Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Short sintering cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of medical porous titanium and titanium alloy

InactiveCN102747245AImprove efficiencyGood mechanical propertiesProsthesisThermal insulationRepair material

The invention discloses a preparation method of medical porous titanium and titanium alloy, which comprises the following steps: proportionally preparing titanium powder, alloy element powder and pore forming agent powder according to needs; carrying out ball milling, mixing and mechanical pressing by a powder metallurgy blank making technique to obtain a blank; putting the blank in a thermal insulation barrel, and putting the thermal insulation barrel into a microwave sintering furnace; and after vacuumizing the furnace chamber to a vacuum degree of 0.1Pa, charging argon with the purity of 99.999% to form cyclic protection, controlling the output power of the microwave sintering furnace at 0.5-3kW, heating to the sintering temperature of 800-1200 DEG C at the heating rate of 5-40 DEG C / minute, keeping the temperature for 5-30 minutes, shutting down the microwave source, and carrying out furnace cooling to obtain the medical porous titanium and titanium alloy. The invention has the advantages of simple preparation method, short sintering period, high efficiency, low sintering temperature and low energy consumption; and the sintered porous titanium and titanium alloy have excellent mechanical properties, and can be used as alternate repair material for bones, joints, artificial radix dentis and other hard tissues.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

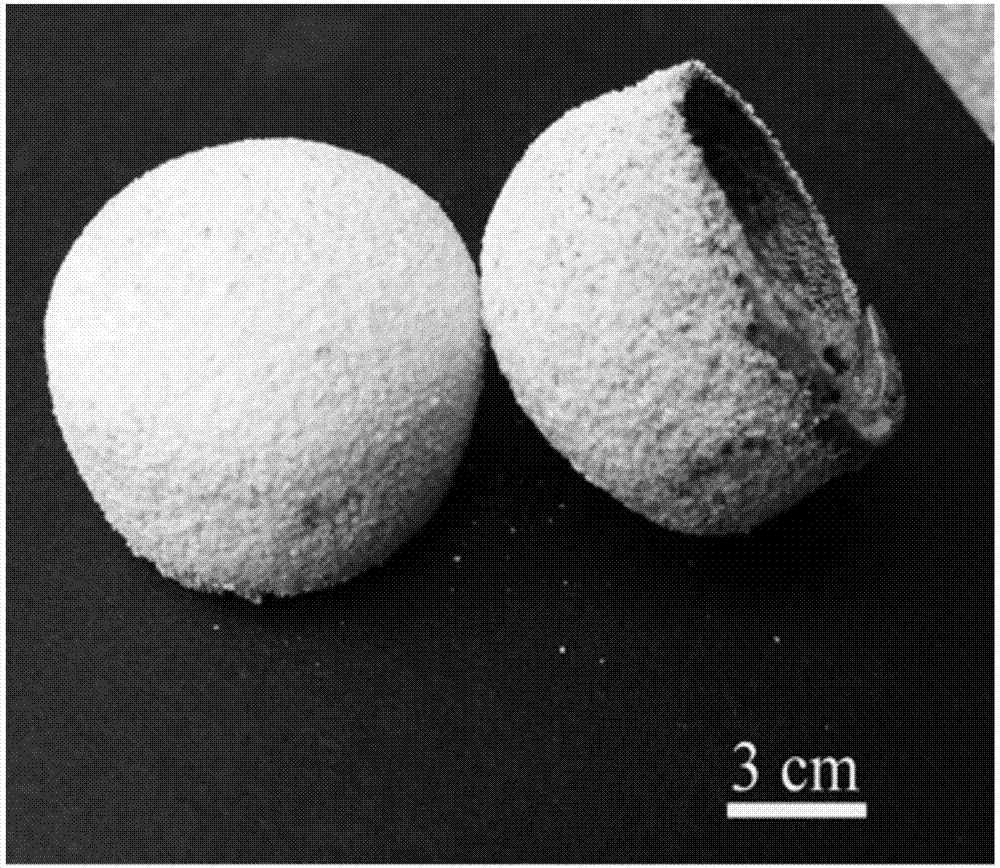

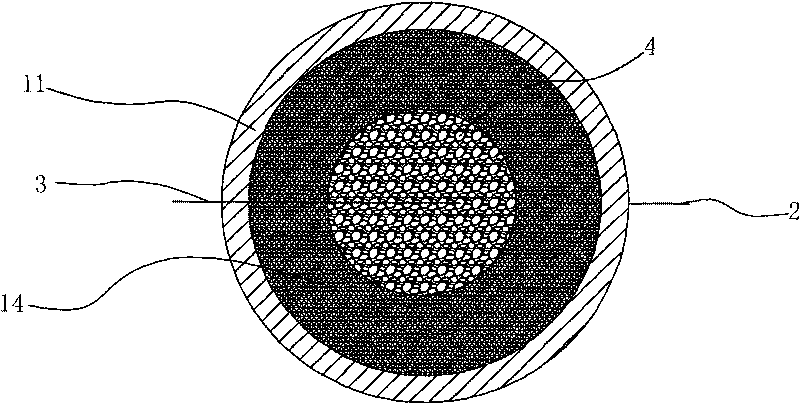

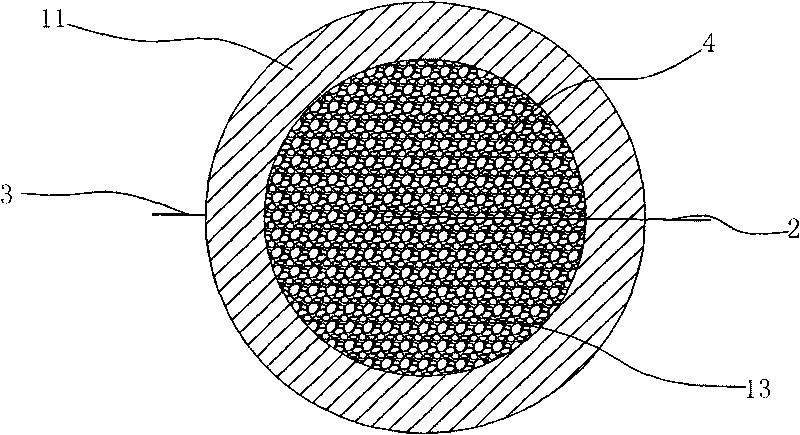

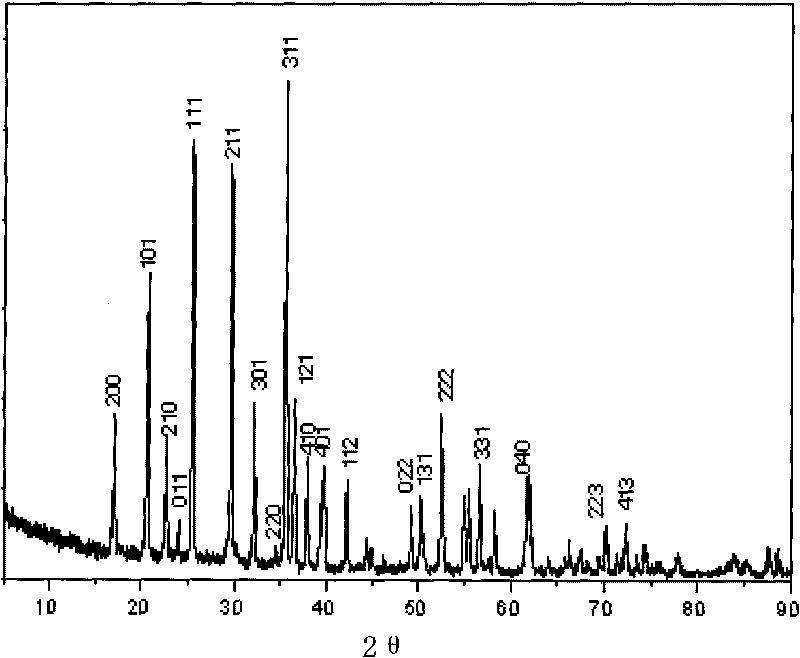

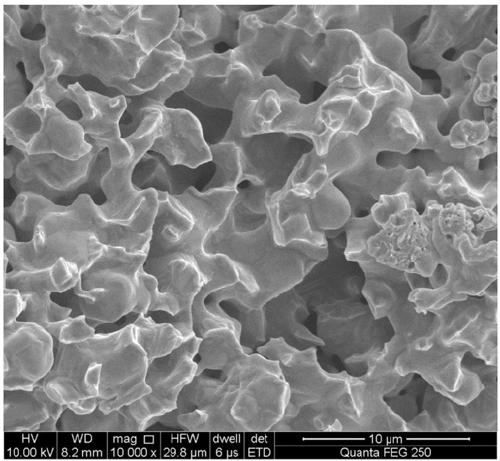

Method for preparing medical porous NiTi shape memory alloy by microwave sintering

The invention relates to a method for preparing a medical porous NiTi shape memory alloy by microwave sintering. The method comprises the following steps of: (1) compounding powder: compounding titanium powder, nickel powder and pore-forming agent powder according to certain mass percentage; (2) performing ball milling: putting the compounded powder body into a stainless steel ball milling pot for ball milling; (3) pressing billets: performing mold pressing on the powder materials after the ball milling at the pressure of between 50 and 500 MPa into pressed billets; (4) charging in a furnace:putting the obtained pressed billets and a microwave auxiliary heating material into a polycrystalline mullite fiber heat insulation barrel, and putting the heat insulation barrel into a microwave sintering furnace; and (5) performing microwave sintering. The method has the advantages that: the preparation method is simple and convenient, the sintering cycle is short, the energy consumption is low, the method is suitable for industrialized production, the porous NiTi shape memory alloy obtained by sintering has good mechanical properties, a pore structure is in three-dimensional communication, the pore ratio is controllable between 20 and 80 percent, the pore sizes are uniform and are controllable between 30 and 600 mu m, and the medical porous NiTi shape memory alloy can be used as materials for repairing and replacing hard tissues such as bones, joints, artificial tooth roots and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

