Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

726 results about "Powder talcum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scratch-resistance French white filled polypropylene composition and its preparing method

InactiveCN1580115AImprove scratch resistanceImproves UV resistanceProcedure AgentsSilicone Elastomers

This invention refers to a kind of component of nick resistant talcum-powder-filling polypropylene, is characterized with strengthened toughness through latex and is composed of the following materials in amounts of weight: between 50 and 80 of polypropylene, between 5 and 35 of filler, between 5 and 25 of latex, between 0.5 and 5 of high molecular silicone elastomer, between 0.05 and 0.5 of nucleater, between 0.1 and 1.0 of stabilizer, between 0.2 and 1.5 of talcum powder surface passiation agent, between 0.05 and 1.0 of processing agent and between 0.3 and 2.0 of toner. The manufacturing method is to weigh the materials in amounts of weight, to mix polypropylene, filler, latex, high molecular silicone elastomer, nucleater, stabilizer, talcum powder surface passiation agent, processing agent and toner in homo mixer, then put them into double-screwed extruder for melting and extruding. After cooling, drying and pelleting, we can get the turnoff. The invention improves the nick resistance of polypropylene, ultraviolet radiation endurance and thermal endurance and the toughness and rigidity of the material reach good balance. It can meet the requirements of the material of automobile limbs. It can demold at a relatively high temperature, improves the moulding efficiency greatly and reduces the processing cost.

Owner:SHANGHAI PRET COMPOSITES

Talc powder filled polypropylene with high rigidity, high toughness and high scratch resistance and method for preparing same

The invention relates to high molecular processing field compound material, especially a high molecular organic sillicon elastomer filled with talcum powder agglomerate, with outstanding rigidity and resistance to heat and its preparing method, which can be applied in auto and toner field, such as pate of tenacity, door, plate of augxiliary tenacity, deconating stick and other polypropylene inside and outside automobile. The invention is comprised of high molecular organic sillicon elastomer and talcum powder agglomerate with high crystal and the percentages of each component are: high molecular organic sillicon elastomer 60-90, talcum powder agglomerate 10-40, scratch 3-10, dust 0.1-1.0, of talcum powder agglomerate 0.2-1.5, 0.05-1.0. The preparing method is: mix the high molecular organic sillicon elastomer, talcum powder agglomerate, dust, of talcum powder agglomerate and in, then place then into to form the particles. Its advantage is that, keeping the tenacity of polypropylene, the rigidity has also been increased, balancing its tenacity and rigidity, as well as its resistance to scratch, it can satisfy the requirements of elements in auto; besides, it also reduces dust, benefiting for protecting the work environment.

Owner:SHANGHAI PRET COMPOSITES

Double-coated hollow glass microbead heat-insulated coating and preparation method thereof

InactiveCN102391754AGood heat insulationEnvironmental protection and energy savingReflecting/signal paintsCelluloseMeth-

The invention discloses double-coated hollow glass microbead heat-insulated coating and a preparation method thereof. The double-coated hollow glass microbead heat-insulated coating is prepared from the following raw materials in percentage by weight: 20 to 30 percent of organic silicon modified styreneacrylic emulsion, 9 to 13 percent of double-coated hollow glass microbead, 8 to 12 percent of titanium dioxide rutile, 5 to 8 percent of talcum powder, 17 to 23 percent of heavy calcium, 1.5 to 2 percent of glycol, 0.13 to 0.2 percent of hydroxymethyl cellulose, 0.6 to 1 percent of dispersing agent, 0.35 to 0.45 percent of defoaming agent, 0.15 to 0.19 percent of wetting agent, 0.08 to 0.13 percent of multifunctional aid, 1.0 to 1.5 percent of film-forming aid and the balance of water. Reflective heat-insulated coating is prepared by performing pretreatment on hollow glass microbeads by a double-coated method, selecting silicone / acrylic emulsion as a base material, using the pretreated hollow glass microbeads, the titanium dioxide rutile, the talcum powder, the heavy calcium and the like as pigment fillers and adding a certain amount of fillers. The coating can improve reflectivity and weather resistance, and has the beneficial effects of environmental friendliness, energy conservation, simple production process, good dispersing effect, low cost, stable performance and long service life.

Owner:SHENYANG JIANZHU UNIVERSITY

Magnesium-alloy metal-type casting coating and preparation method thereof

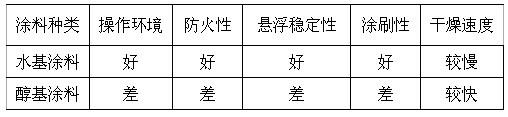

ActiveCN101658899ASimple componentsEasy to prepareFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention relates to a magnesium-alloy metal-type casting coating and a preparation method thereof. Magnesia and forsterite are used as refractory aggregates; titania, asbestos powder or talcum powder or diatomite, and the like are added as heat-insulation aggregates; a mixed caking agent with favorable high-temperature caking property and a compound suspending agent are selected; and boric acid is added as a flame retardant. The preparation method comprises the following steps: mixing the magnesia, the forsterite, the titania, and the asbestos powder or talcum powder or diatomite, and preparing A after ball milling; mixing the caking agent and bentonite, and adding water to activate so as to obtain B; mixing the boric acid, sodium carboxymethyl cellulose and polyacrylamide, and addingwater to activate so as to obtain C; and finally, mixing A, B and C, and carrying out ball milling or colloid milling for more than 30 minutes to obtain the magnesium-alloy metal-type casting coating. The coating has the advantages of favorable heat insulation, caking property, coating property, flame retardance, stability and durability, is beneficial to continuous production and convenient forobtaining magnesium-alloy metal-type castings with favorable surface quality and superior performance, and prolongs the service life of moulds.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of carbon-golden metallic luster crystalline glaze

The invention relates to a preparation method of a carbon-golden metallic luster crystalline glaze. The carbon-golden metallic luster crystalline glaze comprises the following component in parts by mass: 25-30 parts of MnO2 as crystallizing agent, 0.5-1.5 parts of MoO2, 0.5-1.5 parts of V2O5 as crystallization accelerator, 2-4.5 parts of CuO, 2.5-5 parts of Fe2O3, 3-7 parts of ZnO and 0.5-2.5 parts of NiO as colorants, 30-38 parts of potash feldspar produced in Pingjiang, 5-12 parts of quartz produced in Fengyang, 5-10 parts of talcum powder produced in Wuxi, and 5-12 parts of boron fusion cake produced in Yixing. The prepared glaze slip is applied onto a biscuited green body, and subjected to glaze firing according to the temperature curve in the invention. The carbon-golden metallic luster crystalline glaze has carbon-golden metallic luster, rainbow effect and beautiful appearance of crystals. Besides, the carbon-golden metallic luster crystalline glaze has the advantages of low cost, high glaze hardness, high wear resistance and high corrosion resistance, is a brand new glaze of ceramic art, and can be used for decorating ceramic artware.

Owner:山西高陶瓷业有限责任公司 +1

Sintering-strippable red cast iron coating and preparation method thereof

InactiveCN102601300APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresCrack resistancePreservative

The invention relates to a sintering-strippable low-cost red water-based cast iron coating, which is prepared by the following raw materials in percent by mass: 20-45 percent of bauxite powder or powder quartz, 0-25 percent of mullite powder, 1-6 percent of talcum powder, 1-5 percent of iron trioxide powder, 1-3 percent of suspending agent, 1.5-4.5 percent of organic binding agent, 1.5-6 percent of inorganic binding agent, 0.01-0.05 percent of wetting agent, 0.02-0.05 percent of preservative, 0.02-0.1 percent of defoaming agent, 0-0.5 percent of water reducing agent and 30-42 percent of tap water. The sintering-strippable low-cost red water-based cast iron coating has the characteristics that the raw materials are cheap and the source is wide; the product is low-cost, safe, environmental-friendly and convenient to transport; the brushing property, the flowing resistance and the leveling property of the product are good, the suspension percentage, the coating strength and the crack resistance are high and the gas evolution is low; and the sintering-stripping performance is excellent, the most part of the coating can be vastly stripped after castings are taken out of a casting box and are cooled, the defects of sand sticking, sand inclusion, sand drop, voids and the like existing the castings can be effectively avoided, and the castings with excellent surface quality can be obtained.

Owner:湖北省机电研究设计院股份公司

Ceramic tile capable of releasing negative oxygen ions and preparation method thereof

The invention discloses a ceramic tile capable of releasing negative oxygen ions and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 38-56 parts of river sand, 22-34 parts of fluorite, 18-26 parts of volcanic, 10-20 parts of dolomite, 24-36 parts of modified clay, 15-25 parts of magnesite ore, 12-18 parts of tourmaline, 10-15 parts of hexacyclic stone, 8-14 parts of medical stone, 5-10 parts of stove ash residue, 6-12 parts of talcum powder, 4-8 parts of shell powder, 3-6 parts of barium carbonate and 2-4 parts of zinc oxide. The tourmaline, the hexacyclic stone, the medical stone and the like are added into the ceramic tile, so that the ceramic tile can release negative oxygen ions beneficial to human health for a long time, can obviously enhance blood circulation, promote metabolism, improve immunity and soothe mind and body, has an effect of bacteriostat and sterilization and has an obvious deodorization function, the indoor air can be purified, and the indoor air quality is improved.

