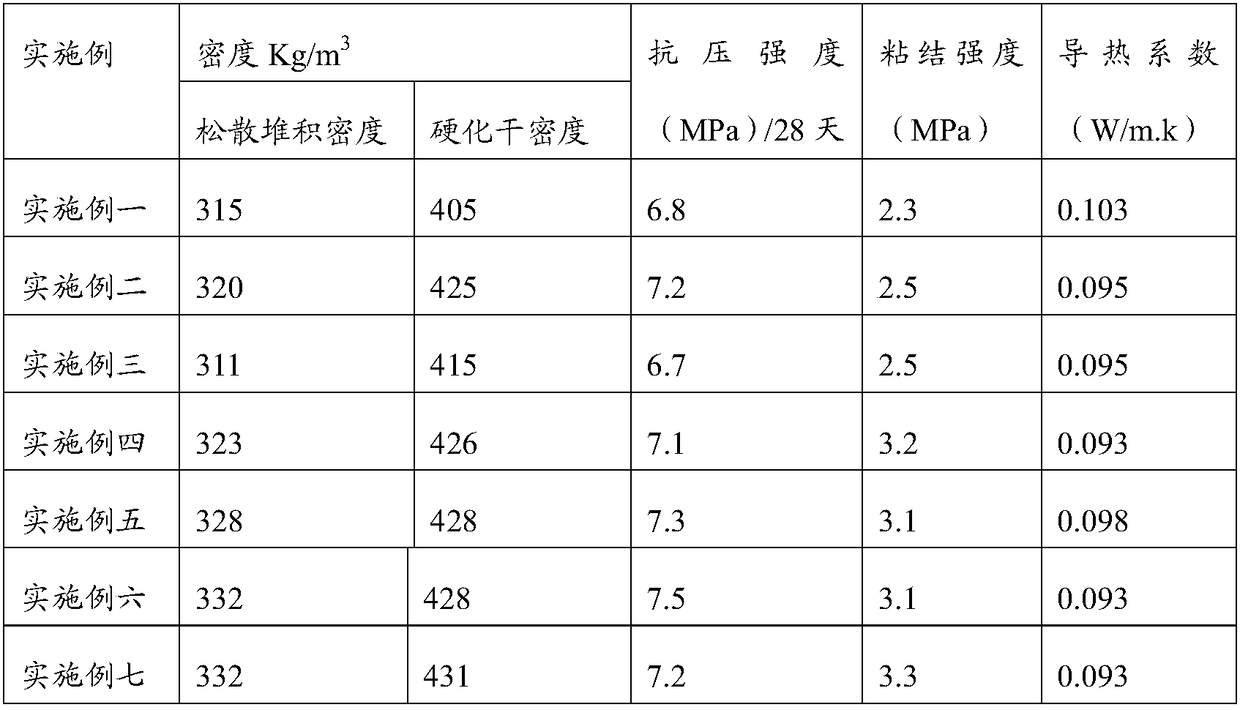

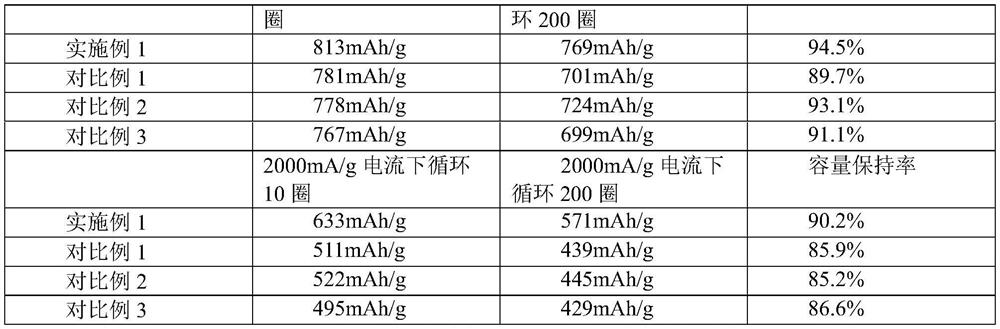

A1-grade fireproof insulation mortar and preparation method thereof

ActiveCN103553480AImprove overall performance and construction performanceSolve easy pulverizationPerliteWeather resistance

The invention discloses an A1-grade fireproof insulation mortar which is prepared from the raw materials of, by weight: common Portland cement, fly ash, expanded vermiculite, expanded glass micro-beads, re-dispersible latex powder, fiber, cellulose ether, and an air-entraining agent. According to the invention, glass micro-beads are adopted as a light aggregate, and the expanded vermiculite with excellent fireproof performance is doped in. Compared with a dry-mix insulation mortar light aggregate with expanded perlite and polystyrene particles, the defects of high water absorption, easy pulverization, high volume shrinkage rate in slurry stirring, and phenomena of product low post-stage strength and hollowing cracking, and the like of expanded perlite are overcome. Also, defects of high inflammability, poor fire retardant performance, harmful gas production under high temperature, low aging resistance, low weather resistance, high resilience during construction, and the like of organic materials such as EPS and XPS are overcome. With the mortar provided by the invention, insulation mortar comprehensive performances and construction performance are improved. On the basis of good safety, energy-saving and comfortableness are realized. With the mortar, building, human, and nature are harmonious and unified.

Owner:宜昌恒达利新材料科技有限公司

Vitrified particulate heat-insulated material for walls

The invention discloses a vitrified particular heat-insulated material for walls, belonging to the field of construction materials. The vitrified particular heat-insulated material for the walls comprises the following components in parts by weight: 100-150 parts of vitrified micro particle, 30-50 parts of expanded perlite, 30-60 parts of cement, 30-60 parts of sodium silicate, 1-10 parts of a hardener, 1-10 parts of a hydrophobic agent and 1-10 parts of a penetrant. The vitrified particulate heat-insulated material for the walls has the advantages of high density, high compressive resistance, low thermal conductivity, good heat-insulated effect and the like, has fire-protection rating A, and is a fireproof and heat-insulated material with excellent comprehensive performance.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

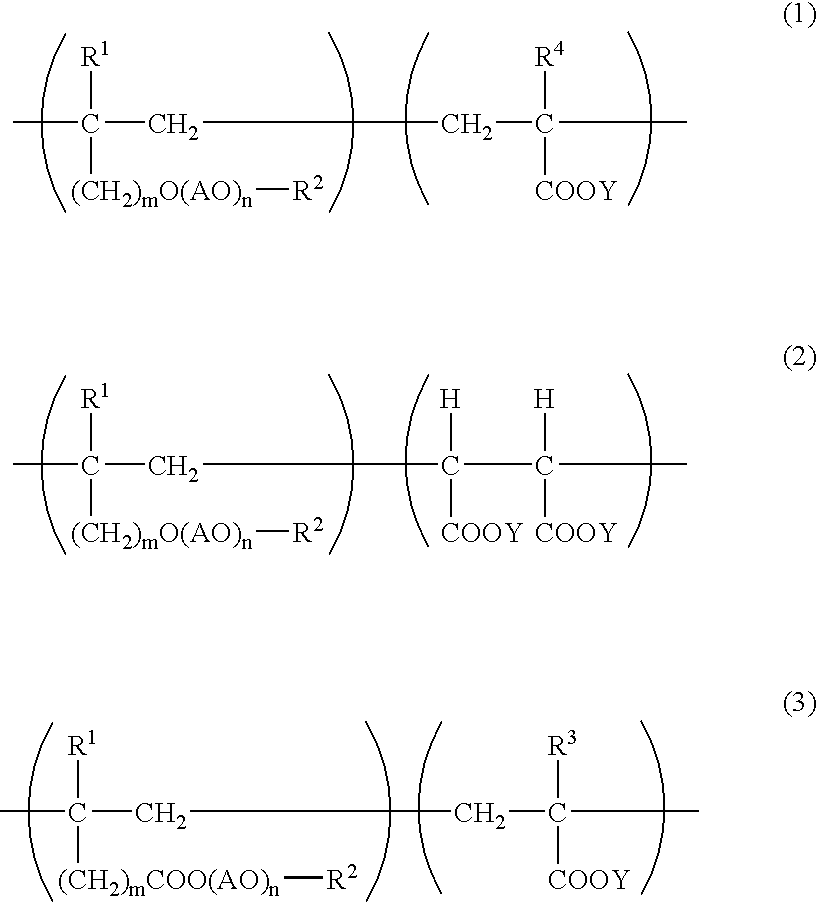

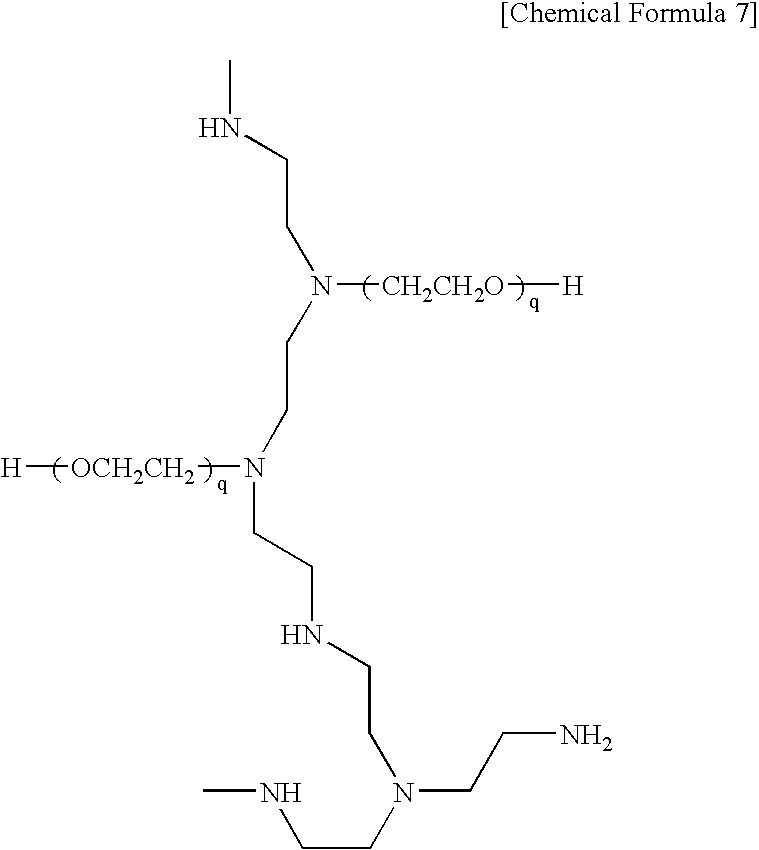

Powdery cement dispersant

InactiveUS20060229388A1Excellent dispersibilityEasily pulverizedRepeat unitSaturated carboxylic acid

The present invention provides a means to express superior dispersibility and to be easily pulverized in the polycarboxylic acid type cement dispersant. The purpose is attained by a powdery cement dispersant having, as a main component, a polycarboxylic acid type copolymer having a repeating unit (I) derived from an unsaturated polyalkyleneglycol type monomer, a repeating unit (II) derived from an unsaturated carboxylic acid type monomer and a repeating unit (III) derived from a branched compound having a branched structure containing 3 or more polyalkyleneimine chains or polyoxyalkylene chains in a molecule, or a powdery cement dispersant comprising a polycarboxylic acid type copolymer (A) having a repeating unit (IV) derived from an unsaturated polyalkyleneglycol type monomer and a repeating unit (V) derived from an unsaturated carboxylic acid type monomer and a branched compound (B) with a branched structure containing 3 or more polyalkyleneimine chains or polyoxyalkylene chains in a molecule.