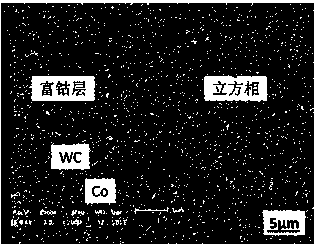

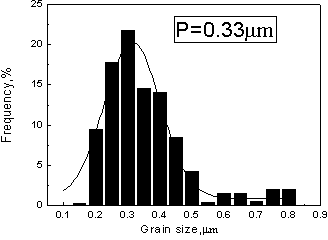

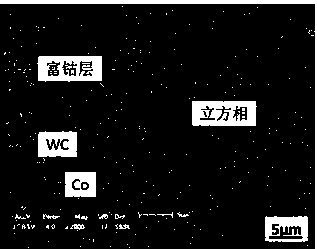

Ultra-fine crystal gradient alloy with rich-cobalt surface and preparation method thereof

The invention belongs to the field of hard alloy preparation, and in particular relates to an ultra-fine crystal gradient alloy with a rich-cobalt surface and a preparation method of the alloy. According to the ultra-fine crystal gradient alloy with the rich-cobalt surface, a gradient layer with the rich-cobalt surface, which is 10-40mu m thick, is formed by taking WC (Wolfram Carbide) and cubic phase carbonitride as a core part hard phase and cobalt as the binding phase, wherein the average size of the crystal particles of WC in the hard phase and the gradient layer is 0.2-0.4mu m, the content of cobalt in the gradient layer with the rich-cobalt surface is 1.2-2 times of the standard content of cobalt of hard alloys, and the gradient layer with the rich-cobalt surface is free of the cubic phase carbonitride. The preparation method comprises the following steps: firstly, preparing the materials, wet-grinding and pressing into a material blank, and supplying an inert gas with the pressure of 5-10MPa before reaching a liquid phase sintering temperature, wherein the liquid phase sintering temperature is 1,350-1,500 DEG C. By charging the gas with certain pressure in the liquid phase sintering period, the ultra-fine crystal gradient alloy with the rich-cobalt surface is prepared, the WC crystal grains are refined, a rich-cobalt surface layer of certain thickness is obtained, the sintering period is shortened, and the production cost is lowered.

Owner:NORTHEASTERN UNIV LIAONING

Method for preparing WC-Co cemented carbide through microwave sintering

The invention provides a method for preparing WC-Co cemented carbide through microwave sintering. The method comprises the steps of WC powder and Co powder batching and mixing, compacting and sintering, wherein in the step of sintering, compacts, SiC chips, carbon black and alumina powder are put in an alumina fiber insulating bag sleeve and then the alumina fiber insulating bag sleeve is put in a microwave high temperature furnace, the products in the furnace are heated to 500-600 DEG C at a heating speed of 5-10 DEG C / min and the heat is preserved and then the products are heated to 1400-1500 DEG C at a heating speed of 30-80 DEG C / min and the heat is preserved, thus obtaining the WC-Co cemented carbide. The method has the advantages of simple process, convenience in operation, short sintering period and low energy consumption, can replace the existing WC-Co cemented carbide processes, is used for producing the WC-Co cemented carbide by adopting the intermittent or continuous microwave sintering mode and is suitable for industrial application. The prepared WC-Co cemented carbide has excellent performances.

Owner:CENT SOUTH UNIV

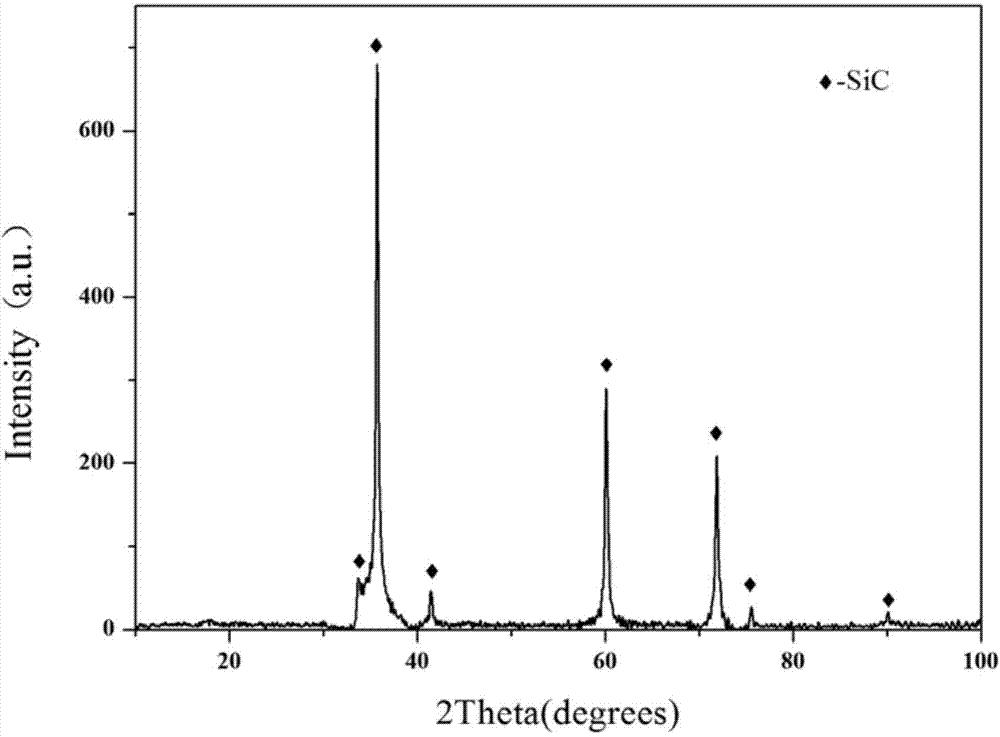

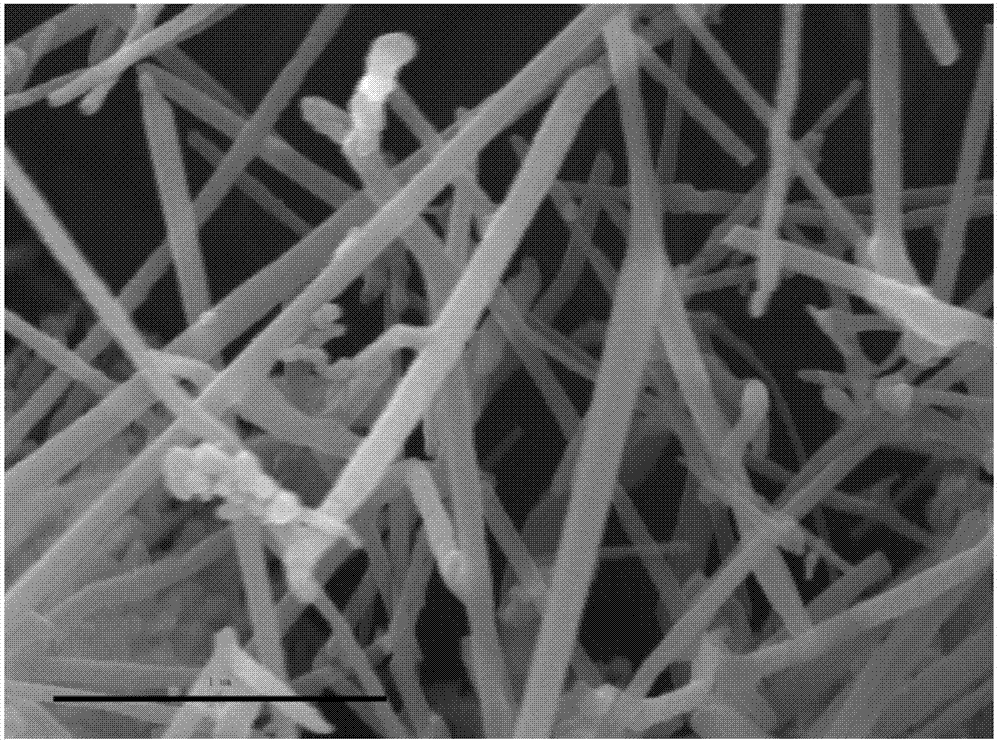

Preparation method of SiC crystal whisker

ActiveCN104328478AShort sintering cycleUniform sizePolycrystalline material growthFrom solid stateDielectric lossCarbon source

The invention discloses a preparation method of SiC crystal whiskers. The preparation method includes following steps: (1) preparing a precursor from a carbon source and a silicon source; and (2) pressing the precursor into chips, embedding the chips in quartz sand and performing a sintering synthetic reaction with microwave to obtain the SiC crystal whisker. In the preparation method, quick synthesis of the SiC crystal whisker is achieved in a manner of direct synthesis through the microwave by means of an excellent wave-absorption performance of carbon to obtain the SiC crystal whisker in which crystallization is excellent. In a microwave sintering method, a material is sintered on the basis of dielectric loss of the material itself. Compared with an industrially conventional heating method, the microwave sintering method can achieve volume heating, is less in pollution, is short in sintering period and is low in energy consumption. The SiC crystal whisker is uniform in size, is high in length-diameter ratio, is good in crystallization degree, is less in defect and is high in yield. The method is simple in technology, is convenient to operate, is short in production period, is low in sintering temperature and energy consumption, is less in pollution, is suitable for large-scale industrialized production and has a wide application prospect.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Preparation method of (TiV)C steel bond hard alloy

The invention provides a preparation method of (TiV)C steel bond hard alloy. Titanium and vanadium whose ratio is 1:1 are prepared, and a mixture and graphite powder are prepared into in-situ synthesized (TiV)C mixed powder, wherein the atomic mole ratio between C and Ti+V is 0.7-1.1; ferrovanadium powder, ferrochromium powder, ferromolybdenum powder, ferroboron powder, ferrous powder, ferrosilicon powder, ferromanganese powder, nickel powder, copper powder, colloidal graphite and a rare earth raw material are prepared according to a required mass ratio of bonded-phase metal chemical components, ball-milling is carried out by a steel ball, absolute ethanol as a medium and PVA (polyvinyl alcohol) are added, after the ball-milling is finished, slurry is dried and pressed for forming, and the steel bond alloy is obtained. In situ reaction synthesis technology and liquid phase sintering technology are combined, and the (TiV)C steel bond hard alloy is prepared. (TiV)C is synthesized in situ in a substrate through reaction in the sintering process, the fineness of particles is improved, no sharp angle is formed on the surface, and a substrate interface is relatively good in adhesion and clean. The comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Preparation method of modified high-manganese steel base TiC steel bonded carbide

The invention relates to a preparation method of modified high-manganese steel base TiC steel bonded carbide. The preparation method is characterized by preparing in-situ synthesized TiC powder in a required proportion from titanium powder and graphite powder according to the atomic ratio of C to Ti, namely 0.8-1.0; preparing the raw materials including ferromolybdenum powder, ferrovanadium powder, ferrochrome powder, ferromanganese powder, ferrosilicon powder, ferrum powder, nickel powder, colloidal graphite and rare earth according to a required proportion of mass ratios of chemical components of bonding phase metals, filling steel balls, performing ball milling, adding absolute ethyl alcohol used as a medium and PVA (polyvinyl alcohol) to the steel balls, drying the slurry after ball milling, and then forming the slurry by pressing and sintering the product, thus obtaining steel bonded carbide. The preparation method has the advantages that the modified high-manganese steel base TiC steel bonded carbide is prepared by combining an in-situ reactive synthesis technology and a liquid phase sintering technology; as TiC is synthesized in situ inside a matrix through reaction in the sintering process, the reinforced particles have small sizes and do not have sharp corners on the surfaces, and the matrix is better in interface bonding and has a clean interface; the preparation method of steel bonded carbide is conductive to improving the comprehensive mechanical properties of carbide, is low in price and is simple and convenient in process.

