Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Play a relieving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

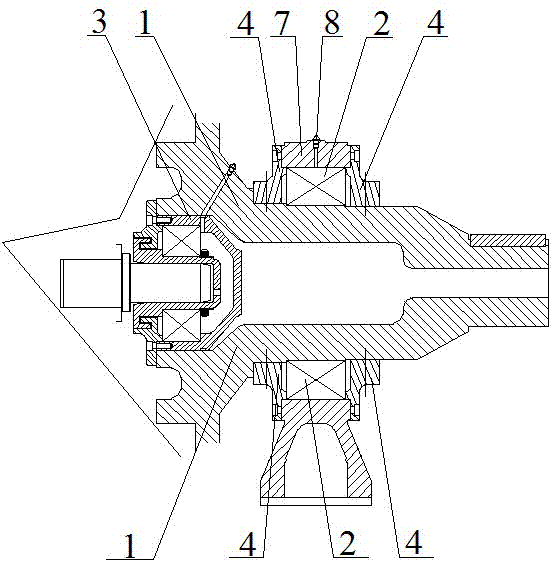

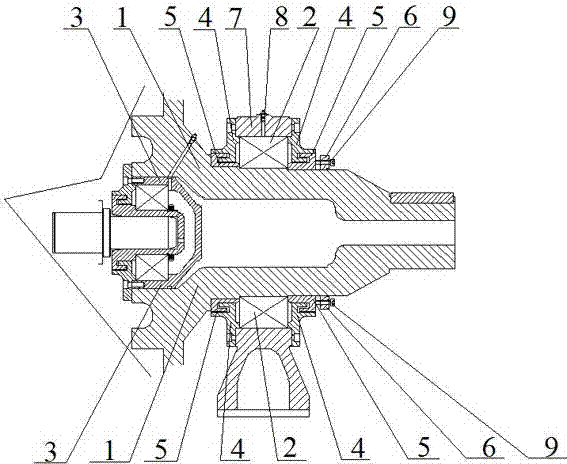

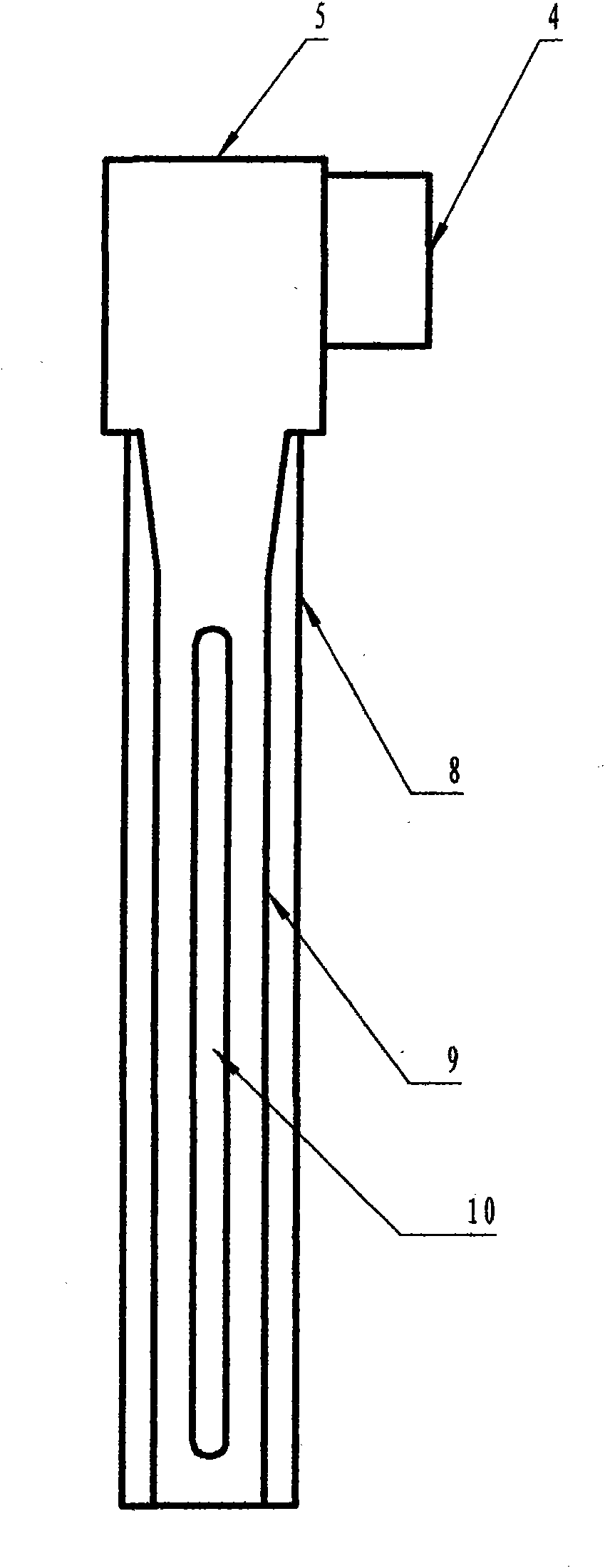

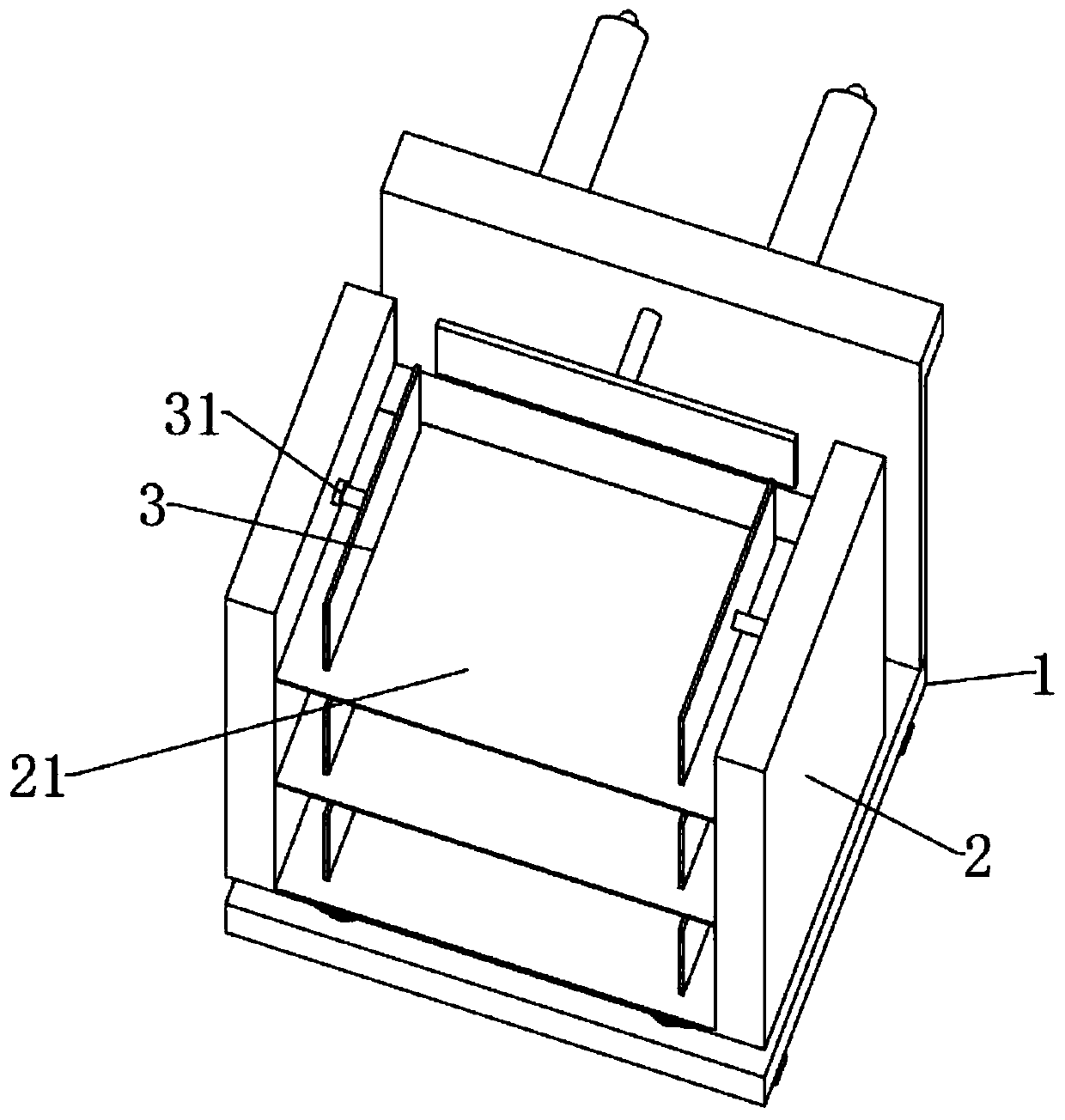

Locking device for vacuum turning roll

InactiveCN102734468AUnable to oozePlay a relieving effectEngine sealsPaper-making machinesEngineeringMechanical engineering

