Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce oxidation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

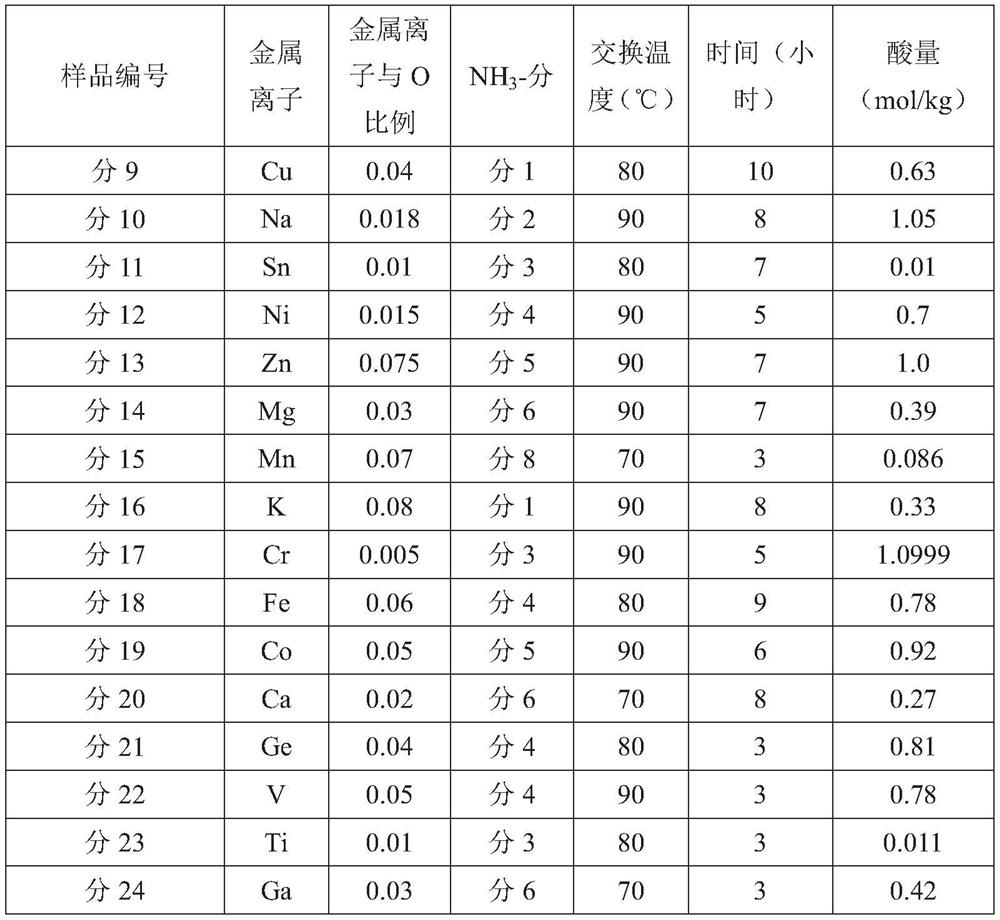

Catalyst for simultaneous denitration, demercuration and dioxin removal and preparation method thereof

ActiveCN111167475AWide active temperature rangeStrong resistance to sulfur poisoningCatalyst carriersGas treatmentPtru catalystEngineering