Owner:NIPPON SHOKUBAI CO LTD

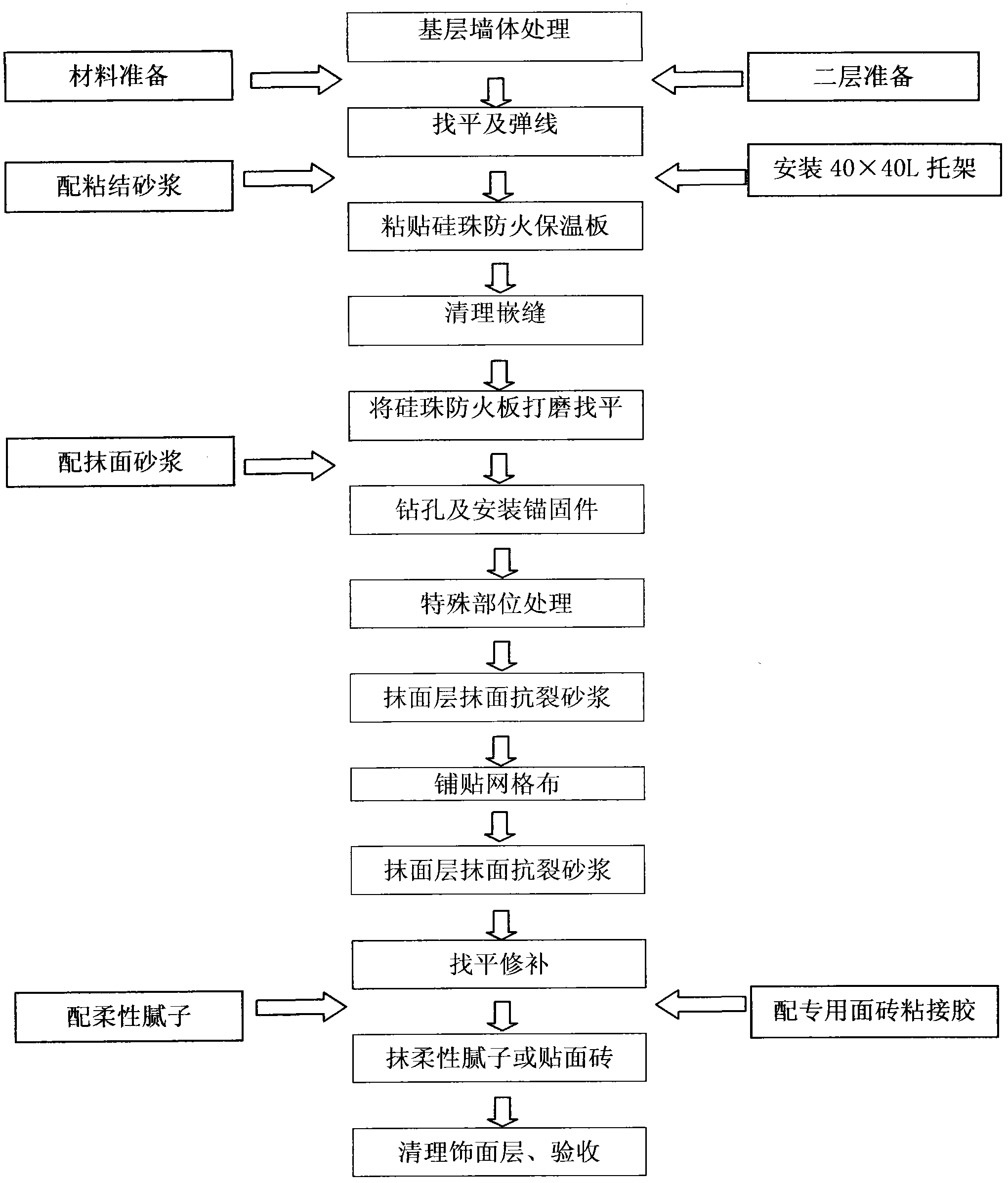

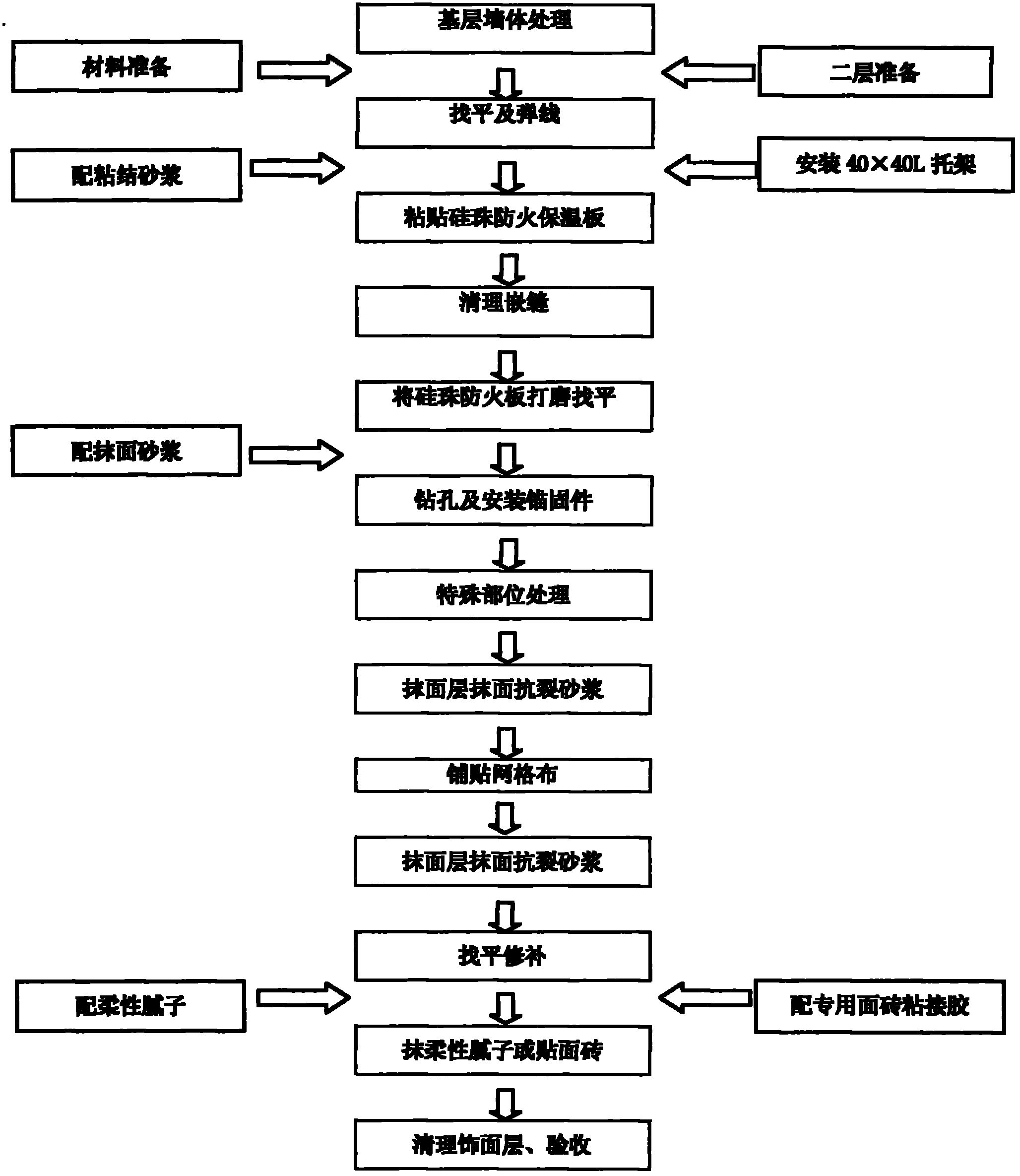

Inorganic heat-insulation fireproof plate

InactiveCN102619287ASolve easy pulverizationIncrease diversityHeat proofingBuilding material handlingPolymer scienceAging resistance

Disclosed is an inorganic heat-insulation fireproof plate, namely a silica bead fireproof heat-insulation plate. The fireproof plate is made of vitrified small balls and xonotlite, the weight ratio of the vitrified small balls to the xonotlite ranges from 1:2 to 1:5, in addition, waterproof materials with the weight ranging from 1% to 5% of the total weight of the fireproof plate and gel materials with the weight ranging from 8% to 10% of the total weight of the fireproof plate are added, and the fireproof plate is manufactured via working procedures including preparation, screening, pressure forming and drying. The vitrified small balls replace traditional common expanded perlite and traditional common polyphenyl particles to be used as lightweight aggregates of dry mixed heat-insulation mortar, shortcomings that the expanded perlite is high in water absorption and easy in pulverization and is high in volumetric shrinkage during slurry stirring, accordingly, low long-term strength, hollowing and cracking of a product are caused easily, and the like are overcome, defects of flammability, poor fireproof performance, harmful gas generation at a high temperature, low ageing resistance and weather fastness, high rebounding during construction and the like of the polyphenyl particles are also overcome, and comprehensive performances and construction property of the heat-insulation mortar are improved. In addition, the hydrophobic vitrified small balls cannot be degraded at a high temperature and are not easy to deform, and the flame retardant property of a polymer can be improved when the vitrified small balls are used as filling materials of the polymer.

Owner:QINGDAO FENGXIANG CHEM

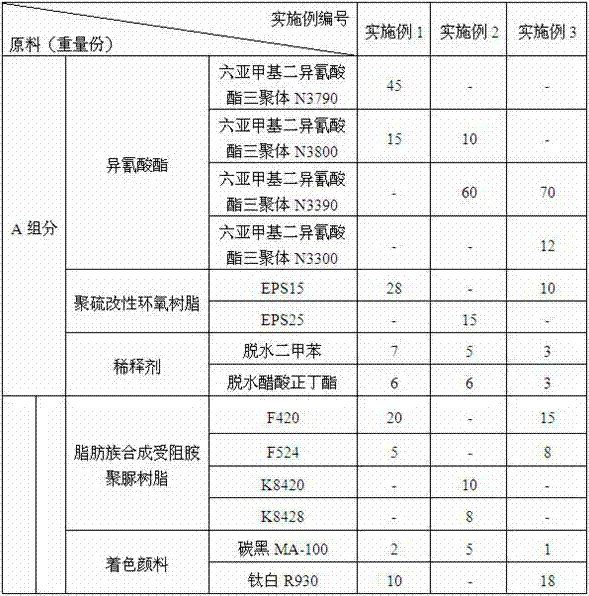

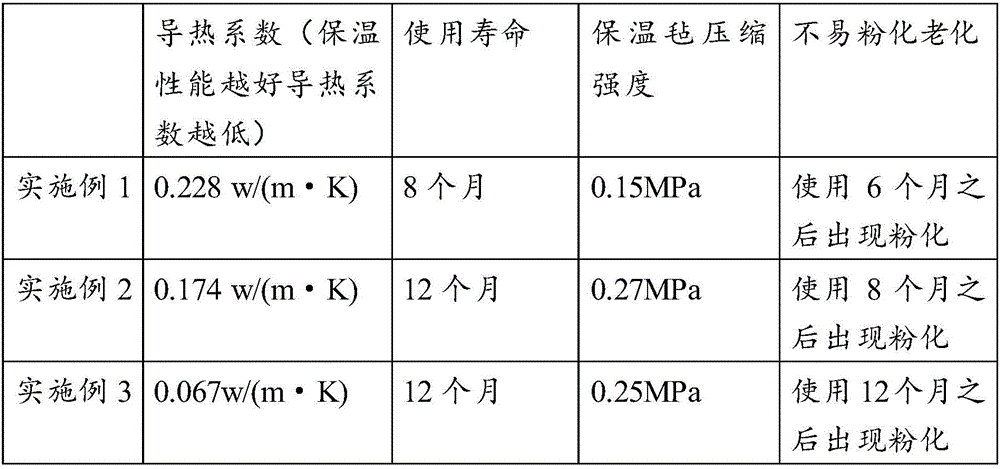

Special primer-topcoat polyurea protection coating for automobile chassis system and preparation method

ActiveCN107446476ASolve easy pulverizationSolve discolorationPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyUltraviolet lights

The invention discloses a special primer-topcoat polyurea protection coating for an automobile chassis system and a preparation method. The coating is prepared from a component A and a component B in a volume ratio of 1:(2-4), wherein the component A comprises isocyanate, a poly-sulfide modified epoxy resin and a diluent; the component B comprises an aliphatic synthetic hindered amine polyurea resin, a coloring pigment, a filler, graphene pulp, organic zinc, a dispersing agent, an ultraviolet absorbent, an ultraviolet light stabilizer, an anti-settling agent, a leveling agent, a defoaming agent, extinction powder and a dissolvent. The invention further discloses a preparation method of the special primer-topcoat polyurea protection coating for the automobile chassis system. The thickness of a disposable coating membrane is greater than or equal to 80mu m, a coating membrane is rapid in drying speed and high in construction efficiency, a coated layer is good in adhesion to a substrate, good in impact resistance, free of color change in long-term outdoor exposure, very good in aging resistance, salt mist resistance and medium resistance, high in product solid content and good in environmental friendliness, and the method provided by the invention is simple in process, low in cost and applicable to industrial production.

