Preparation method of SiC crystal whisker

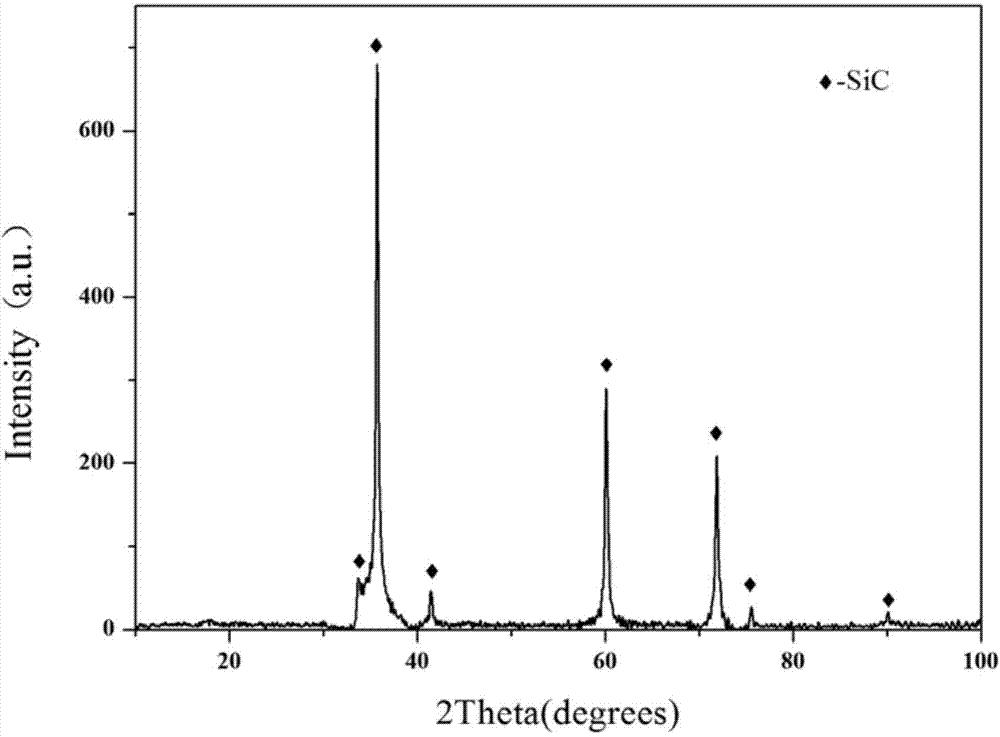

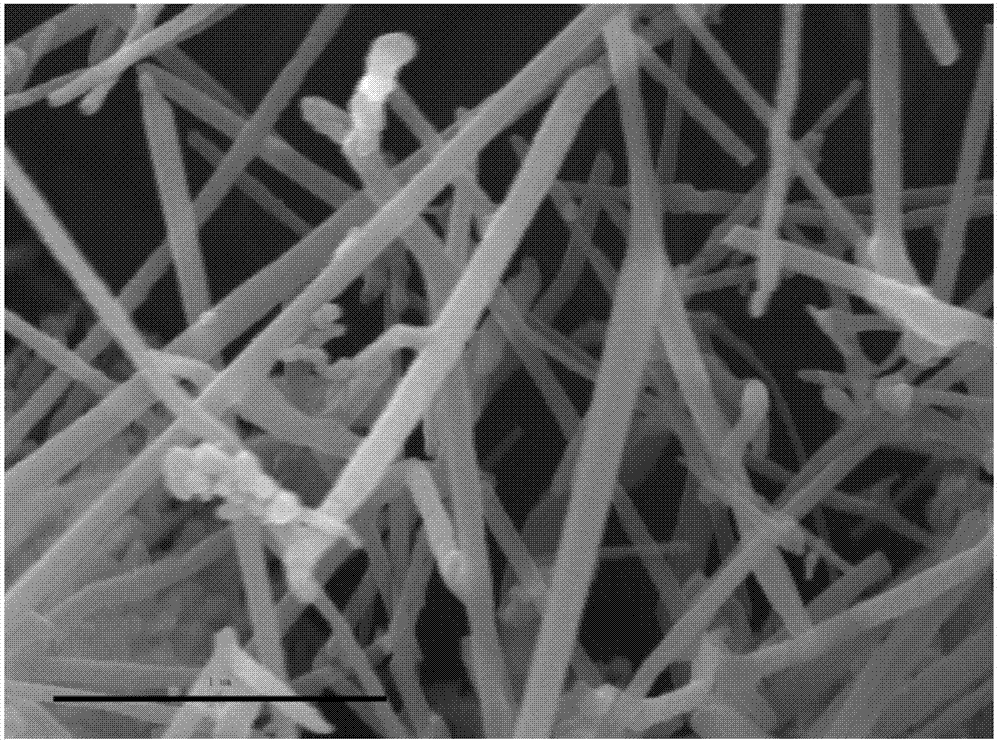

A whisker, sol-gel method, applied in the field of preparation of SiC whiskers, can solve the problems of complex process equipment, large energy consumption, long sintering time, etc., and achieve the effects of simple process, short sintering cycle and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of the SiC whisker of the present embodiment comprises the following steps:

[0051] 1) Take domestic coal with a particle size of less than 50 μm as the carbon source, and tetraethyl orthosilicate as the silicon source, and obtain amorphous SiO by the sol-gel method according to the molar ratio of carbon to silicon of 3:1. 2 Precursors encapsulating coal particles;