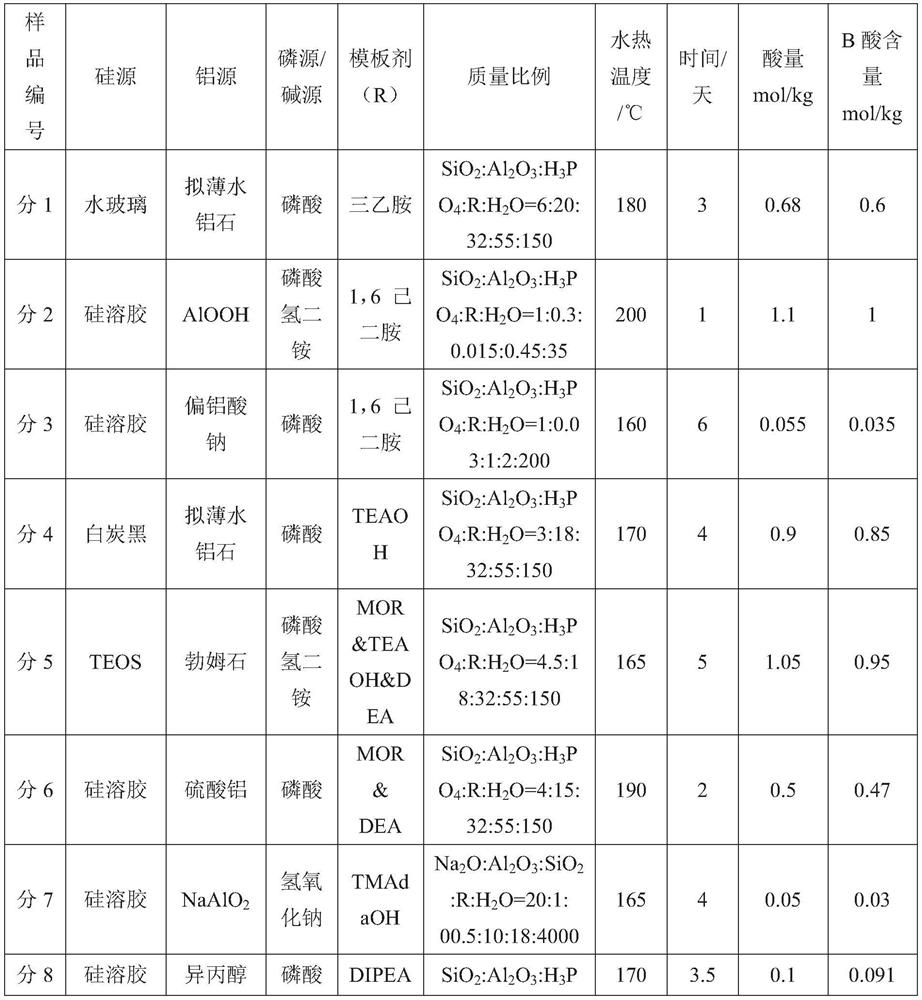

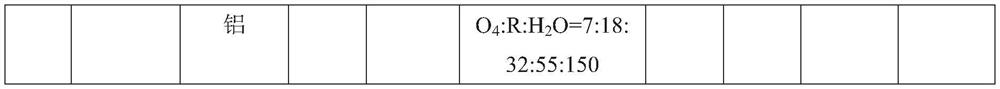

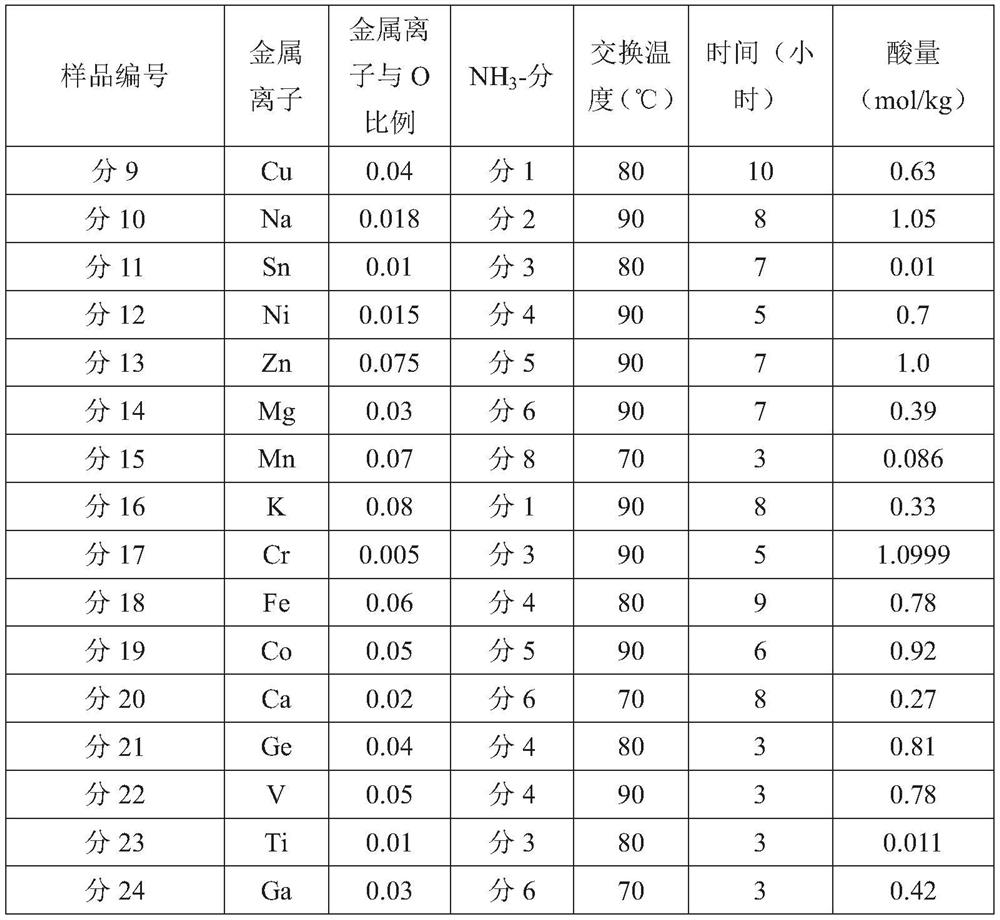

The invention discloses a catalyst for simultaneous denitration, demercuration and dioxin removal and a preparation method thereof. According to the invention, cerium oxide and niobium pentoxide are used as catalytic active components, a mixture of nickel oxide and platinum nanoparticles is used as a cocatalyst, a titanium dioxide nanoneedle generated by modifying tetrabutyltitanate with hydrochloric acid is used as a main carrier, and the catalyst is used after hydrogen pretreatment. Based on the mass of the carrier, the mass percentage of the active components is 10%-30%, and the mass percentage of the cocatalyst is 0.1%-0.15%. The preparation method comprises the following steps: uniformly stirring the active components, a cocatalyst composite colloidal solution and the optimized and modified catalyst carrier, carrying out aging and extrusion molding, and then performing drying and roasting to obtain the catalyst. The catalyst is environment-friendly, can efficiently remove nitrate,mercury and dioxin at the same time, and has a wide active temperature interval and low SO2 oxidation efficiency. Within 240-500 DEG C, the denitration efficiency and the dioxin removal efficiency ofthe catalyst are both higher than 95%, and the mercury removal efficiency of the catalyst is higher than 99%. The catalyst can be widely applied to the fields of coal-fired power plants, chemical plants and the like.

Owner:南京环福新材料科技有限公司

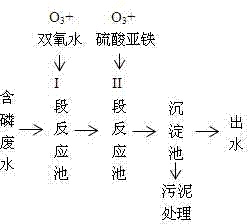

Process and device for removing hypophosphites and phosphites by advanced oxidation coupling technique

ActiveCN103482797AGood removal effectStrong oxidation abilityMultistage water/sewage treatmentWater/sewage treatment by oxidationSludgeSulfate

The invention relates to industrial wastewater treatment, particularly a device for removing hypophosphites and phosphites by an advanced oxidation coupling technique in industrial wastewater treatment. The invention provides the device for removing hypophosphites and phosphites by an advanced oxidation coupling technique, which comprises a I stage reaction pond, a II stage reaction pond, a hydrogen peroxide injection device, an ozone injection device and a ferrous sulfate injection device. The I stage reaction pond is in communication with the II stage reaction pond. The I stage reaction pond is provided with a water inlet. The ozone injection device is connected to the I stage reaction pond. The ferrous sulfate injection device is connected to the II stage reaction pond. The ozone injection device is connected to the II stage reaction pond. The device provided by the invention has the advantages of high reaction speed, favorable removal effect, simple technical process, no need of regulating pH value, and low sludge production quantity.

Owner:深圳市万木水务有限公司

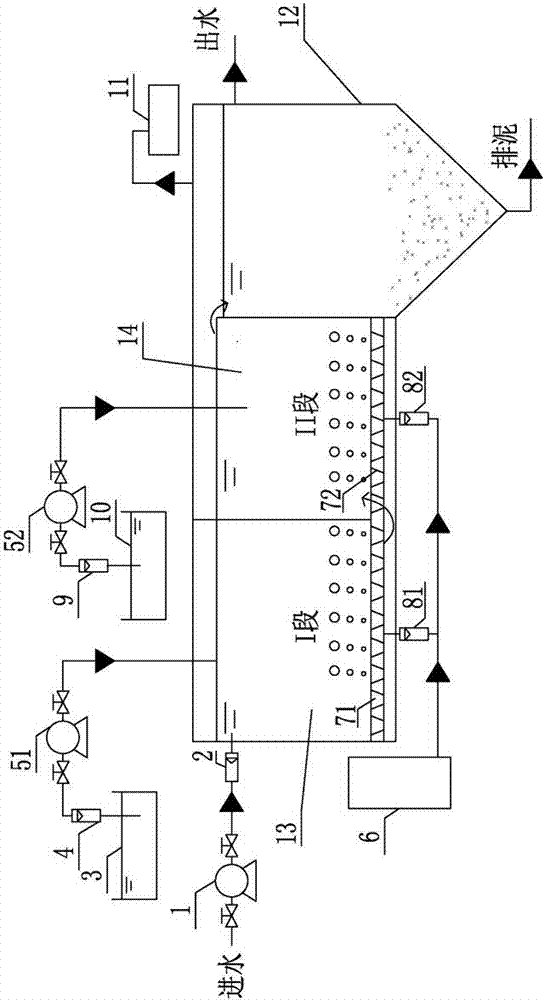

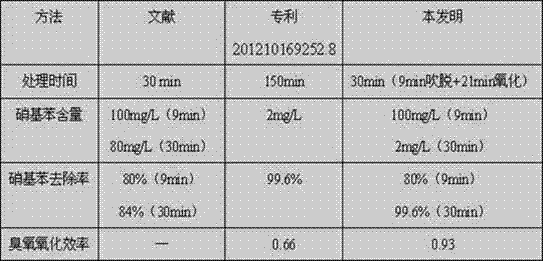

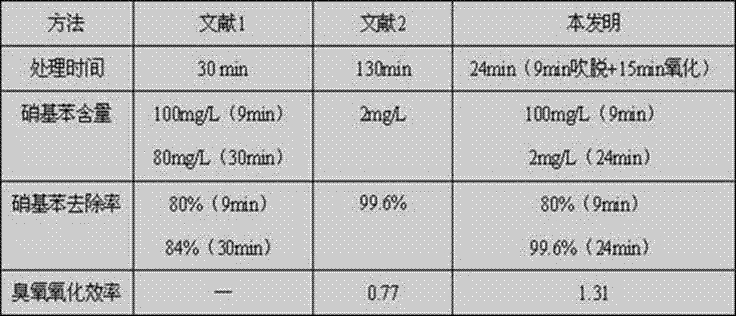

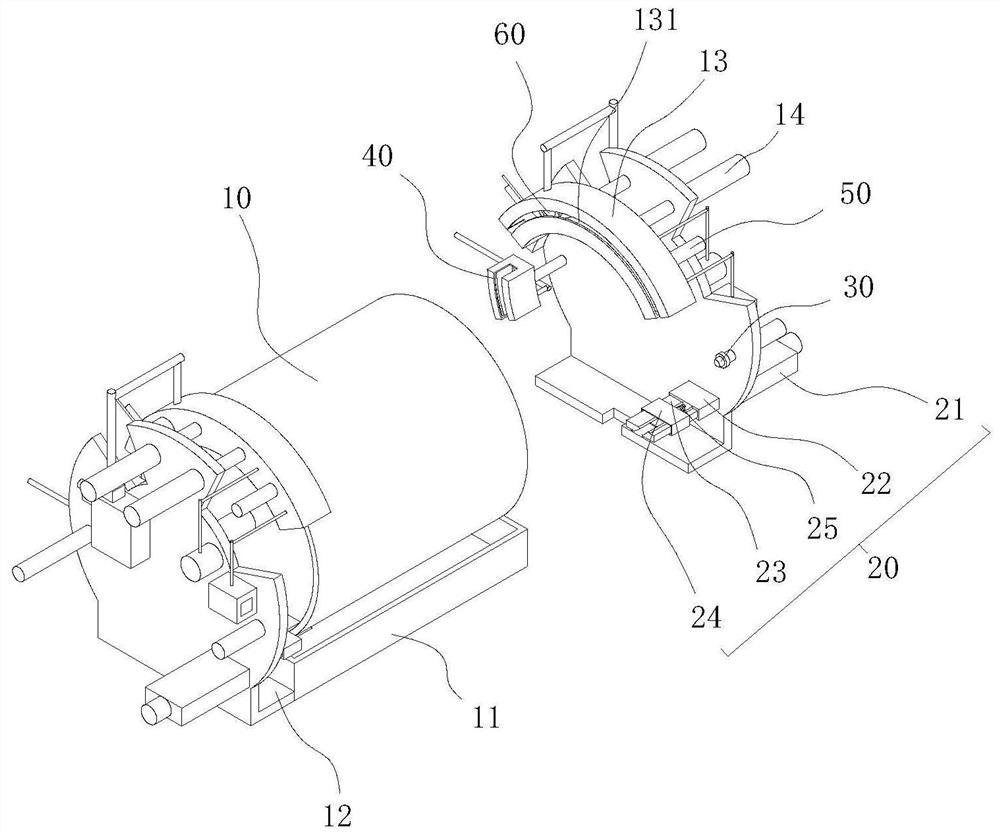

Device for degrading waste water containing high-concentration nitrobenzene through air stripping-ozone/ultrasound oxidation and treatment method of device