Owner:JIANGSU HUICHENG MACHINERY MFG

Preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy

The invention relates to a preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy. The preparation method is characterized by comprising the following steps: preparing titanium powder and graphite powder into in-situ synthesized TiC powder with the required proportion according to the C / Ti atomic ratio of 0.8-1.0; preparing ferromolybdenum powder, ferrovanadium powder, ferrochromium powder, ferromanganese powder, ferrosilicon powder, iron powder, nickel powder, colloidal graphite and rare earth raw materials according to the required mass ratio of bonded-phase metal chemical components, performing ball-milling by a steel ball, adding absolute ethanol as a medium and PVA (polyvinyl alcohol), after the ball-milling process is finished, drying slurry, pressing for forming, and sintering to obtain the steel bond alloy. According to the preparation method, the ultrahigh-manganese steel based TiC steel bond hard alloy is prepared by combining an in-situ reaction synthesis technology with a liquid-phase sintering technology; as TiC is synthesized in situ in a substrate through reaction in the sintering process, the fineness of particles is improved, no sharp angle is formed on the surface, and a substrate interface is relatively good in adhesion and clean; the comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

High-performance niobium oxide target material and preparation method thereof

ActiveCN103572236AImprove conductivityUniform densityVacuum evaporation coatingSputtering coatingVolumetric Mass DensityMaterials science

The invention relates to a high-performance niobium oxide target material, which is prepared from the following raw materials in percentage by mass: 89-98.8% of niobium oxide powder, 0.2-1% of activator carbon powder, and 1-10% of a reductant, wherein the reductant is selected from niobium powder or tantalum powder. The invention also provides a preparation method of the niobium oxide target material. The high-performance niobium oxide target material and preparation method thereof disclosed by the invention have the following advantages that (1) the preparation method is high in efficiency: the sintering cycle of the target material is short, only 10-15 hours; and (2) the target optimal is good in performance: the density is high, and can reach more than 99.95% of the relative density; the electrical conductivity is good, and the electrical resistivity is 3*10<-3>-9*10<-3> omega.cm; the target material is uniform in compactness, and has no pit.

Owner:河北东同光电科技有限公司

Preparation method of TiC high-wear-resistant steel-bonded hard alloy

The invention relates to a preparation method of a TiC high-wear-resistant steel-bonded hard alloy. The preparation method is characterized by comprising the following steps: using titanium powder and graphite powder to prepare in-situ synthesized TiC powder according to the atomic ratio 0.7-1.1 of C to Ti; mixing ferrochromium powder, ferromolybdenum powder, ferrovanadium powder, ferrotungsten powder, ferroniobium powder, nickel powder, ferroboron powder, iron powder, colloidal graphite and a rare earth material according to the chemical component mass ratio of the bonding phase metals; filling the mixed powder in a steel ball mill; adding absolute ethyl alcohol as a medium and PVA (Polyvinyl Acetate) to the ball mill; after ball milling, drying the obtained slurry, pressing, molding and sintering the dried substance to obtain the steel-bonded hard alloy. The preparation method disclosed by the invention combines the in-situ reaction synthesis technology with the liquid-phase sintering technology to prepare the TiC high-wear-resistant steel bonded hard alloy. As TiC is prepared by in-situ synthesis inside the substrate through the reaction during the sintering process, the reinforced particle size is fine, the surface is free of sharp corners, the substrate interface bonding effect is good, and the interface is clean. The preparation method for the steel-bonded alloy can improve the comprehensive mechanical property of the alloy, and is low in price and simple and convenient in the technology.

Owner:JIANGSU HUICHENG MACHINERY MFG

Preparation method of large-size and fine-grain molybdenum tantalum alloy sputtering target material

ActiveCN105714253AEvenly distributedAvoid defectsVacuum evaporation coatingSputtering coatingSputteringLarge size

A preparation method of a large-size and fine-grain molybdenum tantalum alloy sputtering target material comprises steps of cold isostatic pressing molding through combination of a steel mold with a rubber plate, sintering, levelling and reshaping, hot isostatic pressing treatment, rolling and machining. The grain size of the produced target material is smaller than 50 microns, the change of the grain size is maintained within 20%, and grains are evenly distributed in the plane direction and the thickness direction of the target material; the relative density of the target material is higher than 97%; besides, the large-size sputtering target material with the length being about 2 m and the width being about 1.3 m can be produced.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

Preparation method of diamond/copper composite high in heat conduction performance

ActiveCN107916356AImprove protectionSimple separation processTransportation and packagingMetal-working apparatusPowder mixtureRoom temperature

The invention discloses a preparation method of a diamond / copper composite high in heat conduction performance. The preparation method comprises the following steps of 1, uniformly mixing diamond obtained after surface of the diamond is subjected to degreasing and roughening treatment with tungsten powder according to the mass ratio of 1: 4.5, heating a powder mixture under the vacuum condition, conducting heat preservation for 2-8 hours at the temperature of 1030 DEG C, and finally, separating out modified tungsten-plated diamond, wherein the vacuum degree is 10<-2>-10<-4> Pa, and the temperature rising rate is 5 DEG C / min; and 2, uniformly mixing the tungsten-plated diamond, with the mean particle size being 125 microns, obtained after surface modification with copper powder with the mean particle size being 45 microns with the total volume content of the tungsten-plated diamond accounting for 55%, sintering an obtained powder mixture, and then cooling the obtained power mixture to the room temperature, so that the diamond / copper composite is obtained, wherein the sintering parameters are that the pressing pressure is 40 MPa, the temperature is 1000 DEG C, the temperature risingrate is 100 DEG C / min, the sintering time is 10 minutes, and the atmosphere is vacuum.

Owner:ZHENGZHOU UNIV

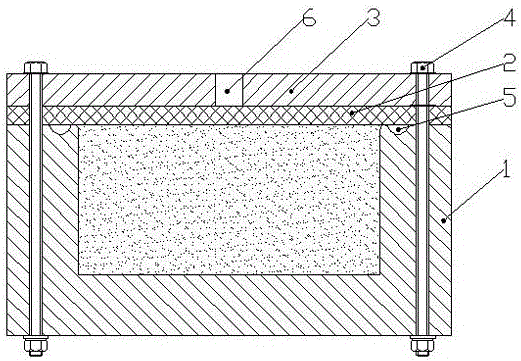

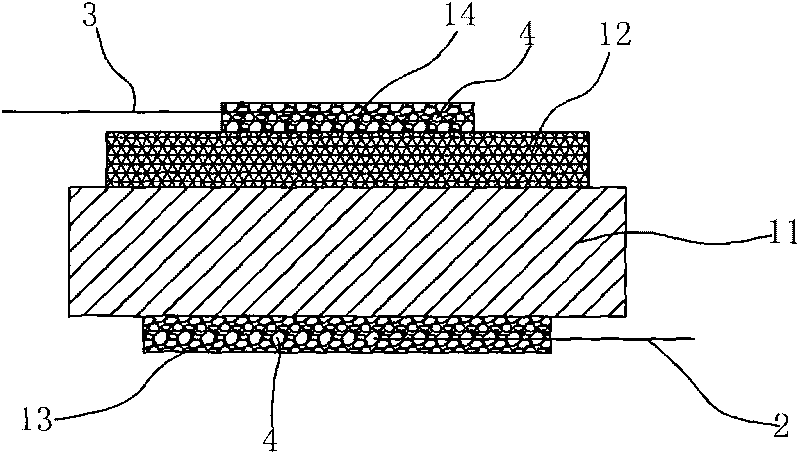

All-solid mixed-potential NOx sensor and preparation method thereof

InactiveCN101706470ASolve the peeling problemStable working signalMaterial analysis by electric/magnetic meansScreen printingRepeatability

The invention discloses an all-solid mixed-potential NOx sensor prepared on the basis of spark plasma sintering technology. The NOx sensor consists of an electrolyte layer, a sensing electrode layer, a reference electrode and a working electrode, wherein the multilayer composite consisting of the electrolyte layer and the sensing electrode layer is directly sintered by the spark plasma sintering technology; and the reference electrode layer and the working electrode layer, which have screen pores, are directly printed in the centers of the upper and lower surfaces of the composite by screen printing. As the NOx sensor is manufactured by the spark plasma sintering technology, the sensing electrode layer and the electrolyte layer of the sensor are well combined without problems of flying up, cracking and the like and have the characteristics of good repeatability, stable performance, simple manufacturing process, short manufacturing period, small volume, quick response and the like. The NOx sensor of the invention can detect NOx concentration ranging from 1 to 75 percent and give a response within 2 minutes and is suitable for the detection of the NOx concentration in a wide range.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for preparing W-Cu alloy in microwave infiltration way

The invention relates to a method for preparing W-Cu alloy in a microwave infiltration way, which comprises the following steps: 1. dispensing W powder and reduced Cu powder according to the weight percentage of W-3Cu, then ball-milling and mixing; 2. fetching the mixed powder and electrolytic copper powder according to design components, and respectively pressing the mixed powder under the pressure of 150-510MPa to form a cylindrical W framework and an infiltrated Cu pressed billet; 3. putting the pressed cylindrical W framework, the infiltrated Cu pressed billet and SiC slices into an alumina fiber heat-preserving sheath and then putting the sheath into an oven chamber of a microwave high-temperature oven, and vacuumizing the oven chamber to the vacuum degree within 100Pa by a vacuum pump; 4. injecting mixed protection gases of N2 and H2 into the oven chamber of the microwave oven, regulating the output power of the microwave high-temperature oven, heating to about 1350 DEG C at a temperature-rise speed of about 30 DEG C / min, preserving the heat, powering the microwave oven off and cooling to obtain the ideal alloy. The invention has simple process, convenient operation, short sintering period, low energy consumption and excellent performance of the obtained W-Cu alloy and can substitute for the prior process for preparing the W-Cu alloy in an infiltration way.

