Preparation method of ternary single crystal material

A single crystal material, ternary material technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problem of long sintering cycle, ternary material dust collection material can not be resource utilization, complex preparation process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a ternary single crystal material, the method comprising the following steps:

[0035] (1) Mix the ternary 523 single crystal precursor, lithium source, zirconia, and ternary material with a D50 of 1-3 μm to pulverize and collect dust to obtain a mixture;

[0036] (2) sintering the mixture obtained in step (1) to obtain a ternary single crystal material;

[0037] Wherein, in step (1), the ratio of the amount of the lithium element in the lithium source to the total amount of the three elements of nickel, cobalt and manganese in the ternary 523 single crystal precursor is (1-1.06):1 ; The mixed material contains 5-15% by weight of ternary material pulverized dust collector and 0.15-0.25% by weight of zirconium element.

[0038] In the present invention, the chemical formula of the ternary 523 single crystal precursor used is Ni 0.5 co 0.2 mn 0.3 (OH) 2 .

[0039]In the present invention, in a preferred embodiment, the t...

Embodiment 1

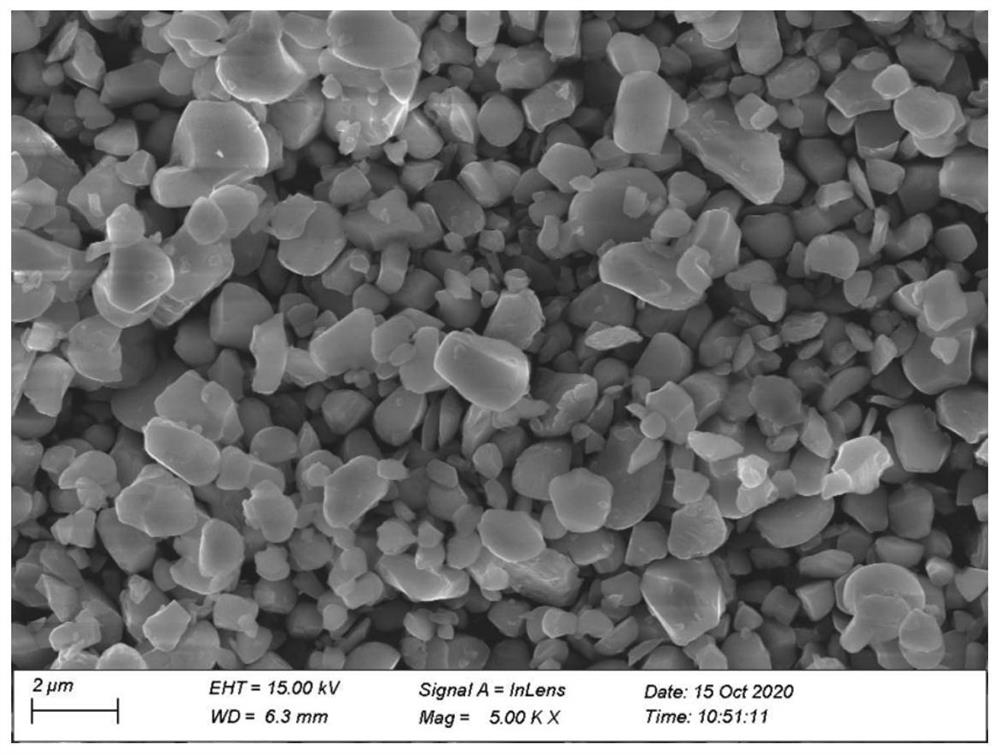

[0058] (1) The ternary 523 single crystal precursor, lithium carbonate, zirconia, and ternary polycrystalline material (the Dmin of the ternary polycrystalline material precursor is 0.79 μm) are pulverized and mixed in a high mixer to obtain Mixture; wherein, the ratio of lithium element in lithium carbonate to the total amount of the three elements of nickel, cobalt and manganese in the ternary 523 single crystal precursor is 1.06:1, and the mixture contains 0.2% by weight of zirconium and 5% by weight % of ternary polycrystalline pulverized dust-collecting material; wherein, the preparation process of ternary polycrystalline pulverized dust-collected material is as follows: the ternary polycrystalline material is pulverized through a mechanical mill, the classification frequency is in the range of 10-30Hz, and the classification wheel , the materials with qualified particle size are collected by the cyclone collector, and the fine dust is collected by the bag filter. When a ...