Owner:安徽省亚欧陶瓷有限责任公司

Paint with spectral selectivity, preparation method, and application

ActiveCN101092533AStrong reflexesWith thermal insulationLiquid surface applicatorsCoatingsReflectivityChemistry

This invention relates to a method for preparing spectrum-selective coating. The spectrum-selective coating is composed of acrylate copolymer or silicone acrylate copolymer as the matrix, titanium dioxide powder, heavy calcium powder, wollastonite and talcum powder as the fillers, hollow microbeads as the additive, and preservative, emulsifier and dofoamer as the auxiliary materials. Both the reflectivity of the spectrum-selective coating in 0.2-2.8 mu.m wave band and the emissivity in 8-13.5 mu.m wave band are higher than 80%. The spectrum-selective coating can cool the surface of the coated object by using the space coating energy, and has good heat insulating function. The spectrum-selective coating has such advantages as simple process, and good radiation cooling effect.

Owner:北京北洋华诚新能源科技发展有限公司

Method for preparing graphene micro-sheets by using counter-jet jet mill

The invention relates to the field of graphene materials, particularly relates to preparation methods for graphene micro-sheets and particularly relates to a method for preparing the graphene micro-sheets by using a counter-jet jet mill. According to the method, the graphene sheets are obtained through enabling melted ferric chloride and potassium chloride to enter an interlayer of graphite, enabling the powder materials to be in collision through high-speed airflow in the counter-jet jet mill by using the characteristic of brittleness of ferric chloride and potassium chloride crystal grains and the characteristics of good fluidity and difficulty in agglomeration of talcum powder, delaminating the graphite and the talcum powder by generated impact force, shearing force and frictional force, carrying out further separation by a grading room, refluxing unqualified powder material to a crushing chamber, and yielding delaminated graphite and talcum powder as well as gas together. The continuous and large-scale production of the graphene micro-sheets, which are uniform in layer number dispersion and good in fluidity and are not prone to agglomeration, is achieved, the yield is high, the cost is low, no pollution is caused, and the layer thickness meets the requirements of use in the fields of rubber reinforcing, plastic reinforcing, coating material anticorrosion, lubrication and sewage treatment, so that the promotion of the large-scale application of graphene is facilitated.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

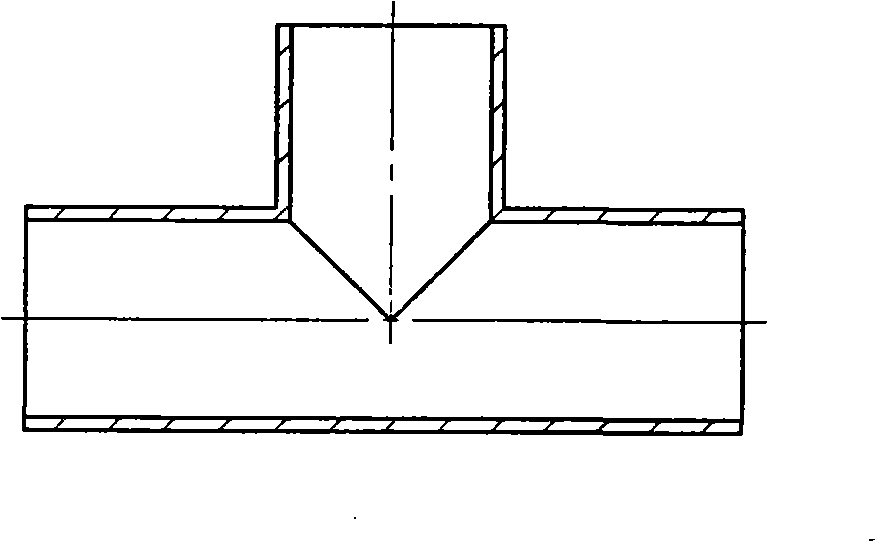

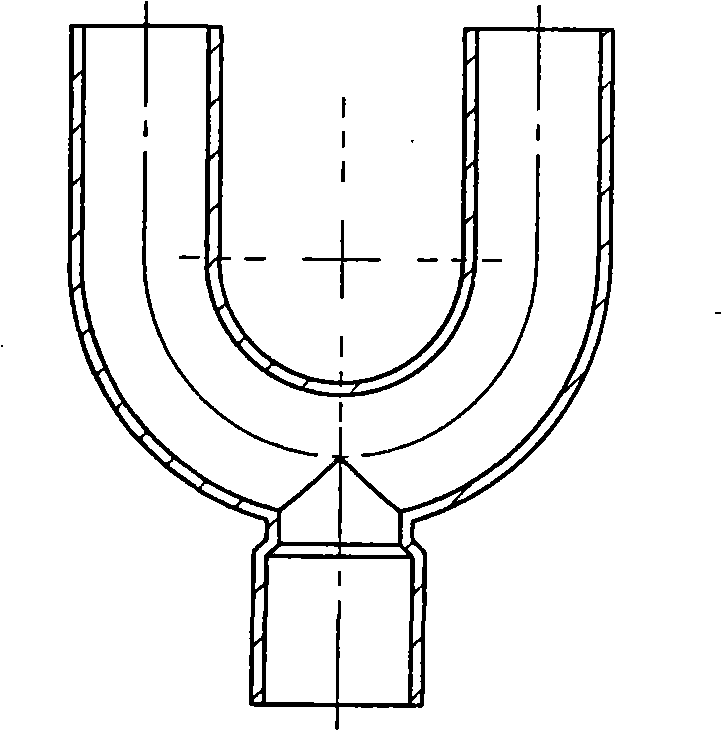

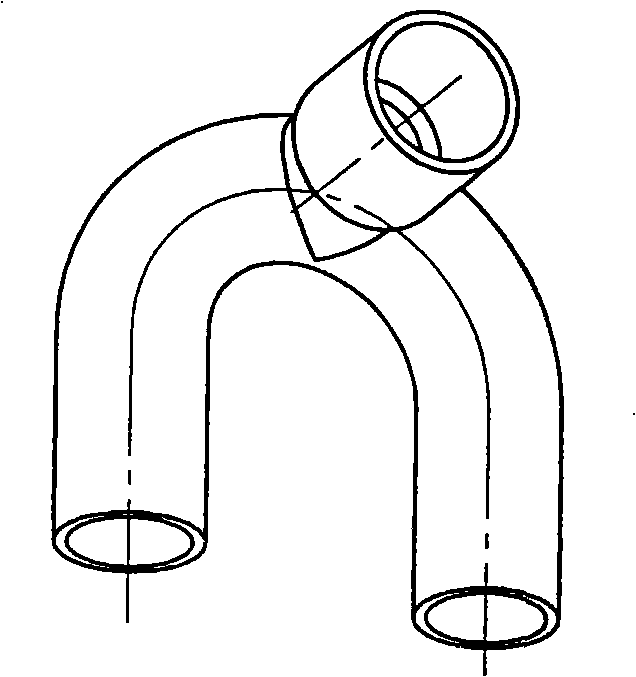

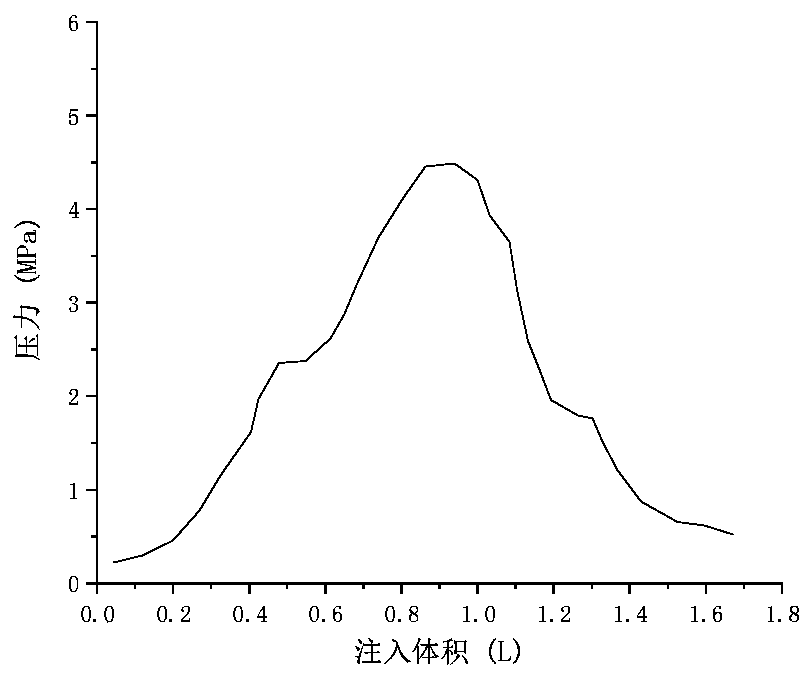

Nonmetal filling medium for producing piping branch junctions and technique for squeezing the piping branch junctions

InactiveCN101288881AShorten the lengthObvious technical advantagesExtrusion profiling toolsPlastic materialsCopper

The invention relates to a non-metal filling medium used for fabricating a three-way pipeline and a process for extruding the three-way pipeline. The filling medium is a non-metal power material which is uniformly mixed and consists of three powders: talcum powders H2Mg3(sio3)4, industrial salts NaCl and urease (NH4)2CO; the three powders are uniformly mixed respectively according to the mass proportion of 5-25%, 95-50% and 0-25%. The extrusion material range of the three-way pipeline of the invention is multiple high-plastic materials such as copper, iron, low carbon steel and cold extrusion stainless steel, etc.; therefore, the three-way pipeline can extrude and fabricate copper three-way pipeline, iron three-way pipeline, low carbon steel three-way pipeline and stainless steel three-way pipeline, etc. The non-metal filling medium and the process of the invention have obvious technical advantages of meeting the instruction requirement which is issued by European, Japan, etc. and contains that lead is not allowed to be added in the three-way pipeline production process, thereby completely avoiding the pollution of heavy metals such as lead, etc., having lower cost than the lead-pouring extrusion, having longer length and higher working efficiency than the oil (water) injection extrusion, and enlarging the ranging of extrusion material to the fields of multiple high-plastic material such as copper, iron, low carbon steel and stainless, etc.