Owner:CENT SOUTH UNIV

Method for synthesizing lithium ferrous phosphate in solution

InactiveCN101696001AAvoid impuritiesReduce manufacturing costCell electrodesPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a method for synthesizing lithium ferrous phosphate in a solution, which relates to an anode material of a lithium ion battery, and the method belongs to the technical field of chemical material preparation. The method comprises the following steps: reacting phosphoric acid, iron trioxide with reduced iron powder at a certain temperature, adding a lithium source and a carbon source, continuing the reaction to obtain a mixing solution, and filtering, drying and calcining the mixing solution to obtain the lithium ferrous phosphate. Compared with a synthetic method of using the reduced iron powder as an iron source, the method adopts the iron trioxide as most of iron sources so as to reduce the cost of raw materials greatly; the obtained product is uniform in component and good in batch stability, and the synthesized lithium ferrous phosphate material serving as the anode material of the lithium ion battery has the excellent electrochemistry performance; 3C multiplying power discharging specific capacity is more than 130mAh / g at room temperature; the synthesized lithium ferrous phosphate material is suitable for being used as power lithium ion batteries; and the method has short sintering period, simple production process, less energy consumption and no pollution, such as tail gas and waste liquor, and is suitable for mass industrial production.

Owner:TSINGHUA UNIV

Method for preparing W-Ni-Fe high-density alloy in microwave sintering way

The invention relates to a method for preparing W-Ni-Fe high-density alloy in a microwave sintering way, which comprises the following steps: 1. dispensing reduced W powder, carbonyl Ni powder and carbonyl Fe powder according to the weight percentage, then ball-milling and mixing; 2. mould-pressing the mixed powder materials under the pressure of 300-400MPa to form a pressed billet; 3. putting the pressed billet and auxiliary heating materials of SiC slices into an alumina fiber heat-preserving sheath and then putting the sheath into an oven chamber of a microwave high-temperature oven, and vacuumizing the oven chamber to the vacuum degree within 100Pa by a vacuum pump; 4. injecting mixed protection gases of N2 and H2 into the oven chamber of the microwave oven, controlling the temperature-rise speed to be 75-85 DEG C / min, heating to 1480-1500 DEG C, preserving the heat, powering the microwave oven off, and cooling to obtain the ideal alloy. The invention has simple process, convenient operation, short sintering period, low energy consumption, excellent performance as well as high compactness, fine crystal grains and even tissues of the obtained W-Ni-Fe high-density alloy, is suitable for industrial production and can substitute for the prior sintering process of the W-Ni-Fe high-density alloy.

Owner:CENT SOUTH UNIV

Preparing method for high-toughness and heat resisting TiC/TiN steel bond hard alloy

The invention relates to a preparing method for a high-toughness and heat resisting TiC / TiN steel bond hard alloy. The preparing method is characterized that one of TiO2 powder, TiH2 powder and Ti powder and colloidal graphite powder are prepared according to the C / Ti atomic ratio of 0.7-1.1, one of the TiO2 powder, the TiH2 powder and the Ti powder and urea ((NH2)2CO) are prepared according to the N / Ti atomic ratio of 0.4-1.1, and accordingly in-situ synthesized TiN mixed powder is prepared; ferro-molybdenum powder, ferro-vanadium powder, ferro-chromium powder, ferro-manganese powder, ferro-silicon powder, iron powder, ferro-boron powder, nickel powder, colloidal graphite and rare earth raw materials are prepared according to the needed proportion for the bonding phase metal chemical component mass ratio to be arranged into a steel ball mill, absolute ethyl alcohol serving as a medium and PVA are added, after ball milling and slurry drying, pressing forming is conducted, and the steel bond alloy is obtained through sintering. The in-situ reaction synthesizing technology and the liquid phase sintering technology are combined, reinforced particles are fine in size, the surfaces are free of sharp corners, base body interface bonding is good, and the interface is clean. Through the method for preparing the steel bond alloy, the comprehensive mechanical performance of the alloy can be improved, cost is low, and the technology is easy and convenient to conduct.

Owner:JIANGSU HUICHENG MACHINERY MFG

Hard alloy sintering process and degumming and vacuum sintering integrated furnace

InactiveCN101596596AAvoid the disadvantage of easy oxidationImprove sintering qualityMuffle furnacesRetort furnacesProduct gasVacuum pump

A hard alloy sintering process comprises the following steps: filling moulded workpiece in a sintering chamber, starting vacuum pump to vacuumize and starting glue pump, raising temperature to 330 to 350 DEG C, making adhesive gasify, at the same time, pumping the gasified adhesive gas from sintering chamber by glue pump, and then, continuously raising temperature to 630 to 660 DEG C, making furnace-residual adhesive gas crack, after finishing degumming, continuously vacuumizing to 140 to 160 Pa and raising temperature to 1410 to 1480 DEG C, at last finishing sintering. The degumming and vacuum sintering integrated furnace of the invention comprises: a furnace, a heat preservation box, a sintering chamber, an adhesive tank, a glue pump and a vacuum pump. The invention has rational design, simple device structure, convenient operation and integration of degumming and vacuum sintering for effectively improving the product sintering quality, shortening sintering period, saving energy resource and reducing product sintering cost. The furnace is a novel product fit for replacing the current hard alloy sintering device because of wide sintering product range, low device cost and safe production process.

Owner:株洲楚天硬质合金股份有限公司

Preparation method of pre-alloyed porous nickel-based electrolytic hydrogen evolution cathode material

InactiveCN109267084AStable physical and chemical propertiesLarge specific surface areaElectrode shape/formsIron powderHydrogen

The invention provides a Ni-Fe-Mo-Mn porous material. The Ni-Fe-Mo-Mn porous material is prepared by the steps of accurately weighing 15 to 21 percent of ferro-molybdenum, 11 to 16 percent of ferro-manganese, 7 to 9 percent of iron powder the balance of nickel, preparing pre-alloyed powder by adopting an atomization technology and sintering in vacuum. The porous material prepared by the inventionhas abundant, uniform and controllable pores and has the advantages of large specific surface area, low hydrogen evolution overpotential, good catalytic performance, good corrosion resistance, stableworking performance, simple and environment-friendly preparation technology and the like; the preparation cost is low and the technology is simple and easy to realize. The porous material prepared bythe invention can be used as the electrolytic hydrogen evolution cathode material.