Embodiment 2

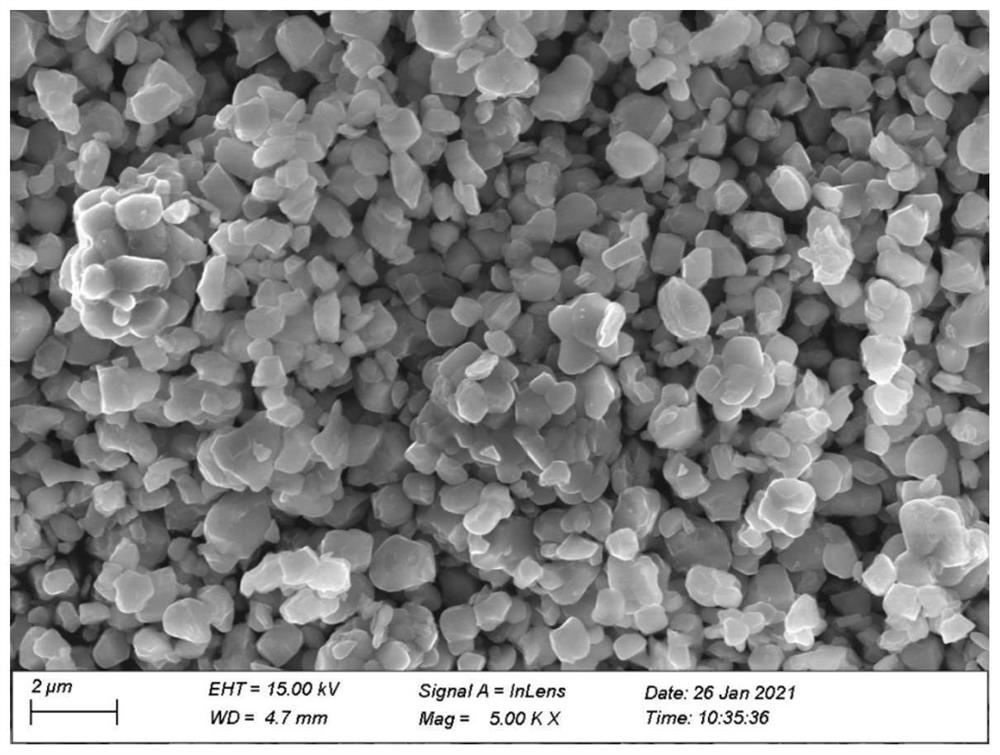

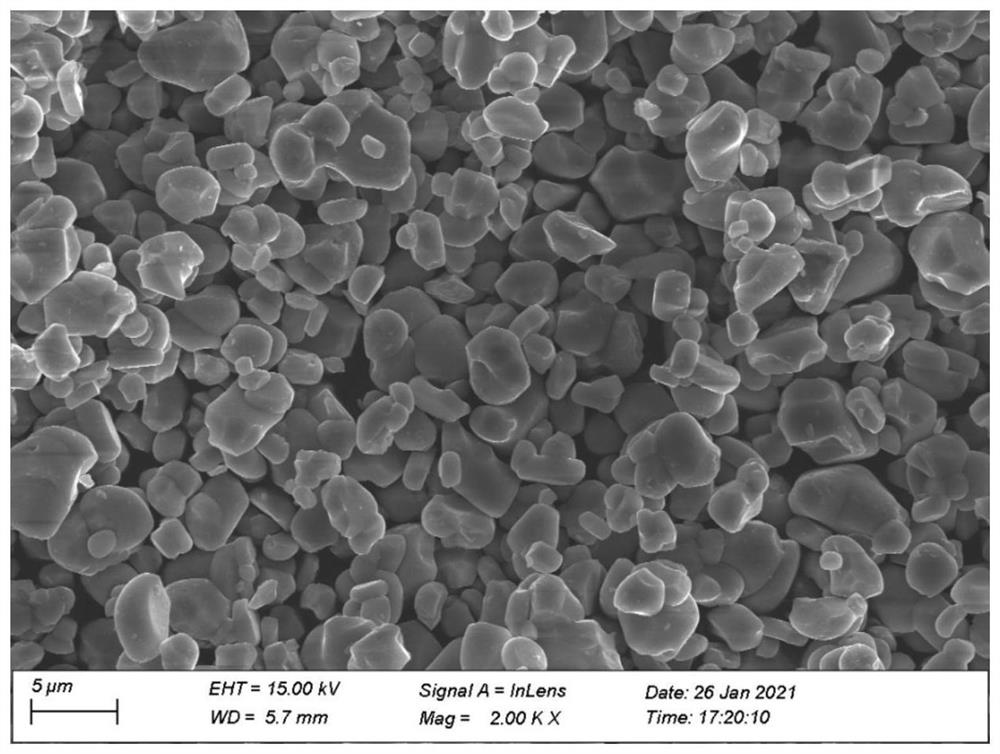

[0061] (1) Mix the ternary 523 single crystal precursor, lithium carbonate, zirconia and ternary single crystal material dust collection material in a high mixer to obtain a mixture; wherein, the lithium element in lithium carbonate and the ternary The ratio of the total amount of the three elements of nickel, cobalt and manganese in the 523 single crystal precursor is 1.02:1, and the mixture contains 0.2% by weight of zirconium element and 10% by weight of ternary single crystal dust collector. After ICP test, The chemical formula of ternary single crystal dust collector is Li 1.012 (Ni 0.497 co 0.196 mn 0.289 )O 2 ; Among them, the SEM picture of the ternary single crystal material pulverized dust collection material is as follows figure 2 As shown, Dmin is 0.17 μm, D10 is 1.167 μm, D50 is 2.704 μm, D90 is 5.481 μm, and Dmax is 11.39 μm. Combining with SEM, it can be seen that the crushed dust collection material of the ternary single crystal material is mainly fine pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com