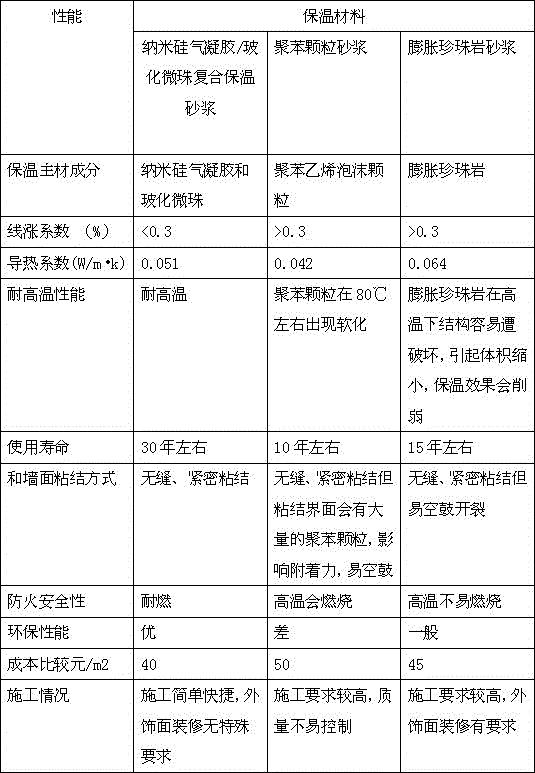

Nano-silica airgel/vitrified microbeads composite thermal insulation mortar

A technology of nano-silicon aerogel and composite thermal insulation mortar, applied in the field of building materials, can solve the problems of low strength, unsafe, increased thickness, etc., and achieve the effects of good weather resistance, excellent thermal insulation and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] A nano-silica airgel / vitrified microbead composite thermal insulation mortar, which is composed of the following raw materials in parts by weight: 80 parts of Portland cement, 15 parts of modified fly ash, 15 parts of modified diatomite, and 12 parts of heavy calcium Parts, 20 parts of nano-silica airgel, 2 parts of vitrified microbeads 0, 1 part of redispersible latex powder, 1 part of cellulose ether, 0.3 part of wood fiber, and 0.2 part of polyimide fiber.

[0018] The modified diatomite is prepared by the following method: first calcinate the diatomite at 700°C for 3 hours, then grind it into a 200-mesh powder, mix in quartz sand nano-powder equivalent to 10% of the powder weight, 10% Plant straw powder and 3% titanate coupling agent TMC-TTS are stirred evenly, dispersed at high speed for 20 minutes, dried, and crushed into powder.

[0019] The particle size of the vitrified microbeads is 0.5mm, and the particle size of the nano silicon airgel is 3nm.

[0020] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com