Owner:佛山市南海飞鹏塑胶金属有限公司

Ru porcelain tea-dust glaze and preparation technology thereof

The invention discloses a Ru porcelain tea-dust glaze and a preparation technology thereof. The Ru porcelain tea-dust glaze comprises, by weight, 28-32 parts of white feldspar, 12-14 parts of calcite, 8-10 parts of quartz stone, 50-53 parts of Ru drug, 1.0-1.5 parts of bone meal and 0.5-1.0 part of talcum powder, and the Ru drug is kaolin from Mangchuan Country in Ruzhou City in Henan Province. The glaze color of the Ru porcelain tea-dust glaze is a tea-dust color, and tea-dust-like tawny fine points flash on the background color of ochre color, so the glaze is unsophisticated, elegant, beautiful and interesting, and porcelains sintered by using the glaze are beautiful, thereby the glaze increases a new glaze color for Ru porcelain, and improves the economic benefit of the Ru porcelain.

Owner:姚瑞平

Method for producing and using water-preserving agent used in desert

InactiveCN1465650APrevent leakageImprove survival rateOrganic fertilisersSoil conditioning compositionsCALCIUM CARBONATE/MAGNESIUM CARBONATEPhosphate

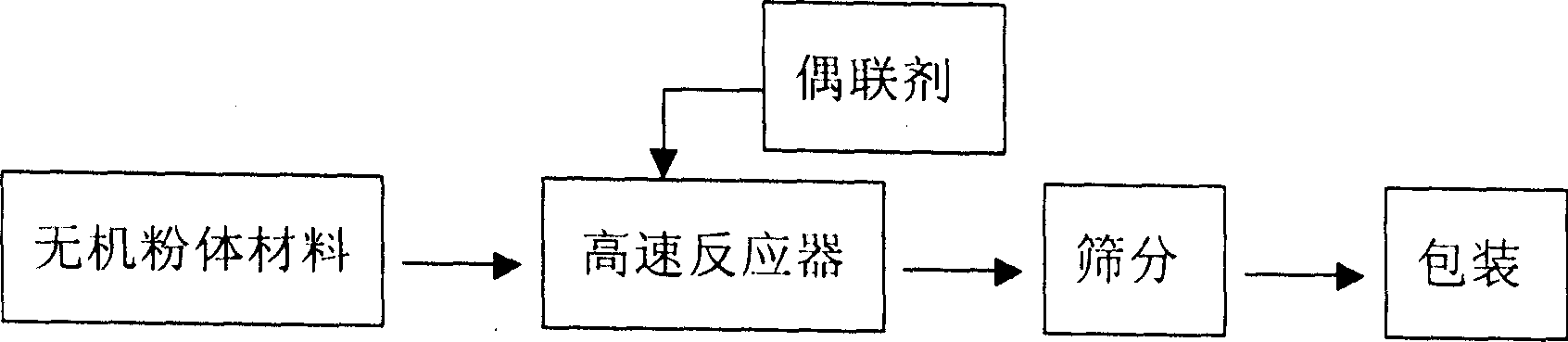

The water-preserving agent for desert zone is made of inorganic powder material and coupling agent according to the weight ratio of 100:0.5-2.5, the described inorganic powder body material is any one of calcium carbonate, magnesium carbonate, talcum powder, pottery clay, wollastonite, coal gangue, flyash, diatomaceous earth or desulfurized gypsum or their any combination, and the described coupling agent is any one of coupling agent of organic titanate, RCA modifying agent, aluminate coupling agent, phosphate coupling agent or silane coupling agent.

Owner:曾敦华

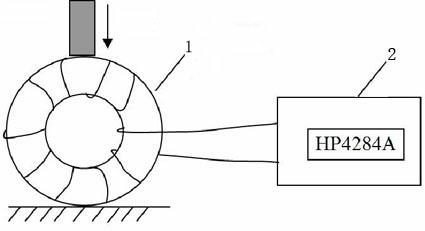

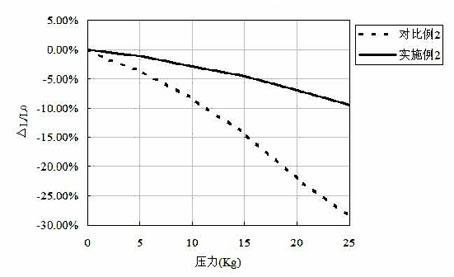

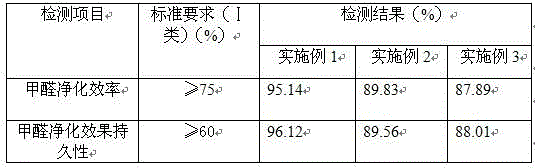

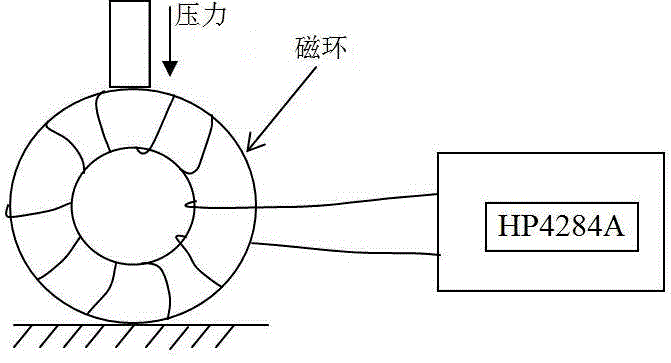

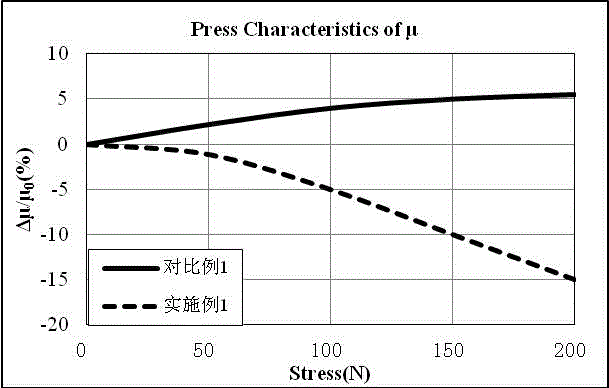

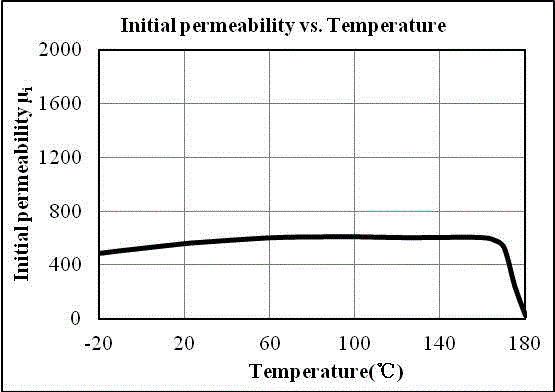

Stress-resistant nickel zinc ferrite with initial permeability of 120, and preparation method of stress-resistant nickel zinc ferrite

The invention relates to a stress-resistant nickel zinc ferrite which has the initial permeability of 120 and is applicable to a power inductor and a preparation method of the stress-resistant nickel zinc ferrite. The stress-resistant nickel zinc ferrite comprises the main components based on respective reference substance: 46.5-50mol% of ferric oxide (Fe2O3), 20-25mol% of nickel oxide (NiO), 20-25mol% of zinc oxide (ZnO) and 9-12mol% of copper oxide (CuO); and the nickel zinc ferrite comprises the accessory ingredient by respective reference substance: 0.1-0.3wt% of calcium carbonate (CaCO3), 0.035-0.10wt% of cobalt oxide (Co2O3), 0.05-0.45wt% of bismuth oxide (Bi2O3), 0.1-1.0wt% of talcum powder and 0.1-1.0wt% of mica powder. The stress-resistant nickel zinc ferrite is prepared by an oxide method and is sintered under a certain condition. After sintering, the product has the crystallized grain size of 20-30mu m, has obvious crystal boundary, and has the characteristic of less inductance change under the stress action, thus meeting the requirement of the power inductor needed to be packaged by resin on the stress resistance of the ferrite material.