InactiveCN104710062AReduce processing timeImprove oxidation efficiencyMultistage water/sewage treatmentNature of treatment waterHigh concentrationAdvanced oxidation process

The invention provides a device for degrading waste water containing high-concentration nitrobenzene through air stripping-ozone / ultrasound oxidation and treatment method of the device, belongs to the technical field of high-concentration nitrobenzene-containing waste water treatment, and aims to solve the problem of high cost of ozone-based advanced oxidation process for treating high-concentration nitrobenzene-containing waste water. The method comprises the following steps: firstly, high-concentration nitrobenzene-containing waste water is in contact with air in a hypergravity device to complete air stripping mass transfer process; after the air stripping mass transfer process is completed, the waste water is subjected to ultrasonic wave degradation, the degraded waste water is fed into the hypergravity device to react with ozone gas, the waste water containing ozone returns to an ultrasound liquid storage pot, and then nitrobenzene is degraded under an ultrasonic wave synergistic effect. The air-stripping method is used to enable target pollutant content in the waste water to be reduced to carry out oxidation reaction, so that waste water quality change is reduced to the largest extent, and the intermediate product production amount is further reduced, the ozone and hydroxyl free radical consumption substance production amount can be reduced, the oxidation efficiency is improved, the ozonation efficiency is improved by 40%-50%, the treatment time is shortened by 80%, the usage amount of ozone is reduced by 70%, and the treatment cost is reduced by 50%.

Owner:ZHONGBEI UNIV

System and process for preparing hydrogen peroxide based on anthraquinone method

InactiveCN112499592AIncreased phase boundary areaImprove hydrogenation efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesUsing liquid separation agentAnthraquinonesEmulsion

The invention relates to a system and process for preparing hydrogen peroxide based on an anthraquinone method. The system comprises a hydrogenation tower, a micro-interface generator, a filtering andcooling unit, an oxidation tower and an extraction tower. Hydrogen is crushed to form micron-sized bubbles, and the micron-sized bubbles are mixed with an anthraquinone derivative-containing workingsolution or a 2-ethylanthraquinone-containing hydrogenated solution to form a gas-liquid emulsion, so that the phase interface area of a gas phase and a liquid phase is increased, the effect of enhancing mass transfer within a relatively low preset operation condition range is achieved, the hydrogenation and oxidation efficiency of the anthraquinone derivative-containing working solution is improved, the hydrogen reaction rate is improved, the cost is saved, and the risk is reduced. A mixture of 2-ethylanthraquinone and hydrogen peroxide is extracted through the extraction tower, countercurrent extraction is carried out on a water phase from top to bottom and the mixture from bottom to top, and rapid extraction is realized.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

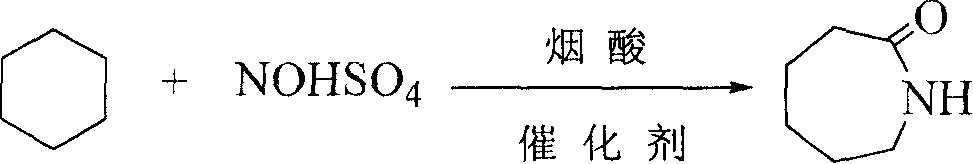

Synthesis of caprolactam and its oligomer

The present invention is synthesis process of caprolactam and its oligomer. Cyclohexane as initial material is nitrosated with nitroso sulfuric acid inside fuming sulphuric acid medium and in the presence of catalyst to synthesize caprolactam and its oligomer directly. The present invention has greatly simplified technological process, lowered cost and greatly raised resource utilization.

Owner:XIANGTAN UNIV

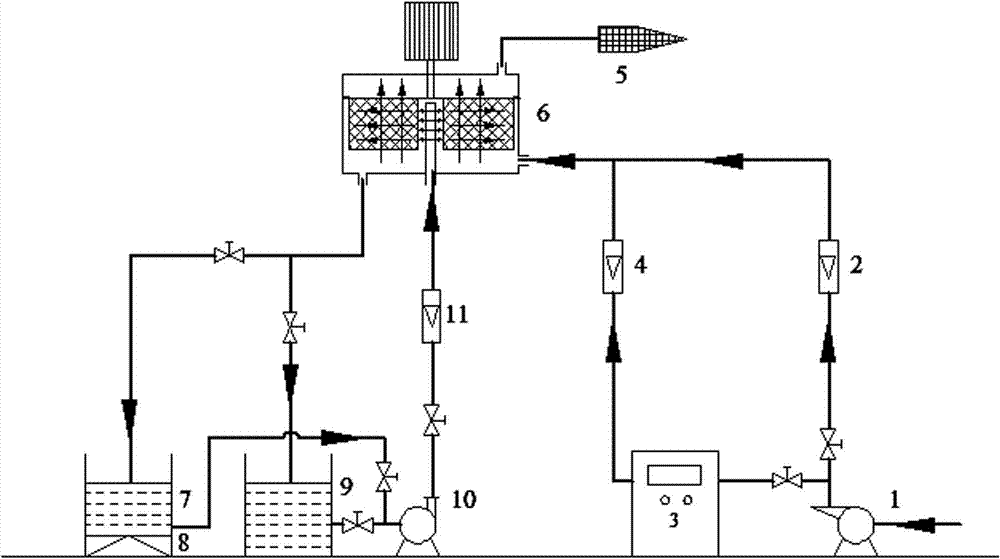

Stripping-ultrasound/electrolysis coupled degradation method and device for high-concentration nitrobenzene-containing wastewater

InactiveCN104724870AReduce processing timeBiochemical effectWater contaminantsMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention belongs to the technical field of nitrobenzene wastewater treatment, and provides a stripping-ultrasound / electrolysis coupled degradation method and device for high-concentration nitrobenzene-containing wastewater, which are designed for solving the problems that existing methods for degrading nitrobenzene wastewater are low in treatment efficiency, long in treatment time and too high in cost. The high-concentration nitrobenzene containing wastewater is fully contacted and reacted with fresh air in a supergravity facility so as to complete stripping mass-transfer for reducing the nitrobenzene content of the wastewater, the wastewater produced after the stripping mass-transfer is completed is conveyed to a coupling reactor consisting of an ultrasound field and an electrolysis field, and then nitrobenzene substances are degraded under the synergistic effect of ultrasound and microelectrolysis. By using a stripping method, after the target pollutant content of wastewater is reduced, the wastewater is subjected to an oxidation reaction, so that the water quality change of the wastewater is minimized and the generation of intermediate products is lowered, therefore, the generation of hydroxyl radical expendables is reduced, and the oxidation efficiency is improved. An effect that the treatment time is reduced by 60-80% and the treatment cost is reduced by 50% under the condition that no ozone oxidizer is additionally added is achieved.

