Preparation method of in-situ synthesized Cu-graphene heteropolymer reinforced aluminum matrix composite

A technology of olefin heteropolymers and composite materials, which is applied in the field of powder metallurgy, can solve the problems of weak interface bonding strength of composite materials, graphene damage, non-wetting of graphene and aluminum substrates, etc., to improve interface bonding and sintering Densification and the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

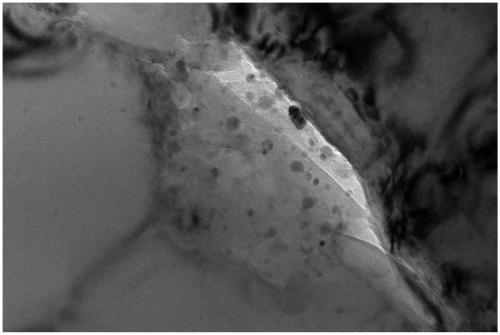

[0017] (1) 2.3g nickel nitrate hexahydrate, 0.94g glucose, 40g sodium chloride were placed in deionized water for magnetic stirring for 6 hours, the resulting mixed solution was placed in a refrigerator for 48h, and the frozen solution was placed in a freeze dryer Freeze-dried for 24 h to obtain the precursor composite powder; the obtained precursor composite powder was placed at 750 °C, reduced and calcined in a hydrogen atmosphere for 2 hours, and finally washed with water to remove sodium chloride to obtain a Cu-graphene heteropolymer, such as figure 1 shown.

[0018] (2) The obtained Cu-graphene heteropolymer / aluminum powder was placed in a ball milling jar according to the ratio of 1:199, and filled with argon as a protective atmosphere. In a planetary ball mill, it is subjected to low-speed and short-time intermittent ball milling (360 rpm, 10 minutes for each ball milling, intermittent 30 minutes, and 80 minutes for ball milling).

[0019] (3) The obtained composite po...

Embodiment 2

[0023] (1) 2.3g nickel nitrate hexahydrate, 0.94g glucose, 40g sodium chloride were placed in deionized water for magnetic stirring for 6 hours, the resulting mixed solution was placed in a refrigerator for 48h, and the frozen solution was placed in a freeze dryer Freeze-dried for 24 h to obtain the precursor composite powder; the obtained precursor composite powder was placed at 750 °C, reduced and calcined in a hydrogen atmosphere for 2 hours, and finally washed with water to remove sodium chloride to obtain a Cu-graphene heteropolymer, such as figure 1 shown.

[0024] (2) The obtained Cu-graphene heteropolymer / aluminum powder was placed in a ball mill in a ratio of 1:135, and filled with argon as a protective atmosphere. In a planetary ball mill, it is subjected to low-speed and short-time intermittent ball milling (360 rpm, 10 minutes for each ball milling, intermittent 30 minutes, and 80 minutes for ball milling).

[0025] (3) The obtained composite powder was cold-press...

Embodiment 3

[0029] (1) 2.3g nickel nitrate hexahydrate, 0.94g glucose, 40g sodium chloride were placed in deionized water for magnetic stirring for 6 hours, the resulting mixed solution was placed in a refrigerator for 48h, and the frozen solution was placed in a freeze dryer Freeze-dried for 24 h to obtain the precursor composite powder; the obtained precursor composite powder was placed at 750 °C, reduced and calcined in a hydrogen atmosphere for 2 hours, and finally washed with water to remove sodium chloride to obtain a Cu-graphene heteropolymer, such as figure 1 shown.

[0030] (2) The obtained Cu-graphene heteropolymer / aluminum powder was placed in a ball mill in a ratio of 1:99, and filled with argon as a protective atmosphere. In a planetary ball mill, it is subjected to low-speed and short-time intermittent ball milling (360 rpm, 10 minutes for each ball milling, intermittent 30 minutes, and 80 minutes for ball milling).

[0031] (3) The obtained composite powder was cold-presse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com