The invention provides a locking device for a vacuum turning roll, which effectively solves the problem of oil leakage due to oil pressure during oiling, saves the cost and largely improves the production efficiency. The locking device comprises a roll neck and a bearing, wherein the roll neck is arranged on a bearing shell, a bearing block is used for fixing the bearing, an oiling opening is arranged on the bearing block, the bearing is fixed at the end part of the roll neck, and bearingcaps are fixedly arranged on the two sides of the bearing. The locker further comprises maze-shaped rings and a retainer ring, wherein the bearing caps and the maze-shaped rings are clamped through corresponding intervals, and the retainer ring fastens the maze-shaped ring on one side through a screw.

Owner:WUXI HONGCHENG PAPER MAKING MACHINERY

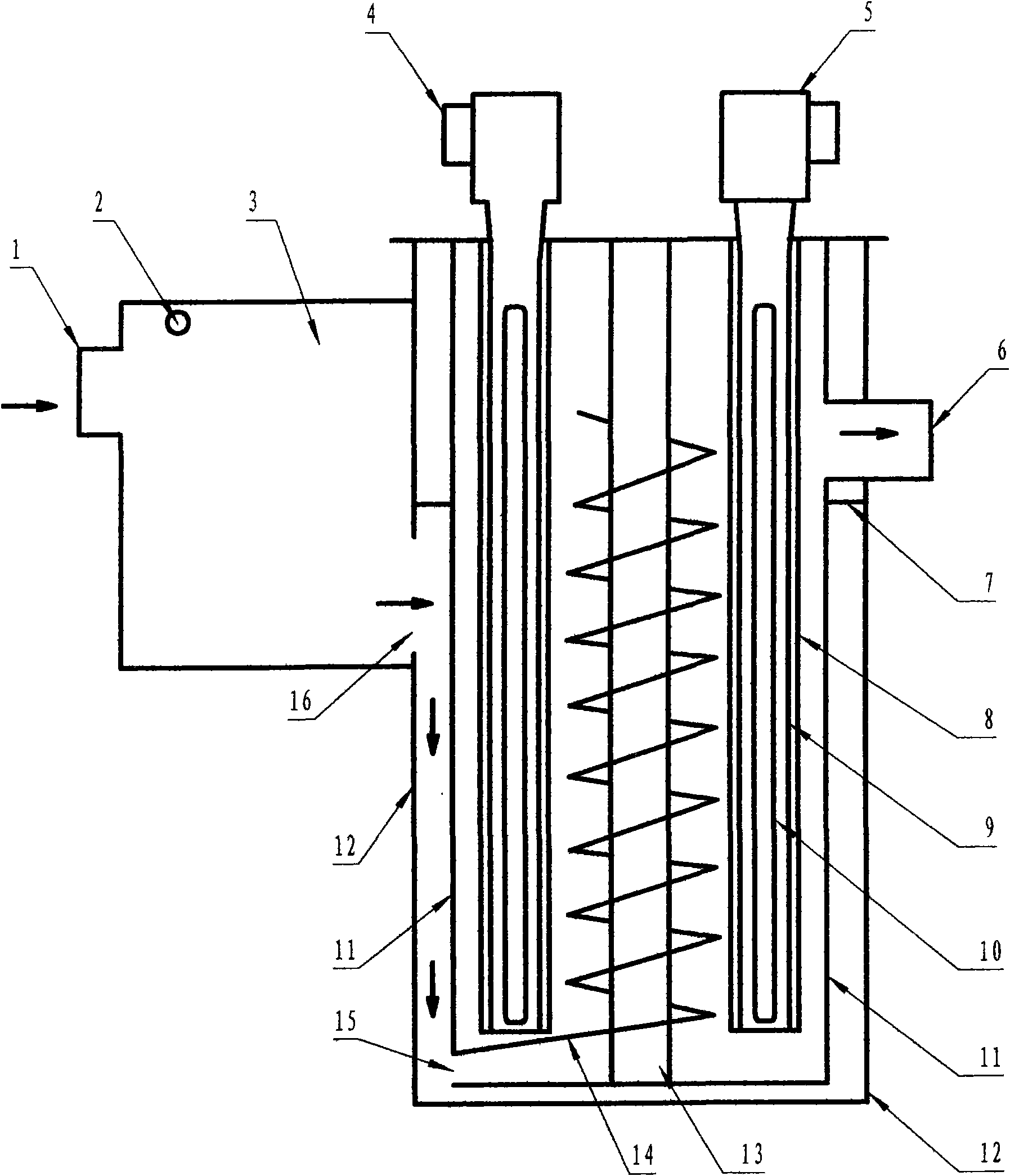

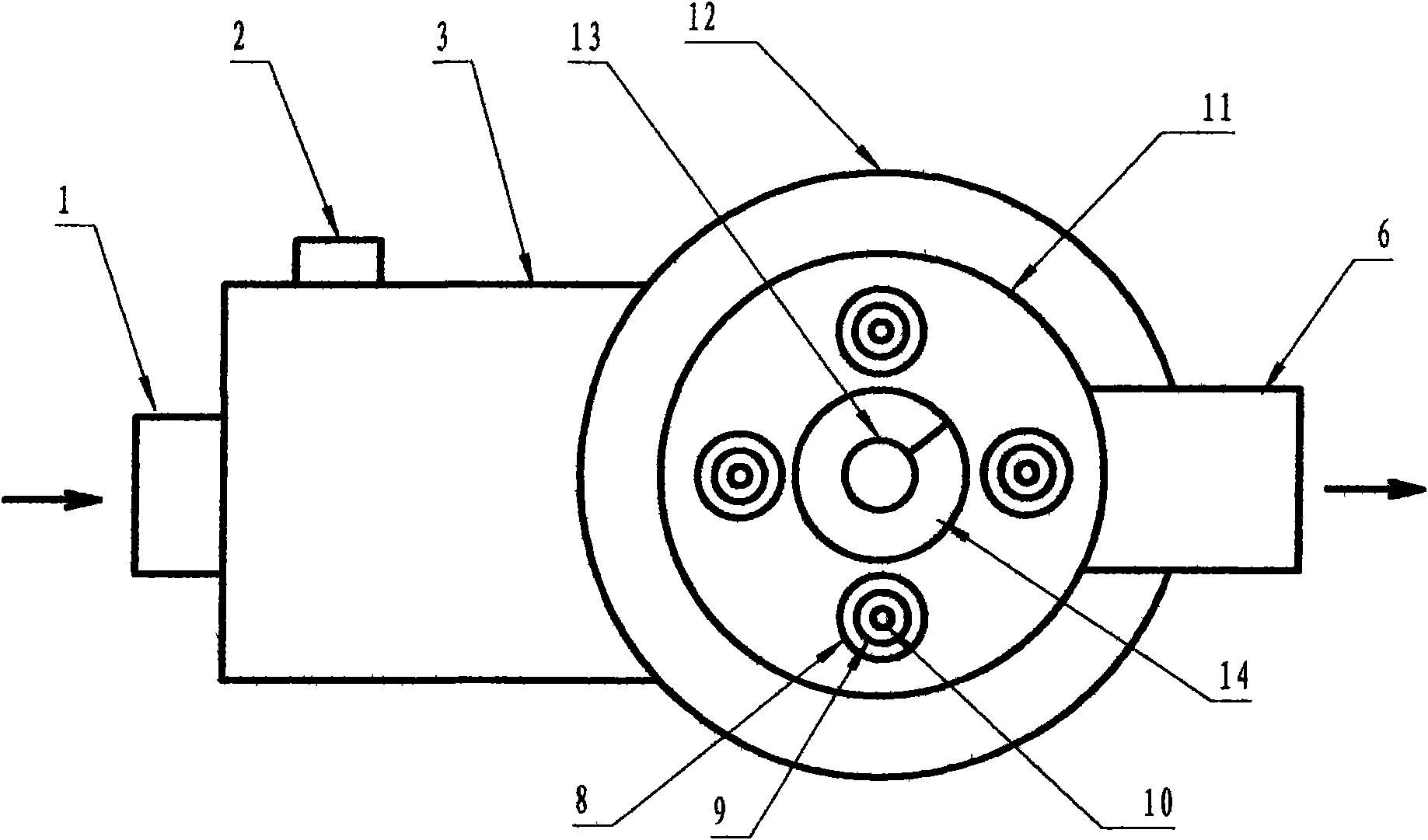

Disinfection well for ultraviolet sewage treatment by using microwaves

InactiveCN101676221AIncrease contact timeNot affected by timeWater/sewage treatment by irradiationUltraviolet lightsWater flow

The invention is applied to ultraviolet sewage treatment in the field of environmental protection. Lamp tubes, the conventional equipment for ultraviolet sewage treatment, have low electrode efficiency and short lives, have large floor areas because of using open channels for flowing and have poor effects. The invention adopts the microwaves sent out by magnetrons as the energy sources. The ultraviolet quartz lamp tubes are arranged in a cylindrical microwave resonance cavity body, are filled with mercury and protective gases, emit ultraviolet light under microwave excitation, have no electrodes and have long lives. A facility for current to flow in and out, with a cylindrical well type structure, and a spiral diversion facility installed in the facility for current to flow in and out canenable water to be fully contacted with the ultraviolet rays, thus obtaining good sterilization effects. The floor area of the invention is only a small percentage of that of the conventional equipment for ultraviolet sewage treatment.

Owner:吕志敏

Chinese medicament additive for improving liver function of Clarias lazera

InactiveCN101822313AIndicators are stablePlay a relieving effectAnimal feeding stuffMixed feedingLiver function