Owner:湘江涂料科技有限公司

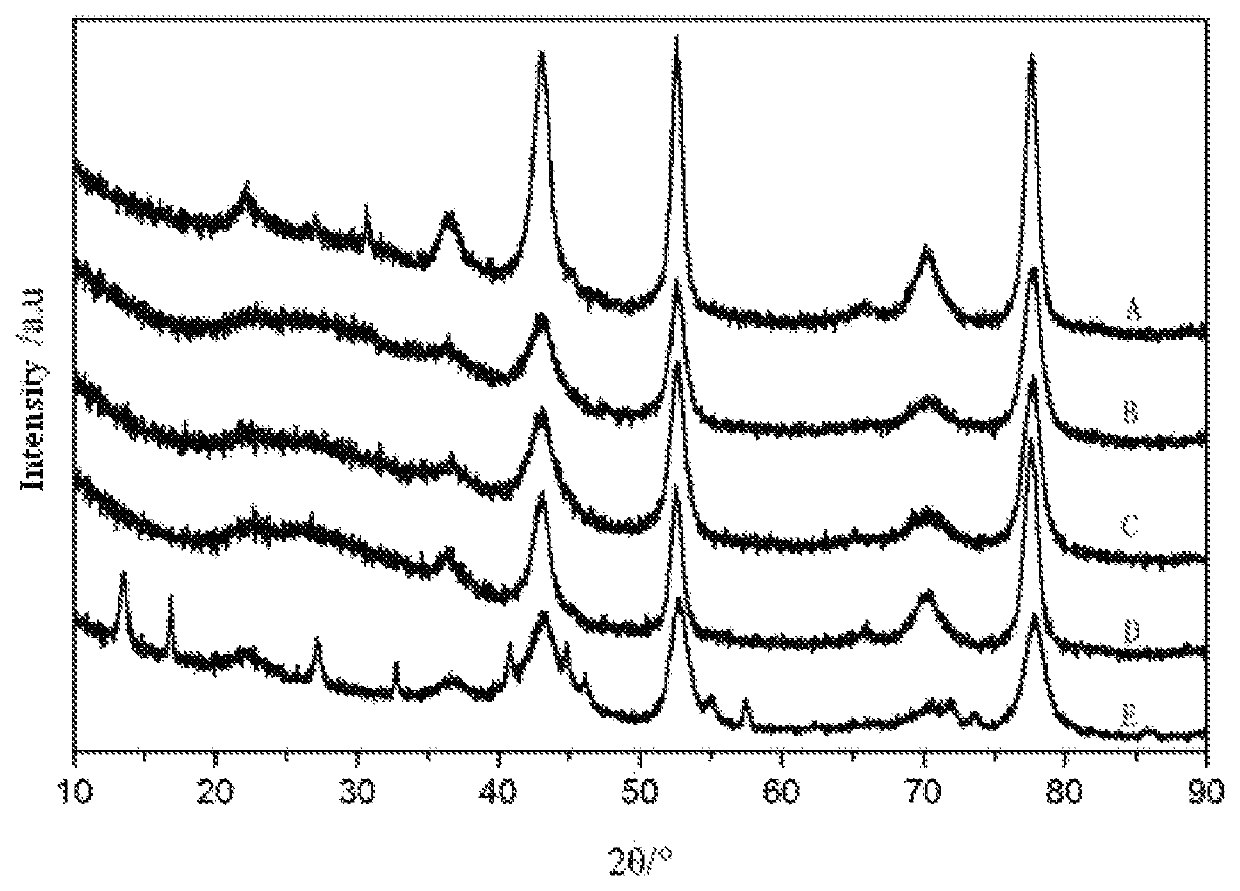

Low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN113083320AImprove denitrification effectHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFlue gas

The invention discloses a low-temperature SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of low-temperature SCR denitration. According to the method, an FCC waste catalyst and modified biochar are used as supporting carriers, transition metal oxides are used as active components, the loading amount of transition metal elements in the components is 5-20% of the weight of the carriers, the active components are loaded on the carriers by adopting an impregnation method, then drying treatment is performed, and finally roasting is performed in a nitrogen atmosphere, and the low-temperature SCR denitration catalyst disclosed by the invention is obtained. The problems of low low-temperature denitration activity and high cost of a vanadium-titanium catalyst are solved, resource comprehensive utilization of the FCC waste catalyst is achieved, damage of industrial solid waste to the environment is reduced, and the prepared SCR catalyst has excellent denitration performance under the low-temperature condition and has good application prospects and market prospects for low-temperature denitration of industrial flue gas.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Glazed hollow bead thermal insulation mortar and preparation process thereof

InactiveCN101993228AIncrease diversityImprove performanceSolid waste managementPolymer scienceThermal insulation

The invention relates to a glazed hollow bead thermal insulation mortar and a preparation process thereof, which are applicable to interior and exterior thermal insulation plastering projects of enclosure walls of multi-storey and high-rise buildings and the like, as well as fire prevention and thermal insulation projects and thermal insulation transformation projects of old buildings. The glazed hollow bead thermal insulation mortar is prepared by the raw materials of ordinary Portland cement, ash calcium powder, sand, lignin, polypropylene staple fiber, silica fume and composite resin rubber powder in parts by weight, and can overcome great hydroscopicity and easy pulverization of expanded perlite, large volume shrinkage during stirring of slurry, and easy emergence of the phenomena of low strength, hollowing, cracking and the like during the late stage of a product, simultaneously make up for defects of flammability of polyphenyl granular organic material, poor fireproof performance, production of harmful gas due to high temperature, low aging resistance and weather resistance, large rebound resilience during construction and the like, and enhance and improve comprehensive performance and construction performance of the thermal insulation mortar.

Owner:沈杰铭

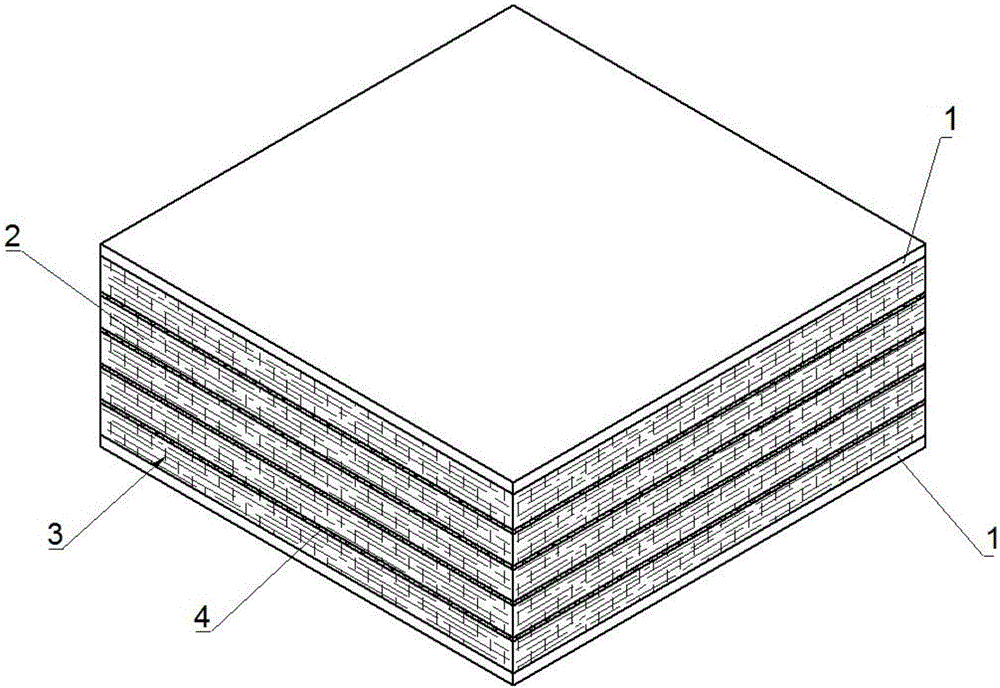

Carbon fiber insulation hard felt and preparation method thereof

InactiveCN106626710AImprove insulation effectExtended service lifeLamination ancillary operationsLaminationCardingPunching

The invention provides a preparation method of a carbon fiber insulation hard felt, comprising the steps of A) performing sequential steps, to be specific, chopping carbon fibers, heating for pretreatment, carding and opening, layering, and compositing by needle punching to obtain a unit layer; B) gluing the unit layer many times, and drying to obtain a treated unit layer; C) applying glue among the multiple unit layers treated, and stacking and spreading to obtain a composite unit layer; stacking and spreading protective layers to the uppermost and lowermost layers of the composite unit layer respectively, hot-pressing, and carbonizing to obtain the carbon fiber insulation hard felt; a heating procedure in carbonizing refers to: heating to 1000 DEG C at heating rate of 20-50 DEG C / h; heating to 1500 DEG C and above at heating rate of 30-70 DEG C / h. The preparation method of the carbon fiber insulation hard field provided herein integrates the carbonizing and high-temperature procedures of the prior art, so that the production cycle is shortened, and process stability and product quality stability can also be improved.

Owner:JIAXING QISHENG CARBON MATERIALS

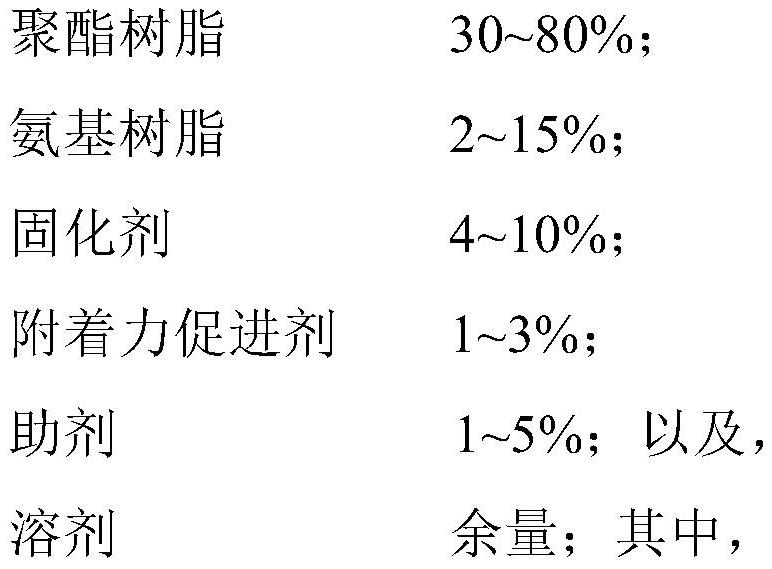

High-weather-resistance coiled material coating composition and application thereof

PendingCN114426796ASolve easy pulverizationResolve gloss lossLiquid surface applicatorsAntifouling/underwater paintsPolymer scienceWeather resistance

The invention provides a high-weather-resistance coiled material coating composition, which comprises the following components in percentage by mass: 30-80% of polyester resin, 10-20% of a curing agent, 1-10% of a curing agent, 1-10% of a curing agent, 1-10% of a curing agent and 1-10% of a curing agent. 2-15% of amino resin; 4-10% of a curing agent; 1-3% of an adhesion promoter; 1-5% of an auxiliary agent; and the balance of a solvent, wherein the polyester resin is saturated polyester resin, the number-average molecular weight Mn of the polyester resin is 3000-20000, the hydroxyl value of the polyester resin is 30-70 mg KOH / g, the acid value of the polyester resin does not exceed 10 mg KOH / g, and a molecular chain of the polyester resin contains a neopentyl structure. The high-weather-resistance coiled material coating composition does not need pretreatment, can be directly coated on a metal substrate such as stainless steel and the like, and has excellent machinability and adhesive force, meanwhile, a cured paint film has excellent weather resistance, pollution resistance, MEK resistance, corrosion resistance and wear resistance, and the high-weather-resistance coiled material coating composition is mainly applied to external coating of metal coiled materials such as stainless steel and the like.

Owner:NIPPON PAINT IND COATINGS SHANGHAI

Method of manufacturing resin particles

Owner:SHARP KK

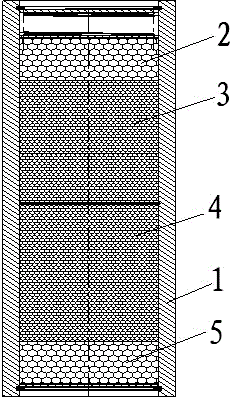

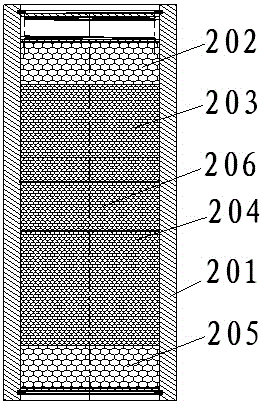

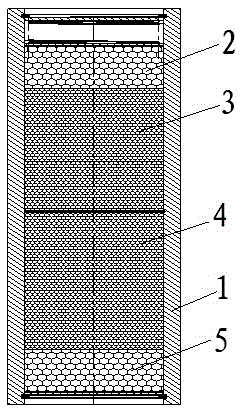

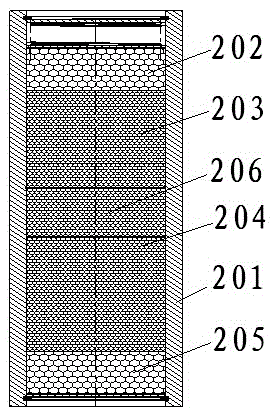

Adsorption material applicable to adsorption type air dryer and combined adsorption method of adsorption material

ActiveCN104084123ASolve the adsorption problemSolve easy pulverizationAluminium silicatesDispersed particle separationMolecular sieveChemistry

The invention discloses an adsorption material applicable to an adsorption type air dryer and a combined adsorption method of the adsorption material. The absorption material is formed by aluminum oxide and molecular sieves with different particle diameters in a sectional combining manner so as to form a composite absorption material combination body, wherein the aluminum oxide comprises two types of absorption particles with particle diameters being phi3 to phi5mm or phi5 to phi8mm; the molecular sieves also comprise two types of absorption particles with the particle diameters being phi3 to phi5mm or phi5 to phi8mm; the aluminum oxide and the molecular sieves with the different particle diameters are staggered, layered and packed in an absorption cylinder of the absorption type air dryer and combined to form a composite absorption material combination body; compressed air output by the absorption type air dryer is absorbed by the composite absorption material combination body which is combined and formed by the aluminum oxide and the molecular sieves with the different particle diameters.