Owner:TDG HLDG CO LTD

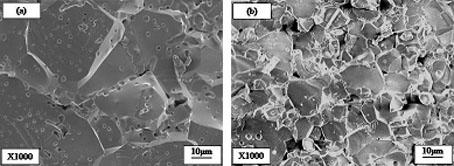

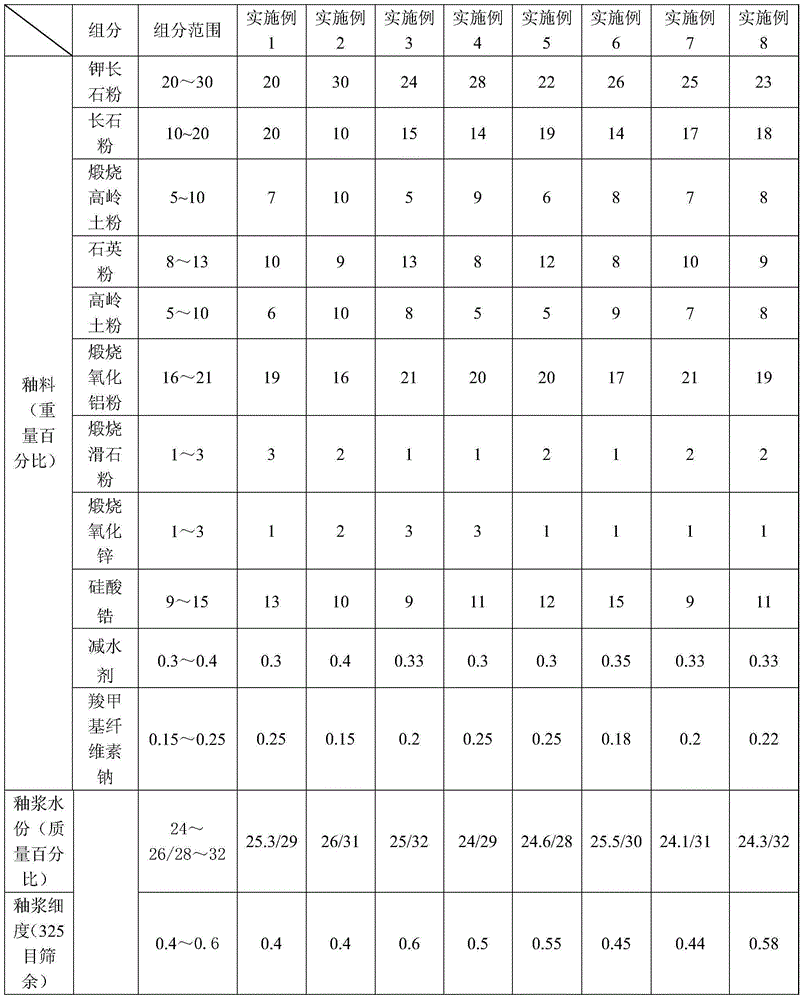

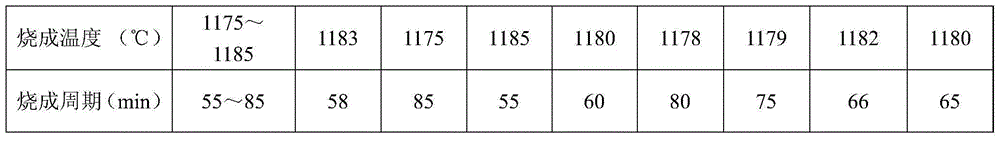

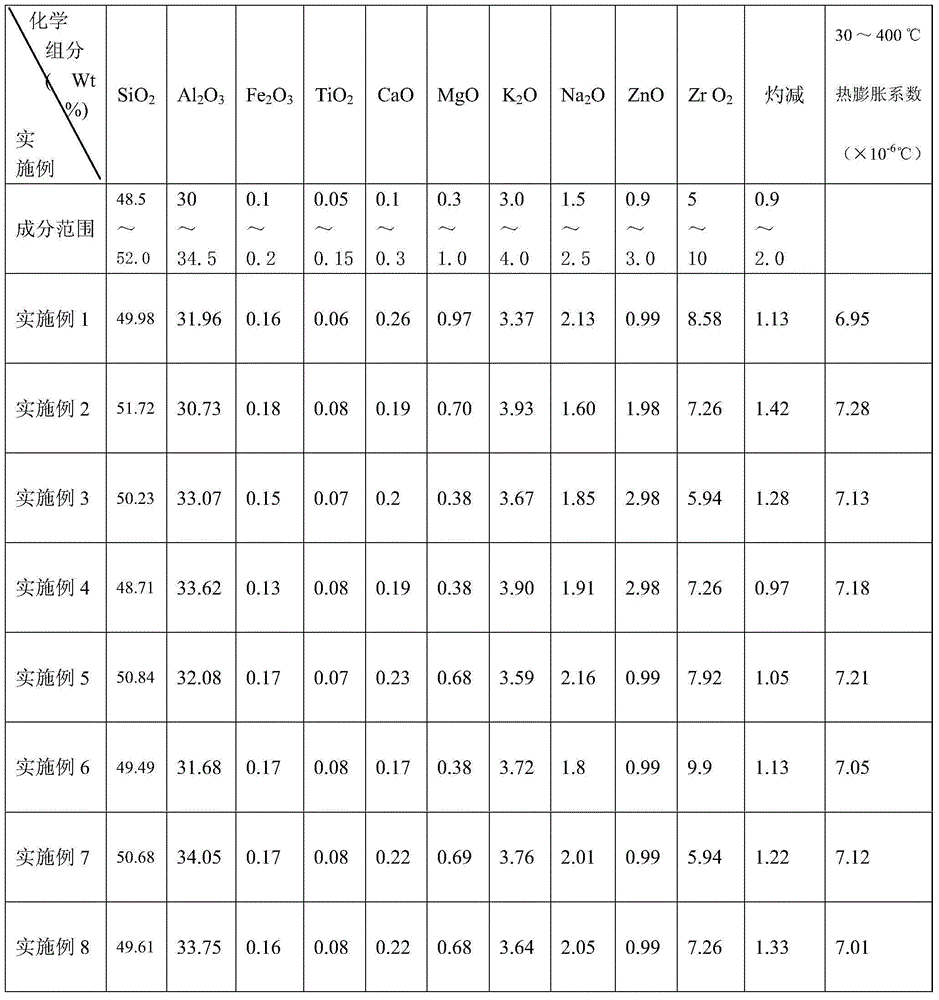

Ground coat used for producing fully-glazed ceramic tile and beneficial to color development of ceramic ink

The invention discloses a ground coat used for producing a fully-glazed ceramic tile and beneficial to color development of ceramic ink. The ground coat is mainly prepared from, by weight, 20%-30% of potassium feldspar powder, 10%-20% of feldspar powder, 5%-10% of calcined kaolin powder, 8%-13% of quartz powder, 5%-10% of kaolin powder, 16%-21% of calcined alumina powder, 1%-3% of calcined talcum powder, 1%-3% of calcined zinc oxide, 9%-15% of zirconium silicate, 0.3%-0.4% of water reducing agent and 0.15%-0.25% of methyl. The content of single raw material chemical component CaO is smaller than 3%. The raw material chemical components of the ground coat comprise 48.5%-52.0% of SiO2, 30%-34.5% of Al2O3, 0.1%-0.2% of Fe2O3, 0.05%-0.15% of TiO2, 0.1%-0.3% of the CaO, 0.3%-1.0% of MgO, 3.0%-4.0% of K2O, 1.5%-2.5% of Na2O, 0.9%-3.0% of ZnO, 5%-10% of ZrO2 and 0.9%-2.0% of igloss. The technological process of the ground coat includes the steps of blending, ball milling, sieving, deironing and glaze slip staling. The using method of the ground coat includes the step of glazing through a bell jar glaze pouring technology or a linear glaze pouring technology. By the adoption of the ground coat, the colors of the product are enriched, color development of the ceramic ink is facilitated, color development of each color is deeper, the hue is pure, and the rate of qualified products is high.

Owner:GUANGDONG XINRUNCHENG CERAMICS

Rigidity enhanced, modified dedicated material of plastic pipe material

This invention relates to a specific modification material for increasing the rigidity of plastic pipes. The specific modification material is composed of: ultra-fine talcum powder 20-30 parts, toughening agent 10-15 parts, coupling agent 1-2 parts, plasticizer 5-8 parts, dispersant 3-5 parts, and high density polyethylene (HDPE) 50-55 parts. Plastic pipes modified with the specific modification material have rigidity 5-6% higher than that of neat HDPE pipes, thus can solve the problems of easy deformation, large influence to ground smoothness and easy breakage of HDPE pipes. Besides, plastic pipes modified with the specific modification material have improved impact strength and physical properties. Talcum powder can partly replace synthetic resin to reduce the cost.