Owner:XIANGTAN UNIV +1

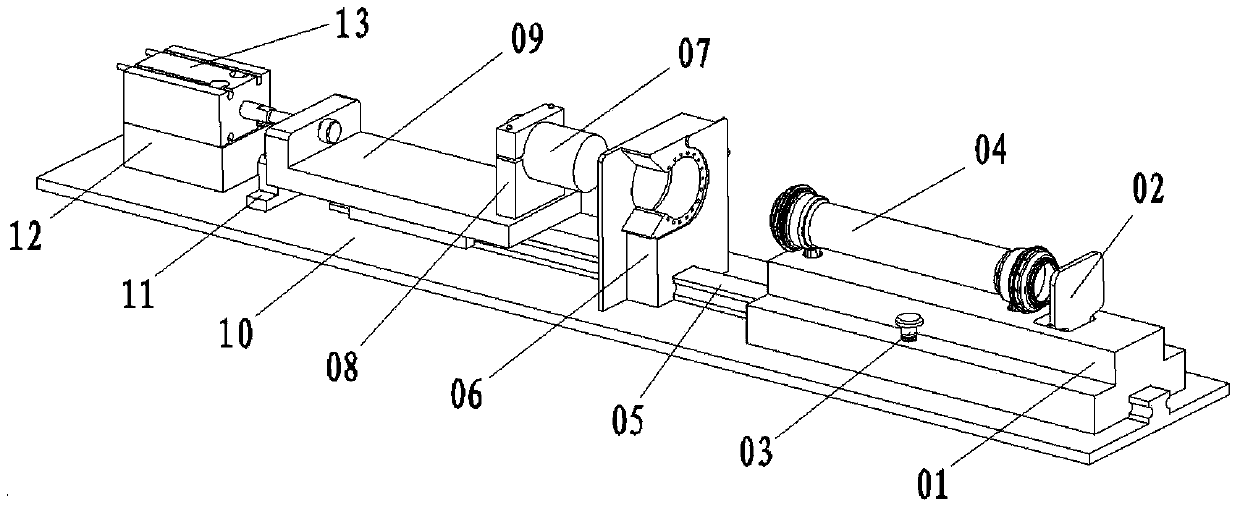

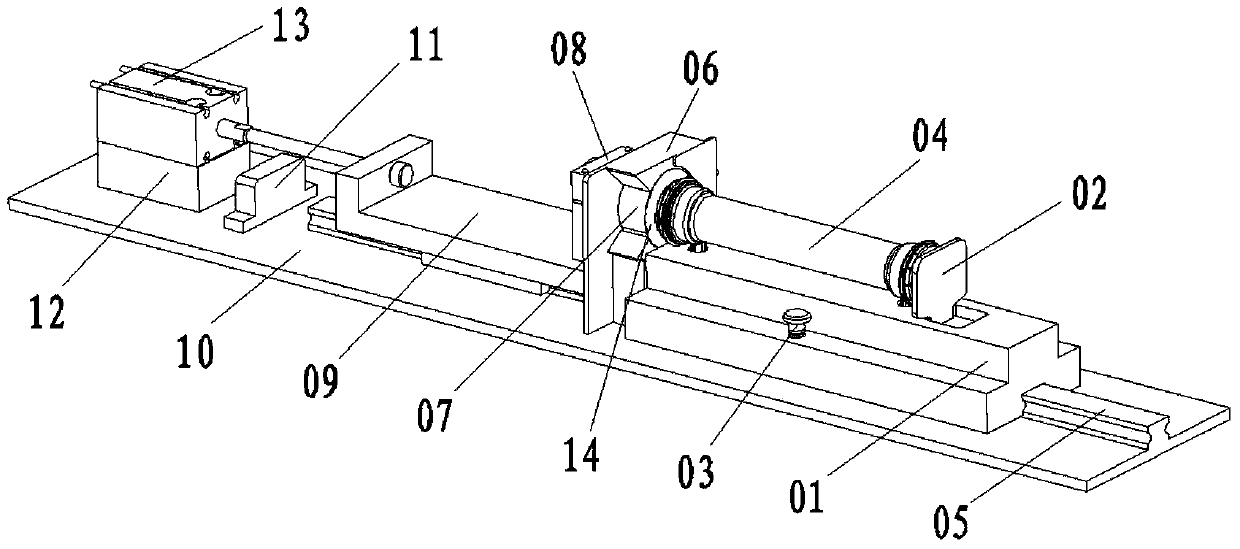

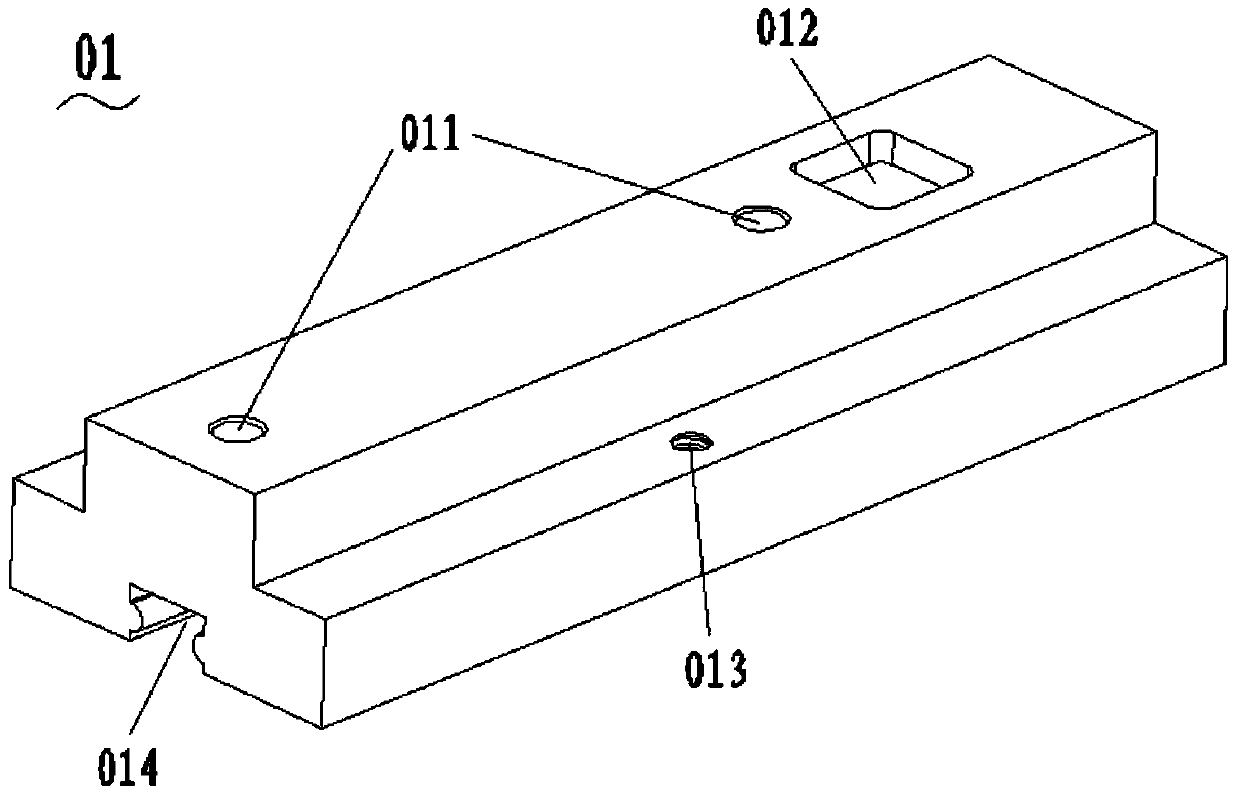

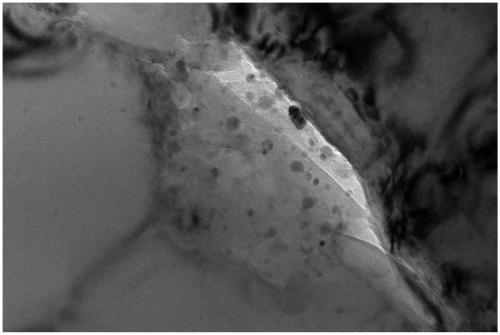

Method and device for sealing end faces of film bundle

The invention discloses a method and device for sealing the end faces of a film bundle. The device for sealing the end faces of the film bundle comprises a base plate, a working part arranged on the base plate, a base and a hot plate, wherein the base and the hot plate are located on the two sides of the working part respectively. A through hole is formed in a working plate of the working part, a plurality of suction holes are formed in the edge of the circumference of the through hole and connected with an air pipe, two positioning holes are formed in the top of the base, a rail groove is formed in the bottom of the base and matched with a guide rail of the base plate, the hot plate is fixed through a hot plate base, and a driving mechanism is connected to the hot plate base. The method for sealing the end faces of the film bundle includes the step that the end faces of the hollow fiber film bundle are sealed in the mode that aluminum foil sheets are arranged on the end faces of a glue injecting cover in a hot-seal mode. Secondary glue injecting is avoided, production working procedures are reduced, the production and manufacturing cost is effectively reduced, and the complete film silk sealing effect can be played.

Owner:SUZHOU JUN KANG MEDICAL TECH

Preparation method of in-situ synthesized Cu-graphene heteropolymer reinforced aluminum matrix composite

ActiveCN109022868AImprove mechanical propertiesImprove the status quo of non-wettingGas phaseCopper nitrate

The invention relates to a preparation method of an in-situ synthesized Cu-graphene heteropolymer reinforced aluminum matrix composite. The preparation method of the in-situ synthesized Cu-graphene hybrid polymer reinforced aluminum matrix composite comprises the following steps of preparation of a Cu-graphene heteropolymer: uniformly mixing copper nitrate trihydrate, glucose and sodium chloride in deionized water; placing uniformly mixed solution in an environment with temperature of -20 degrees centigrade for 48 h; using a freezing and drying technology to obtain a precursor powder; using achemical vapor deposition method to calcine and reduce the precursor powder; and finally, using the deionized water to wash off sodium chloride template to obtain the Cu-graphene heteropolymer; and mixing of the Cu-graphene / aluminum matrix composite powder: placing the obtained composite powder under a condition of 500 MPa to be formed through cold pressing; sintering a cold-pressed block body material in a tube furnace for 1 h through argon shielding, and finally hotly extruding the sintered block body material under an environment condition of 600 MPa according to an extrusion ratio of 1:40so as to obtain a Cu-graphene / aluminum block body composite.

Owner:TIANJIN UNIV

Preparation method of prealloyed high-entropy alloy porous material

InactiveCN109622979AOvercome increased energy consumptionOvercoming uneven powder spreadTransportation and packagingMetal-working apparatusHigh entropy alloysOxidation resistant

The invention relates to a preparation method of a prealloyed CrNiFeTiMoW high-entropy alloy porous material. The preparation method mainly comprises the steps that ultrasonically-treated Cr, Ni, Fe,Ti, Mo and W materials are weighed according to an equimolar ratio; the weighed materials are molten through vacuum arc and then are atomized to prepare prealloyed CrNiFeTiMoW high-entropy alloy; stearic acid accounting for 2-4% of the total powder content is added into the powder, and after drying, a pressed blank is obtained through cold press forming; and the pressed blank is placed in a vacuumsintering furnace to be sintered to prepare the high-entropy alloy porous material. According to the prealloyed CrNiFeTiMoW high-entropy alloy porous material prepared through the preparation method,the production process is simple and easy to implement, the sintering period is short, the preparation cost is low, the high open porosity and rich connected pores are obtained, ingredients are uniform, the structure is controllable, and the material can be used for liquid-solid or gas-solid separation conditions of corrosion resistance and high temperature oxidation resistance.