Owner:ZHONGBEI UNIV

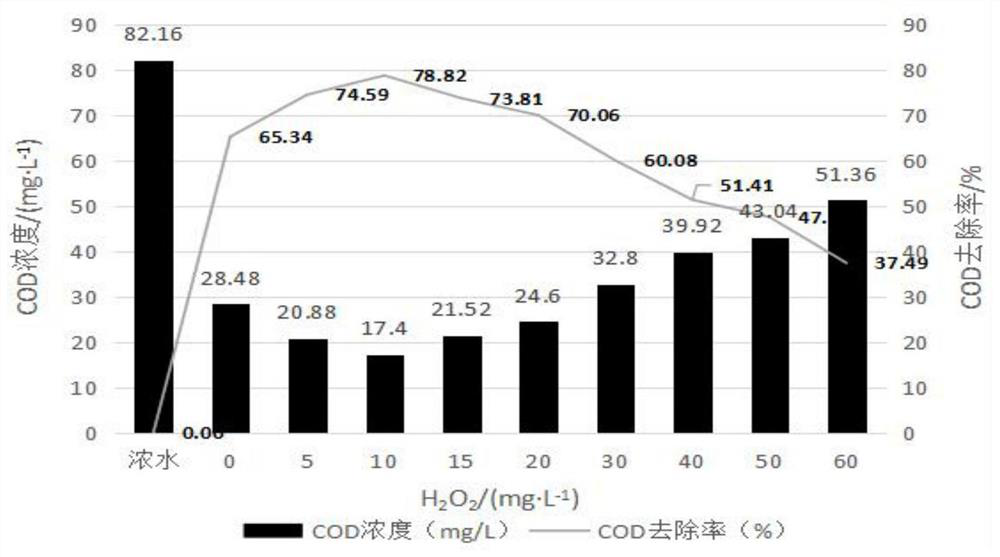

Reverse osmosis concentrated water treatment process for Fenton reagent oxidation enhanced adsorption

InactiveCN113415924ALarge specific surface areaHigh operating costsWater treatment compoundsSpecific water treatment objectivesIndustrial wastewater treatmentActivated carbon

The invention discloses a reverse osmosis concentrated water treatment process for Fenton reagent oxidation enhanced adsorption, and relates to the technical field of industrial wastewater treatment. An activated carbon adsorption technology can effectively adsorb organic matters in reverse osmosis concentrated water, and a Fenton reagent oxidation technology utilizes high-activity free radicals to attack macromolecular organic matters and react with the macromolecular organic matters, so that organic matter molecular structures are destroyed; According to the process, Fenton reagent oxidation and activated carbon adsorption technologies are combined, the organic matters in reverse osmosis concentrated water are diffused and adsorbed into a microporous structure of activated carbon by the activated carbon, and then the hydroxyl radicals generated by Fenton reagent oxidation can efficiently degrade organic pollutants in the microporous structure of the activated carbon. The Fenton reagent oxidation enhanced activated carbon adsorption can achieve a good synergistic effect, the saturated adsorption capacity and the adsorption efficiency of the activated carbon are improved, and the deep treatment efficiency of the reverse osmosis concentrated water is improved.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

Method for activating lignite

ActiveCN108083860AImprove oxidation capacityReduce dosageOrganic fertilisersFertilizer mixturesEnvironmental resistanceWater soluble

The invention discloses a method for activating lignite. The method comprises the following steps: mixing lignite powder, a photocatalytic oxidizing agent and water uniformly; and completely stirringunder the condition of ultraviolet irradiation, adding the oxidizing agent in batches, and reacting at 30 to 60 DEG C for 0.15 to 24 hours to obtain activated lignite, wherein the photocatalytic oxidizing agent is titanium dioxide. By the method provided by the invention, the water-soluble organic humus content and the active group content of the lignite can be increased very obviously and large-scale application of the lignite is further realized; and the method provided by the invention is environment-friendly, pollution-free, short in process route, low in cost, simple in requirement on equipment and mild in condition, and can be applied to industrialized mass production.

Owner:QUJING NORMAL UNIV +2

System for treating anaerobic digestion liquid of sludge through acidification-free Fenton oxidation, and treatment method for anaerobic digestion liquid of sludge

PendingCN112028320ALower pHReduce dosageWater treatment compoundsMultistage water/sewage treatmentFenton reactionCatalytic oxidation

The invention discloses a system for treating anaerobic digestion liquid of sludge through acidification-free Fenton oxidation, and a treatment method for the anaerobic digestion liquid of sludge. Thesystem comprises an adjusting tank, a coagulating sedimentation device, a Fenton catalytic oxidation device and a neutralization and sedimentation device. The method comprises the following steps: introducing the anaerobic digestion liquid of sludge into the adjusting tank; conveying the anaerobic digestion liquid of sludge in the adjusting tank into the coagulating sedimentation device for coagulating sedimentation treatment; conveying effluent obtained after coagulating sedimentation treatment into the Fenton catalytic oxidation device for Fenton catalytic oxidation treatment; allowing a part of effluent obtained after Fenton catalytic oxidation treatment to flow back to the water inlet end of the Fenton catalytic oxidation tank and the rest effluent to enter the neutralization and precipitation device; and adjusting the pH value of the rest effluent entering the neutralization and sedimentation device in a neutralization and sedimentation tank, and then carrying out neutralizationand sedimentation treatment. According to the method, acidification-free treatment is realized, the dosage of Fenton reaction chemicals is reduced, operation cost is reduced, and the utilization efficiency of hydroxyl radicals and the removal rate of organic matters are improved.

Owner:BEIJING DRAINAGE GRP CO LTD

A treatment method and equipment for recycling industrial waste salt

ActiveCN110117115BPromote productionPromote decompositionWater/sewage treatment by irradiationSpecific water treatment objectivesFiltrationToxic industrial waste

The invention discloses a treatment method and equipment for recycling industrial waste salt, belonging to the field of environmental protection. It specifically includes the following steps: including the steps of processing through the following units: 1) pretreatment unit, adjusting the pH value of high-salt wastewater and mechanically removing impurities; 2) resin adsorption unit, passing part of the macromolecular organic matter in high-salt wastewater through Removal by resin adsorption; 3) advanced oxidation unit, using the combination of ozone, ultraviolet radiation, and hydrogen peroxide to degrade organic matter simultaneously; 4) advanced treatment unit, using anodic oxidation to treat the effluent of the advanced oxidation unit; the step 4 ) after fine filtration, the effluent can be used as the raw material of ion membrane caustic soda production process for resource utilization directly. The advanced oxidation unit in this process effectively improves the advanced oxidation efficiency of high-salt wastewater, and the treated waste salt is used in the ion membrane caustic soda production process, creating economic benefits for the enterprise and realizing the resource utilization of waste salt.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

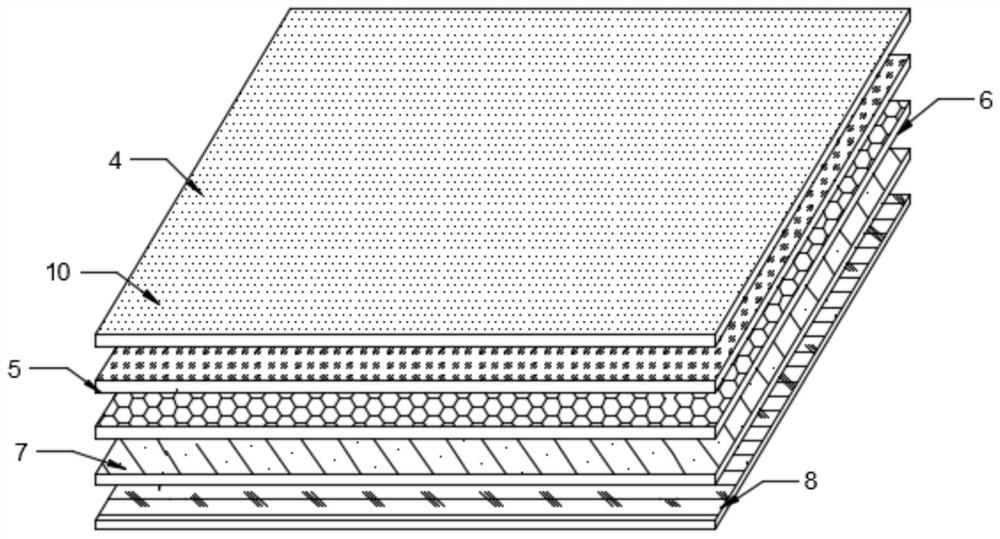

PE partition plate with anti-oxidation function

InactiveCN113258214AHas antioxidant functionImprove antioxidant capacitySecondary cellsCell component detailsPolymer scienceHot melt

The invention discloses a PE partition plate with an anti-oxidation function, which relates to the technical field of PE partition plates. The PE partition plate comprises a partition plate body, the front face and the back face of the partition plate body are connected with anti-oxidation protective films in an adhesive mode through hot melt adhesive layers, the top of the back face of each anti-oxidation protective film is connected with a PE base plate in an adhesive mode through an adhesive film, and the bottom of each PE base plate is connected with a flame-retardant film in an adhesive mode through an adhesive film. By arranging the PE base plate, the PE base plate is effectively protected on the outer wall of the partition plate body, ultraviolet rays and electric waves generated in the use environment of the partition plate are absorbed under the action of the ultraviolet ray absorption film and the electric wave absorption film arranged in the PE base plate, the mechanical strength of the partition plate is guaranteed, and the overall service life of the partition plate is prolonged; and meanwhile, through the action of an anti-aging protective film and an antioxidant coating film which are arranged outside the PE base plate, the use of the partition plate is effectively protected, the oxidation efficiency of the partition plate is reduced, the anti-oxidation effect of the PE partition plate is further improved, and the practicability of the partition plate is enhanced.