Owner:辽宁艾海滑石有限公司

Nano SiO2-organosilicon coating and preparation method thereof

The invention relates a nanometer SiO2- organosilicon coating and preparation method. The coating comprises the 60-82% organosilicon resin, 3-10% nanometer SiO2, 5-15% dimethylbenzene, 3-8% toluene, 3-6% butyl acetate, 0.2-0.6% dispersing agent, 0.1-0.3% levelling agent, 0.2-0.4% defoaming agent, and 3-10% talcum powder. The method comprises the following steps: 1 weighing nanometer SiO2, adding dimethylbenzene, dispersing agent and butyl acetate, disperse with ultrasonic, and getting nanometer SiO2 slurry; 2 weighing organosilicon resin, adding defoaming agent and dispersing agent, then adding nanometer SiO2 sluury and talcum powder, dispersing and grinding; 3 adding left resin, solvent and adjuvant, and dispersing. The invention can improve the erosion-resisting characteristics, protect material, and extend the life.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

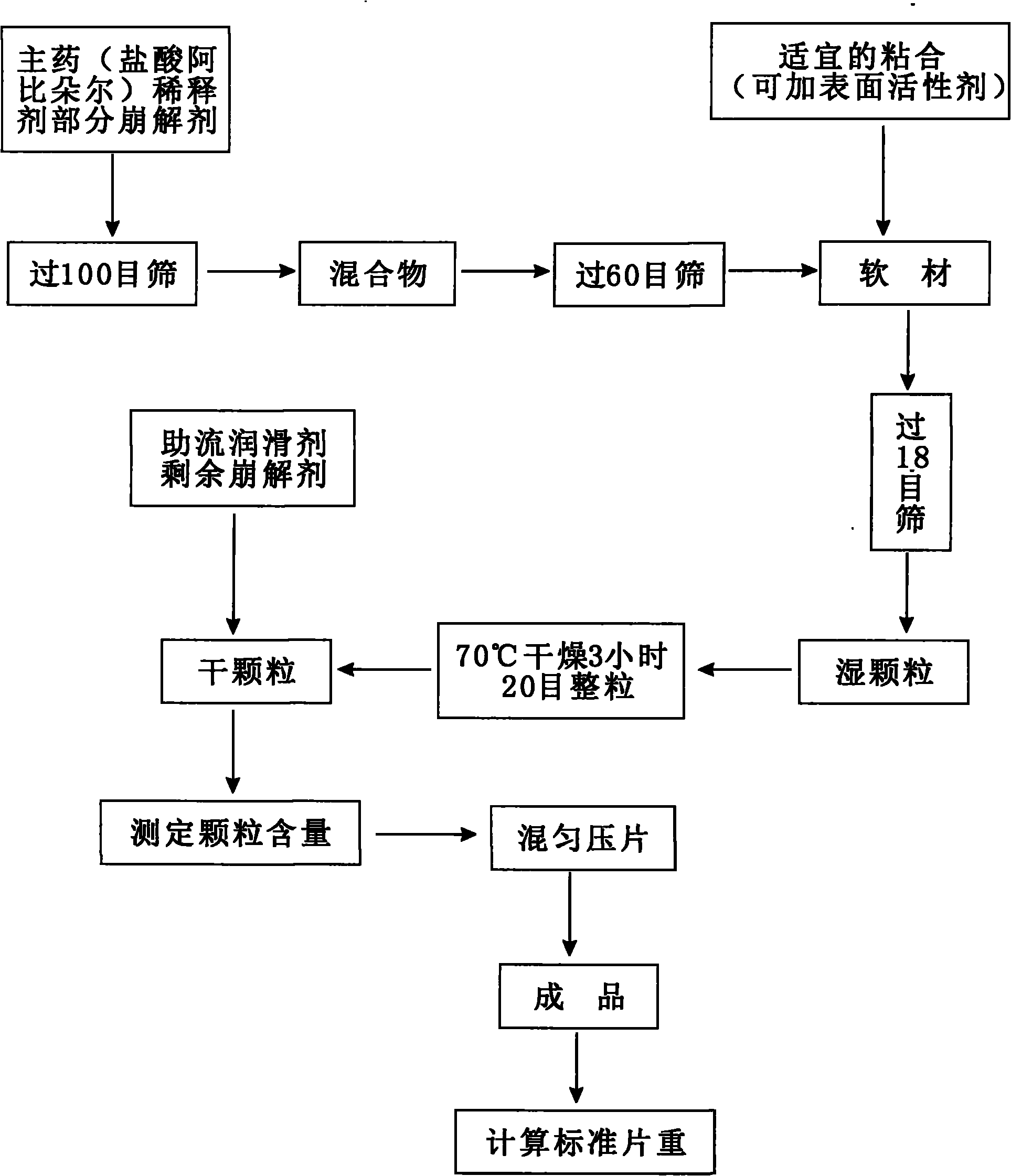

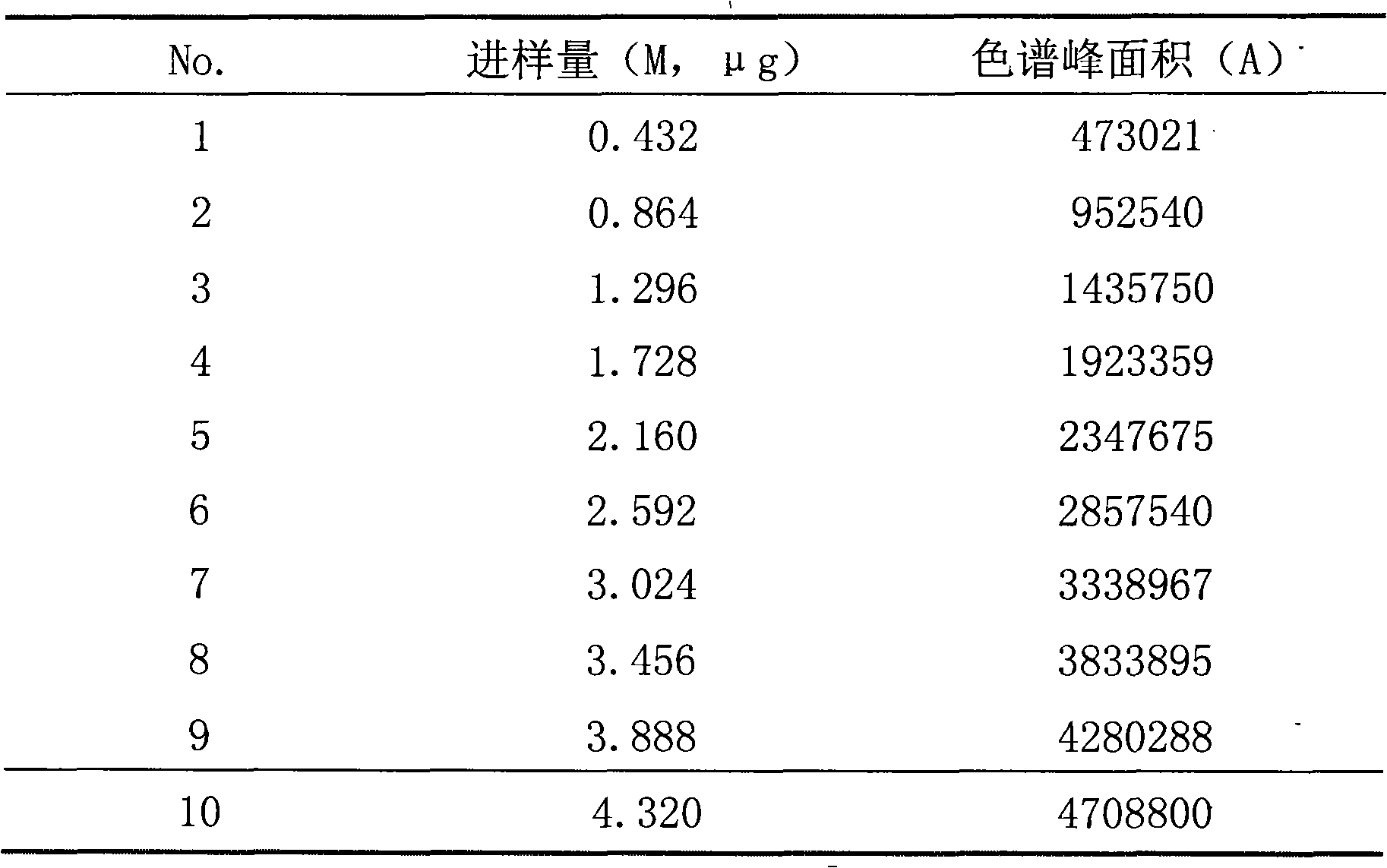

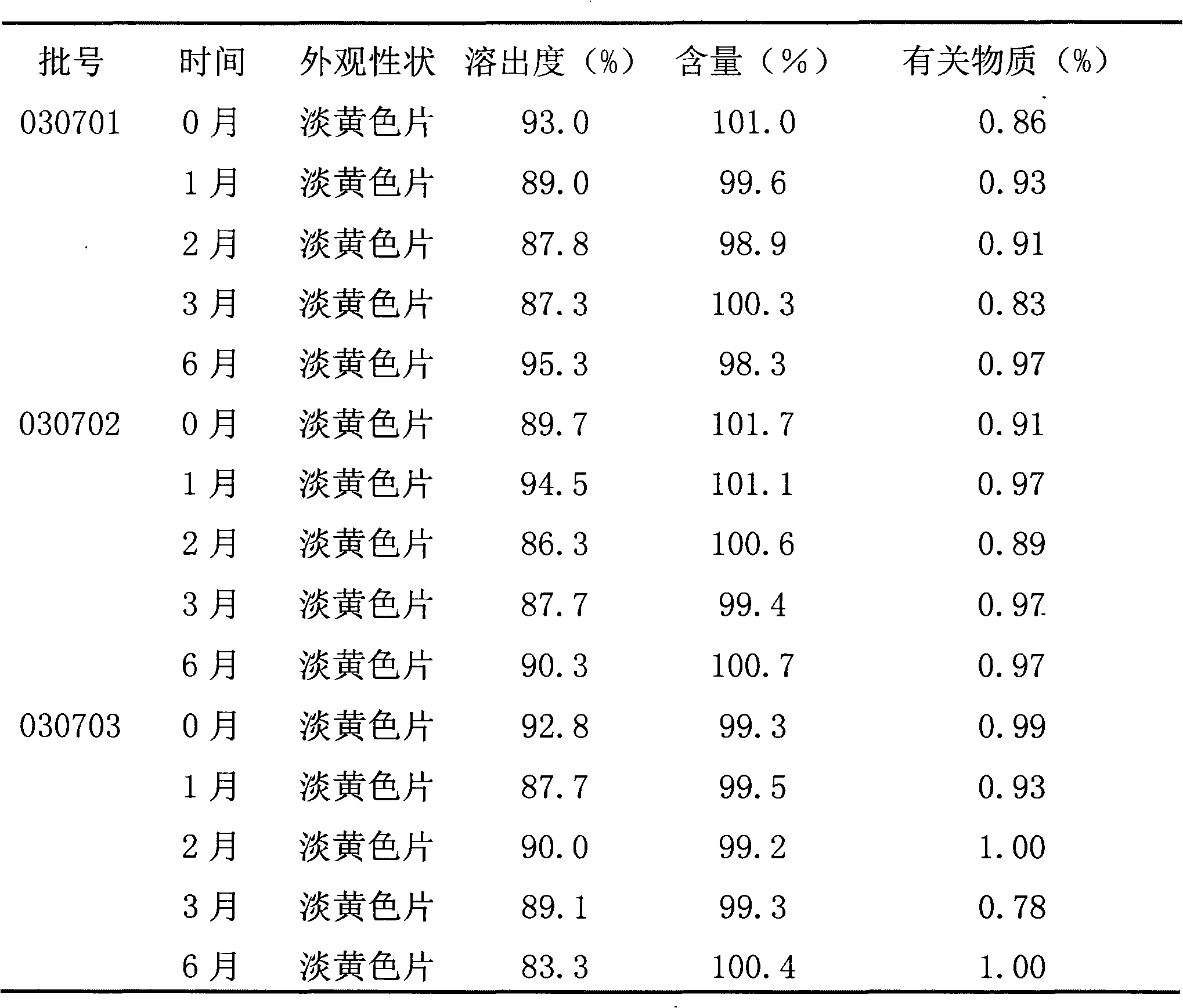

Preparation method and quality control method of arbidol hydrochloride tablet

InactiveCN102091048AQuality improvementQuantitatively accurateOrganic active ingredientsComponent separationPatient acceptanceDissolution

The invention relates to a preparation method and a quality control method of an arbidol hydrochloride tablet. The arbidol hydrochloride tablet comprises the following major ingredients: arbidol hydrochloride, microcrystalline celluloses, milk sugar, starch, low-substituted hydroxypropyl celluloses, talcum powder, magnesium stearate and a right amount of adhesive starch slurry. The preparation method of the arbidol hydrochloride tablet comprises the following steps of: preprocessing; preparing granules; and tabletting. The quality control method of the arbidol hydrochloride tablet comprises the following steps of: measuring dissolution rate, related substances and content. For overcoming the defects of the traditional variety, the invention provides the preparation method of the arbidol hydrochloride tablet, which has the advantages of broad spectrum, high efficiency, stable quality, simple process, low cost, easy patient acceptance, and the quality control method of the arbidol hydrochloride tablet, which has the advantages of convenience, fastness, accurate quantification, good specificity and high applicability.

Owner:HUBEI QIANJIANG PHARMA

Preparation method of snowflake enamel decorative domestic ceramic and manufactured product thereof

The invention relates to a preparation method of a snowflake enamel decorative domestic ceramic and a manufactured product thereof. The formula of the snowflake enamel decorative domestic ceramic consists of the following green bodies and glazes in percentages by weight: a preform body: 40% to 45% of talcum, 25% to 30% of feldspars, 4% to 8% of talcum powder, 15% to 20% of quartz, and 5% to 10% of child-mother sections; mat glaze: 35% to 40% of feldspar, 20% to 25% of quartz, 15% to 20% of calcined talc, 15% to 20% of kaolin, and 5% to 10% of zinc oxide; high white glaze: 45% to 50% of feldspar, 20% to 25% of quartz, 10% to 15% of burned talc, 10% to 15% of kaolin, and 5% to 10% of barium carbonate. The formula is scientific and reasonable, the technology is advanced, the finished product rate is high, and the product quality is good, so that better decorative effect can be achieved for the domestic ceramic, the application range of snowflake glaze is obviously widened, therefore, the ceramic has wide market prospect.

Owner:景德镇市精业陶瓷有限公司

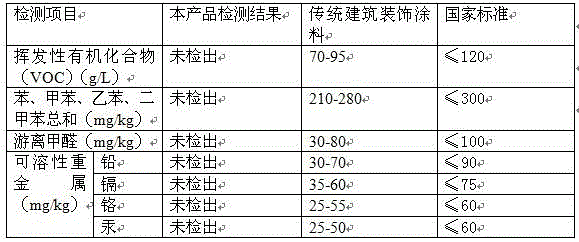

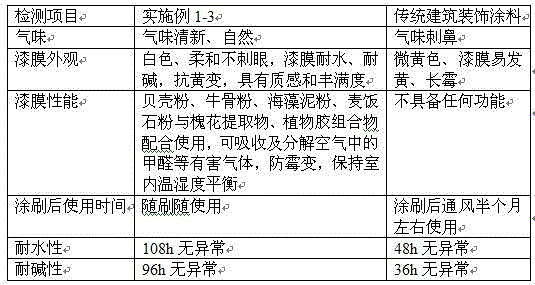

Environmental-protection coating and preparation method