The invention discloses a Chinese medicament additive for improving the liver function of a Clarias lazera. The additive comprises the following Chinese medicaments in percentage by weight: 15 percent of astragalus, 25 percent of white paeony root, 20 percent of rhubarb, 15 percent of liquoric root, 15 percent of Himalayan teasel root and 10 percent of gardenia. The Chinese medicaments are dried crude medicaments and are mixed together and crushed into particles having a particle size by which the particles can pass through a 30-mesh standard screen. A method for using the Chinese medicament additive for improving the liver function of the Clarias lazera comprises the following steps of: mixing the prepared Chinese herbal medicament powder into a compound feed in a proportion of 5 percent; preparing the mixture into a granulated feed; and performing mixed feeding in a weight ratio of the compound feed to fresh chicken and duck internal organs of 1:5. The Chinese medicament additive has the following advantages that: the average value of glutamic alanine amino transferase of 5 percent of feed-fed experimental groups using the Chinese medicament additive for improving the liver function of the Clarias lazera has a stationary trend, while the glutamic alanine amino transferase of the groups which do not use the medicament additive increases exponentially, so the Chinese herbal medicament additive has certain repairing function to liver injuries.

Owner:TIANJIN AGRICULTURE COLLEGE

Nutritional adsorbent used for relieving pigling mycotoxin poisoning

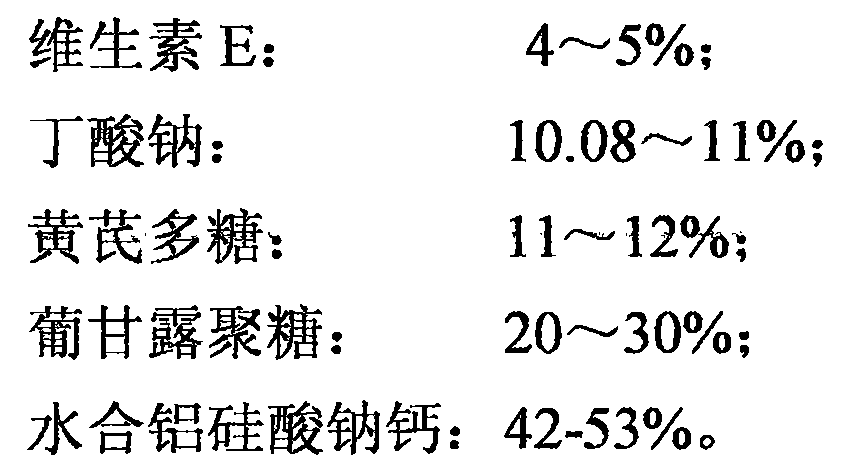

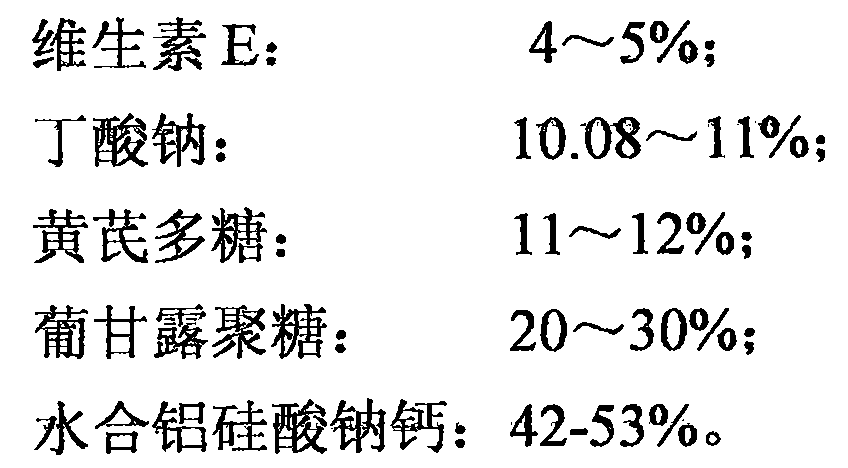

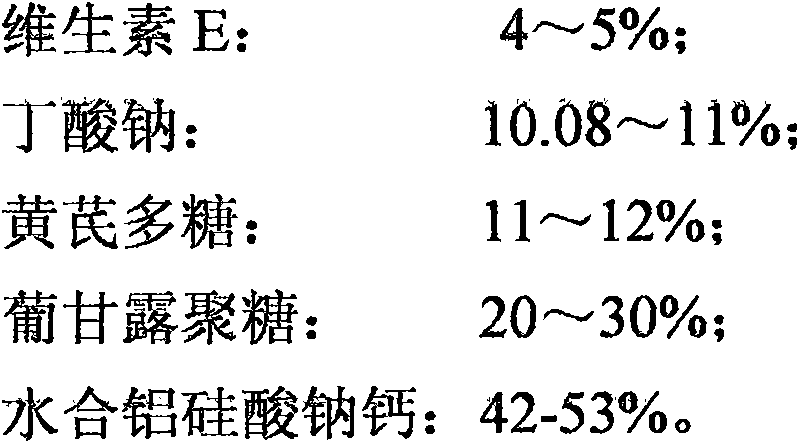

InactiveCN105104783AReduce absorptionProtect healthAnimal feeding stuffFeed conversion ratioMycotoxin

The invention discloses a nutritional adsorbent used for relieving pigling mycotoxin poisoning. The nutritional adsorbent is composed of, by mass, 4 to 5% of vitamin E, 10.08 to 12% of sodium butyrate, 11 to 12% of astragalus polysaccharide, 20 to 30% of glucomannan, and 42 to 53% of HSCAS. The intestinal nutritional agent is capable of providing enterocytes with nutrients, so that under mycotoxin stressed conditions, the nutritional adsorbent is beneficial for protection of structural and functional completeness via intestinal mucosa rapid repairing, is capable of promoting transportation and absorption of glucose and amino acid, and reducing feed conversion ratio obviously; the nutritional adsorbent is capable of increasing pigling intestinal antioxidant capacity, and relieving intestinal oxidative damage caused by mycotoxin; the nutritional adsorbent is used for maintaining intestinal health via adjusting pigling intestinal flora; and excellent improvement effects on poisoning caused by a plurality of mycotoxins are achieved via nutrition regulation.

