Reverse osmosis concentrated water treatment process for Fenton reagent oxidation enhanced adsorption

A technology of reverse osmosis concentrated water and oxidation enhancement, which is applied in special compound water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of complex process flow, difficult operation, and large project investment, and achieve Efficient oxidation treatment, high operating cost, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

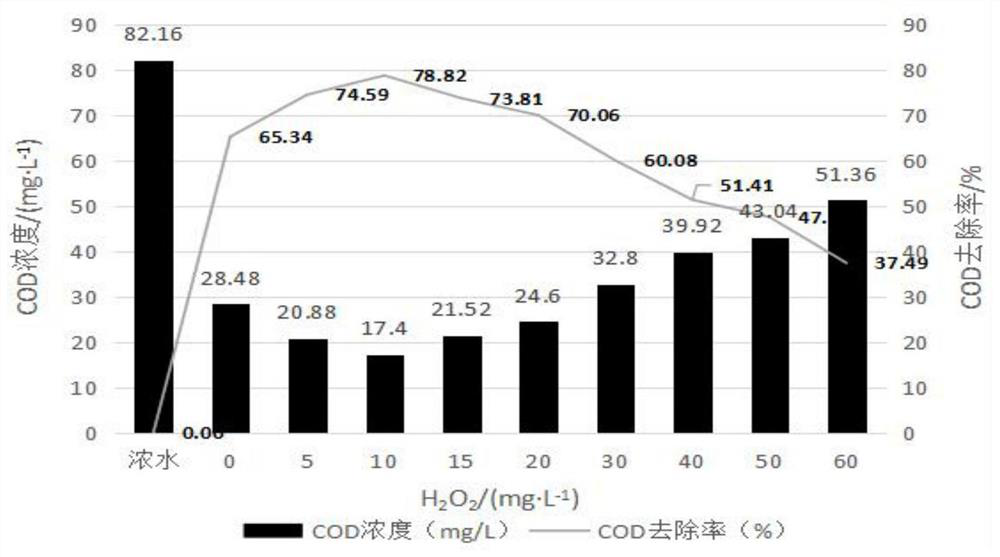

[0063] refer to figure 1 As shown, this embodiment is the reverse osmosis concentrated water treatment process of Fenton reagent oxidation enhanced adsorption. Cr The content is 82.16mg / L, the TDS content is 3250mg / L, and the salts included are mainly sodium chloride and sodium sulfate;

[0064] A1, Fenton reagent oxidation enhanced activated carbon adsorption: take nine 2000ml beakers, start the mechanical stirring, add 1000ml reverse osmosis concentrated water for experiment, add powdered activated carbon to the reverse osmosis concentrated water respectively, the dosage is 1.0g / L, Add ferrous sulfate at the same time, the dosage is 60mg / L, and then add different amounts of H to 9 reverse osmosis concentrated water samples 2 o 2 , H 2 o 2 The dosages are 0mg / L, 5mg / L, 10mg / L, 15mg / L, 20mg / L, 30mg / L, 40mg / L, 50mg / L, 60mg / L, and the reaction starts, and the reaction time is 30min respectively;

[0065] After the reaction, take the supernatant to measure COD Cr value, see...

Embodiment 2

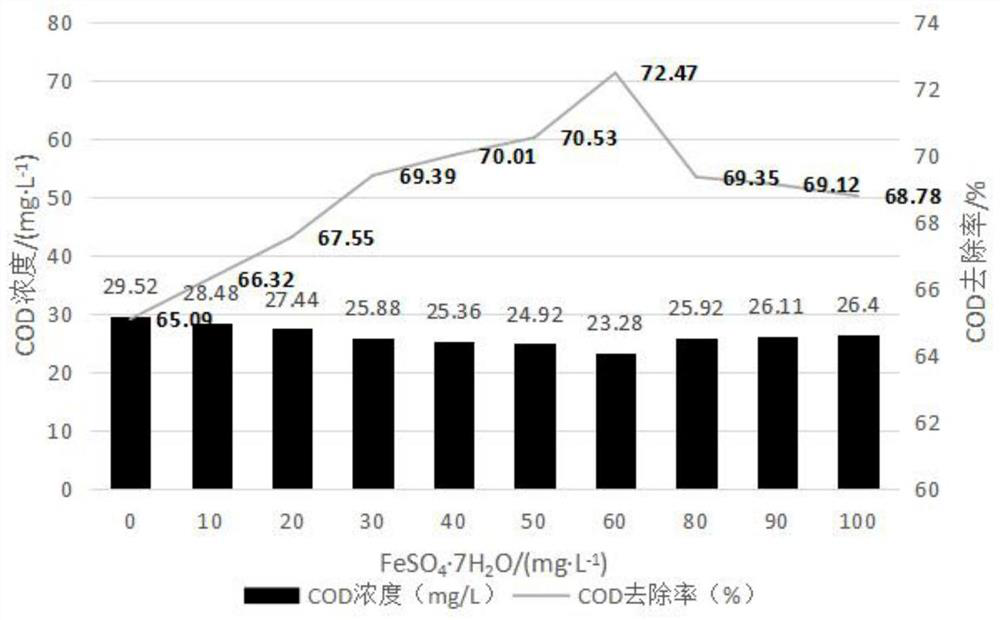

[0070] refer to figure 1 As shown, this embodiment is the reverse osmosis concentrated water treatment process of Fenton reagent oxidation enhanced adsorption. Cr The content is 84.56mg / L, the TDS content is 4230mg / L, and the salts included are mainly sodium chloride and sodium sulfate.

[0071] Including the following steps:

[0072] B1, Fenton reagent oxidation enhanced activated carbon adsorption: take 10 2000ml beakers, start the mechanical stirring, add 1000ml of reverse osmosis concentrated water for experiment, add powdered activated coke amount of 0.6g and powdered activated carbon amount to the reverse osmosis concentrated water respectively 0.5g, while adding 27% H 2 o 2 solution, the dosage is 33ml, and different amounts of FeSO with a mass fraction of 10% are added to 10 reverse osmosis concentrated water samples. 4 ·7H 2 O solution, where FeSO 4 ·7H 2 The dosage of O is 10mg / L, 20mg / L, 30mg / L, 40mg / L, 50mg / L, 60mg / L, 70mg / L, 80mg / L, 90mg / L, 100mg / L, and the...

Embodiment 3

[0078] This embodiment is a reverse osmosis concentrated water treatment process with Fenton reagent oxidation enhanced adsorption. This embodiment is an engineering scale-up test with continuous water inflow and a test period of 48 hours. The size of the activated carbon oxidation adsorption pool is 8500×8500×5000mm, the effective water depth is 4200mm, and the effective volume is 300m 3 Calculated, the activated carbon oxidation adsorption tank is stirred by aeration; the size of the coagulation sedimentation tank is 8500×8500×5000mm, the effective water depth is 4200mm, and the effective volume is 300m 3 Calculation; regeneration reaction adopts PE tank with a volume of 20m 3 ;The size of catalyst A and oxidant B dosing pools are both 2200×2200×5000mm, with a total volume of 20m 3 . Both flocculant C and coagulant D are made of PE tanks with a volume of 1.0m 3 ;Water inflow rate is 80~150m 3 / h, the residence time of the activated carbon oxidation adsorption pool is 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com