Lithium ion battery

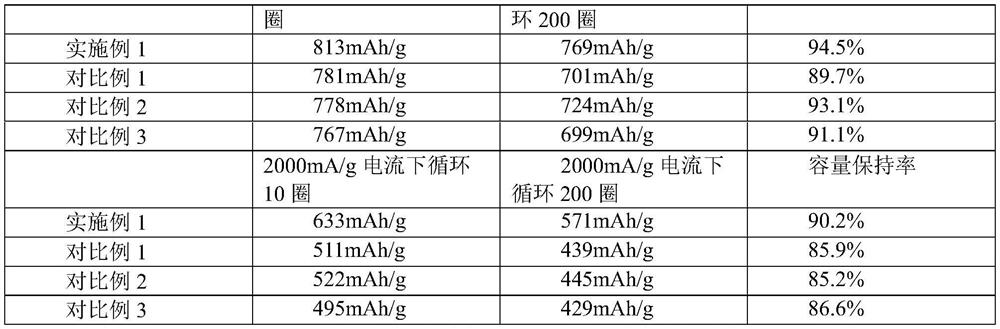

A lithium-ion battery, cobalt nitrate technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems affecting the rate and cycle performance, volume expansion/shrinkage, powdering of electrode materials, etc., to improve cycle performance and stability performance, improve the transmission speed, and facilitate the effect of load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

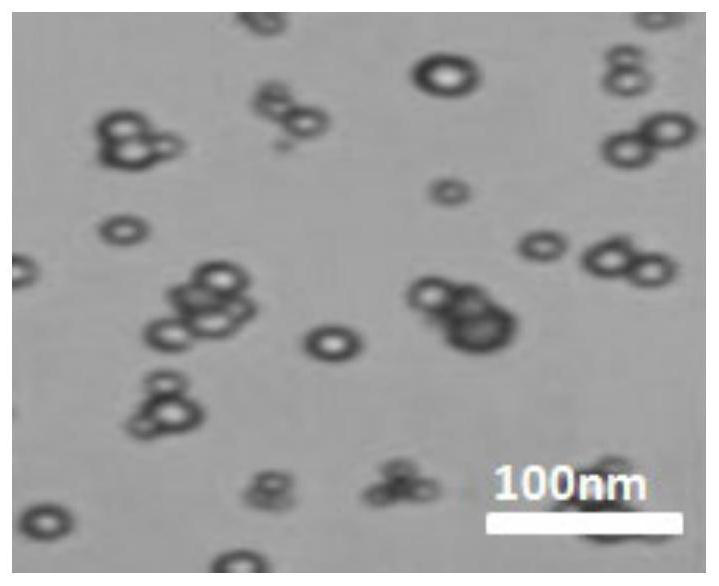

[0014] Dissolve 10mmol of cobalt nitrate, 20mmol of ferric nitrate and 0.5mmol of yttrium acetate in 20ml of deionized water, then add 3mmol of hexamethylenetetramine and 8mmol of urea, stir well, and place the mixture in a high-pressure hydrothermal reaction kettle for Hydrothermal reaction, the temperature is 180 degrees Celsius, the reaction time is 10h; hollow nano-spherical Y-doped CoFe 2 o 4 ;

[0015] Y-doped CoFe 2 o 4 Wash with deionized water and ethanol alternately, then dissolve in 20ml of ethylene glycol to form a suspension, add 3mmol potassium permanganate and 1mmol glycine to the suspension, heat and reflux at 100°C for 12h, and calcinate the product at 250°C for 30min, Thus, nano-core-shell spherical Y-doped CoFe 2 o 4 / γ-MnO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com