Owner:SICHUAN AGRI UNIV

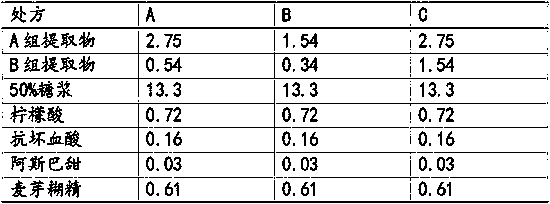

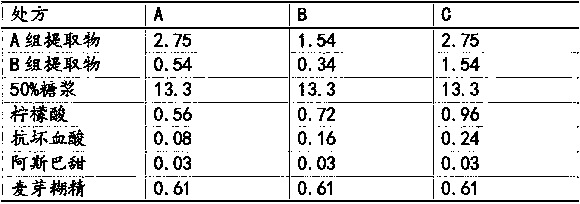

Oral liquid with functions of hangover alleviating and sobering and preparation method thereof

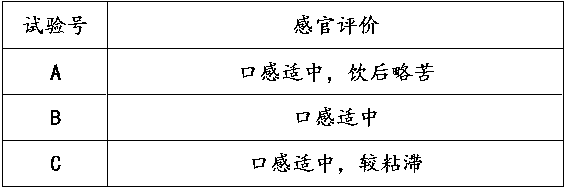

InactiveCN107412378ALow investment requirementLow costDispersion deliveryAntinoxious agentsSide effectThirst

The invention relates to a traditional Chinese medicine composition for alleviating hangover and sobering, in particular to an oral liquid with the functions of hangover alleviating, sobering, thirst slaking, saliva produce helping, phlegm resolving and vomit stopping and a preparation method thereof. The oral liquid comprises, by weight, 60-100 parts of flos puerariae, 10-30 parts of semen hoveniae, 10-30 parts of poria cocos, 10-30 parts of hawthorn, 10-40 parts of momordica grosvenori, 0.1-1 part of aspartame containing phenylalanine, 3-12 parts of maltodextrin, and 50% of syrup which can be converted to 50-300 parts of saccharose, 0.1-2.4 parts of ascorbic acid, 2-10 parts of citric acid, and 0.1-0.3 part of polylysine. The preparation method comprises the steps of raw material preparing, water extraction and alcohol precipitation treating, freeze drying, vacuum drying, bending, high pressure steam sterilizing and the like. According to the oral liquid with the functions of hangover alleviating and sobering and the preparation method thereof, the best ratio between raw materials and good odor and taste are obtained through sensory evaluation, and the pharmacodynamic test shows that the oral liquid has the functions of hangover preventing and alleviating. The oral liquid has the characteristics of being stale in efficacy, high in practicability, small in side effects, big in market potential, wide in range of target audience, and worth in popularizing.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE +1