Owner:XIANGTAN UNIV

Preparation method of high-strength/toughness super-high manganese steel-based TiC/TiN steel bonded hard alloy

The invention relates to a preparation method of a high-strength / toughness super-high manganese steel-based TiC / TiN steel bonded hard alloy. The preparation method is characterized by mixing one of TiO2 powder, TiH2 powder or Ti powder with colloidal graphite according to a C / Ti atomic proportion of 0.7 to 1.1, thus preparing in-situ synthetic TiC powder; mixing one of the TiO2 powder, the TiH2 powder or the Ti powder with urea ((NH2)2CO) according to an N / Ti atomic proportion of 0.4 to 1.1, thus preparing in-situ synthetic TiN mixed powder; preparing Mo-Fe powder, V-Fe powder, Cr-Fe powder, Mn-Fe powder, Si-Fe powder, Fe powder, Ni powder, the colloidal graphite and a rare-earth raw material according to proportions required by adhesive-phase metal chemical component mass proportions, filling and ball-milling in a steel ball, adding absolute ethyl alcohol as a medium and PVA (Polyvinyl Acetate) in the steel ball, drying slurry after ball milling, pressing, forming and sintering, thus obtaining steel bonded alloy. According to the preparation method disclosed by the invention, an in-situ reaction synthesis technology and a liquid-phase sintering technology are combined, the particle size is small, the surface has no sharp corner, a matrix interface is better in bonding, and the interface is clear. The preparation method of the steel bonded alloy is capable of increasing the comprehensive mechanical property of the alloy, the cost is low, and the technology is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

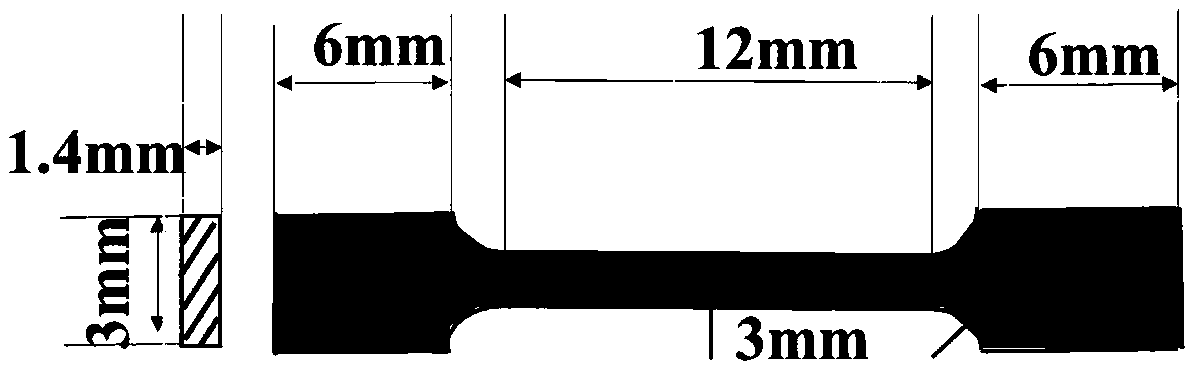

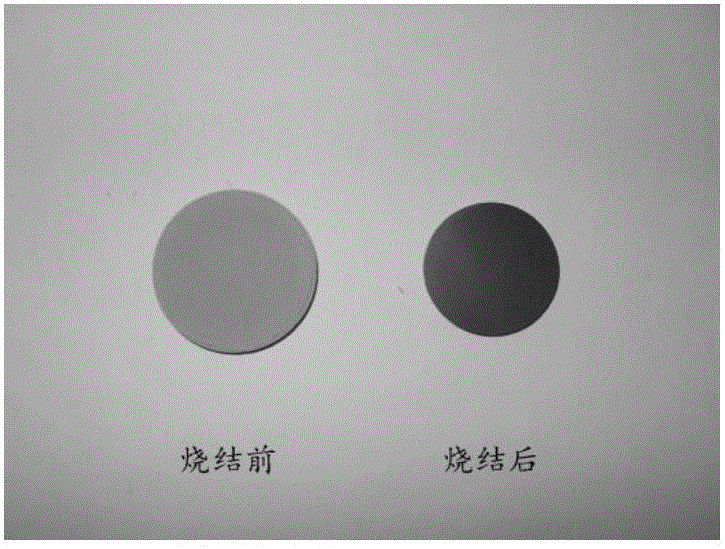

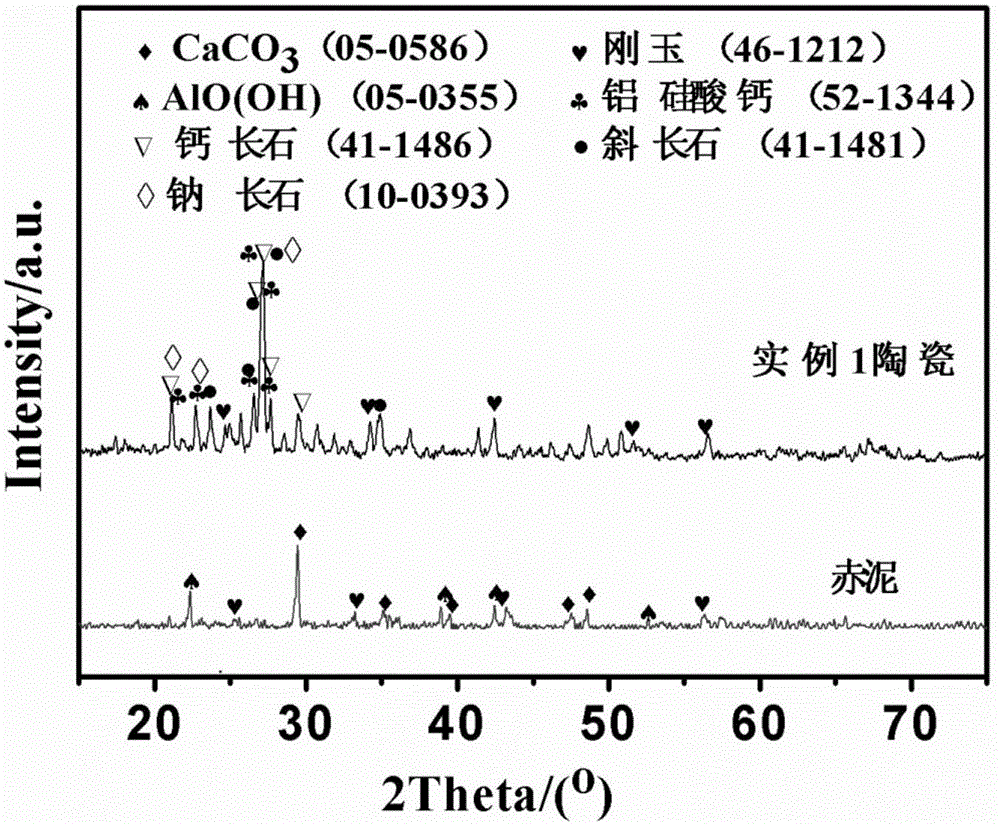

Ceramic material and preparation method therefor

The invention discloses a ceramic material and a preparation method therefor. The ceramic material is mainly prepared from the following raw materials in percentage by mass: 40% to 50% of red mud, 20% to 30% of bauxite, 5% to 10% of potash feldspar, 5% to 10% of kaolin and 5% to 10% of quartz sand. The ceramic material disclosed by the invention is prepared by taking the red mud as a main raw material and is high in hardness, good in density and low in production cost, so that the problems, i.e., environmental pollution and floor-occupied stacking caused by aluminum mineral industry are solved, industrial wastes can be sufficiently utilized, the waste is changed into the valuable, and the economic and environmental benefits are remarkable.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Preparation method of high-strength-and-toughness high-wear-resistance TiC/TiN steel bond hard alloy

The invention relates to a preparation method of high-strength-and-toughness high-wear-resistance TiC / TiN steel bond hard alloy. The preparation method of the high-strength-and-toughness high-wear-resistance TiC / TiN steel bond hard alloy is characterized in that one of TiO2 powder, TiH2 powder and Ti powder is mixed with aquadag powder with the atomic ratio of C / Ti being 0.7-1.1, and one of the TiO2 powder, the TiH2 powder and the Ti powder is mixed with carbamide ((NH2) 2CO ) with the atomic ratio of N / Ti being 0.4-1.1 and made into in-situ synthesized TiN mixed powder; ferrochromium powder, ferromolybdenum powder, ferrovanadium powder, ferrotungsten powder, ferroniobium powder, nickel powder, ferroboron powder, iron power, aquadag and rare earth raw materials are mixed according to the needed chemical component mass ratio of adhesive phase metal and placed in a steel ball mill, absolute ethyl alcohol is added and used a medium, and PVA is also added; and after ball milling, slurry is dried, and then the steel bond hard alloy is obtained through pressing forming and sintering. According to the preparation method of the high-strength-and-toughness high-wear-resistance TiC / TiN steel bond hard alloy, the in-situ reaction and synthesis technology and the liquid phase sintering technology are combined, the reinforced particles are fine in size, the surfaces of the particles are free of sharp corners, matrix interface bonding is good, and the matrix interface is clean. By the adoption of the preparation method of the steel bond hard alloy, the comprehensive mechanical performance of the prepared steel bond hard alloy can be improved, the cost is low, and the technology is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