Owner:ZHUZHOU YIXING TECH CO LTD

Energy-saving thermal-insulation soundproof environment-friendly building mortar and preparation method thereof

InactiveCN108203284AHigh strengthImprove waterproof performancePerformance enhancementThermal insulation

The invention discloses energy-saving thermal-insulation soundproof environment-friendly building mortar and a preparation method thereof. The energy-saving thermal-insulation soundproof environment-friendly building mortar is prepared from the following raw materials in parts by weight: 20-30 parts of compound cement, 25-35 parts of modified ore stuffing, 4-8 parts of a waterproof adhesion promoter, 20-30 parts of treated building waste, 8-10 parts of anti-cracking performance-enhancement additive, 2-4 parts of calcium stearate, 8-10 parts of hollow additive and 20-30 parts of water. The building mortar disclosed by the invention is low in heat conduction coefficient, is good in thermal insulation property, is outstanding in compactness, is resistant to water and seepage, further has excellent soundproof performance, adopts a great deal of building waste, and saves resources. The energy-saving thermal-insulation soundproof environment-friendly building mortar has the advantages of safe and reliable raw material component, relatively low cost, wide raw material source, relatively high practical value and good application prospect.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

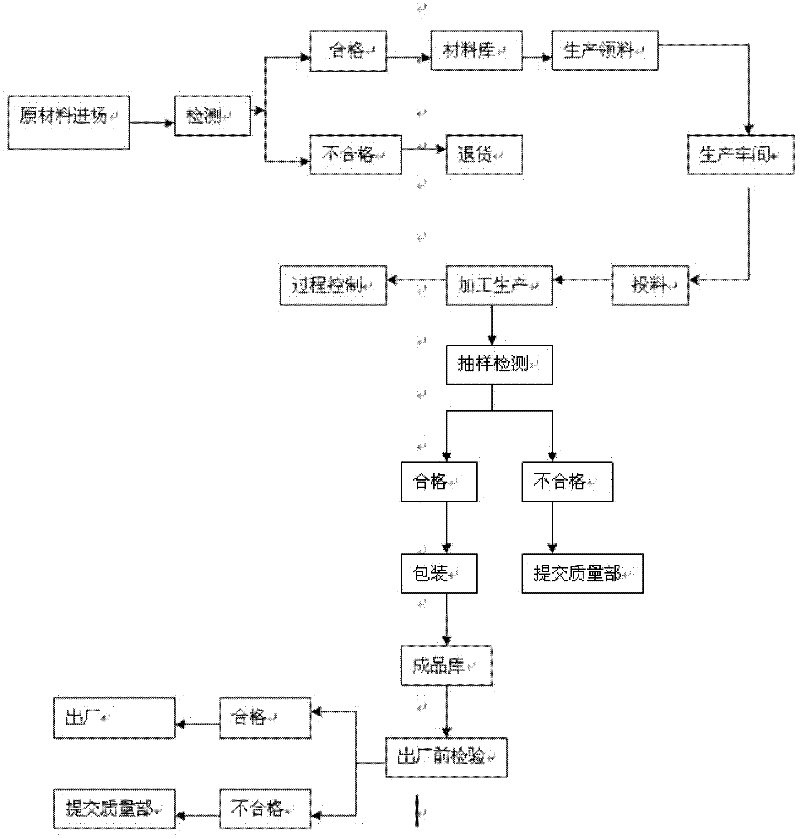

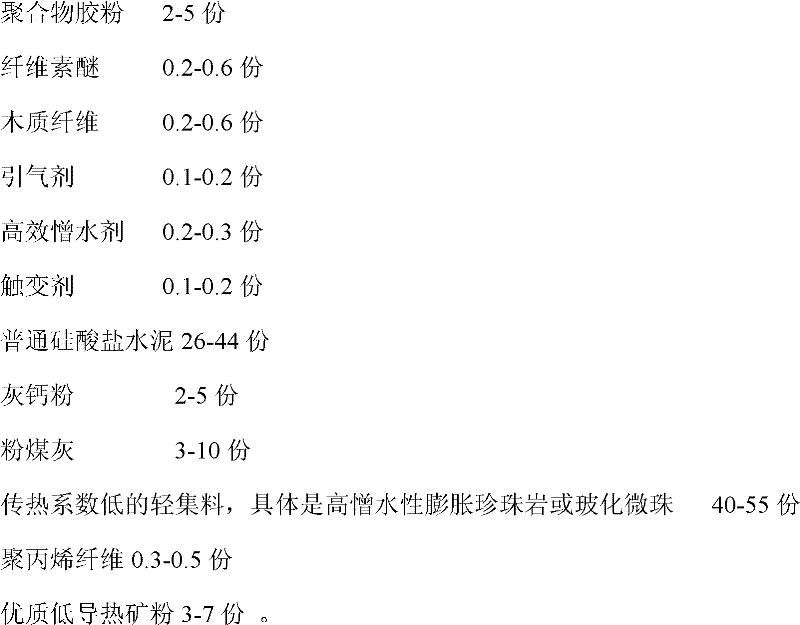

EIA (Environmental Impact Assessment) ecological environment-friendly type inorganic active building heat-insulating mortar

The invention relates to an EIA (Environmental Impact Assessment) ecological environment-friendly type inorganic active building heat-insulating mortar which comprises polymer rubber powder, cellulose ethers, wood fibers, air entraining agents, efficient moisture repellents, thixotropic agents, ordinary portland cement, calcium powder, coal ash, light aggregates with low coefficient of heat transfer, such as high-hydrophobicity expanded perlite or vitrified micro-beads, polypropylene fibers and excellent mineral powder with low heat conductivity. The defects of the traditional heat-insulating material of low fireproof performance, easiness in generating harmful gas at high temperature, low weather resistance, hollowing resistance, cracking resistance, air pressure resistance and impact resistance are overcome by the mortar provided by the invention. The mortar is suitable for the inner and outer heat-insulating plastering projects for retaining walls, such as reinforced concrete, aerated concrete, built blocks, baked bricks and non-baked bricks, of multilayer and high-rise buildings, is suitable for the fireproof heat-insulating projects, such as basement, garage, stair, corridor and fire engine access, and is also suitable for the heat-insulating modifying projects of various old buildings. During a construction process, the process is more convenient than the process of the traditional heat-insulating system, and the uncertain hidden danger caused by the mixing use of different materials is avoided.