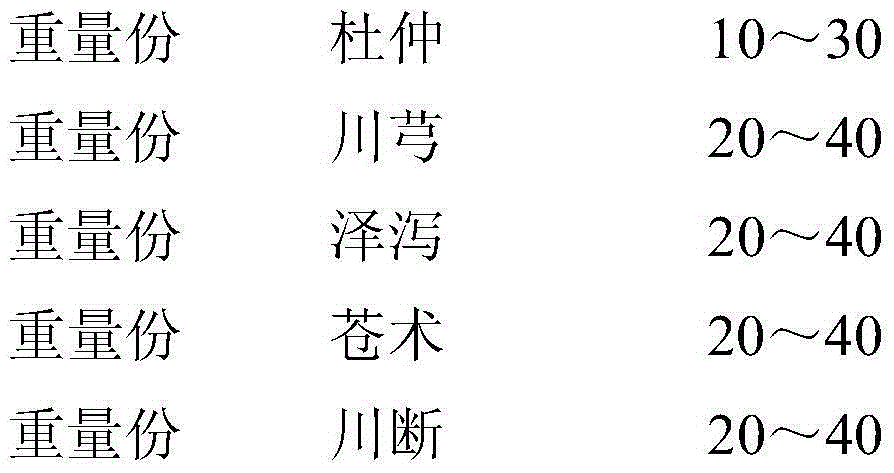

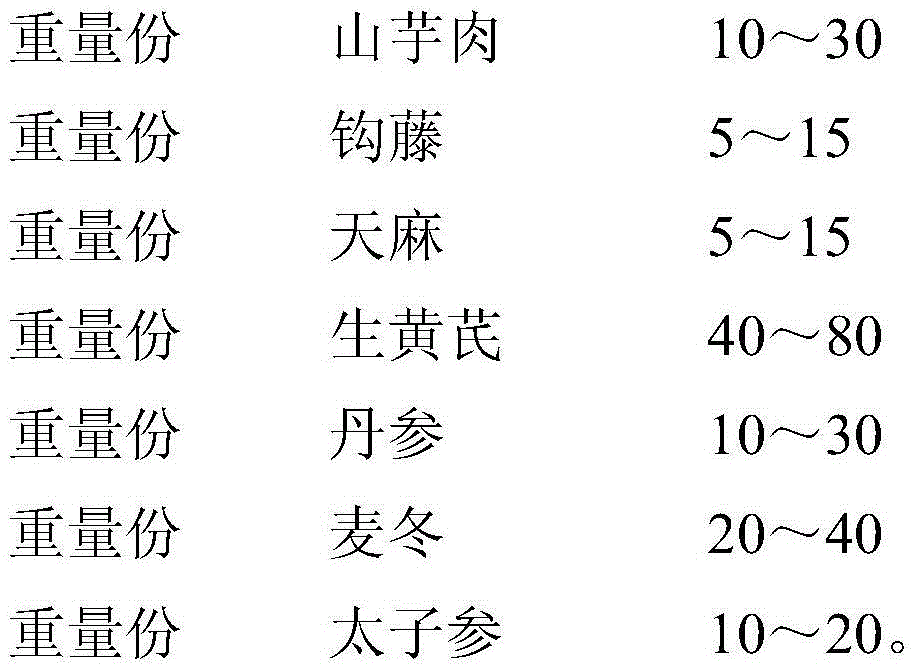

Traditional Chinese medicine for treating hypertension

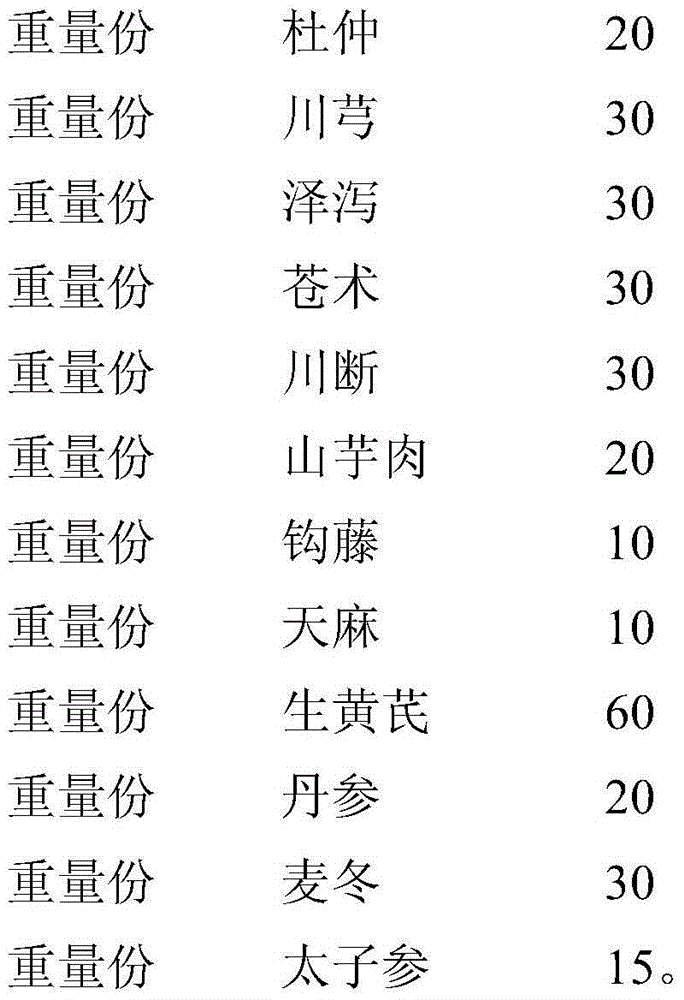

ActiveCN103599394AGood effectWill not polluteCardiovascular disorderPlant ingredientsDiseaseSalvia miltiorrhiza

A traditional Chinese medicine for treating hypertension relates to the technical field of hypertension treating medicines, and is characterized by comprising the following compositions in parts by weight: 10-30 parts of eucommia, 20-40 parts of ligusticumwallichii, 20-40 parts of alismaorientalis, 20-40 parts of rhizomaatractylodis, 20-40 parts of dipsacusasperoides, 10-30 parts of cornusofficinalis, 5-15 parts of uncaria, 5-15 parts of rhizomagastrodiae, 40-80 parts of raw radix astragali, 10-30 parts of salvia miltiorrhiza, 20-40 parts of radix ophiopogonis and 10-20 parts of radix pseudostellariae. The traditional Chinese medicine is capable of treating hypertension disease, furthest reducing cardio cerebrovascular accident incidence rate and mortality, and prolonging the life of patients, and has the advantages of being good in medicine property, good in safety, pure natural, free of pollution and free of side effect.

Owner:四川省十尚科技有限公司

Drill-feeding plugging agent

The invention discloses a follow-drilling plugging agent, which comprises the following compositions: 50 to 70 portions of fruit shell powder, 20 to 60 portions of limestone powder and 2 to 20 portions of oil-soluble resin. The follow-drilling plugging agent can be well applied to follow-drilling plugging in a drilling well and does not require stopping drilling and stopping a vibrating screen.

Owner:COSL CHEM TIANJIN

P-type cap layer enhanced HEMT device and preparation method thereof

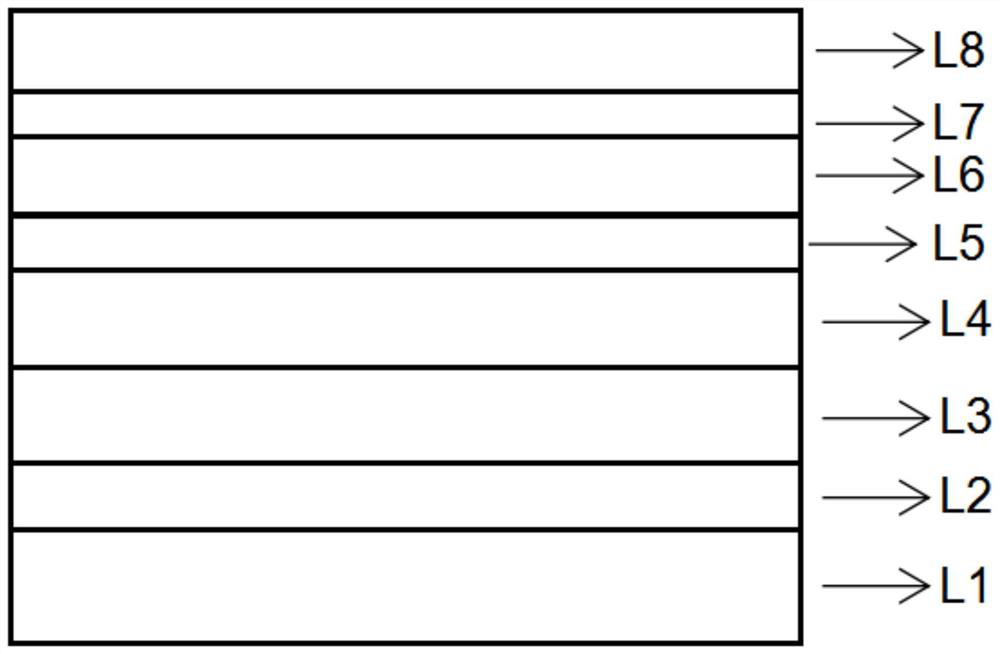

PendingCN112133749AAchieve epitaxial preparationEnabling Enhanced Epitaxy FabricationSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryMaterials science

The invention discloses a P-type cap layer enhanced HEMT (High Electron Mobility Transistor) device and a preparation method thereof, and belongs to the technical field of microelectronics. The devicecomprise a substrate, a low-temperature nucleating layer, a buffer layer, a high-resistance layer, a channel layer, a barrier layer, an insertion layer and a P-GaN cap layer which are sequentially stacked from bottom to top. The invention provides a new structure and a new growth method, so that the epitaxial preparation of the enhanced HEMT device is realized, and the stability of the performance of the enhanced HEMT device is ensured.