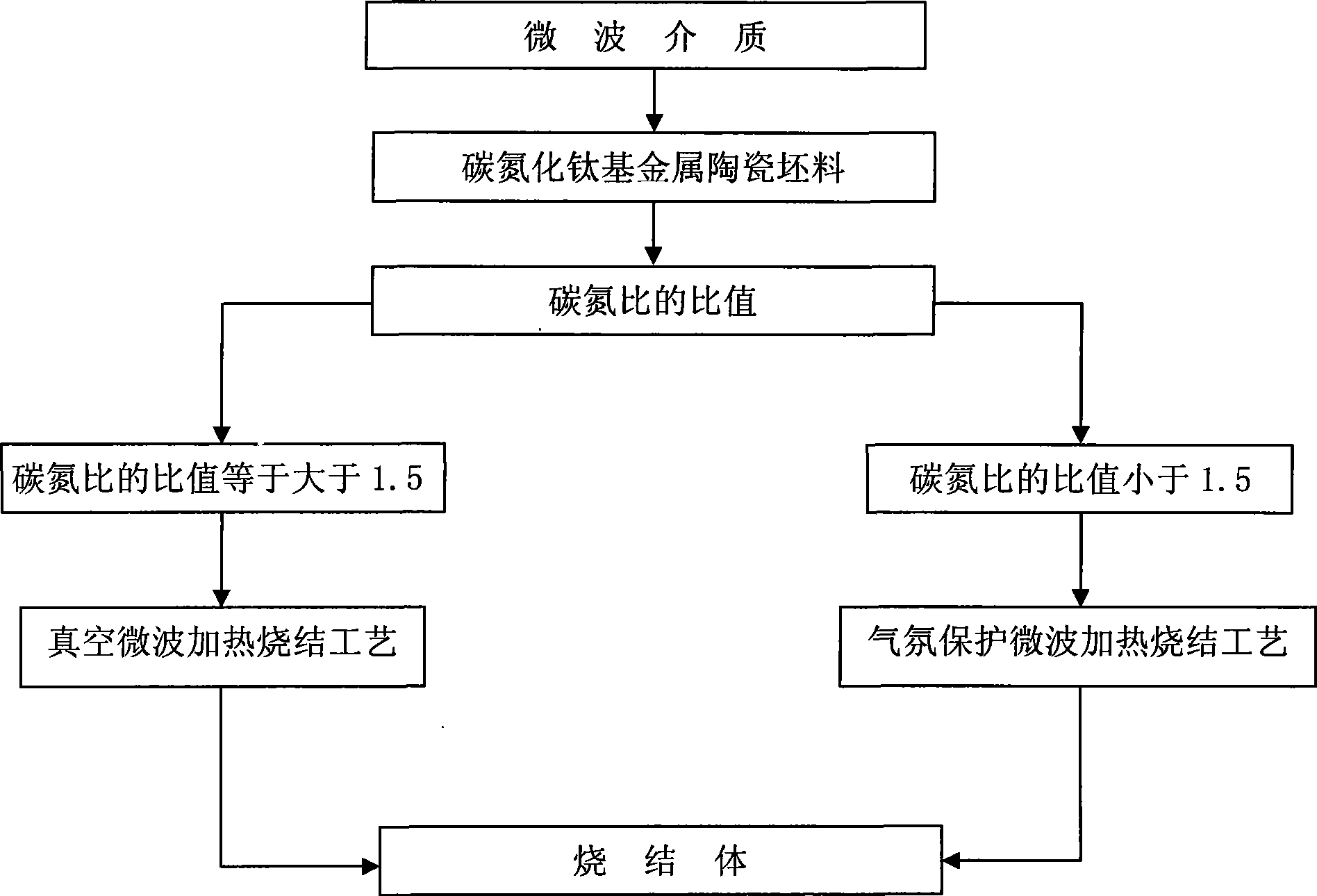

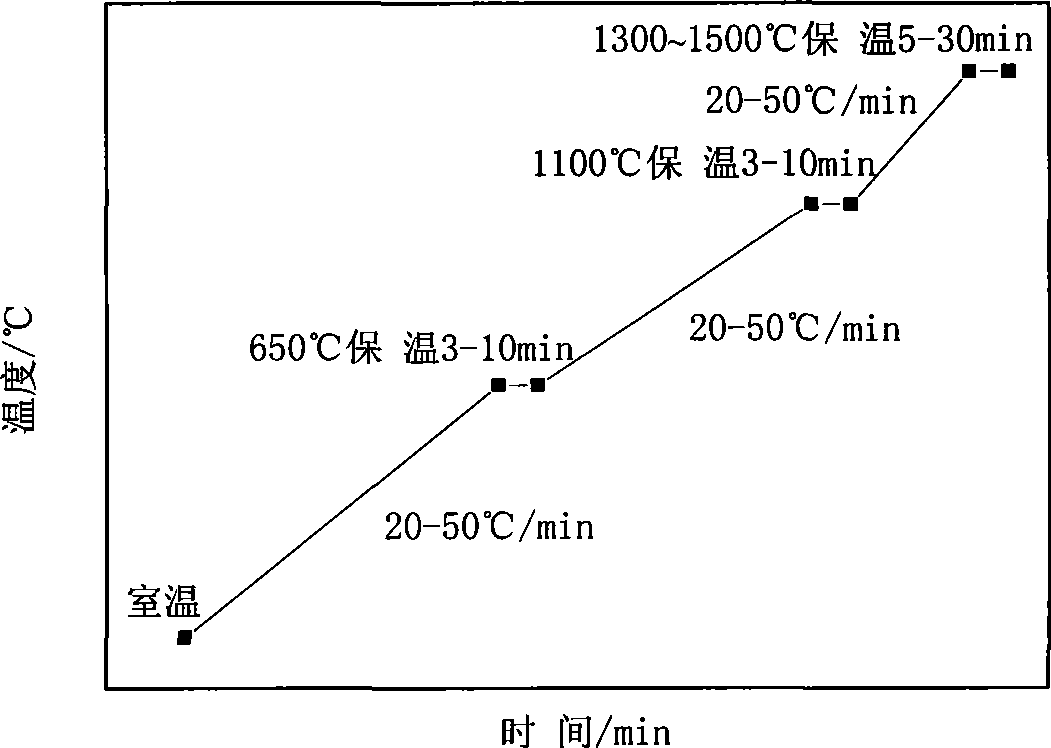

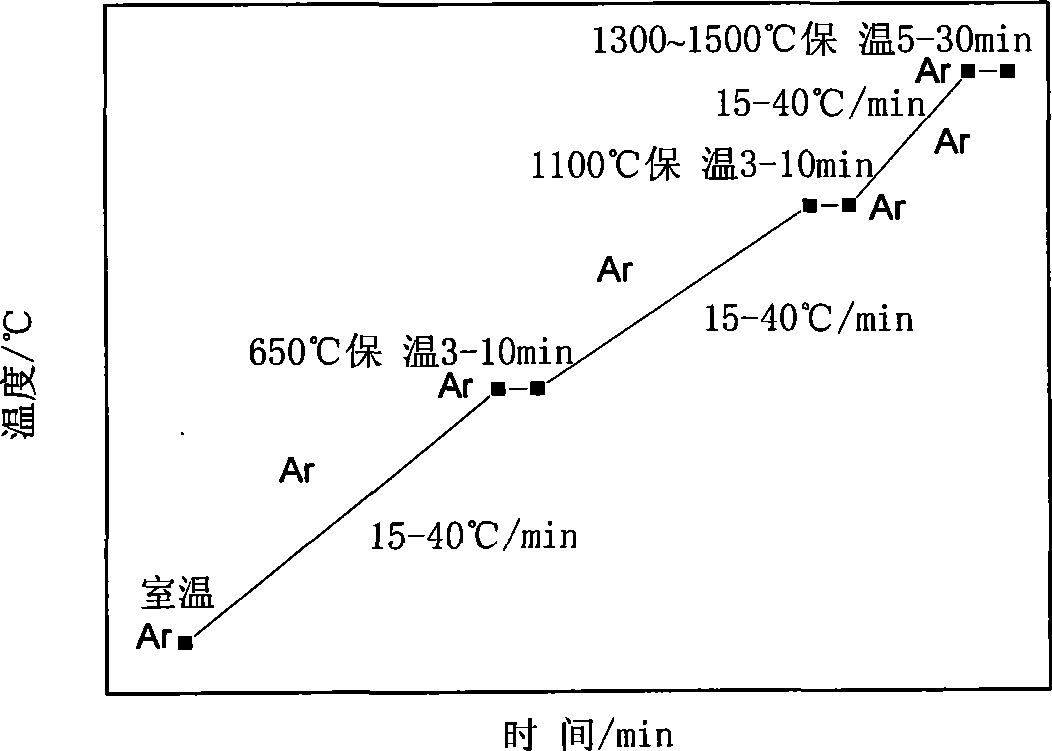

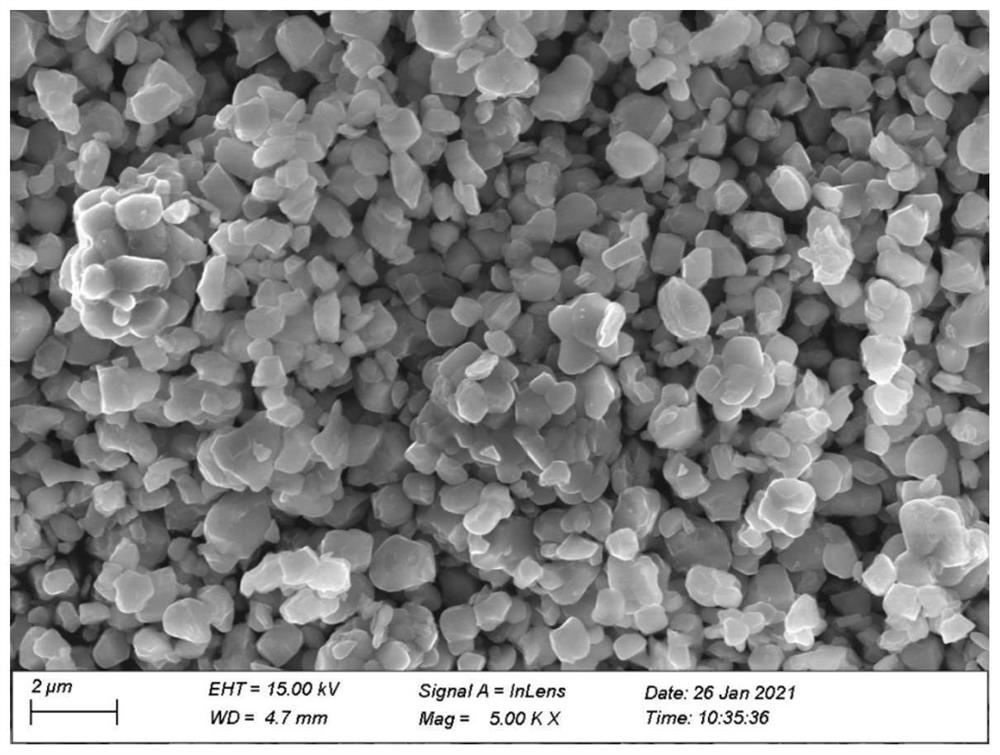

Microwave sintering of superfine grain base titanium carbonitride

The utility model provides microwave sintering of an ultra-fine grain titanium carbonitride group cermet. A 300MHz to 8GHz microwave frequency medium is used as a heat source to enable a billet of the ultra-fine grain titanium carbonitride group cermet to absorb microwave energy to complete the sintering process. During the sintering process, vacuum and atmosphere protection microwave heating and sintering techniques are adopted respectively according to the ratio of carbon to nitrogen of the billet of the ultra-fine grain carbon titanium nitride cermet. The 300MHz to 8GHz microwave frequency is used to heat and sinter the billets of the titanium carbonitride group cermet with different ratio of carbon to nitrogen and vacuum microwave sintering and atmosphere protection microwave sintering technological proposals are used respectively for the billets of the titanium carbonitride group cermet with the different ratio of carbon to nitrogen, which overcomes the defects of the prior vacuum or atmosphere protection sintering techniques, such as low heating efficiency, long sintering time, large energy consumption, serious environment pollution and oversized grains, and the like. The microwave sintering can be widely applied to sintering other ceramics, ceramic matrix composites and intermetallic compound materials with stronger microwave absorbing capacity.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method for high-toughness modified high-manganese steel-based TiC/TiN steel-bonded hard alloy