Owner:TIANJIN ENGICO TECH DEV

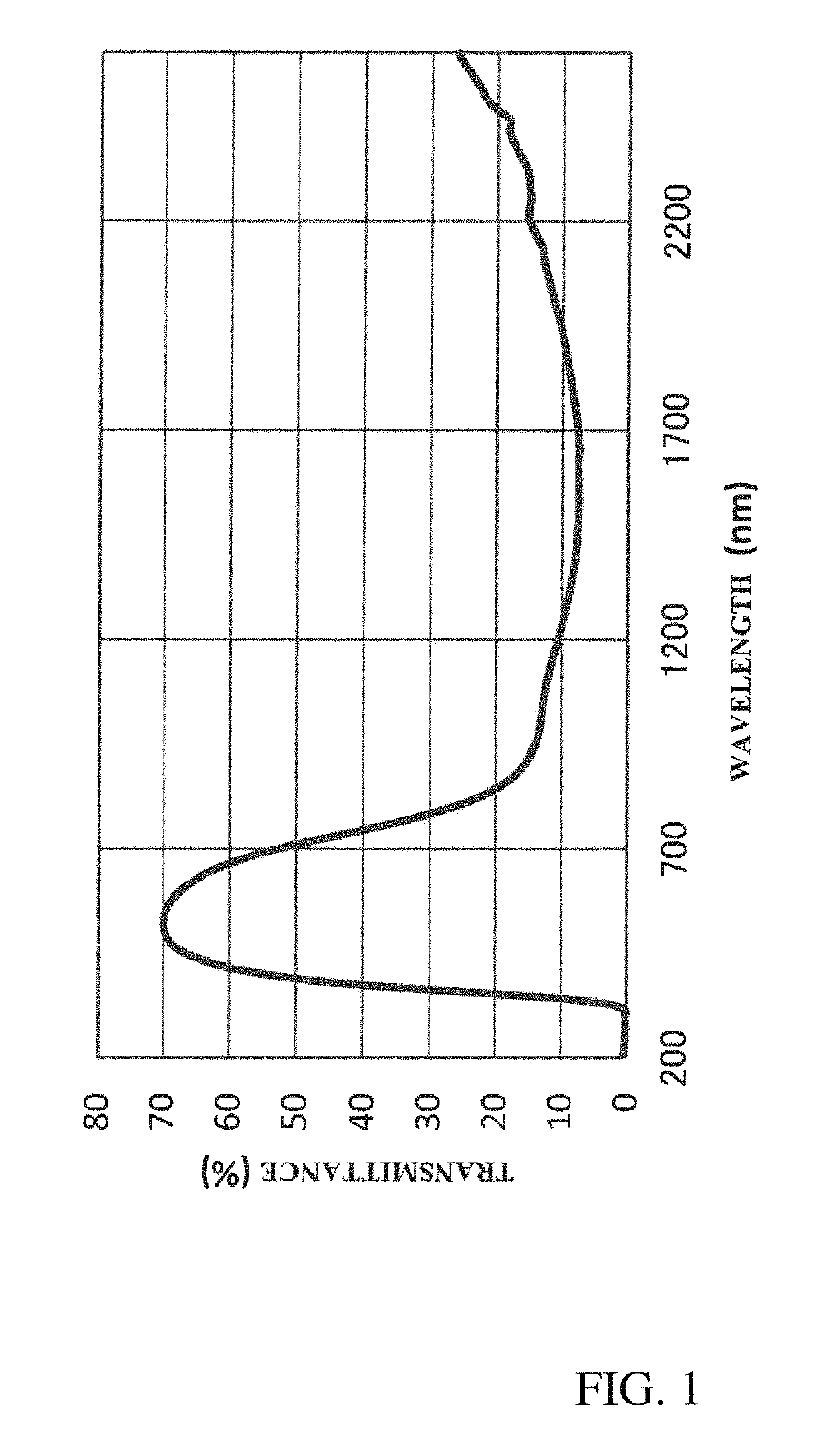

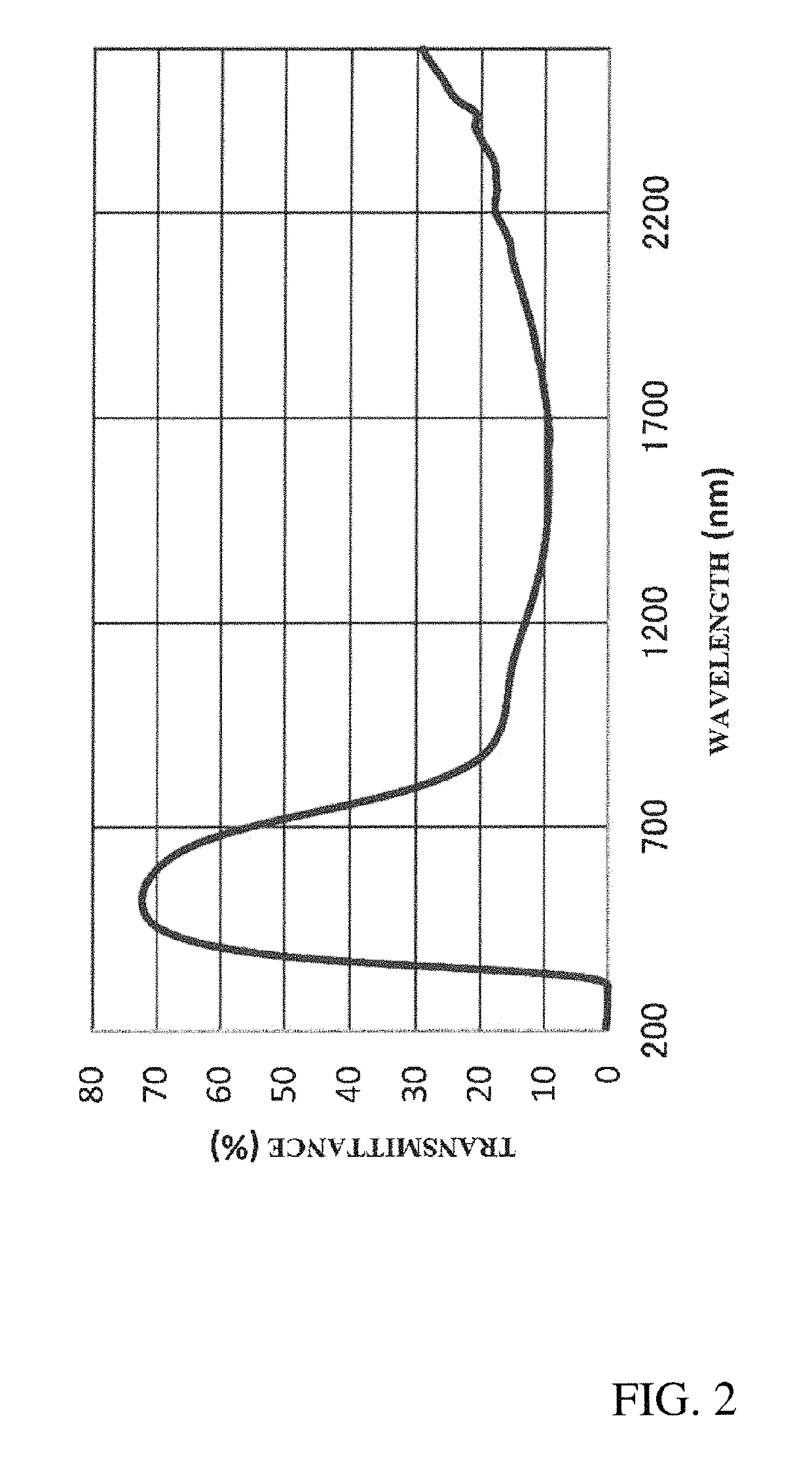

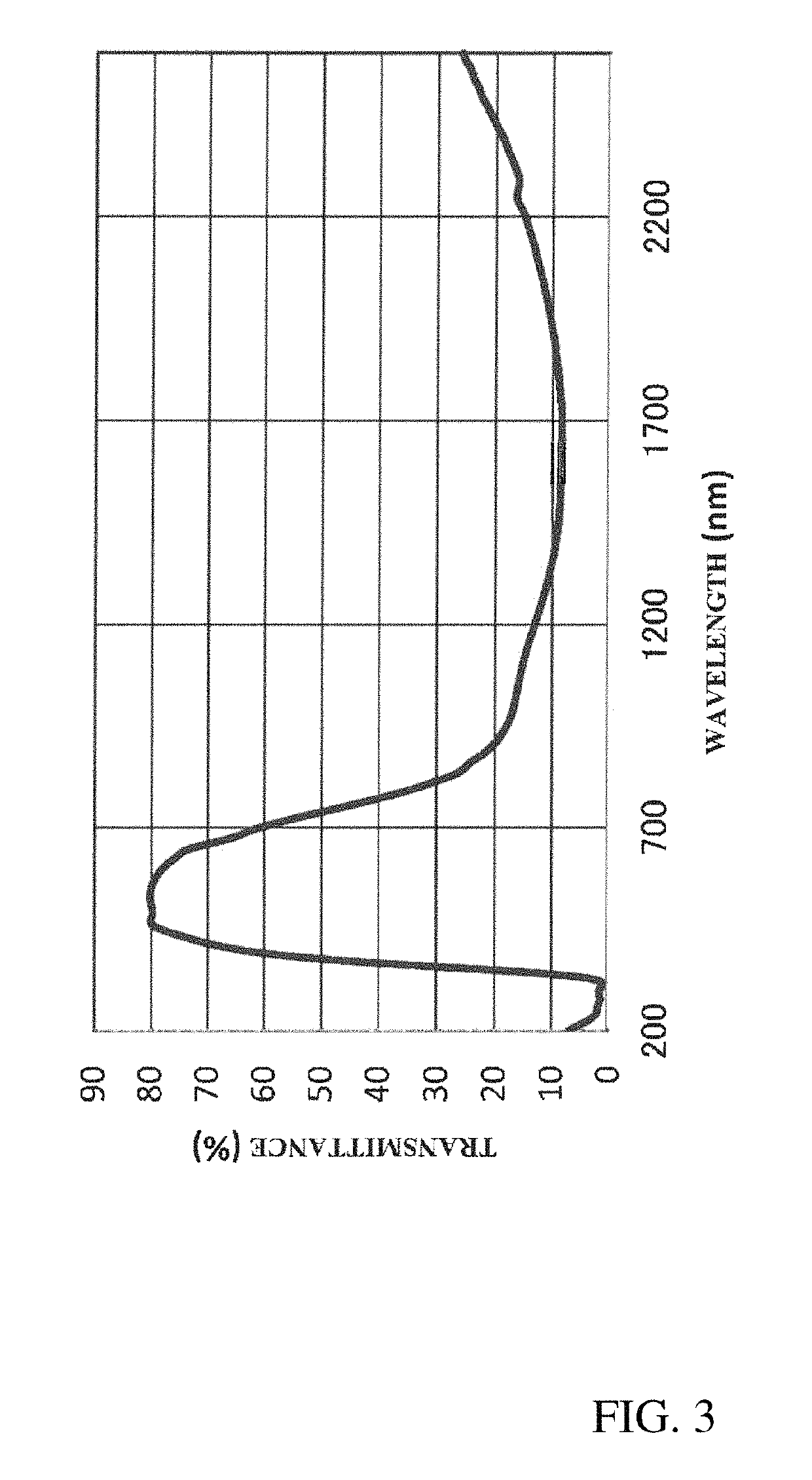

Near-infrared absorbing fine particle dispersion liquid and method for producing the same

ActiveUS10442948B2Efficient use ofSharp contrastPigmenting treatmentOther chemical processesVegetable oilNear infrared absorption

Provided is a near infrared absorbing fine particle dispersion liquid, which can be applied to offset printing, including: a solvent of one or more kinds selected from vegetable oils and vegetable oil-derived compounds; near infrared absorbing fine particles of one or more kinds selected from 10 mass % more and 25 mass % or less of a composite tungsten oxide expressed by MxWyOz, and / or a tungsten oxide having a Magneli phase expressed by a general formula WyOz; and a dispersant soluble in the solvent and having a fatty acid in its structure, wherein a viscosity is 180 mPa / S or less.

Owner:SUMITOMO METAL MINING CO LTD

Method for preparing magnesium oxide fibers by ligand analysis technology

ActiveCN104404654ASolve easy pulverizationSolve the strength problemInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberWater vapor

The invention relates to a method for preparing magnesium oxide fibers by a ligand analysis technology. The method comprises the following steps: putting fully dried magnesium oxide precursor fibers into an alkaline gas, alkaline steam or / and water vapor atmosphere, performing ligand analysis treatment under a condition that the temperature is higher than 100 DEG C, and performing dissociation reaction on the magnesium oxide precursor fibers to generate magnesium hydrate; enabling magnesium hydrate to be shrunk to form the magnesium oxide fibers. By the ligand analysis technology, the technical difficulties that the fibers are easy to pulverize and difficultly formed are solved; by an optimized thermal treatment program, the mechanical property of the magnesium oxide fibers can be effectively enhanced.