Owner:江苏明冠电源科技有限公司

A high-strength low-density steel welding process

ActiveCN112427796BReduce releaseReduce thermal decompositionNon-electric welding apparatusCalcium bicarbonatePhysical chemistry

The invention discloses a high-strength low-density steel welding process, which belongs to the technical field of steel processing. The temperature during welding can promote the thermal decomposition of calcium bicarbonate powder in the built-in storage cavity and generate a large amount of carbon dioxide gas. The increase of air pressure and temperature can make the thermally variable guide rope return to its high-temperature phase state, thereby lifting the rubber sealing sheet upwards, so as to promote the release of carbon dioxide. On the one hand, it can reduce The possibility of the external temperature of the steel is too high. On the other hand, the release of carbon dioxide can reduce the possibility of the steel being oxidized due to high temperature during the welding process. At the same time, the expansion of the attached guide ball can relieve the built-in magnetic The spherical magnetic shield makes the bottom of the anti-oxidation block stick closely to the steel, which can not only accelerate the thermal decomposition of the calcium bicarbonate powder, but also reduce the gap between the anti-oxidation block and the steel, thereby reducing the oxidation of the steel.

Owner:广西天正钢结构有限公司

Synthesis of caprolactam and its oligomer

The present invention is synthesis process of caprolactam and its oligomer. Cyclohexane as initial material is nitrosated with nitroso sulfuric acid inside fuming sulphuric acid medium and in the presence of catalyst to synthesize caprolactam and its oligomer directly. The present invention has greatly simplified technological process, lowered cost and greatly raised resource utilization.

Owner:XIANGTAN UNIV

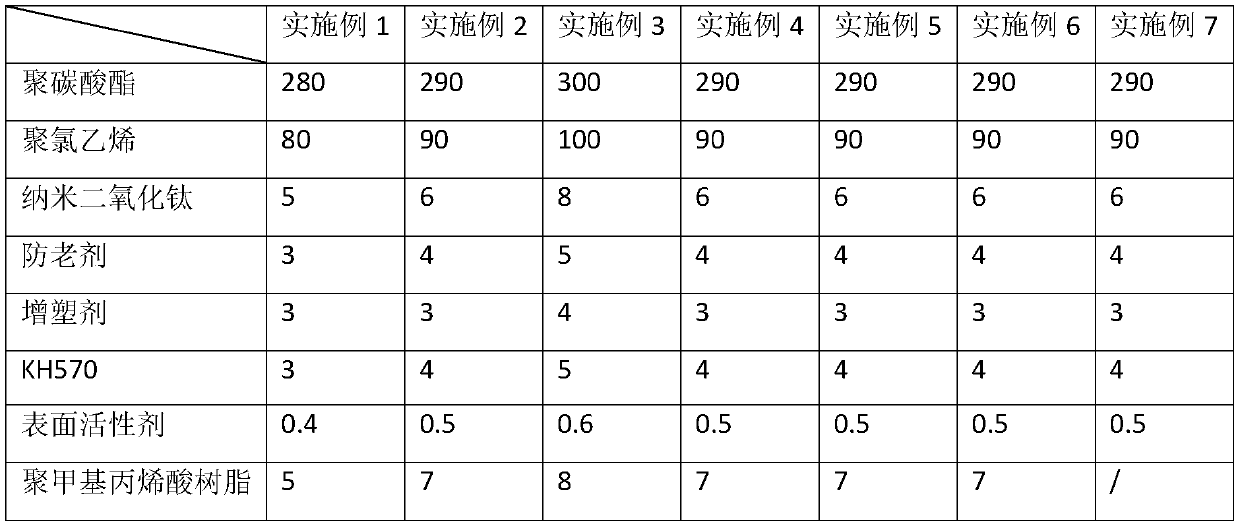

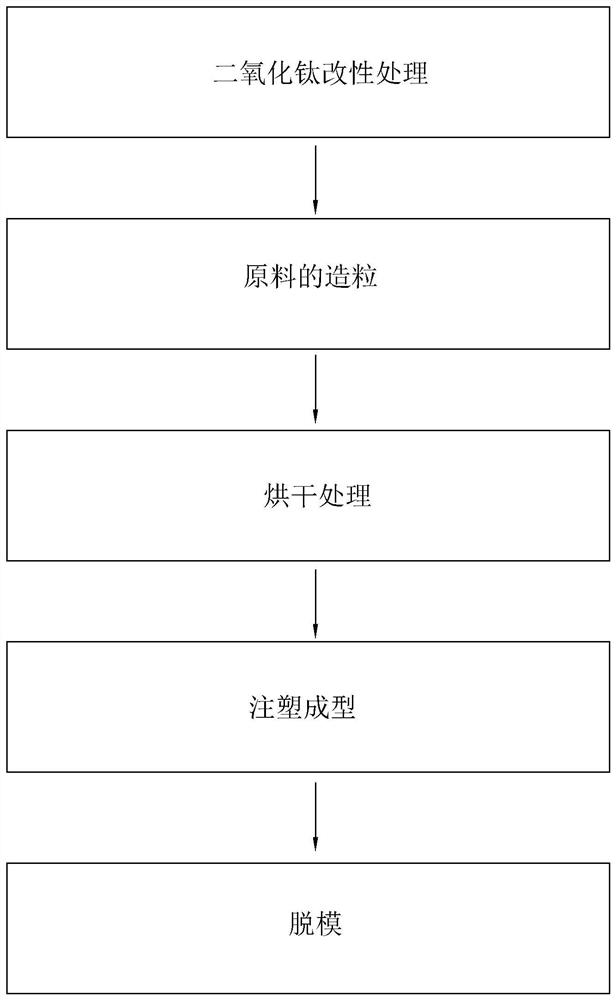

Lampshade for motorcycle headlamps and preparation method thereof

ActiveCN110684332AImproves UV resistanceHigh chemical activityGlobesSignalling/lighting devicesActive agentPolyvinyl chloride

The invention discloses a lampshade for motorcycle headlamps and a preparation method of the lampshade, and relates to the technical field of motorcycle accessories. The lampshade comprises, by weight, 280 to 300 parts of polycarbonate, 80 to 100 parts of polyvinyl chloride, 5-8 parts of titanium dioxide, 3-5 parts of an anti-aging agent, 3-4 parts of a plasticizer, 3-5 parts of a silane couplingagent, and 0.4 to 0.6 part of a surfactant. Titanium dioxide is an important inorganic chemical material and has the characteristics of high ultraviolet resistance, good visible light permeability, high chemical activity and the like. Titanium dioxide has good absorption capacity on UVA (300-400 nm) and UVB (280-300 nm), cannot be decomposed or discolored after absorbing ultraviolet rays, and hasultraviolet absorption capacity due to the fact that titanium dioxide is filler for enhancing mechanical properties, therefore, titanium dioxide can enhance the strength of the lampshade and improve the ageing resistance of the lampshade. Meanwhile, the anti-aging effect of the anti-aging agent is adopted for cooperation, so that the anti-aging performance of the lampshade is further effectively improved, and the light transmittance of the lampshade is guaranteed.

Owner:温岭市科珵机械股份有限公司

An engine exhaust device and an engine exhaust method

ActiveCN113027577BGuaranteed conversion efficiencyControl discharge pathInternal combustion piston enginesExhaust apparatusExhaust gas emissionsExhaust fumes

The invention discloses an engine exhaust device and an engine exhaust method, and relates to the technical field of engine exhaust gas treatment. The engine exhaust device includes a main pipeline, a bypass pipeline, a first temperature sensor and a second temperature sensor. The main pipeline is sequentially connected with a supercharger, DOC, DPF and SCR, and one end of the bypass pipeline is connected to the supercharger Between the device and the DOC, the other end of the bypass line can be communicated with the air inlet of the DPF. The first temperature sensor is arranged between the supercharger and the DOC for detecting the temperature of the exhaust gas entering the DOC; the second temperature sensor is arranged between the DPF and the SCR for detecting the temperature of the exhaust gas entering the SCR. The outlet port of the supercharger can selectively communicate with the inlet port or bypass line of the DOC. The exhaust device of the engine not only avoids the low oxidation efficiency caused by the rapid aging of the DOC, but also ensures the conversion efficiency of the SCR, so that the exhaust gas emission meets the requirements.