Owner:西安电子科技大学芜湖研究院

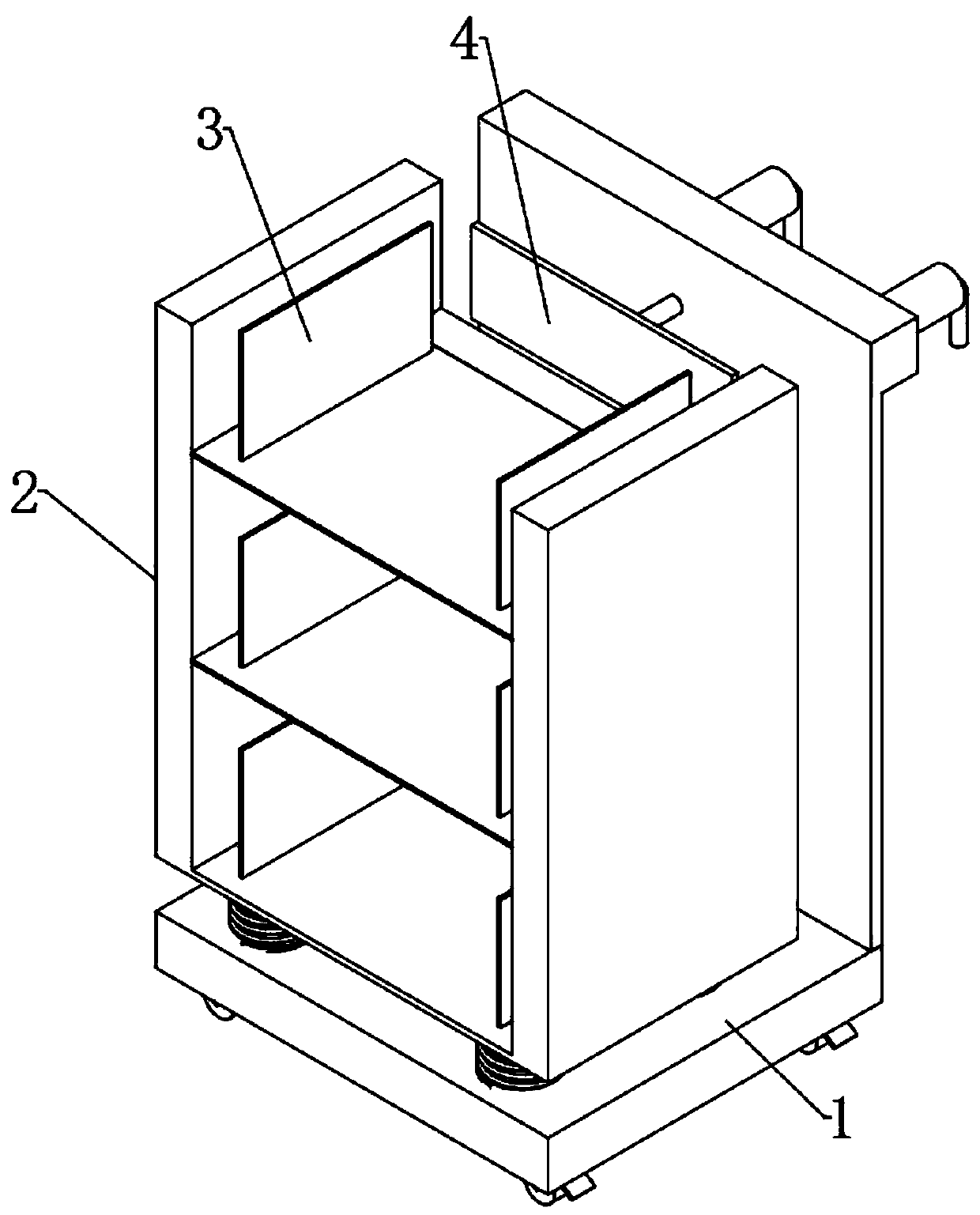

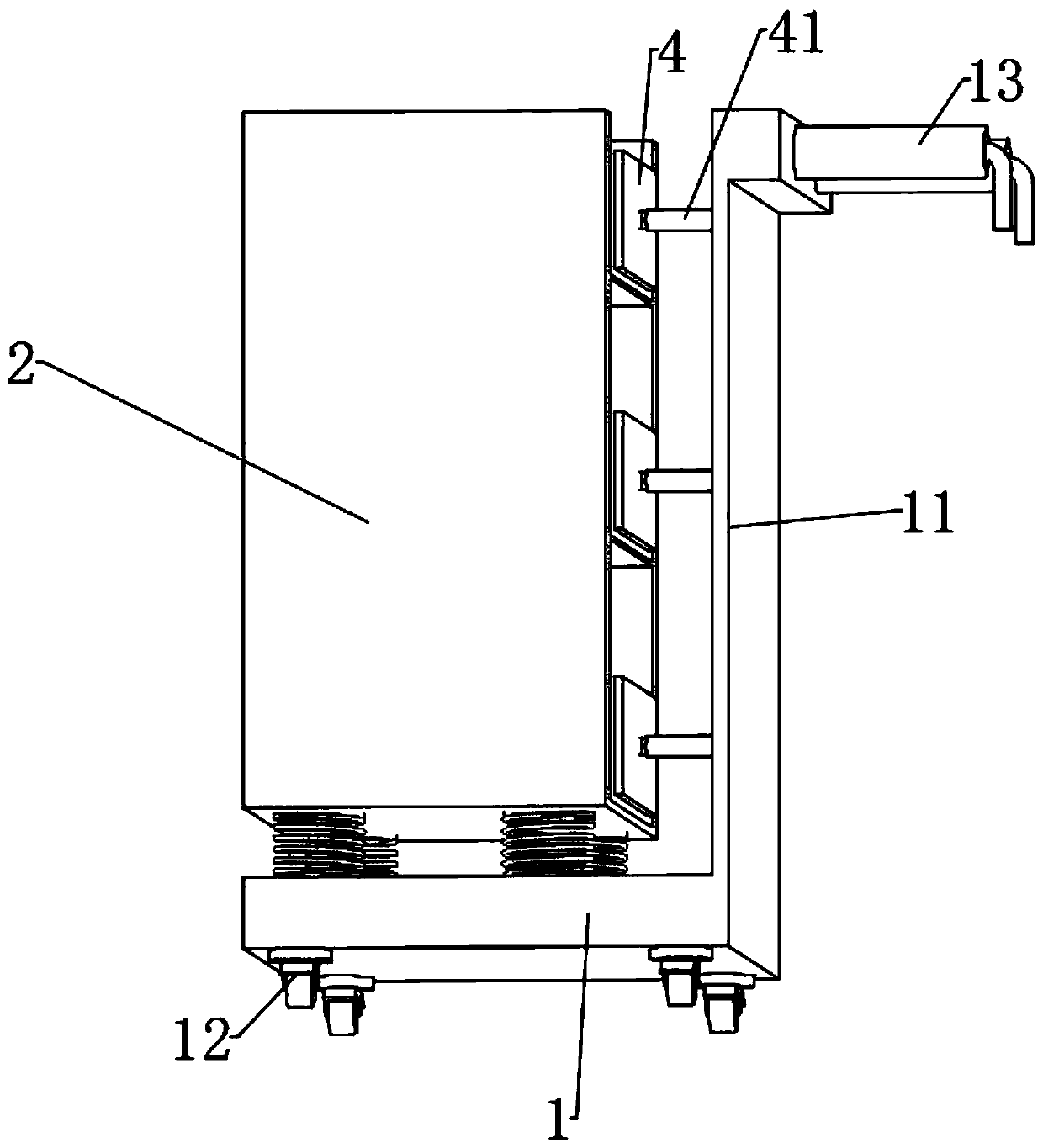

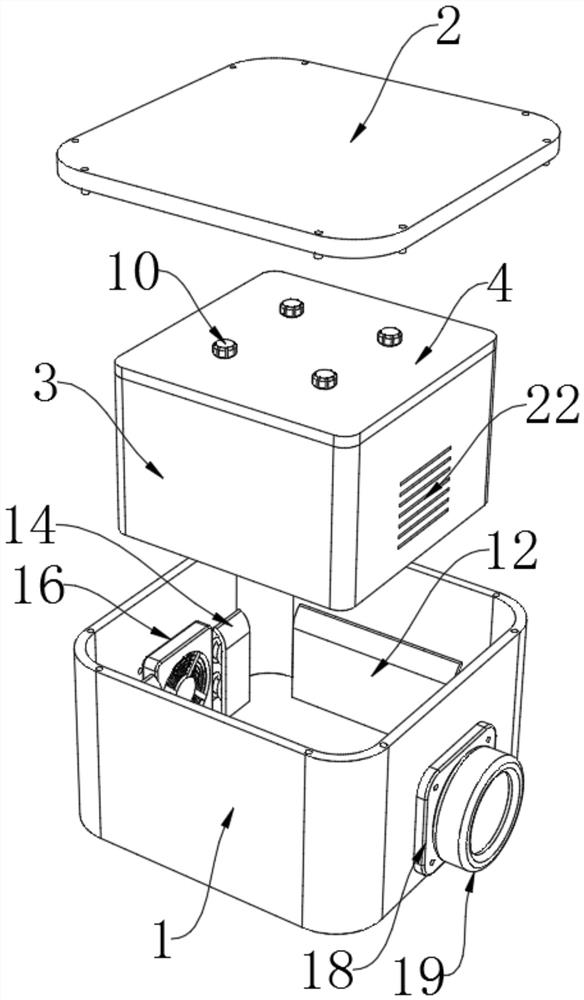

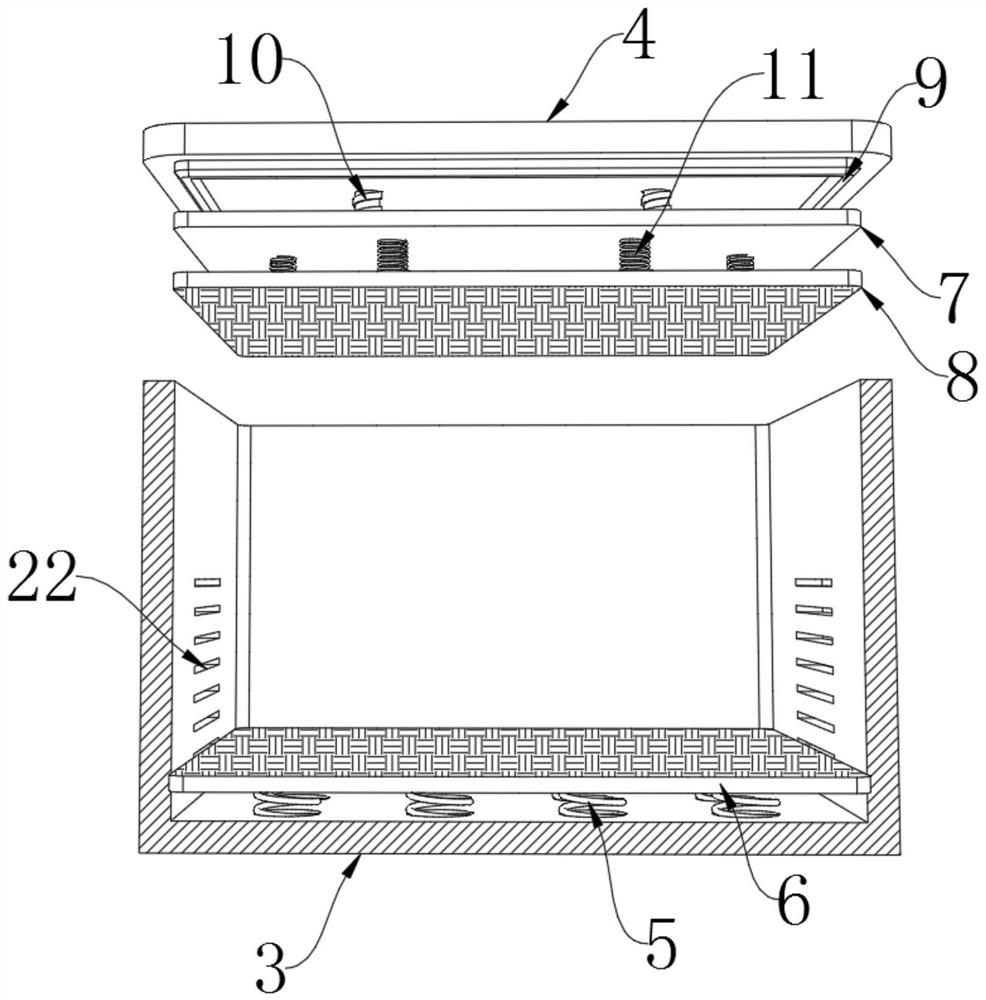

E-commerce logistics commodity auxiliary processing device

InactiveCN111452851APrevent fallingAvoid damageVibration suppression adjustmentsHand carts with multiple axesLogistics managementStructural engineering

The invention relates to the technical field of electronic commerce, in particular to an e-commerce logistics commodity auxiliary processing device. The device includes a base, a carrying frame is arranged at the top of the base; a plurality of partition plates are arranged in an inner cavity of the carrying frame. A spring seat is fixedly arranged at the bottom of the carrying frame. The spring seat is fixedly arranged at the top of the base; and limiting plates are slidably arranged on the inner wall of the carrying frame. A plurality of first pressure reducing springs are arranged in an inner cavity of the limiting plates; the two limiting plates are symmetrical to each other; a side plate is arranged at the top edge of the base; a push plate is slidably arranged on the outer wall, close to the carrying frame, of the side plate. A plurality of second pressure reducing springs are arranged in an inner cavity of the push plate, the push plate is arranged in an inner cavity of the carrying frame in a sliding mode, universal wheels are arranged at the positions, close to the four corners, of the bottom of the base, and brake pads are arranged on the universal wheels. The e-commercelogistics commodity auxiliary processing device can provide buffering protection for commodity in the carrying process and provides convenience for unloading.

Owner:安徽西尔艾智能科技有限公司

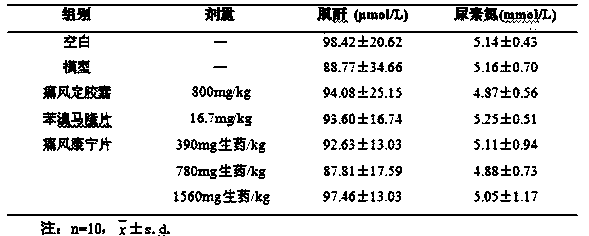

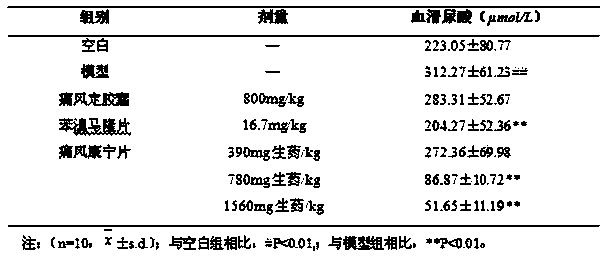

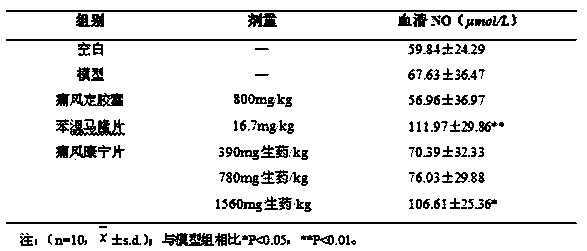

Traditional Chinese medicine composition for treating gout and hyperuricemia and preparation method thereof

ActiveCN104069391APrevent recurrencePlay a therapeutic roleSkeletal disorderUnknown materialsGrape seedPharmaceutical manufacturing