Owner:SHANDONG UNIV

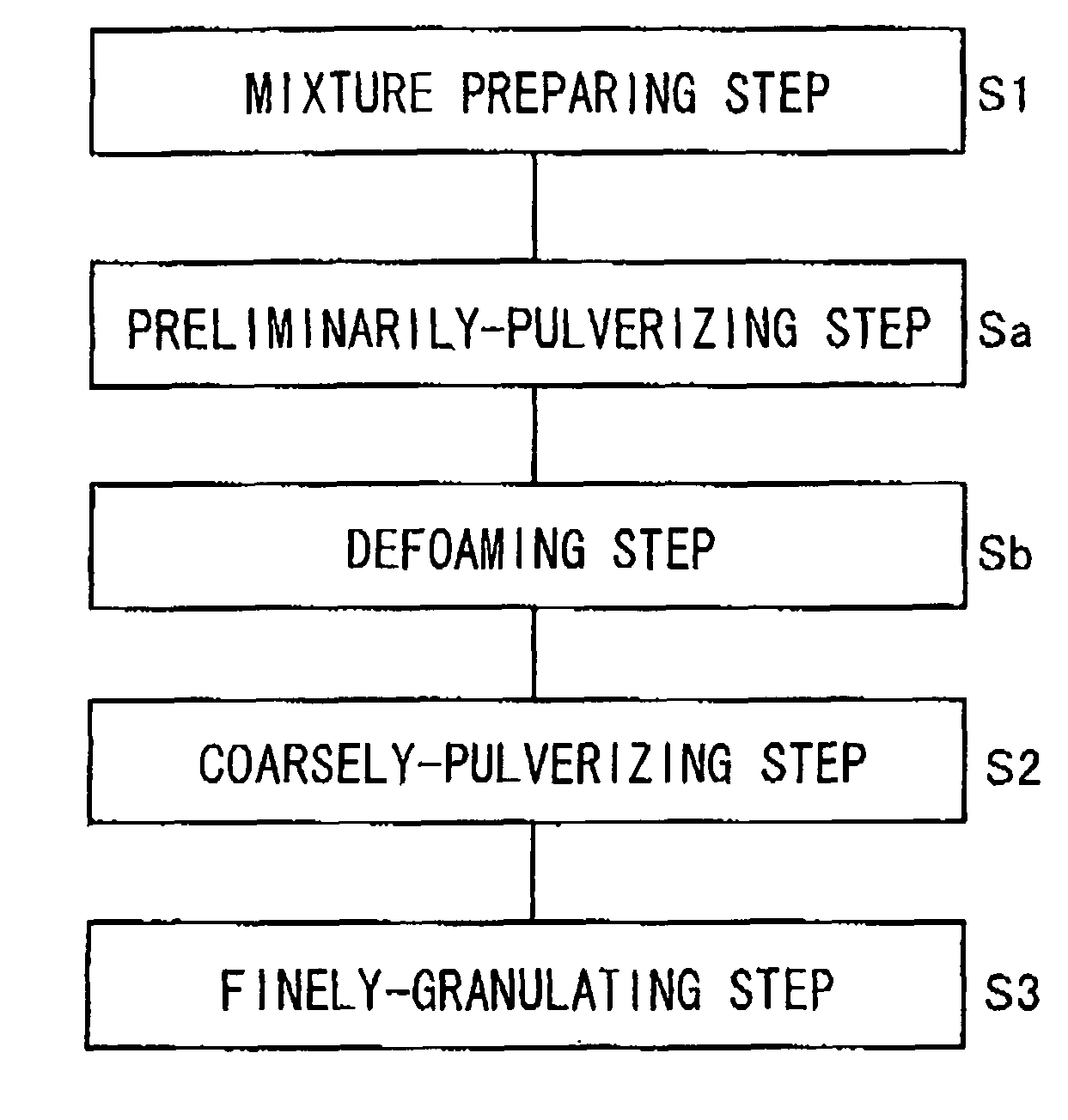

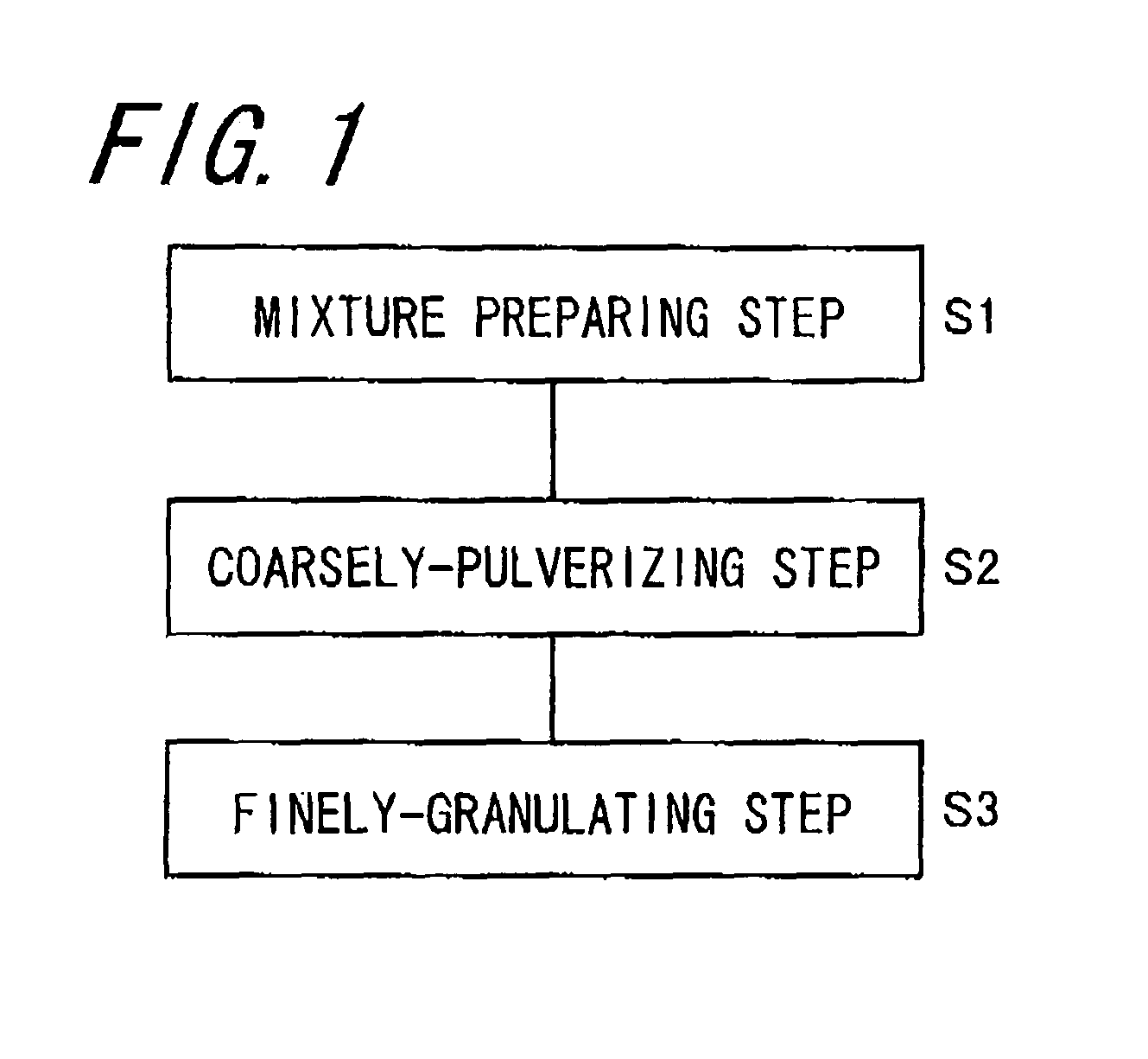

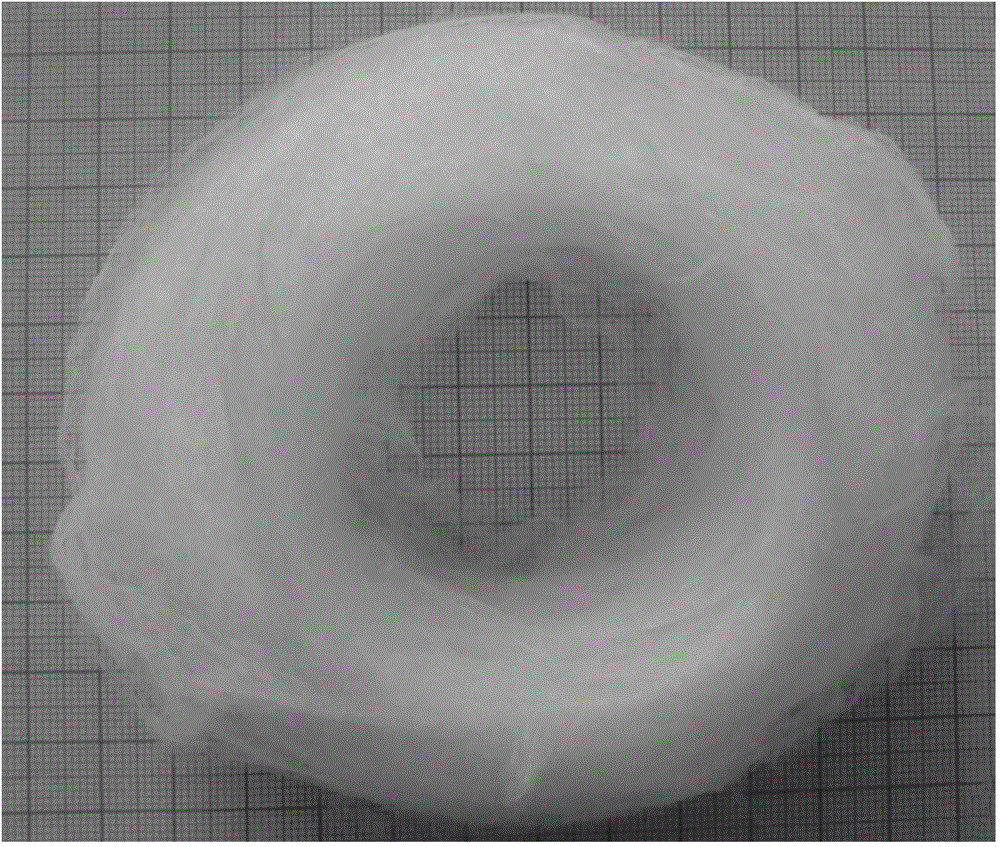

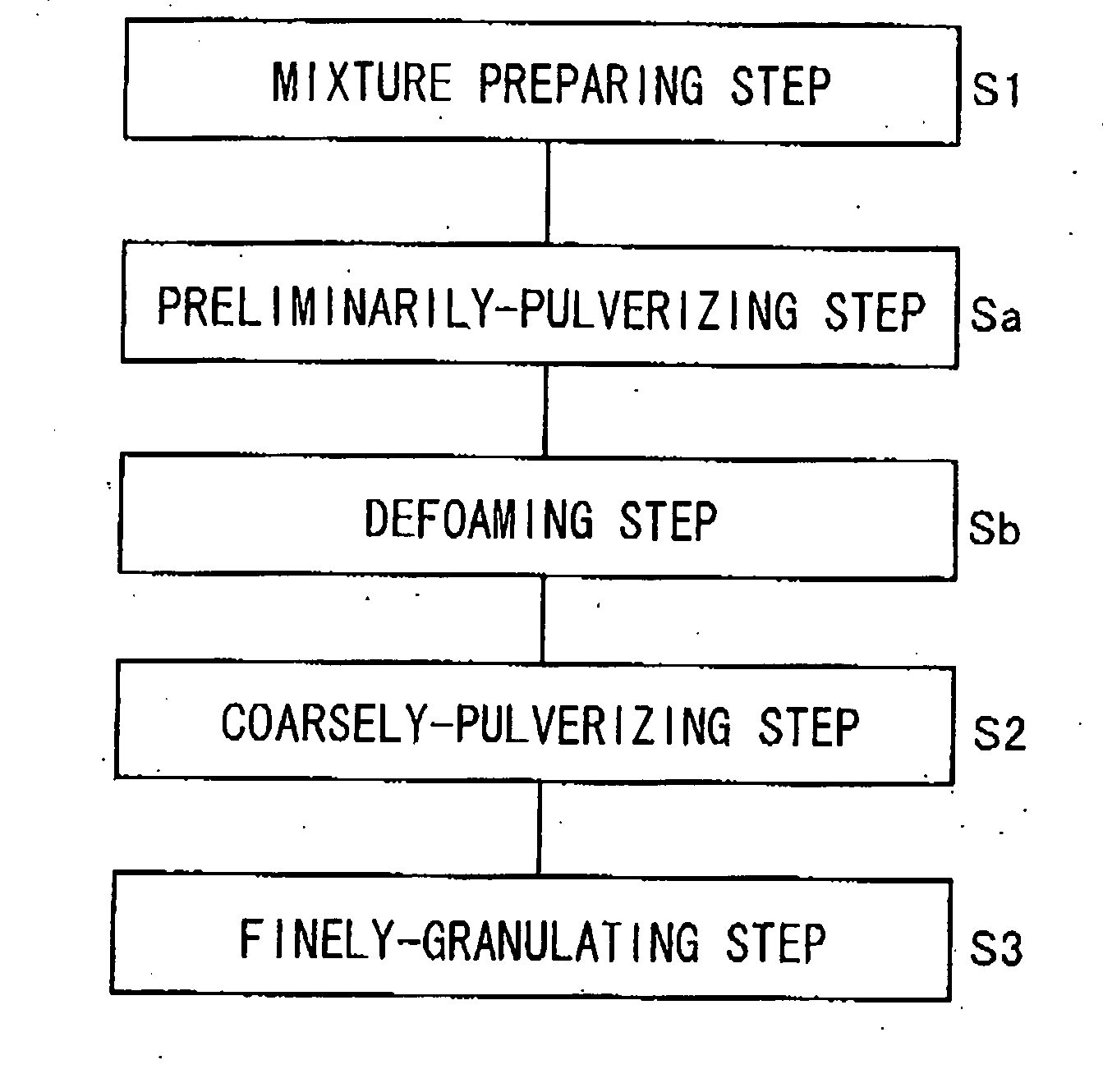

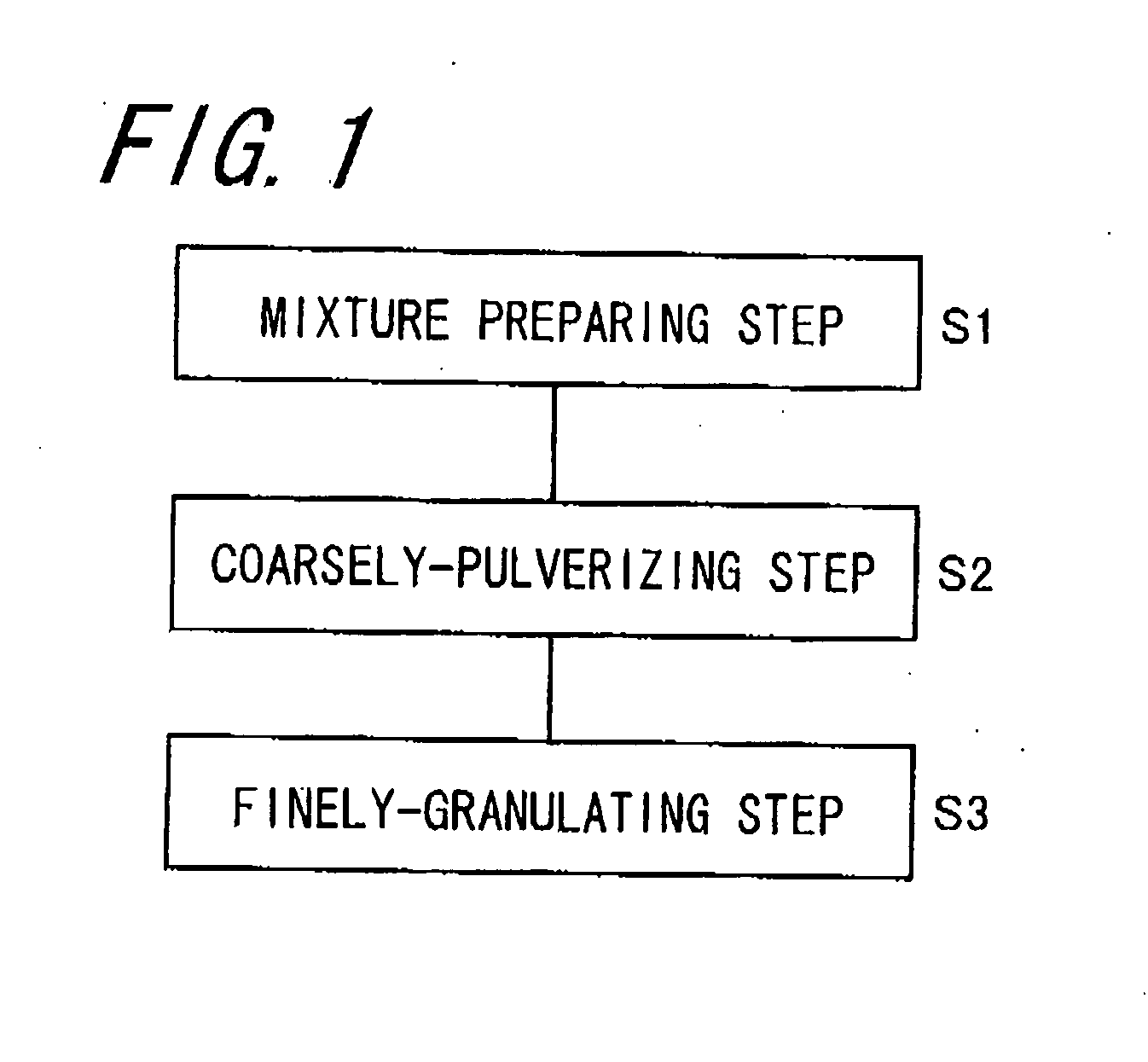

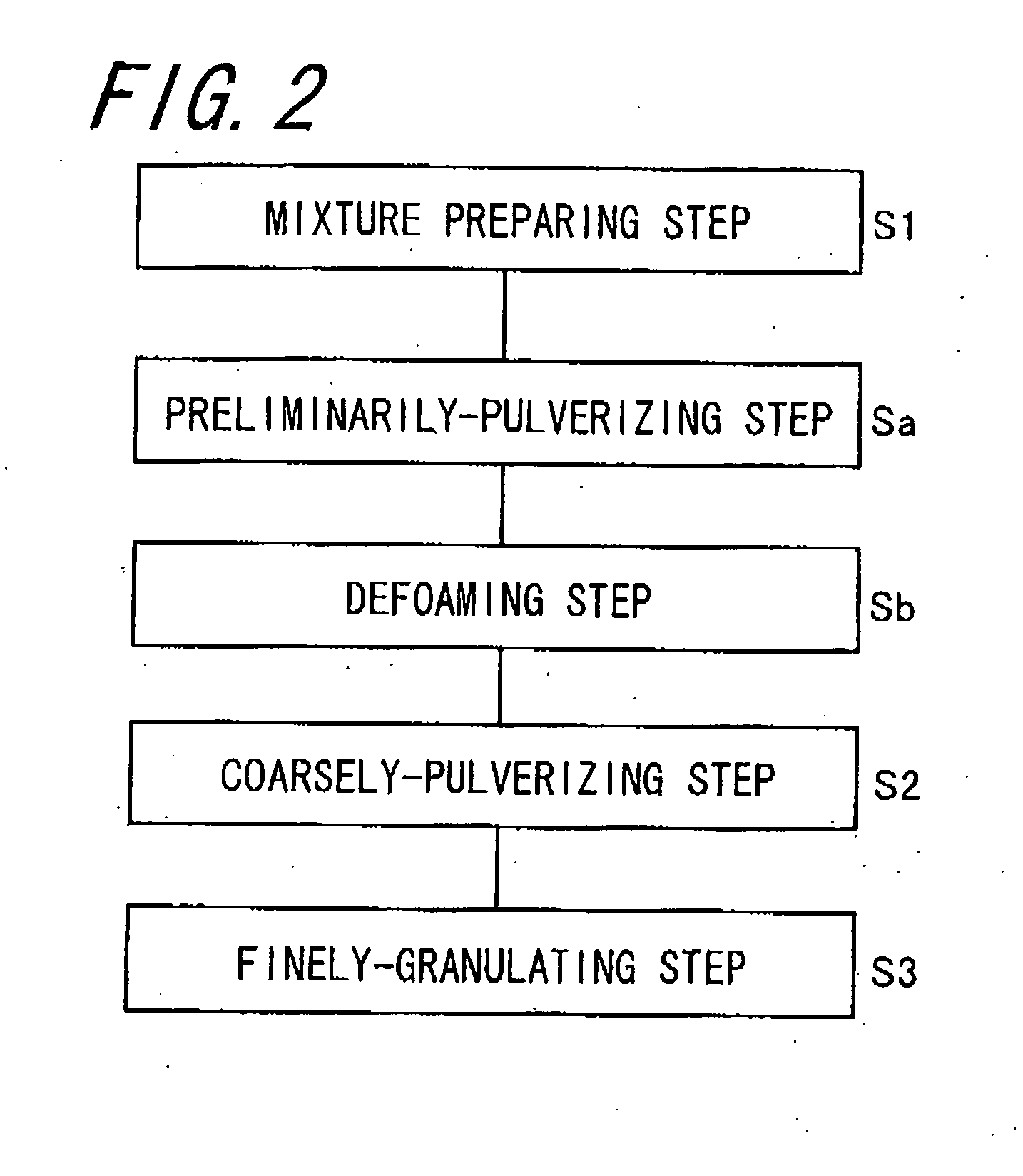

Method of manufacturing resin particles

InactiveUS20090020899A1Short timeSuppress depositionDevelopersCentrifugesParticle methodHigh pressure

