Ceramic material and preparation method therefor

A technology of ceramic materials and raw materials, applied in the field of ceramic materials and their preparation, can solve the problems of low density and hardness, less red mud usage, etc., and achieve the effects of low production cost, reduced land occupation, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

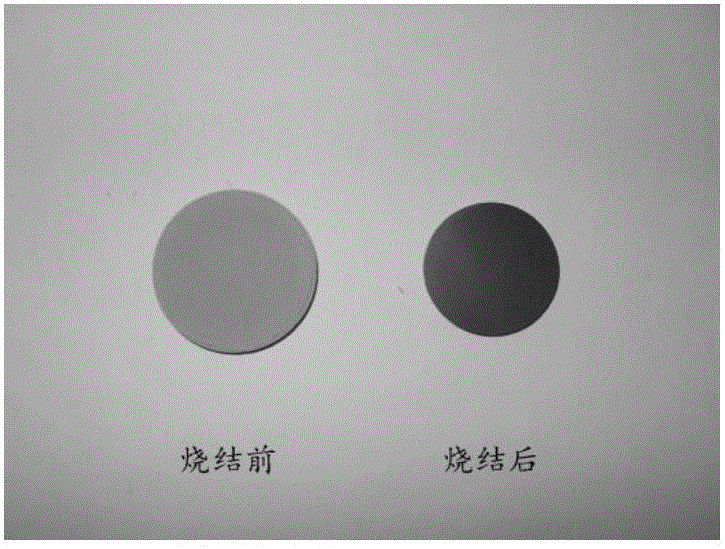

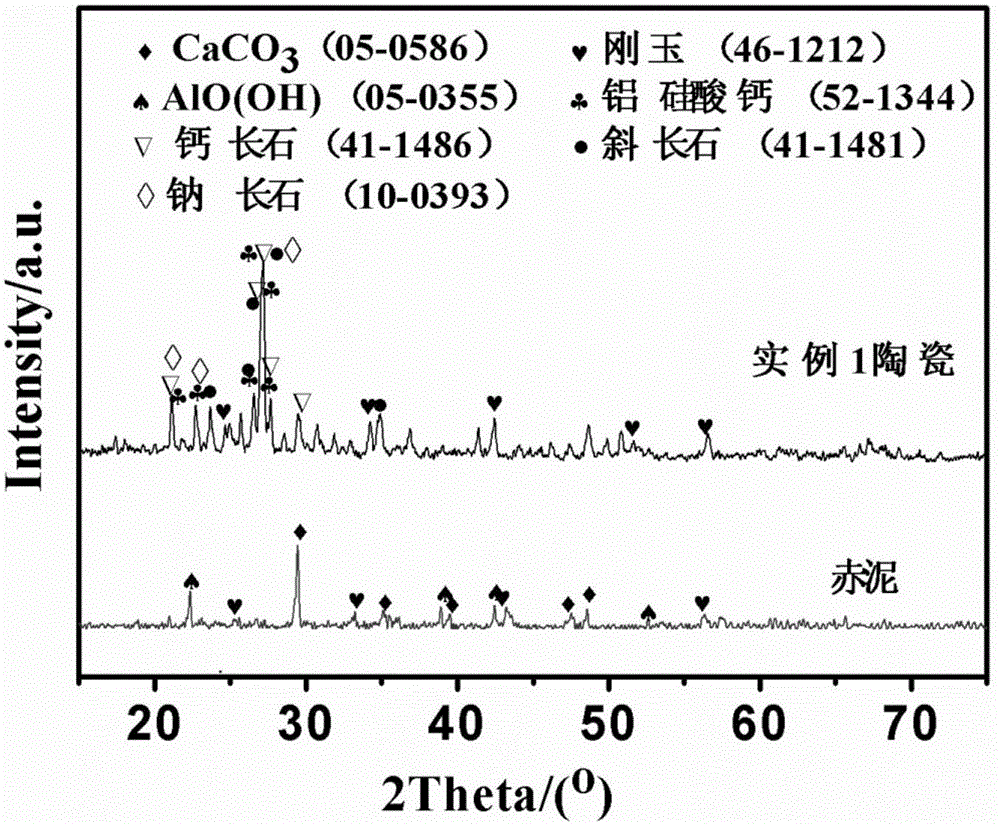

Embodiment 1

[0025] The ceramic material in this embodiment is mainly made of the following raw materials in mass percentage: 40% red mud, 30% bauxite, 10% potassium feldspar, 10% kaolin, and 10% quartz sand.

[0026] The preparation method of the ceramic material of the present embodiment comprises the following steps:

[0027] 1) Red mud, bauxite, potassium feldspar, kaolin, and quartz sand are mixed in a ball mill for 6 hours according to the proportion, and the mixed material is blown and dried to obtain a dry mixture;

[0028] 2) Add water to the dry mixture until the water content is 5%, stir evenly to obtain the wet mixture; use the upper and lower pressure molding method to form a green body; during the molding process, the pressure is 8MPa, and the pressure is maintained for 2min ;

[0029] 3) Put the green body into an atmospheric sintering furnace, raise the temperature to 1250°C at a heating rate of 10°C / min, keep it at this temperature for 1 hour, and cool it down to obtain t...

Embodiment 2

[0031] The ceramic material in this embodiment is mainly made of the following raw materials in mass percentage: 40% red mud, 30% bauxite, 10% potassium feldspar, 10% kaolin, and 10% quartz sand.

[0032] The preparation method of the ceramic material of the present embodiment comprises the following steps:

[0033] 1) Red mud, bauxite, potassium feldspar, kaolin, and quartz sand are mixed in a ball mill for 6 hours according to the proportion, and the mixed material is blown and dried to obtain a dry mixture;

[0034] 2) Add water to the dry mixture until the water content is 5%, stir evenly to obtain the wet mixture; use the upper and lower pressure molding method to form a green body; during the molding process, the pressure is 8MPa, and the pressure is maintained for 2min ;

[0035] 3) Put the green body into an atmospheric sintering furnace, raise the temperature to 1200°C at a heating rate of 10°C / min, keep it at this temperature for 2 hours, and cool it down to obtain ...

Embodiment 3

[0037] The ceramic material in this embodiment is mainly made of the following raw materials in mass percentage: 40% red mud, 30% bauxite, 10% potassium feldspar, 10% kaolin, and 10% quartz sand.

[0038] The preparation method of the ceramic material of the present embodiment comprises the following steps:

[0039] 1) Red mud, bauxite, potassium feldspar, kaolin, and quartz sand are mixed in a ball mill for 6 hours according to the proportion, and the mixed material is blown and dried to obtain a dry mixture;

[0040] 2) Add water to the dry mixture until the water content is 5%, stir evenly to obtain the wet mixture; use the upper and lower pressure molding method to form a green body; during the molding process, the pressure is 8MPa, and the pressure is maintained for 2min ;

[0041] 3) Put the green body into an atmospheric sintering furnace, raise the temperature to 1240°C at a heating rate of 10°C / min, keep it at this temperature for 1 hour, and cool it down to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com