The invention belongs to the technical field of pharmaceutical manufacturing and particularly relates to a traditional Chinese medicine composition for treating gout and hyperuricemia and a preparation method thereof. The traditional Chinese medicine composition consists of the following herbs: 20-40 g of ash bark, 5-20 g of dark plum, 5-25 g of honeysuckle stem, 5-25 g of glabrous greenbrier rhizome, 5-20 g of longhairy antenoron herb, 5-20 g of plantain, 5-20 g of giant knotweed, 5-20 g of raw coix seed, 5-20 g of atractylodes macrocephala, 5-25 g of rhizoma dioscoreae nipponicae, 5-25 g of clematis root, 5-20 g of grape seed, 5-20 g of rhizoma dioscoreae hypoglaucae, 5-20 g of lily, 5-25 g of salvia chinensis and 10-30 g of raw oyster shell. The traditional Chinese medicine composition provided by the invention consists of 10 herbs, and is mainly used for treating and relieving hyperuricemia caused by various reasons and various complications caused by hyperuricemia, including normal rise of blood urea and pain, swelling, erythema, stiffness, pyrexia and the like of joints.

Owner:刘鸿生

Fuel cell proton exchange membrane with micro texture and processing method of fuel cell proton exchange membrane

ActiveCN111864244AIncrease profitIncrease the three-phase reaction interfaceFuel cellsFuel cellsPtru catalyst

The invention provides a fuel cell proton exchange membrane with a micro texture and a processing method of the fuel cell proton exchange membrane. A plurality of petal-shaped concave-convex compositetextures are distributed on the surface of a cathode of the fuel cell proton exchange membrane in a gradient manner that the inside is dense and the outside is sparse. The concave-convex composite texture comprises pits and protrusions, a circle of protrusions are arranged on the edges of the pits, and a plurality of semi-ellipsoid micro pits are evenly distributed in the inner surfaces of the pits. The surface of the cathode is divided into a central area, a middle area and a peripheral area according to the distance between every two adjacent concave-convex composite textures, and in each area, the distance between every two adjacent concave-convex composite textures is gradually increased from inside to outside in a gradient mode. The concave-convex composite texture can effectively increase the surface area of the cathode surface of the proton exchange membrane, facilitates full contact between the catalyst and reaction gas, and improves the reaction efficiency; and the carbon-supported platinum catalyst can be stably embedded in the structure, and the active area of the catalyst is increased, so that the utilization rate of the catalyst is increased.