The invention relates to a preparation method for high-toughness modified high-manganese steel-based TiC / TiN steel-bonded hard alloy. The preparation method is characterized in that one of Ti02 powder, TiH2 powder or Ti powder and colloidal graphite powder are prepared according to the atomic ratio being 0.7-1.1 to be in-situ synthesized TiC mixed powder; one of Ti02 powder, TiH2 powder or Ti powder and urea ((NH2)2CO) are prepared according the atomic ratio being 0.4-1.1 to be in-situ synthesized TiN mixed powder; ferromolybdenum powder, ferrovanadium powder, ferrochrome powder, ferromanganese powder, ferrosilicon powder, ferrous powder, nickel powder, colloidal graphite and rare earth raw materials are prepared according to the needed proportion of the adhesive phase metal chemical composition mass ratio; steel balls are stored, and ball milling is conducted, wherein absolute ethyl alcohol is added to serve as a medium and PVA; and after ball milling is conducted, slurry is dried and then subjected to pressing forming, sintering is conducted, and the steel-bonded alloy is obtained. According to the preparation method, in-situ reaction synthetic technology and liquid phase sintering technology are combined, the fineness of particle sizes is enhanced, the surface has no sharp corners, combination of the substrate interface is good, and the interface is clean; the preparation method for the steel-boned alloy can improve the comprehensive mechanical property of the alloy, the price is low, and the technique is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Method for preparing SiC whiskers through interface reaction, and SiC whiskers

InactiveCN110387583AImprove adsorption capacitySynthesis fastPolycrystalline material growthFrom solid stateMicrowave effectSilicon dioxide

The invention relates to a method for preparing SiC whiskers through an interface reaction, and the SiC whiskers, and belongs to the technical field of preparation of high-performance ceramic materials. The method for preparing the SiC whiskers through the interface reaction comprises the following steps: (1) according to the situation that the molar ratio of carbon to silicon is (1.5 to 3):1, a silicon source and a carbon source are taken to be mixed with boric acid to prepare a silicon dioxide-carbon-boric acid precursor, wherein the silicon source is silicate ester or silicon dioxide, and the carbon source is activated carbon or coal; and (2) the obtained silicon dioxide-carbon-boric acid precursor is pressed into a sheet and then buried in quartz sand to be subjected to microwave sintering, then the surface wrapped quartz sand is removed, then washing is conducted through hydrofluoric acid, and the SiC whiskers are obtained. According to the method, the adsorption property of the activated carbon can be fully utilized to form a good nuclear shell structure, the boric acid is adopted to adjust the pH of the precursor, a reaction can be accelerated through B2O3, and the couplingheat effect of microwave sintering can be fully utilized through the microwave effect to achieve rapid synthesis of the SiC whiskers.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Preparation method of ternary single crystal material

InactiveCN113388882AImprove electrochemical performanceSmall particlesPolycrystalline material growthCell electrodesPhysical chemistryLithium-ion battery

The invention relates to the technical field of lithium ion batteries, and discloses a preparation method of a ternary single crystal material. The method comprises the steps of (1) mixing a ternary 523 single crystal precursor, a lithium source, zirconium oxide and a ternary material crushing dust collection material with D50 of 1-3 [mu] m to obtain a mixture; and (2) sintering the mixture obtained in the step (1) to obtain the ternary single crystal material. According to the method, the ternary material dust collection material is introduced into the preparation process of the ternary single crystal material as a seed crystal, so that the dust collection material can be recycled, and the purposes of green circulating production, capacity increase and yield increase are achieved; and due to the introduction of the seed crystal, the sintering period can be shortened in the solid-phase sintering process, the production efficiency is improved, and the ternary single crystal material with good electrochemical performance can be obtained.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

High-strength siliceous brown glaze electric porcelain and preparation method thereof

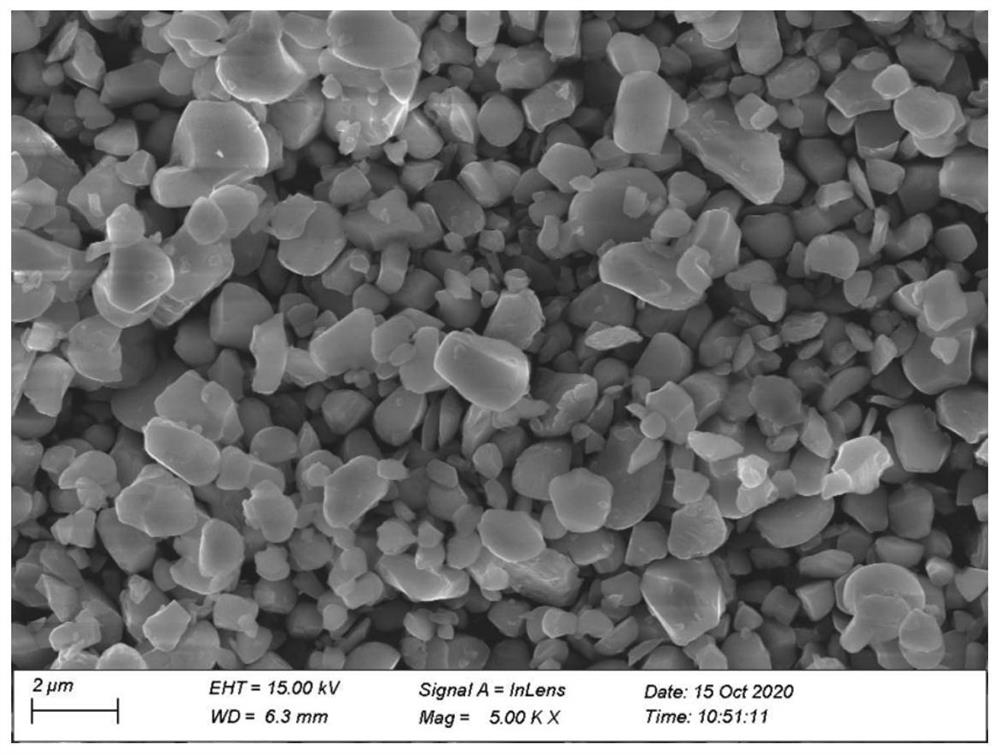

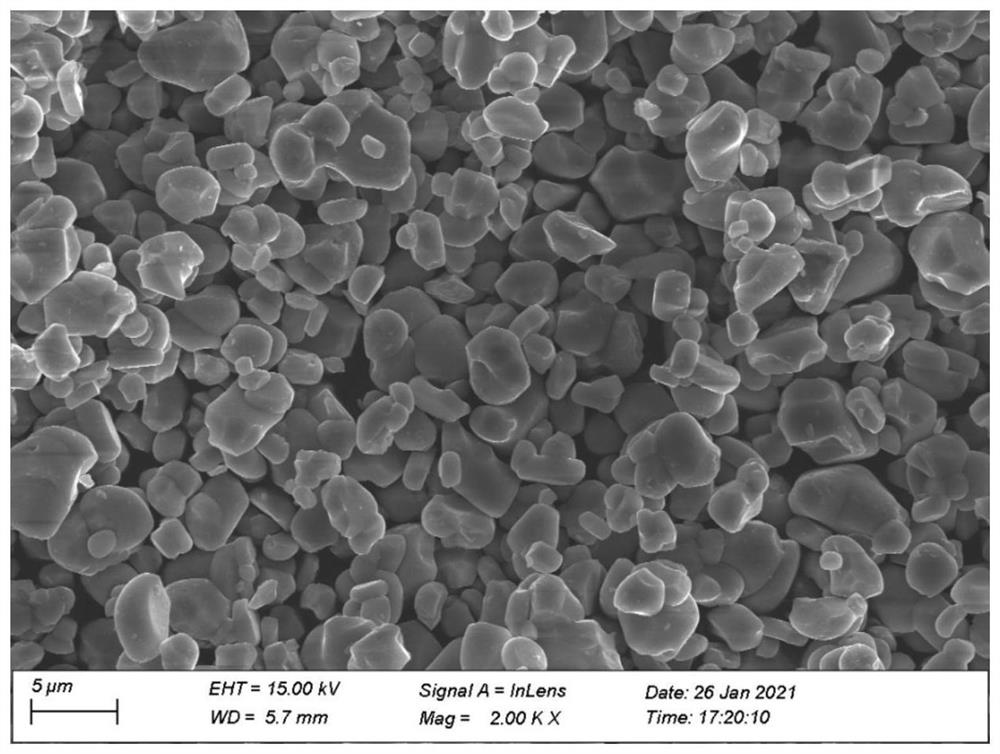

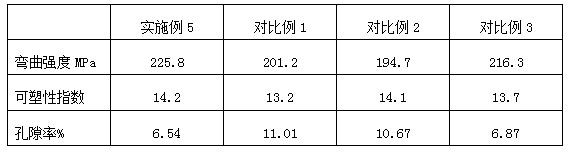

ActiveCN112898003ALow softening temperatureImprove liquidityCeramic materials productionClaywaresSesquioxideManganese

The invention discloses high-strength siliceous brown glaze electric porcelain and a preparation method thereof, and relates to the technical field of siliceous electric porcelain. The invention discloses a high-strength siliceous brown glaze electric porcelain, the raw materials comprise a blank material and a brown glaze material; the blank material comprises the following raw materials: kaolin, wollastonite, Jiepai mud, siliceous porcelain waste powder, low-melting-point glass powder, spodumene, yttrium oxide, ceramic-grade talcum powder and a nucleating agent; the brown glaze material is composed of the following raw materials: potassium feldspar powder, quartz powder, blank mud, calcite powder, cooked talcum powder, iron oxide, chrome green, manganese sesquioxide and Jiepai mud. The invention also discloses the preparation method of the brown glaze electric porcelain. The siliceous brown glaze electric porcelain has the advantages of simple and easily available raw materials, low cost, high bending strength, good plasticity and good stability; and the brown glaze is low in cost, short in glaze dipping time, good in glazing effect, ruddy and full in glaze surface, bright in luster, stable in color generation and free of color difference, and the strength of the brown glaze electric porcelain is improved by 10% or above compared with the strength of the brown glaze electric porcelain before glazing.

Owner:湖南省醴陵市华电电瓷制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com