The invention discloses an environmental-protection coating which is composed of following components, by weight, 200-300 parts of water, 1-3 parts of an alkaloid composition, 1-3 parts of an wetting agent, 4-6 parts of a dispersing agent, 4-6 parts of a defoaming agent, 200-250 parts of titanium dioxide, 40-80 parts of talcum powder, 30-70 parts of seaweed mud powder, 30-70 parts of bovine bone powder, 30-70 parts of shell powder, 30-50 parts of medical stone powder, 200-250 parts of an acrylic emulsion, 20-50 parts of a vegetable gum composition, 15-30 parts of glycerin, 2-4 parts of alcohol and 2-4 parts of an extract of flos sophorae. The invention is simple in technology and low in cost. With combination of components such as the shell powder and the like with the extract of flos sophorae, functions such as strong adsorption, sterilization, and anti-mildew are achieved and the coating is fresh in small. The coating is free of toxic substances such as formaldehyde and the like and can absorb harmful substances volatilized from in-door floors. In addition, the coating has excellent air penetrability so that a wall surface has a breathing function and in-door air humidity can be adjusted automatically.

Owner:浙江绿财新材料科技有限公司

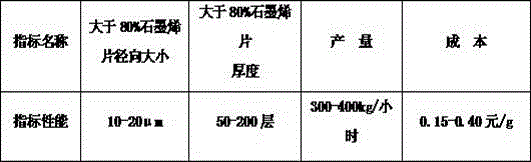

Single-sheet talcum powder and preparation method thereof

ActiveCN104098930AIncrease surface areaHigh activityPigment physical treatmentPigment treatment with non-polymer organic compoundsPowder talcumSheet structure

The invention relates to single-sheet talcum powder and a preparation method thereof. The preparation method specifically comprises the following steps: pre-treating talcum powder with an intercalator to enable the interval between layers of the talcum powder to increase, so that water molecules can immerse into the space between layers of the talcum powder; enabling the layers of the talcum powder to be stripped under the pressure generated through the instant vaporization of the water molecules by using the high temperature and high pressure provided by a bulking machine, so that the talcum powder with a single-layered sheet structure can be obtained. According to the invention, the efficiency is high, the effect is excellent, the sheet structure of the talcum powder cannot be damaged; the prepared single-layered sheet talcum powder is high in additional value and good in functionality, can greatly improve the tensile strength, tensile modulus, bending strength and bending modulus of the composite material under the premise that the loss of impact strength, tenacity and transparency of the product is avoided, is large in surface area and high in activity, can be used as filler to be added in a product in a large amount, reduces the production cost of the product, and has the market application value.

Owner:HAICHENG XINDA MINING

Method for preparing composite talcum powder filled material of polypropylene

This invention relates to a method for preparing talcum powder-filled polypropylene composite material. The method comprises: adding maleic anhydride-grafted polypropylene, talcum powder, epoxy resin and curing agent to polypropylene resin in an internal mixer, open mill or screw extruder at a certain blending temperature, blending, and curing epoxy resin in situ. The interfacial force between epoxy resin and polypropylene or talcum powder increased, and the mechanical properties of the obtained composite material are obviously improved. Compared with traditional surface treatment of talcum powder with coupling agent, or the addition of compatibilizer, the talcum powder-filled polypropylene composite material in this invention has improved rigidity and toughness. The method has such advantages as simple process, high processability and high adaptability. The talcum powder-filled polypropylene composite material can be used in buildings, automobile fittings and electric appliances.