Owner:WEICHAI POWER CO LTD

Composite catalyst and method for catalyzing complete oxidation and elimination of formaldehyde via composite catalyst

ActiveCN112808301AIncrease the active siteHigh catalytic activityMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention relates to the technical field of environmental catalysis, and aims to provide a composite catalyst and a method for catalyzing complete oxidation and elimination of formaldehyde via the composite catalyst. According to the invention, formaldehyde and air are used as reaction raw materials and are subjected to a conversion reaction on a fixed bed or a moving bed; and a used catalyst is the composite catalyst and is formed by compounding a component I and a component II in a mechanical mixing mode, wherein the active component of the component I is a molecular sieve with medium-strong acid sites, the active component of the component II is a noble metal catalyst, a weight ratio of the component I to the component II is in a range of 0.01-20, and the axis distance between particles of the component I and the component II is in a range of 50 nm-40 mm. The composite catalyst is high in the activity of low-temperature catalysis of formaldehyde oxidation, and can oxidize formaldehyde in the atmospheric environment into non-toxic and harmless CO2 and H2O via O2 molecules in air within a temperature range of 20-80 DEG C; and the concentration of formaldehyde in the treated air is lower than a room concentration required by national environmental protection in China.

Owner:DALIAN UNIV OF TECH

Photo-induced energy storage method and device of nickelous hydroxide-titanic oxide base

InactiveCN101465216BImprove bindingImprove stabilityLight-sensitive devicesPhotoluminescenceUltraviolet

The invention discloses a nickel hydroxide- titanium dioxide-based photoluminescence energy storage method and a device thereof. In alkaline solution, a TiO2 porous membrane is sequentially prepared on the conductive surface of an ITO substrate; a double-film working electrode of a Ni(OH)2 membrane is deposited on the TiO2 porous membrane; a Pt counter electrode is arranged at one side of the double-film working electrode; and the two electrodes are connected through lead wires. In the ultra-violet Hv radiation, the potential difference of the two electrodes is used to push the electrons to transfer from an external circuit to the Pt counter electrode and react with the oxidation substances so as to be consumed, thereby reducing the composition between electrons and cavities, improving the oxidation efficiency of cavities which oxidate Ni (II) into Ni (III) and increasing the oxidation energy storage efficiency of the device.

Owner:ZHEJIANG UNIV

A kind of composite catalyst and method for catalyzing complete oxidation and elimination of formaldehyde

ActiveCN112808301BIncrease the active siteHigh catalytic activityMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention relates to the technical field of environmental catalysis and aims to provide a composite catalyst and a method for catalyzing the oxidation and elimination of formaldehyde. It takes formaldehyde and air as the reaction raw materials, and carries out the conversion reaction on a fixed bed or a moving bed. The catalyst is a composite catalyst, which is composed of component I and component II by mechanical mixing. The active ingredient of component I is Molecular sieve with medium-strong acid sites, the active ingredient of component II is a noble metal catalyst; the weight ratio of component I to component II is in the range of 0.01-20, and the axial distance between the particles of component I and component II is between Between 50nm‑40mm range. The composite catalyst has high catalytic formaldehyde oxidation activity at low temperature, and can utilize O in the air in the temperature range of 20-80°C 2 Molecules oxidize formaldehyde in the atmosphere to non-toxic and harmless CO 2 and H 2 O. The formaldehyde concentration in the air after treatment is lower than the indoor concentration required by the national environmental protection.

Owner:DALIAN UNIV OF TECH

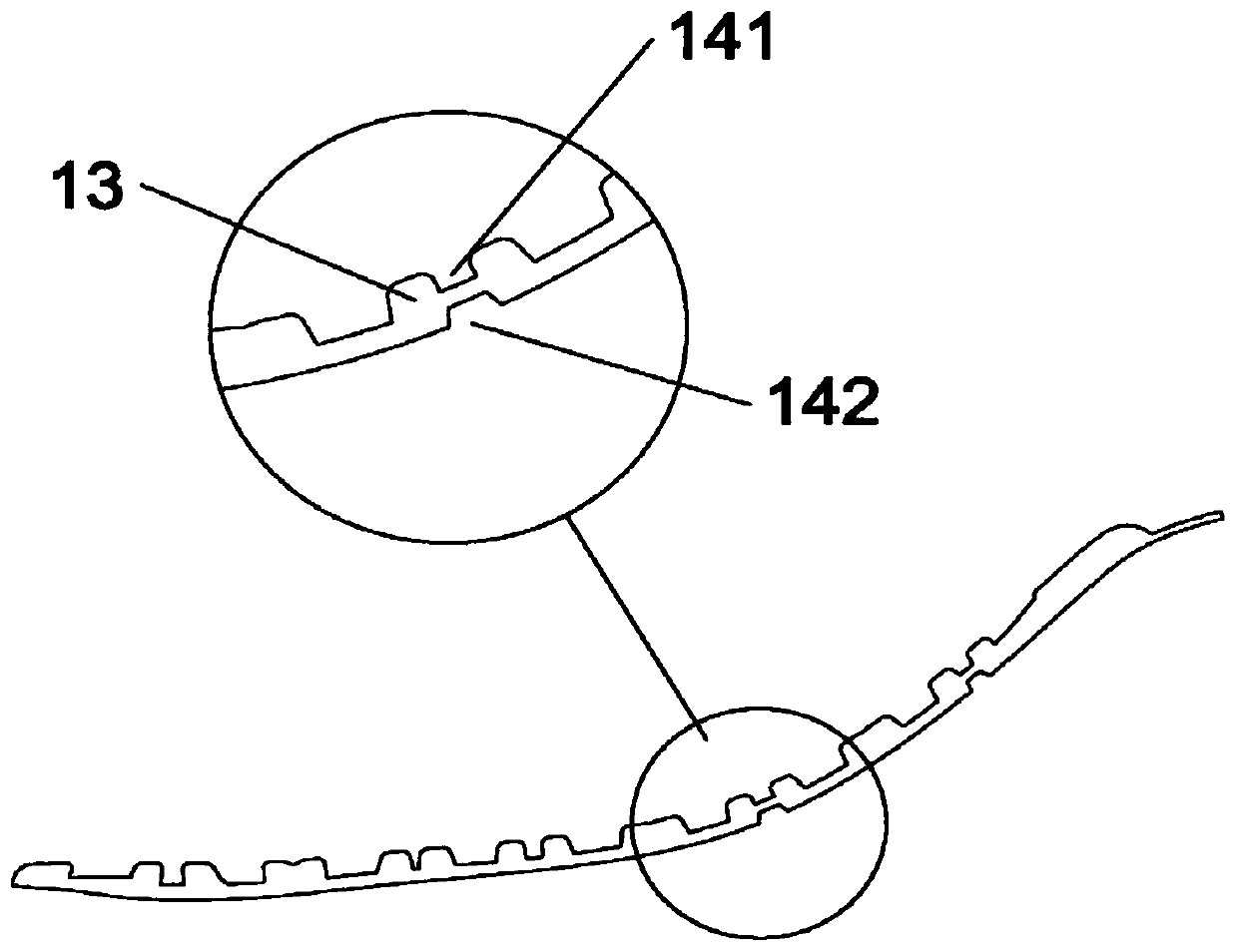

A kind of prefabricated curtain wall panel unit and curtain wall panel construction method

ActiveCN111549946BAvoid extensive exposureReduce dustWallsBuilding insulationsMechanical engineeringCurtain wall

The invention discloses an assembled curtain wall panel unit and a curtain wall panel construction method, and relates to the technical field of curtain wall installation. The side is provided with a curtain wall connecting piece, the curtain wall unit is arranged on the dragon frame through the curtain wall connecting piece, one side of the dragon skeleton is provided with a basic connecting piece, and the dragon skeleton is arranged on the building through the basic connecting piece. The invention replaces the traditional sealing strip by setting the clamping piece, which is used to seal the gap between the aluminum alloy frame and the curtain wall glass, so as to avoid the large-area exposure of the sealing material to the outside, reduce its oxidation efficiency, and reduce the The possibility of dust and water entering the interior of the curtain wall unit, at the same time, a dehumidification unit is added to treat the moisture inside the curtain wall unit and keep the interior of the curtain wall dry.

Owner:深圳市湛艺建设集团有限公司

A catalyst for simultaneous denitration, mercury removal and dioxin removal and preparation method thereof

ActiveCN111167475BWide active temperature rangeStrong resistance to sulfur poisoningCatalyst carriersGas treatmentPtru catalystPlatinum nanoparticle

The invention discloses a catalyst for simultaneous denitration, mercury removal and dioxin removal and a preparation method thereof. Cerium oxide and niobium pentoxide are used as catalytic active components, a mixture of nickel oxide and platinum nanoparticles is used as a co-catalyst, and hydrochloric acid is used to modify the catalyst. The titanium dioxide nanoneedles generated from tetrabutyl titanate were used as the main carrier, and the catalyst was used after hydrogen pretreatment. Based on the quality of the carrier, the mass percentage of the active component is 10% to 30%, and the mass percentage of the cocatalyst is 0.1% to 0.15%. The composite colloidal solution of active components and co-catalyst, and the optimized and modified catalyst carrier are evenly stirred, aged, extruded, dried and calcined. The catalyst is environmentally friendly, capable of high-efficiency denitrification, mercury and dioxin removal at the same time, with a wide active temperature range, SO 2 The oxidation efficiency is low. The denitrification and dioxin removal efficiencies are both greater than 95% at 240-500°C, and the mercury removal efficiencies are both greater than 99%. The product can be widely used in coal-fired power plants, chemical plants and other fields.

