Device for degrading waste water containing high-concentration nitrobenzene through air stripping-ozone/ultrasound oxidation and treatment method of device

A technology for nitrobenzene wastewater and oxidative degradation, which is applied in the directions of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high cost of high-concentration nitrobenzene-containing wastewater, Achieve the effect of improving ozone oxidation efficiency, improving oxidation efficiency, and improving ozone oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

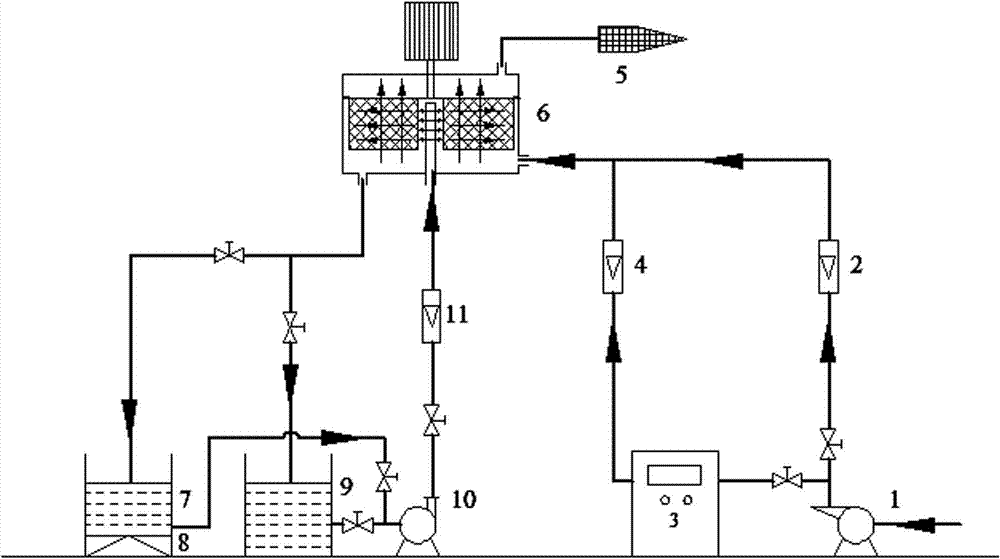

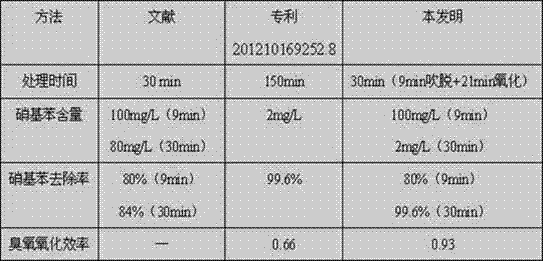

[0031] Example 1: Utilization figure 1 The procedure shown treats a water sample containing nitrobenzene at a concentration of 500 mg / L. The supergravity reactor speed was 700 rpm. When the gas-liquid ratio is 200 in the stripping process, when the concentration of nitrobenzene in the wastewater is reduced to 80 mg / L, the treatment time can be shortened by 80% compared with the traditional stripping equipment, and the stripping efficiency is significantly reduced after that. At this time, the advanced treatment is carried out by ozone / ultrasonic oxidation technology. In the wastewater after stripping, preliminary oxidation and degradation are firstly carried out in the ultrasonic storage tank, and the ultrasonic sound intensity is 100W / cm 2 , the frequency is 100kHz, and then it enters the hypergravity reactor to fully contact and react with ozone. The ozone concentration is 10 mg / L, the liquid-gas ratio is 0.5, the circulating treatment is 21 min, and the nitrobenzene con...

Embodiment 2

[0032] Example 2: Utilization figure 1 The process shown is to treat wastewater containing nitrobenzene. The concentration of nitrobenzene in the wastewater was 800 mg / L, and the pH was 7.1. The supergravity reactor speed was 500 rpm. In the stripping process, the gas-liquid ratio is 400. When the concentration of nitrobenzene in the wastewater is reduced to 100 mg / L, the treatment time can be shortened by 80% compared with the traditional stripping equipment, and the stripping efficiency is significantly reduced after that. Utilize ozone / ultrasonic oxidation technology to carry out advanced treatment, in the wastewater after stripping, first carry out preliminary oxidation degradation in ultrasonic storage tank, ultrasonic sound intensity is 50W / cm 2 , the frequency is 50kHz, and then it enters the hypergravity reactor to fully contact and react with ozone. The ozone concentration is 15 mg / L, the liquid-gas ratio is 1.0, the circulating treatment is 15 min, and the nitro...

Embodiment 3

[0033] Example 3: Utilization figure 1 The process shown is to treat wastewater containing nitrobenzene. The concentration of nitrobenzene in the wastewater was 1500 mg / L and the pH was 6.8. The supergravity reactor speed was 300 rpm. In the stripping process, the gas-liquid ratio is 500. When the concentration of nitrobenzene in the wastewater is reduced to 90 mg / L, the treatment time can be shortened by 80% compared with the traditional stripping equipment, and the stripping efficiency is significantly reduced after that. Utilize ozone / ultrasonic oxidation technology to carry out advanced treatment, in the wastewater after stripping, firstly carry out preliminary oxidation degradation in ultrasonic storage tank, ultrasonic sound intensity is 1 W / cm 2 , the frequency is 20 kHz, and then it enters the hypergravity reactor to fully contact and react with ozone. The ozone concentration is 30 mg / L, the liquid-gas ratio is 2.0, and the circulating treatment is 30 min. The nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com