Owner:SHANGHAI JIAO TONG UNIV

Low-temperature-factor anti-stress nickel zinc ferrite and preparation method thereof

The invention relates to low-temperature-factor anti-stress nickel zinc ferrite with initial permeability for a power inductor being 500 and a preparation method of nickel zinc ferrite. Principal components of the nickel zinc ferrite are calculated in oxides as follows: 43.8 to 48.2 percent by mol of Fe2O3, 15.3 to 20.2 percent by mol of NiO, 28.8 to 31.2 percent by mol of ZnO, and 4.3 to 6.1 percent by mol of CuO; auxiliary components of the nickel zinc ferrite are: 0.90 to 1.3 percent by weight of nano SiO2, 0.13 to 0.25 percent by weight of nano Bi2O3, 0.05 to 0.08 percent by weight of Co3O4, 0.10 to 0.25 percent by weight of TiO2 and 0.1 to 0.45 percent by weight of talcum powder. The nickel zinc ferrite is prepared in an oxide method and sintered under certain conditions. The average size of crystal grains of a sintered product is 25 to 35 micrometers, the sintered product has an obvious crystal interface, the product has characteristics that the magnetic permeability is relatively small in variation in the temperature range of -40DEG C to 125 DEG C under the stress effect, and the requirement of the power inductor needing the resin encapsulation for the stress resistance of the ferrite material can be met.

Owner:TDG HLDG CO LTD

Alcoholic-group coating

The invention discloses a novel alcoholic-group coating which comprises forsterite, high aluminium bauxite, crystalline graphite powder, talcum powder, quartz powder, composite adhesives, composite suspoemulsions and solvents, wherein the forsterite can be replaced with a mixture of 150-200-mesh forsterite, 200-250-mesh forsterite and 250-300-mesh forsterite. The novel alcoholic-group coating has the advantages that crystalline graphite powder and talcum powder are added in refractory aggregates with different particle sizes, and cooperate with the composite adhesives and the composite suspoemulsions, so as to ensure the coating strength, the effect that the coating is not cracked in use and is easy to strip in clean is achieved, and the surface precision of a casting is high.

Owner:CHINA THREE GORGES UNIV +1

Hybrid gel particle while drilling plugging agent and preparation method thereof

ActiveCN110760296AEffective blockingImprove pressure bearing capacityDrilling compositionMeth-(Hydroxyethyl)methacrylate

The invention provides a hybrid gel particle while drilling plugging agent and a preparation method thereof. The hybrid gel particle while drilling plugging agent is prepared from the following raw materials in parts by mass: 20-35 parts of reactive monomer, 1.0-3.0 parts of a crosslinking agent, 0.3-0.5 part of an initiator, 3.0-5.0 parts of a silane coupling agent and 0.5-2.0 parts of nano-scalerigid particle; the reactive monomer is a composition of three or more than three kinds of methacrylamide, hydroxyethyl methacrylate, lauryl acrylate, tert-butyl methacrylate, dibutyl adipate, sodiump-styrene sulfonate, ethenyl-Benzenesulfonic acid or divinyl benzene; and the nano-scale rigid particle is a composition of one or more than two kinds of nano calcium carbonate, nano silicon dioxide,talcum powder or wollastonite powder. The gel particle plugging agent prepared by the preparation method has the advantages of high toughness, high temperature resistance, high pressure bearing capacity under high temperature and good plugging effect.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Preparation method of superfine talc powder

InactiveCN103665960AImprove surface activityImprove interface affinityPigment treatment with organosilicon compoundsPigment physical treatmentStearic acidPowder talcum

The invention provides a preparation method of superfine talc powder. The preparation method has the effects of improving the interface affinity of the talc power and polymers and improving the disperse state of the talc powder filler in polymer base materials by carrying out surface modification on the talc powder. The preparation method comprises the following steps: 1) breaking raw materials; 2) milling the raw materials into fine powder with a ball mill; 3) adding water to the milled materials to prepare pulp; 4) after mixing a silane coupling agent, ethanol and stearic acid uniformly to obtain a mixture, adding the mixture to the pulped materials, stirring the materials at 80-105 DEG C for 30-60 minutes and then cooling the materials; 5) grinding the materials for 6-8 hours; and 6) drying the powder and collecting the product. The preparation method has the beneficial effects that the surface activity of the talc powder particles is improved, so that the process is simplified and the cost is reduced; the interface affinity of the talc power and the polymers is improved and the disperse state of the talc powder filler in the polymer base materials is improved, so that talc is well applied and the application field of talc is expanded.

Owner:YANGZHOU TIANLI NON METALLIC MATERIAL

Preparation method of anti-falling corrosion-resistant double-metal composite coating

The invention discloses a preparation method of an anti-falling corrosion-resistant double-metal composite coating. The composite coating consists of a composition A, a composition B and heat-resistant filler in a weight ratio of 1.5: 1: 1; 0.5-1 part of compound rare earth, 30-35 parts of a vapor phase inhibitor, 20-25 parts of deionized water and 10-15 parts of a thixotropic agent are added into the composition B; the heat-resistant filler comprises nanosilicon dioxide, blocking functional filler and powdered aluminum in a mass ratio of 1.5: 1: 1; the blocking functional filler comprises the following components in parts by mass: 2-6 parts of hollow glass beads, 10-15 parts of graphite, 20-35 parts of black silicon carbide, 25-30 parts of fine crystal aluminum oxide, 5-10 parts of molybdenum disulfide, 1-5 parts of zinc oxide and 3-6 parts of talcum powder.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Hot mould centrifugal cast iron pipe mold paint and preparation method thereof

ActiveCN101693281AImprove breathabilityGood heat insulationFoundry mouldsFoundry coresSodium BentoniteEconomic benefits

The invention relates to a hot mould centrifugal cast iron pipe mold paint and a preparation method thereof. The invention mainly solves the technical difficulties of poor quality and low yield and poor economic benefit of a cast iron pipe produced by the traditional paint. The technical scheme is achieved as follows: the hot mould centrifugal cast iron pipe mold paint comprises the following components in percentage by weight: 14-16 percent of kaoline, 14-16 percent of burned diatomite, 2-4 percent of sodium base bentonite, 2-3.5 percent of talcpowder and 64-68 percent of water. The preparation method comprises the following steps: firstly, adding the kaoline, the burned diatomite, the sodium base bentonite and the talcpowder in percentage by weight into a mixing pan for dry mixing; secondly, adding 1 / 4 of water with weight percentage of 64-68 percent into the mixing pan; thirdly, mixing and rolling into a hard paste material for storage for later use; fourthly, when in use, putting the material into a wheel-rolling mixer, adding the left 3 / 4 of water into the wheel-rolling mixer for mixing-rolling and obtaining the mold paint when the concentration reaches 1.2.

Owner:绛县恒通铸造有限公司

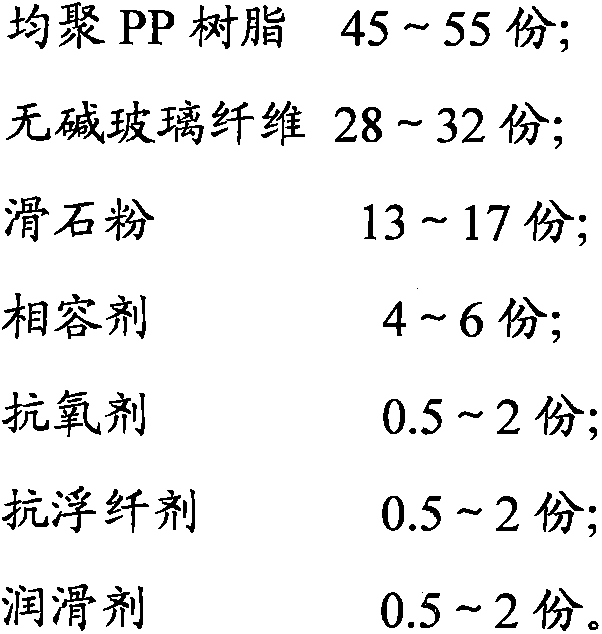

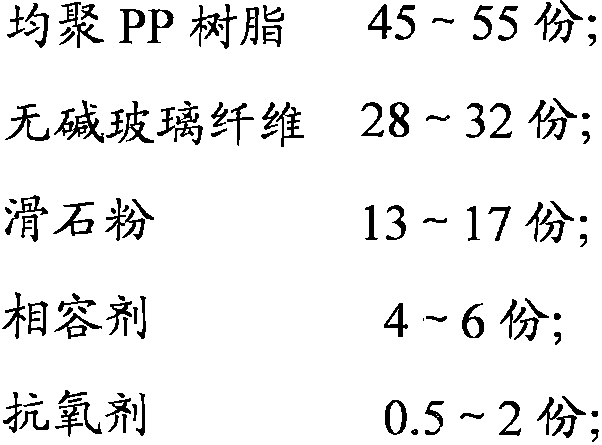

Alkali-free glass fiber reinforcing modified polypropylene composite material and preparing method thereof

InactiveCN105504489AHigh surface finishImprove processing fluidityPolypropylene compositesGlass fiber

The invention relates to an alkali-free glass fiber reinforcing modified polypropylene composite material and a preparing method thereof. The alkali-free glass fiber reinforcing modified polypropylene composite material comprises, by mass, 45-55 parts of homopolymerized PP resin, 28-32 parts of alkali-free glass fibers, 13-17 parts of talcum powder, 4-6 parts of compatilizer, 0.5-2 parts of antioxidant, 0.5-2 parts of anti-fiber-floating agent and 0.5-2 parts of lubricating agent. The alkali-free glass fiber reinforcing modified polypropylene composite material has the advantages that the superfine talcum powder is added into a PP glass fiber reinforcement material for replacement, the talcum powder with the length-diameter ratio smaller than that of the glass fibers is used, the large-particle lubricating dispersion effect can be achieved in the mixture of the formula, the alkali-free glass fibers with the large length-diameter ratio can be better and evenly dispersed in the material accordingly, the surface bright-clean performance and the processing fluidity of a nylon composition can be effectively improved, and therefore a product with the bright and clean surface can be better processed.