Method of manufacturing resin particles capable of manufacturing resin particles of controlled particle size stably and efficiently by removing bubbles from the surface of a molten kneaded product as the raw material for resin particles thereby sufficiently ensuring action sites for a surfactant on the surface of the molten kneaded product, is provided. The method includes a coarsely-pulverizing step of pressurizing a mixture of a molten kneaded product containing a synthetic resin and an aqueous medium containing a surfactant to 15 MPa to 120 MPa thereby removing bubbles attached to the molten kneaded product containing the synthetic resin, and a finely-granulating step of finely granulating, by a high pressure homogenizer method, an aqueous slurry containing coarse particles of a molten kneaded product passing through a pressure proof nozzle in the coarsely-pulverizing step and in a state where bubbles attached to the surface are removed.

Owner:SHARP KK

Method for using calcium sulfate dihydrate to rapidly prepare short cylindrical calcium sulfate hemihydrate material

The invention belongs to the field of inorganic nonmetallic materials, and discloses a method for using calcium sulfate dihydrate to rapidly prepare a short cylindrical calcium sulfate hemihydrate material. The initial structure of common calcium sulfate dihydrate after being processed recrystallizes, the crystal grows to be complete without the problem of shrinkage cavity, and the prepared shortcylindrical calcium sulfate hemihydrate material has the high using value. By means of different energy possessed by different crystal faces of the crystal, calcium sulfate dihydrate controls dissolution and recrystallization speed of crystal faces in different solution systems according to differences of energy of each crystal face, and accordingly growth behavior control of the short cylindricalmaterial is completed. The method comprises the steps of grinding of calcium sulfate dihydrate, material distribution, thermal solution reaction, separation and cooling. The method can not only effectively solve the problems that calcium sulfate dihydrate is easy to pulverize, the strength is poor, and the stability is low, but also can widen the application field of calcium sulfate, and has theimportant practical meaning on high-efficiency utilization of smoke desulfurized products and gypsum resources.

Owner:NORTHEASTERN UNIV

CO Shift Catalyst Carrier, Catalyst Based on the Catalyst Carrier and Preparation Process Thereof

ActiveUS20180117569A1Improve mobilityLow melting pointHydrogenCatalyst activation/preparationAluminum IonIron oxide

The present invention provides a catalyst carrier with shift and adsorption purification performance, comprising modified bauxite in the raw material components which fluxing and pore forming effects. Most iron oxide contained in the bauxite is removed after modification, so that there are a large amount of highly active aluminosilicate compounds in the modified bauxite. When preparing the catalyst, the aluminosilicate compound serves as a low melting point flux and can significantly increase the migration rate of magnesium and aluminum ions during the calcinating process and promote the generation of MgAl2O4 at low temperatures, thereby the catalyst carrier of the present invention has strong anti-hydration capacity and mechanical strength. In addition, when the modified bauxite is used as macroporous hard template for the preparation of the catalyst, macro pores can be formed in the structure of the catalyst carrier after calcinating treatment, so that the catalyst carrier of the present invention has strong adsorption purification ability on macromolecular particles including oil pollution and dust