Owner:南京环福新材料科技有限公司

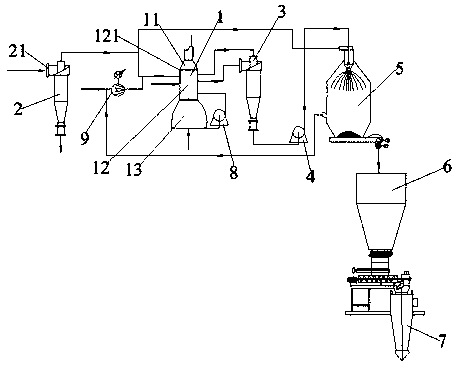

Environmentally-friendly process with complete reaction in ammonia desulfurization device

InactiveCN110270204AAvoid enteringAvoid wastingGas treatmentDispersed particle separationCycloneParticulates

The invention discloses an environmentally-friendly process with a complete reaction in an ammonia desulfurization device. The process comprises the following steps: when the ammonia desulfurization device is used, boiler flue gas with a temperature of 120-150 DEG C is subjected to gas-solid separation by a first cyclone separator, a part of flue gas after gas-solid separation is subjected to desulfurization and oxidation treatment, after treatment is performed by a second cyclone separator, the treated gas flows into an evaporative dryer through a second circulation pump, the other part of the boiler flue gas with the temperature of 120-150 DEG C treated by the first cyclone separator is introduced into the evaporative dryer, the dried particulate matter obtained by the evaporative dryer enters an ammonium sulfate bin, and packaging treatment is performed by using an automatic packaging machine. According to the process provided by the invention, the first cyclone separator is arranged to separate dust in the boiler flue gas to prevent desulfurization efficiency for sulfur dioxide in the flue gas from being reduced, an ammonia concentration in ammonia water is controlled at 10%-20% to prevent the ammonia water concentration from being too high, if the ammonia water concentration is high, ammonia escapes, and if the ammonia water concentration is too low, desulfurization is incomplete, so that under the ammonia concentration condition, the desulfurization effect is good, and an ammonia escape phenomenon is inhibited; and the process has a novel structure and is convenient to operate.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

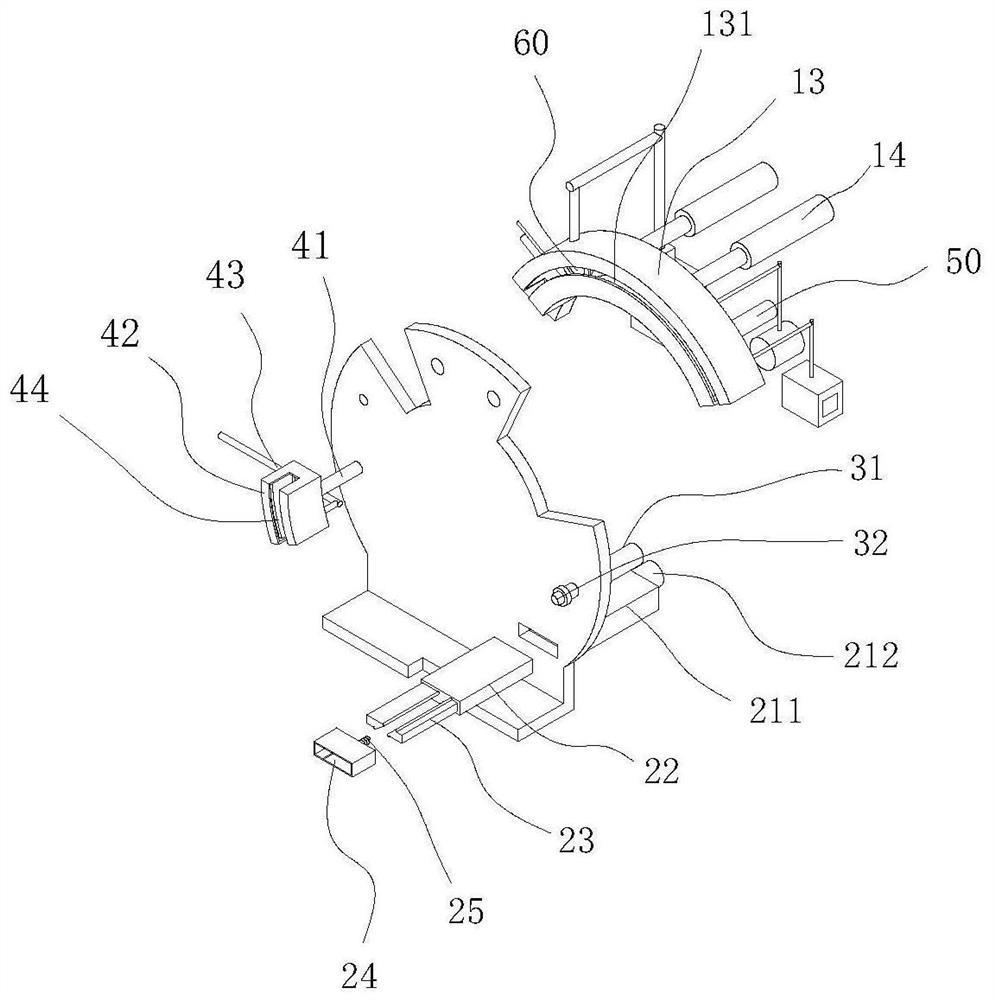

Protective component and protective shoe

The invention discloses a protective component, which is used for being combined with a shoe sole to form a vamp or combined with the vamp to form a vamp protective layer, and comprises a surface layer, an inner layer and a protective layer arranged between the surface layer and the inner layer, and the protective layer is formed by ESA materials in an injection molding mode. A body part is used for covering the instep, the wing parts extend to the two sides of the body part, and the wing parts are used for covering the ankle surface; wherein a rib structure is formed, and a plurality of firstconcave parts are arranged on the upper surface of an area defined by the rib structure. The invention further discloses two kinds of protective shoes which are provided with the protective components. The protection component is used for providing comprehensive protection for the instep and the ankle surface, and the protection effect is good; and the protective component is integrally light andeasy to install. The protective shoe not only can provide comprehensive protection for the instep, but also is ideal in foot holding wrapping performance, light, convenient and suitable for wearing.

Owner:ANTA CHINA

A lampshade of a motorcycle headlight and a preparation method thereof

ActiveCN110684332BImproves UV resistanceHigh chemical activityGlobesSignalling/lighting devicesActive agentPolyvinyl chloride

The invention discloses a lampshade of a motorcycle headlight and a preparation method thereof, and relates to the technical field of motorcycle accessories. The raw material of the lampshade includes the following components in parts by weight: 280-300 parts of polycarbonate; 80-100 parts of ethylene; 5-8 parts of titanium dioxide; 3-5 parts of anti-aging agent; 3-4 parts of plasticizer; 3-5 parts of silane coupling agent; 0.4-0.6 parts of surfactant. Titanium dioxide is an important inorganic chemical material, which has the characteristics of high UV resistance, good visible light transmission and high chemical activity. Titanium dioxide has good absorption ability to UVA (300-400nm) and UVB (280-300nm), and it will not decompose or change color after absorbing ultraviolet rays, because it is not only a filler to enhance mechanical properties, but also has ultraviolet absorption ability . Titanium dioxide can enhance the strength of the lampshade while improving its anti-aging performance. At the same time, anti-aging effect is combined with anti-aging agent to further effectively improve the aging resistance of the lampshade to ensure the light transmittance of the lampshade.