Owner:ZHEJIANG PINNUO NEW MATERIALS

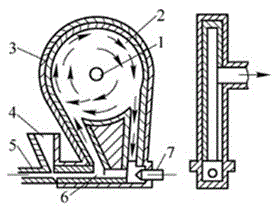

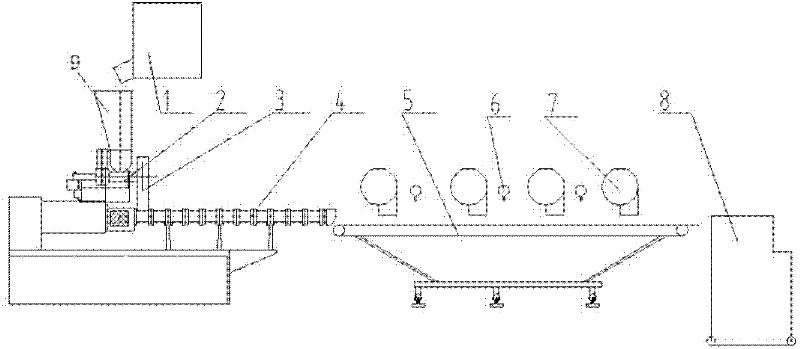

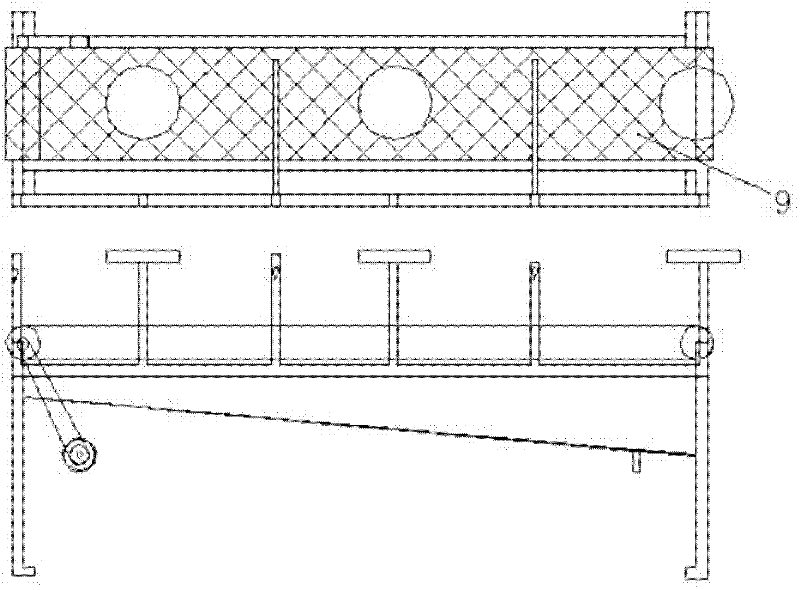

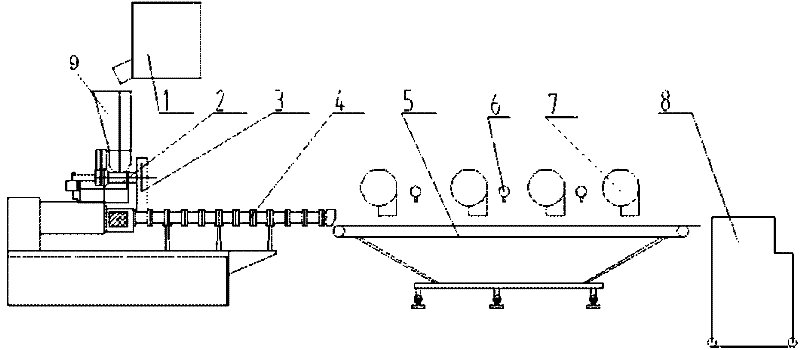

Superfine talcum powder-polypropylene filled master batch, preparation method and equipment thereof

The invention discloses a talcum powder-polypropylene filled master batch. The talcum powder-polypropylene filled master batch comprises the following components in percentage by weight: 75-85% of talcum powders, 10-15% of polypropylene materials, 0.5-0.7% of antioxidants and 1-5% of processing agents. Production equipment of the talcum powder-polypropylene filled master batch comprises a high-speed mixer, a feeding machine, a double-screw extrusion machine, a caterpillar track conveying and cooling device and a hob granulator, wherein the high-speed mixer is arranged above the feeding machine, a material outlet of the feeding machine is connected with a material inlet of the double-screw extrusion machine, a material outlet of the double-screw extrusion machine is connected with a material inlet of the caterpillar track conveying and cooling device, and a material outlet of the caterpillar track conveying and cooling device is connected with a material inlet of the hob granulator. Compared with the technology that an internal mixer is used for producing the superfine talcum powder master batch, the production equipment provided by the invention has the following advantages: the proper raw material formula, the forcing of the feeding machine, the double-screw extrusion with a deep spiral groove and a caterpillar track conveying and cooling granulation mode are adopted, so that the low-stacking-density powder can be fed into the double-screw extrusion machine with high efficiency; as the talcum powder-polypropylene filled master batch contains high inorganic powder content and the adopted spiral groove is deep, the talcum powder-polypropylene filled master batch can be conveyed conveniently; the plasticized dispersing efficiency of the talcum powder-polypropylene filled master batch is high; and the talcum powder-polypropylene filled master batch is not easy to break when adopting a water-cooling brace to granulate; and the normal granulation can be ensured.

Owner:KINGFA SCI & TECH CO LTD +1

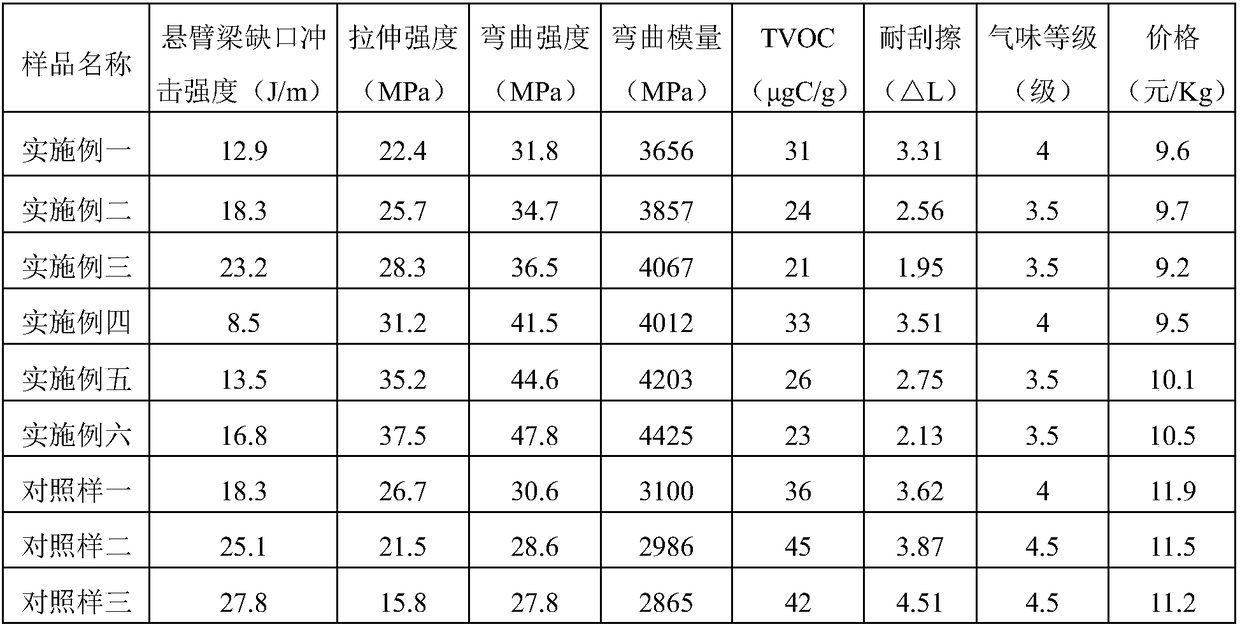

Polypropylene composite material for automobile interior decoration, and preparation method thereof

The invention discloses a polypropylene composite material for automobile interior decoration, and a preparation method thereof. The polypropylene composite material comprises 33.5-47 parts of homopolymerized PP, 20-33.5 parts of copolymerized PP, 15-30 parts of talcum powder, 0.2-0.5 part of an antioxidant, 1-1.5 parts of a deodorant, 0.1-0.3 part of a dispersant, 0.5-1 part of calcium stearate,0.1-0.2 part of a light stabilizer and 0.3-0.5 part of a nucleating agent. The invention also provides the preparation method of the composite material. The composite material is obtained by mixing, co-extruding, cooling, pelletizing and drying. The compounding of the homopolymerized PP and the copolymerized PP under the synergistic effects of the talcum powder, a nucleating agent and the dispersant improves the modulus of the composite material, improves the scratch resistance, avoids the use of a scratch-resistant agent, reduces the production cost, reduces the odor and the VOC content of the composite material, and makes the composite material meet the requirements of the automotive interior decoration for the use environment.

Owner:QINGDAO GON TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com