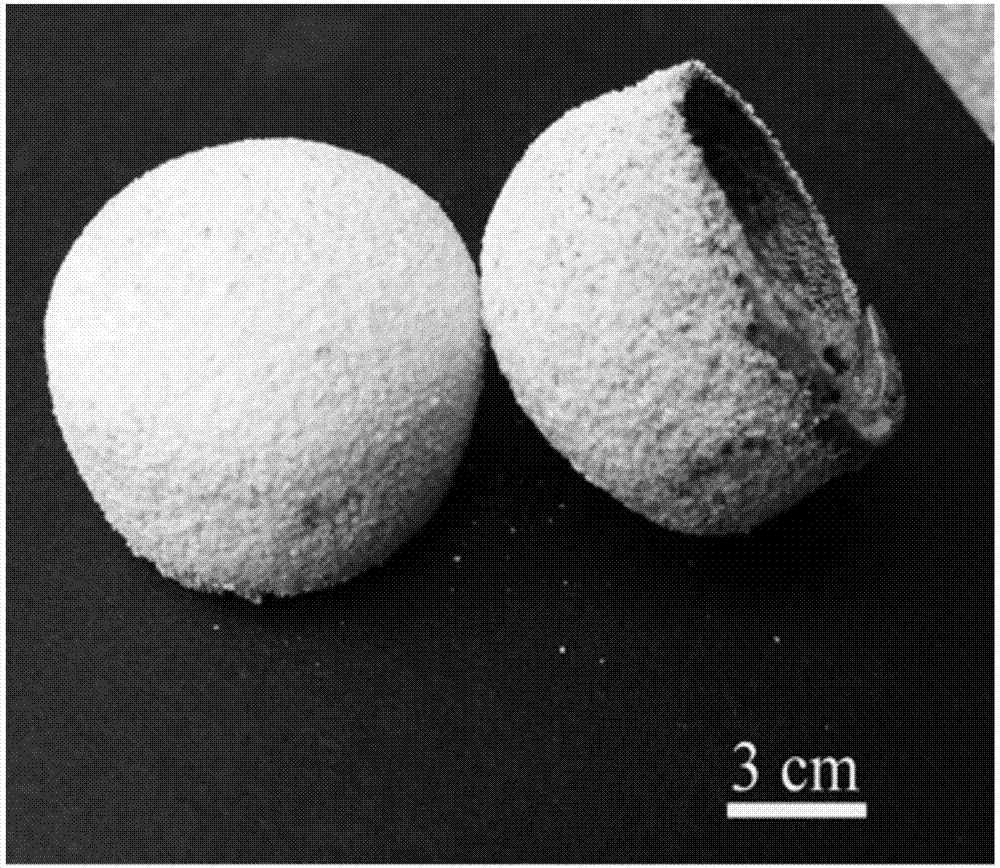

[0052]2) Under the pressure of 4MPa, press the precursor obtained in step 1) into a cylindrical piece with a diameter of 28mm and a thickness of 10mm, and embed it in an alumina crucible with quartz sand, and place the crucible in a frequency of 2.45GHz In the multi-mode resonant cavity microwave oven, with the insulation structure, microwave sintering synthesis reaction is carried out in the absence of protective atmosphere:

[0053] First turn on the microwave source, adjust the microwave input power, first raise the temperature to 600°C at a rate of 5°C / min, that is, the dehumidi...

Embodiment 2

[0063] The preparation method of the SiC whisker of the present embodiment comprises the following steps:

[0064] 1) Take ethyl orthosilicate as the silicon source, and use ethyl orthosilicate to make amorphous silica through the sol-gel method; take domestic coal with a particle size of less than 50 μm as the carbon source, and according to the molar ratio of carbon to silicon The ratio of coal and amorphous SiO was 7.5:1 2 Mechanically mix to obtain the precursor;

[0065] 2) Under the pressure of 200MPa, press the precursor obtained in step 1) into a cylindrical piece with a diameter of 30mm and a thickness of 20mm, and embed it in an alumina crucible with quartz sand, and place the crucible in a frequency of 2.45GHz In the multi-mode resonant cavity microwave oven, with the insulation structure, microwave sintering synthesis reaction is carried out in the absence of protective atmosphere:

[0066] First turn on the microwave source, adjust the microwave input power, fir...

Embodiment 3

[0076] The preparation method of the SiC whisker of the present embodiment comprises the following steps:

[0077] 1) Take domestic coal with a particle size of less than 50 μm as the carbon source, and tetraethyl orthosilicate as the silicon source, and obtain amorphous SiO by the sol-gel method according to the molar ratio of carbon to silicon at a ratio of 5:1. 2 Precursors encapsulating coal particles;

[0078] 2) Under the pressure of 100MPa, press the precursor obtained in step 1) into a cylindrical sheet with a diameter of 32mm and a thickness of 25mm, and embed it in an alumina crucible with quartz sand, and place the crucible in a frequency of 2.45GHz In the multi-mode resonant cavity microwave oven, with the insulation structure, microwave sintering synthesis reaction is carried out in the absence of protective atmosphere:

[0079] First turn on the microwave source, adjust the microwave input power, first raise the temperature to 620°C at a rate of 15°C / min, that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size long | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com