Owner:温岭市科珵机械股份有限公司

Cathode roller edge grinding device for electrolytic copper foil

ActiveCN113789551AEasy to collectReduce oxidation rateLapping machinesCleaning using toolsElectrolytic agentCopper foil

The invention discloses a cathode roller edge grinding device for electrolytic copper foil. The cathode roller edge grinding device for electrolytic copper foil comprises a cathode roller, an electrolytic tank and an L-shaped base plate, the side wall of the L-shaped base plate is sequentially provided with an electrolyte scraping device, an oxidation degree detection device, a grinding positioning box and a drying device, and one side of the L-shaped base plate is provided with two driving cylinders. The execution ends of the two driving cylinders penetrate through the L-shaped base plate to be connected with the grinding positioning box, and an airflow grinding device and a wet grinding device are arranged in the grinding positioning box. The airflow grinding device comprises an air grinding positioning part and an airflow part; and the wet grinding device comprises a grinding disc grinding component arranged on the outer wall of the grinding positioning box and provided with an execution end extending into the grinding positioning box, and a circulating leaching component arranged on the outer wall of the side, away from the cathode roller, of the L-shaped base plate and communicated with the grinding positioning box through a pipeline, and the circulating leaching component is used for circularly introducing grinding liquid into the grinding positioning box. According to the cathode roller edge grinding device for electrolytic copper foil, the oxidation rate of the edge of the cathode roller can be reduced conveniently, and grinding objects can be collected conveniently.

Owner:云南惠铜新材料科技有限公司

Preparation method of compound material for inhibiting oxidation corrosion by using potassium oleate modified metal sulfide

The invention relates to a preparation method of a composite material for inhibiting oxidation corrosion by using potassium oleate modified metal sulfide, and belongs to the technical field of surface passivation. The preparation method comprises the following steps of ball-milling pyrite for 5 minutes, sieving with a 100-mesh sieve, washing with ultrapure water (volume: 1: 5) for five times, refrigerating in a refrigerator at-20 DEG C for 12 hours, drying in a freeze dryer for 48 hours, preparing potassium oleate into 5% (volume ratio) by using ultrapure water, putting 1mL and 0.5 g of pyrite samples into a 50mL beaker, shaking the beaker to uniformly spread the samples at the bottom of the beaker, and drying in a fuming cupboard to obtain the composite material. The composite material can be applied to oxidation of surface-passivated pyrite; under the simulated sunlight condition, pyrite oxidation is inhibited in a hydrochloric acid solution with the pH value of 2, and the inhibition rate can reach 80%.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Device for removing hypophosphites and phosphites by advanced oxidation coupling technique

ActiveCN103482797BGood removal effectStrong oxidation abilityMultistage water/sewage treatmentWater/sewage treatment by oxidationSludgeCoupling

The invention relates to industrial wastewater treatment, particularly a device for removing hypophosphites and phosphites by an advanced oxidation coupling technique in industrial wastewater treatment. The invention provides the device for removing hypophosphites and phosphites by an advanced oxidation coupling technique, which comprises a I stage reaction pond, a II stage reaction pond, a hydrogen peroxide injection device, an ozone injection device and a ferrous sulfate injection device. The I stage reaction pond is in communication with the II stage reaction pond. The I stage reaction pond is provided with a water inlet. The ozone injection device is connected to the I stage reaction pond. The ferrous sulfate injection device is connected to the II stage reaction pond. The ozone injection device is connected to the II stage reaction pond. The device provided by the invention has the advantages of high reaction speed, favorable removal effect, simple technical process, no need of regulating pH value, and low sludge production quantity.

Owner:深圳市万木水务有限公司

A method and device for blowing off oxidation degradation wastewater containing high concentration of nitrobenzene

ActiveCN104724852BReduce processing timeImprove oxidation efficiencyWater contaminantsMultistage water/sewage treatmentHigh concentrationNitrobenzene

The invention belongs to the technical field of high-concentration nitrobenzene-containing wastewater treatment, and provides a method for stripping and oxidatively degrading high-concentration nitrobenzene-containing wastewater in order to solve the problem of high cost of treating high-concentration nitrobenzene-containing wastewater by an ozone advanced oxidation method and device. The high-concentration nitrobenzene-containing wastewater is contacted with fresh air in the supergravity equipment to complete the stripping mass transfer process; after the stripping and mass transfer is completed, the wastewater is sent to the storage tank to be mixed with hydrogen peroxide, and then mixed with ozone in the supergravity equipment The gas contact reaction, the remaining organic matter in the wastewater is in the ozone and H 2 O 2 synergistically degrade. Improve the efficiency of ozone oxidation, shorten the treatment time, use the stripping method to reduce the pollutant content in the wastewater and then carry out the oxidation reaction, minimize the change of the wastewater quality, reduce the generation of intermediate products, and reduce the generation of ozone and hydroxyl radicals. The oxidation efficiency is increased by 65~75%, the treatment time is shortened by 80%, the ozone consumption is reduced by 70%, and the treatment cost is saved by 50%.

Owner:ZHONGBEI UNIV

A method and device for treating high-concentration nitrobenzene-containing wastewater by stripping-micro-electrolysis-fenton oxidation

ActiveCN104710052BReduce processing costsIncrease the activity of the benzene ringMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention provides a method and device for treating high-concentration nitrobenzene-containing waste water by using air-stripping-microelectrolysis-fenton oxidation method, belongs to the technical field of high-concentration nitrobenzene-containing waste water treatment, and aims to solve the problems that the fenton method is high in treatment cost and toxic intermediate products are easy to produce to cause secondary pollution, and the nitrobenzene contaminants cannot be mineralized into inorganic small molecular materials through a single micro electrolysis method. According to the method, air-stripping mass transferring between the high-concentration nitrobenzene-containing waste water and the air can be completed in a hypergravity device, after air stripping is finished, the waste water is introduced into a ferric-carbon microelectrolysis tank with a stirring device for microelectrolysis reduction reaction, then hydrogen peroxide is added into the microelectrolysis tank, ferrous ions in the waste water and the hydrogen peroxide form a fenton reagent, hydroxyl free radicals with a high oxidizing property can be generated, and finally organic matters in the waste water can be oxidized and degraded. The process is simple, the function of each technology is maximized, so that the purpose of using waste to treat waste is achieved, the treatment cost is reduced to the largest extent, the treatment efficiency is improved by 20%, the reaction time is shortened by 25%, and the treatment cost is greatly reduced.

Owner:ZHONGBEI UNIV

A kind of simultaneous denitrification, demercury and dedioxin rare earth-based catalyst, its preparation method and application

ActiveCN109603804BWide active temperature rangeStrong resistance to sulfur poisoningGas treatmentDispersed particle separationRare earthManganese oxide

The invention discloses a rare-earth-based catalyst achieving denitration, demercuration and dioxin removal simultaneously, a preparation method and application. Cerium oxide and erbium oxide are adopted as catalytic active components, a mixture of zirconium oxide and / or yttrium oxide and / or manganese oxide is adopted as a promoter, and titanium dioxide submicro spheres generated by optimizing andmodifying tetrabutyl titanate with hydrochloric acid are adopted as a main carrier. An active component and promoter precursor compound solution, the optimized and modified catalyst carrier and an organic forming additive are stirred to be uniform, mixed, aged and extrude-molded, drying and roasting are carried out, and the rare-earth-based catalyst is prepared. The catalyst is environmentally friendly, denitration, demercuration and dioxin removal can be carried out efficiently at the same time, the active temperature interval is wide, the mechanical strength is high, the oxidation efficiency of SO2 is low, and the cost is low. The denitration efficiency and the dioxin removal efficiency at the temperature of 220 DEGC to 400 DEG C are higher than 90%, and the demercuration efficiency ishigher than 95%. The rare-earth-based catalyst can be widely suitable for the fields of coal-fired power plants, chemical plants and the like.

Owner:NANJING TECH UNIV +1

A cathode roll edge grinding device for electrolytic copper foil

ActiveCN113789551BEasy to collectReduce oxidation rateLapping machinesCleaning using toolsElectrolytic agentCopper foil

The invention discloses a cathode roller edge grinding device for electrolytic copper foil, which comprises a cathode roller, an electrolytic cell and an L-shaped base plate, and the side wall of the L-shaped base plate is sequentially provided with an electrolyte scraping device and an oxidation degree detection device , Grinding and positioning box and drying device. There are two driving cylinders on one side of the L-shaped base plate. The execution ends of the two driving cylinders are connected to the grinding and positioning box through the L-shaped base plate. The grinding and positioning box is equipped with an airflow grinding device. And a wet grinding device; the airflow grinding device includes an air grinding positioning part and an airflow part; the wet grinding device includes a grinding disc grinding part arranged on the outer wall of the grinding positioning box and the execution end extends into the grinding positioning box, and the L-shaped base The plate is away from the outer wall of the side of the cathode roller and the pipeline is connected to the circulating rinsing part of the grinding positioning box. The circulating rinsing part is used to circulate the grinding liquid into the grinding positioning box. The invention is a grinding device which is convenient for reducing the oxidation rate of the edge of the cathode roll and collecting grinding objects.

Owner:云南惠铜新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com