High-strength siliceous brown glaze electric porcelain and preparation method thereof

A high-strength, siliceous technology, applied in the production of clay products, other household appliances, ceramic materials, etc., can solve the problems of difficult crushing of siliceous electric porcelain waste, low resources of high-aluminum minerals, low efficiency, etc., and achieve enhanced fracture strength. and flexural strength, improve the density, improve the effect of bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

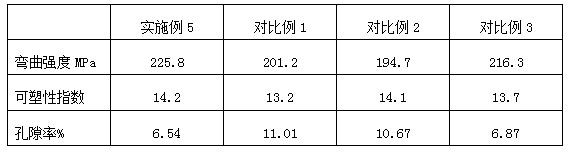

Examples

Embodiment 1

[0036] A high-strength siliceous brown glaze electric porcelain, including a blank and a brown glaze glaze, the blank is composed of the following raw materials in weight percentage: 10% kaolin, 30% wollastonite, 10% Jiepai mud, siliceous porcelain waste powder 10%, low melting point glass powder 20%, spodumene 10%, yttrium oxide 3%, ceramic grade talcum powder 4% and fluorite 3%. The brown glaze glaze is composed of the following raw materials in weight percentage: 30% of potassium feldspar powder, 25% of quartz powder, 1.5% of this mud, 15% of calcite powder, 3.5% of cooked talcum powder, 3% of iron oxide, 2.5% of network green %, manganese trioxide 4.5% and Jiepai mud 15%.

[0037] The preparation method of the above-mentioned high-strength siliceous brown-glazed electric porcelain is as follows: dry the above-mentioned blank raw materials at 120°C for 12-18 hours, then weigh them by weight percentage, and mix them evenly; mix the above-mentioned mixture, zirconium balls an...

Embodiment 2

[0039] A high-strength siliceous brown glaze electric porcelain, including a blank and a brown glaze glaze, the blank is composed of the following raw materials in weight percentages: kaolin 20%, wollastonite 15%, Jiepai mud 20%, siliceous porcelain waste powder 5%, low melting point glass powder 10%, spodumene 10%, yttrium oxide 6%, ceramic grade talc 8% and titanium dioxide 6%. The brown glaze glaze is composed of the following raw materials in weight percentage: 40% of potassium feldspar powder, 15% of quartz powder, 3% of this mud, 14% of calcite powder, 2.5% of cooked talcum powder, 2% of iron oxide, and 3.5% of network green %, Manganese Trioxide 4% and Jiepai Mud 16%.

[0040] The preparation method of the above-mentioned high-strength siliceous brown-glazed electric porcelain is as follows: Weigh an appropriate amount of siliceous porcelain waste, first use a jaw crusher for coarse crushing, then use a hammer crusher for fine crushing, and then carry out coarse grindin...

Embodiment 3

[0042] A high-strength siliceous brown glaze electric porcelain, including a blank and a brown glaze glaze, the blank is composed of the following raw materials in weight percentage: 15% kaolin, 20% wollastonite, 15% Jiepai mud, siliceous porcelain waste powder 8%, low melting point glass powder 15%, spodumene 15%, yttrium oxide 4%, ceramic grade talc powder 5%, titanium dioxide 1% and phosphorus pentoxide 2%. The brown glaze is composed of the following raw materials in weight percentage: 40% of potassium feldspar powder, 23.5% of quartz powder, 2.5% of this mud, 10% of calcite powder, 3% of cooked talcum powder, 2.7% of iron oxide, 3% of network green %, manganese trioxide 3.3% and Jiepai mud 12%.

[0043] The preparation method of the above-mentioned high-strength siliceous brown-glazed electric porcelain is as follows: Weigh an appropriate amount of siliceous porcelain waste, first use a jaw crusher for coarse crushing, then use a hammer crusher for fine crushing, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com