Owner:FUJIAN PROVINCE SINOGASHOLDER EQUIP INSTALLATION CO LTD

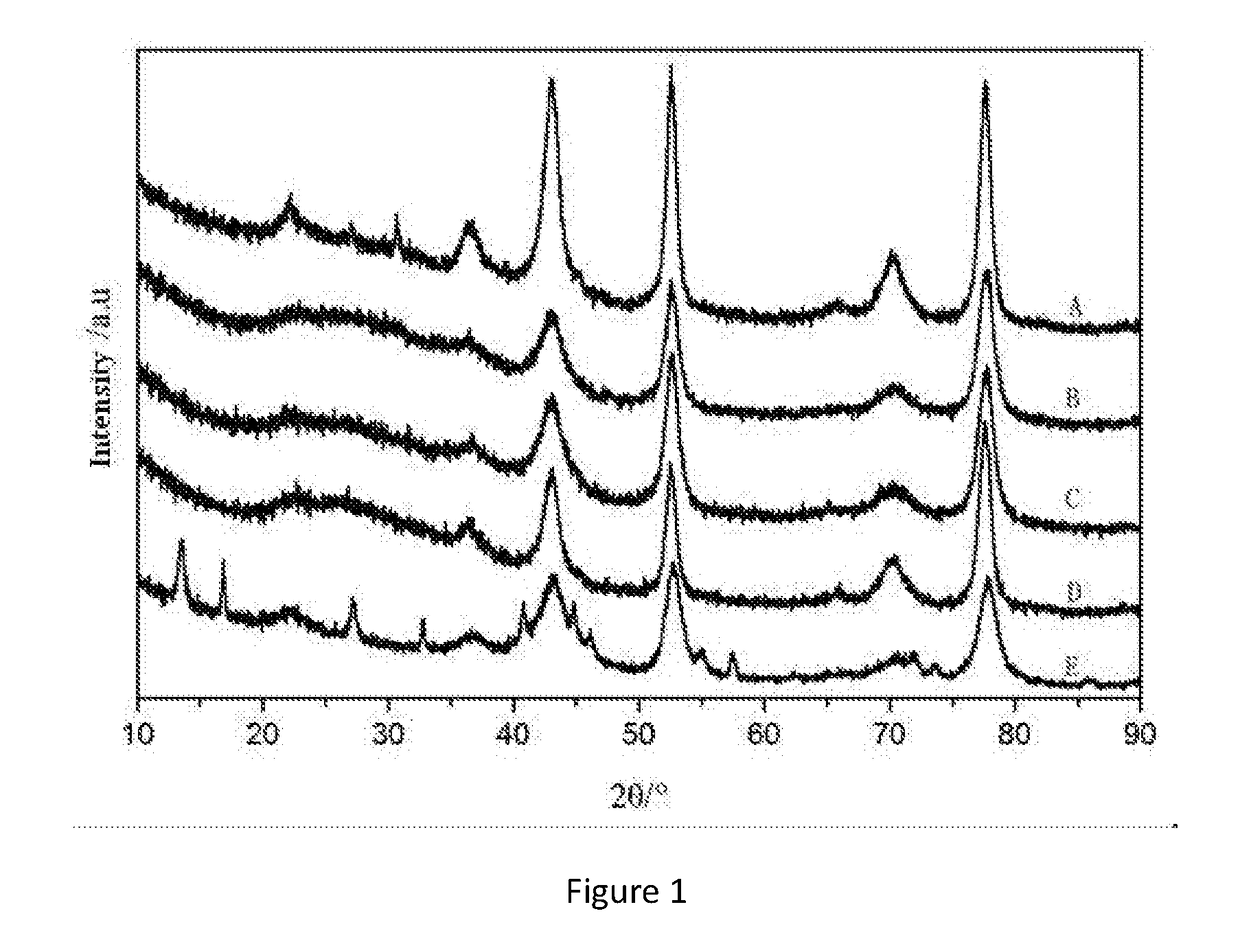

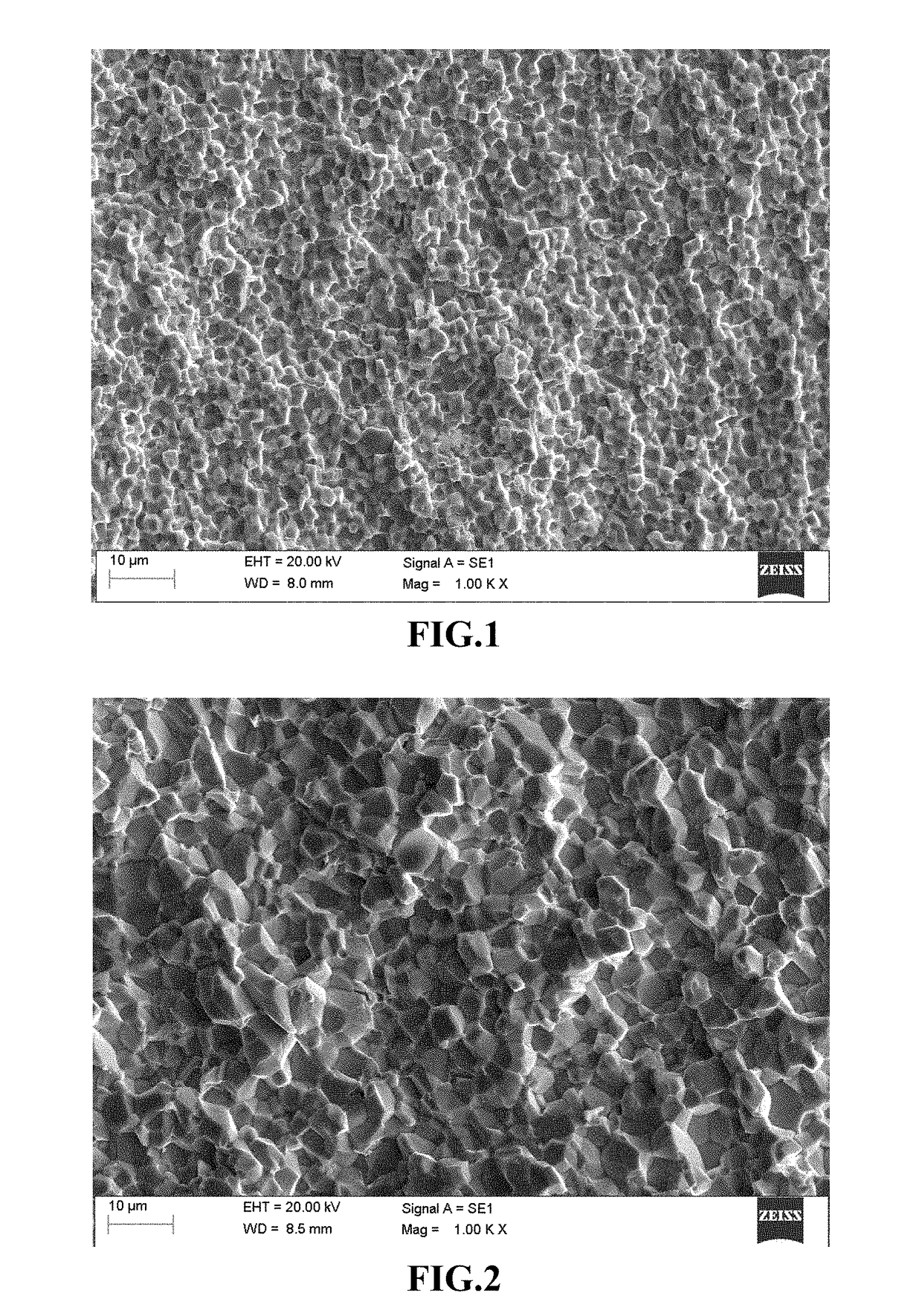

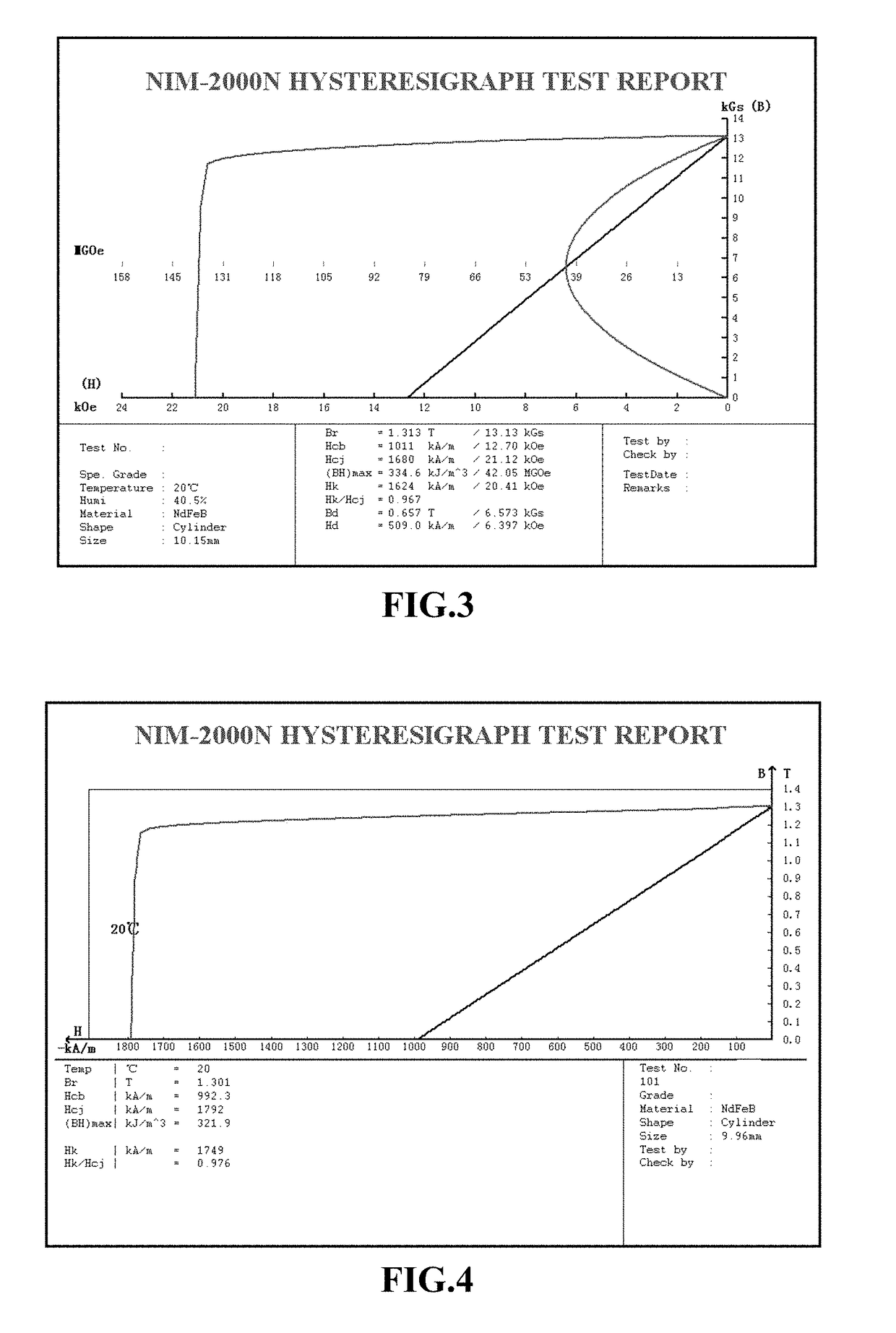

Sintered magnet composition without heavy rare earth element and a method of making the sintered magnet

ActiveUS20170213627A1Improve magnetic propertiesReduce material costsTransportation and packagingMetal-working apparatusRare-earth elementNitrogen

A method of making a rare earth magnet containing zero heavy rare earth elements includes a step of mixing the fine grain power with the lubricant having a weight content of at least 0.03 wt. % and no greater than 0.2 wt. % for a period of between 1 and 2 hours. The step of pulverizing is further defined as jet milling the alloy powder with the lubricant using a carrier gas of argon or nitrogen. The method further includes a step of controlling oxygen content during the steps of melting, forming, disintegrating, mixing, pulverizing, molding, and sintering whereby the impurities including Carbon (C), Oxygen (O), and Nitrogen (N) satisfies 1.2C+0.6O+N≦2800 ppm. A rare earth magnet composition including C, O, and N whereby C, O, and N satisfies 1.2C+0.6O+N≦2800 ppm and has zero heavy rare earth elements.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

Light weight thermal insulation dry-mixed mortar

The invention relates to a light weight thermal insulation dry-mixed mortar, which comprises following raw materials in parts by weight: 20 to 40 parts of cementing material, 60 to 80 parts of light weight aggregate, and 0.5 to 1.5 parts of high performance polymer additive; wherein the cementing material comprises following raw materials in parts by weight: 20 to 40 parts of fly ash and 60 to 80parts of cement; the light weight aggregate is pitchstone vitrified micro beads; and the high performance polymer additive comprises following raw materials: organic silicone resin, hydroxypropyl methyl cellulose ether, VAE dry powder, polycarboxylic acid water reducer dry powder, and an early strength agent. The light weight thermal insulation dry-mixed mortar has the advantages of light weight,thermal insulation property, good fireproof performance, good caking property, good bleeding resistance, aging resistant property, green, environmental friendliness, resistance to biological biting, prolonged service life, high strength, high flexibility, and strong cracking resistant performance.

Owner:福建三凯建筑材料有限公司

Aluminum-containing ferroalloy for steelmaking deoxidizing

The invention discloses a deoxidizing agent for steelmaking, which contains 40% to 70% of aluminum, 0.5% to 20% of tungsten and / or molybdenum, the remaining are iron and unavoidable impurity. The alloy solves the problem of easy pulverization of current aluminum matrix complex deoxidizer.

Owner:谢应凯

Glass bead wall thermal insulation material with good fireproof performance

The invention discloses a glass bead wall thermal insulation material with good fireproof performance in the field of building materials. The glass bead wall thermal insulation material with good fireproof performance comprises 100-150 parts of glass beads, 30-50 parts of talcum powder, 30-60 parts of cement, 30-60 parts of sodium silicate, 1-10 parts of curing agent, 1-10 parts of water repellentand 1-10 parts of penetrating agent. The glass bead wall thermal insulation material with good fireproof performance has the advantages of being high in density, high in compressive strength, low inheat conduction coefficient, good in heat preservation effect and the like, the fireproof grade is grade A, and the material is a fireproof thermal insulation material with excellent comprehensive performance.

Owner:四川方壹特建筑工程有限公司

Modified ammonium sulfate

InactiveCN105175098AHigh mechanical strengthReduce thermal decomposition and volatilizationFertilizer mixturesAmmonium sulfateChemistry

The present invention discloses modified ammonium sulfate which is prepared from ammonium sulfate, bentonite, paraffin, and 3,4-dimethylpyrazole phosphate. According to the present invention, the modified ammonium sulfate has higher mechanical strength, reduces caking and powdering, reduces ammonia volatilization, increases a utilization rate after application in farmlands and solves the problem that common ammonium sulfate produces irritating odour after been heated in storage and in use.

Owner:魏占波

CO shift catalyst carrier, catalyst based on the catalyst carrier and preparation process thereof

ActiveUS10525450B2Improve mobilityLow melting pointHydrogenCatalyst activation/preparationAluminum IonPtru catalyst

The present invention provides a catalyst carrier with shift and adsorption purification performance, comprising modified bauxite in the raw material components which fluxing and pore forming effects. Most iron oxide contained in the bauxite is removed after modification, so that there are a large amount of highly active aluminosilicate compounds in the modified bauxite. When preparing the catalyst, the aluminosilicate compound serves as a low melting point flux and can significantly increase the migration rate of magnesium and aluminum ions during the calcinating process and promote the generation of MgAl2O4 at low temperatures, thereby the catalyst carrier of the present invention has strong anti-hydration capacity and mechanical strength. In addition, when the modified bauxite is used as macroporous hard template for the preparation of the catalyst, macro pores can be formed in the structure of the catalyst carrier after calcinating treatment, so that the catalyst carrier of the present invention has strong adsorption purification ability on macromolecular particles including oil pollution and dust.

Owner:FUJIAN PROVINCE SINOGASHOLDER EQUIP INSTALLATION CO LTD

A kind of modified ammonium bicarbonate

ActiveCN105000995BHigh mechanical strengthExtend the fertilizer periodFertilizer mixturesSodium bicarbonatePhosphate

The invention discloses a modified ammonium bicarbonate, which is made of ammonium bicarbonate, bentonite, paraffin, and 3,4-dimethylpyrazole phosphate. The modified ammonium bicarbonate particles have strong mechanical strength, reduce the volatilization of ammonia, improve the utilization rate after being applied to farmland, and solve the problem of pungent odor in storage and use of common ammonium bicarbonate.

Owner:魏占波

Adsorption material for adsorption air dryer and combined adsorption method

ActiveCN104084123BSolve the adsorption problemSolve easy pulverizationAluminium silicatesDispersed particle separationMolecular sieveAluminium oxide

The invention discloses an adsorption material applicable to an adsorption type air dryer and a combined adsorption method of the adsorption material. The absorption material is formed by aluminum oxide and molecular sieves with different particle diameters in a sectional combining manner so as to form a composite absorption material combination body, wherein the aluminum oxide comprises two types of absorption particles with particle diameters being phi3 to phi5mm or phi5 to phi8mm; the molecular sieves also comprise two types of absorption particles with the particle diameters being phi3 to phi5mm or phi5 to phi8mm; the aluminum oxide and the molecular sieves with the different particle diameters are staggered, layered and packed in an absorption cylinder of the absorption type air dryer and combined to form a composite absorption material combination body; compressed air output by the absorption type air dryer is absorbed by the composite absorption material combination body which is combined and formed by the aluminum oxide and the molecular sieves with the different particle diameters.

Owner:ZHUZHOU YIXING TECH CO LTD

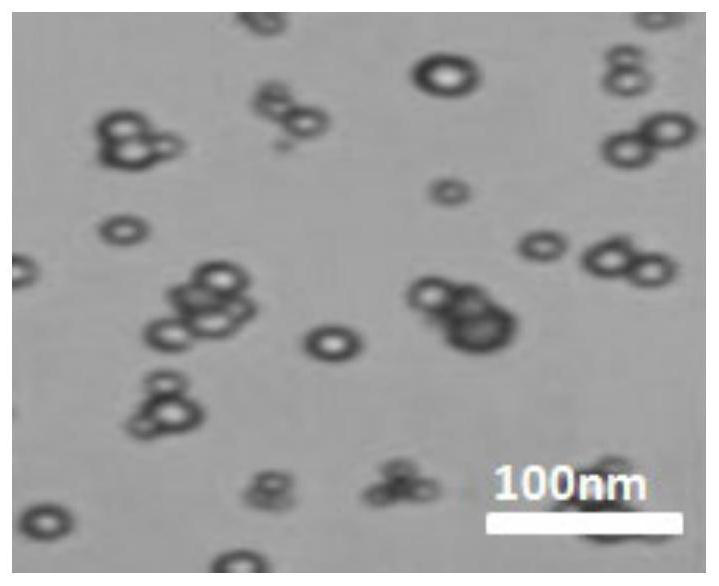

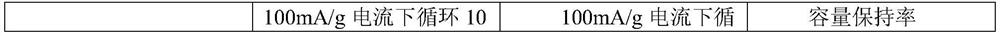

Lithium ion battery

ActiveCN114221024ALarge specific surface areaFacilitates a high degree of load distributionMaterial nanotechnologySecondary cellsHexamethylenetetraminePotassium manganate

The invention relates to a lithium ion battery, which is characterized in that Y-CoFe2O4 / gamma-MnO2 is adopted as a negative electrode material, and a preparation process of the lithium ion battery comprises the following steps: dissolving cobalt nitrate, ferric nitrate and yttrium acetate in deionized water, then adding hexamethylenetetramine and urea, uniformly stirring, putting the mixed solution into a high-pressure hydrothermal reaction kettle, carrying out hydrothermal reaction at the temperature of 180-200 DEG C, filtering, washing, and drying to obtain the lithium ion battery. The reaction time is 10 to 20 hours; the Y-doped CoFe2O4 in the nanometer spherical shape is obtained; and alternately washing the Y-doped CoFe2O4 with deionized water and ethanol, dissolving the Y-doped CoFe2O4 in ethylene glycol to form a suspension, adding potassium permanganate and glycine into the suspension, carrying out heating reflux at 90-100 DEG C for 12-20 h, and calcining the product at 200-400 DEG C for 30-60 min to obtain the nano core-shell spherical Y-doped CoFe2O4 / gamma-MnO2.

Owner:广东顺盈森能源有限公司

Nano-silica airgel/vitrified microbeads composite thermal insulation mortar

InactiveCN102910870BGood weather resistanceImprove thermal insulationEnvironmental resistanceCellulose

The invention discloses nano-silicon aerogel / vitrified microball composite thermal-insulation mortar, which consists of the following raw materials by weight parts: 70-80 parts of silicate cement, 15-20 parts of modified fly ash, 10-20 parts of modified diatomaceous earth, 10-15 parts of coarse whiting, 10-20 parts of nano-silicon aerogel, 10-20 parts of vitrified microballs, 0.5-1 part of redispersible latex powder, 0.5-1 part of cellulose ether, 0.2-0.3 parts of wood fibers and 0.1-0.2 parts of polyimide fibers. The thermal-insulation mortar prepared in the invention has the advantages that the thermal-insulation property, the fire resistance and the construction performance are excellent, the intensity is high, the weather resistance is good, the mortar is environmentally friendly, etc. The mortar is especially suitable for the composite thermal insulation of inner and outer wall bodies in various brick-concrete structures, frame structures and shear wall structures and for the fire proofing and the thermal insulation of public facilities such as basements, garages, fire fighting accesses and has great market space and development prospect in the construction energy-saving application field.

Owner:池州市崇源节能建筑材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com