Owner:JIANGSU UNIV

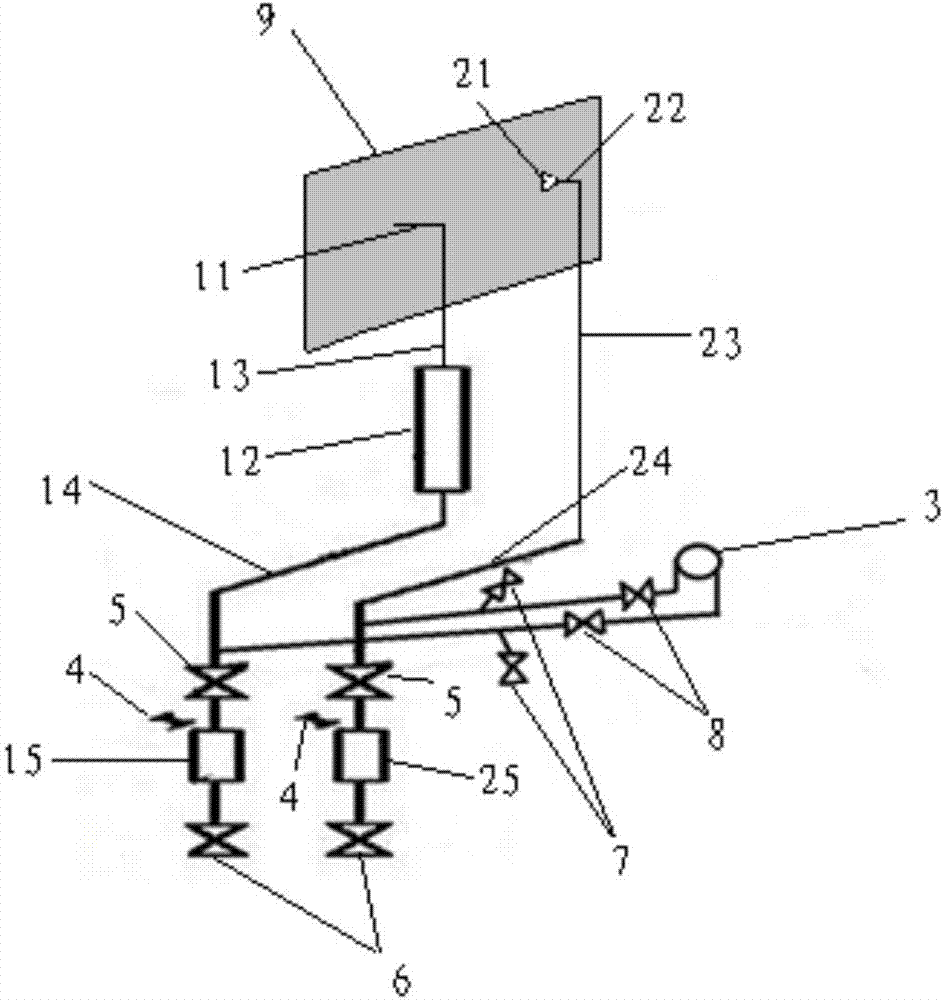

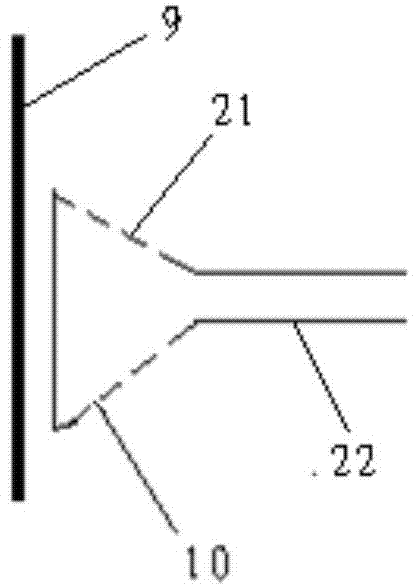

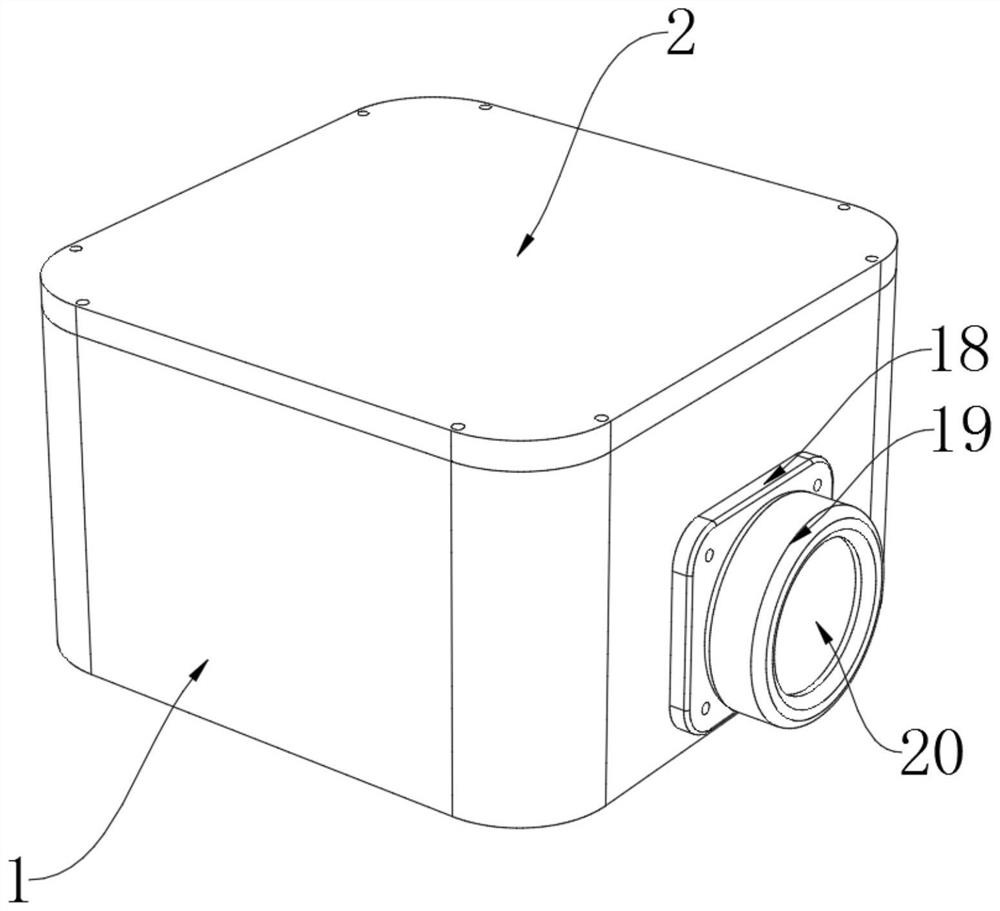

Furnace pressure detecting device for glass melting furnace and furnace pressure control system using furnace pressure detecting device

ActiveCN104743771AAccurate pressureAvoid interferenceGlass furnace apparatusGlass productionInternal pressureDifferential pressure

The invention provides a furnace pressure detecting device for a glass melting furnace. The furnace pressure detecting device comprises an inner pressure detecting pipeline and an external pressure detecting pipeline of the melting furnace as well as a differential pressure transmitter connected with the two detecting pipelines, wherein the inner pressure detecting pipeline comprises a high-temperature pipe communicated with the inner part of the glass melting furnace, and the high-temperature pipe is horizontally or downwards arranged so that the inlet end of the high-temperature pipe is higher than the outlet end of the high-temperature pipe; the external pressure detecting pipeline comprises a receiving device for receiving an external flow of the melting furnace, the receiving device comprises a receiving pipe provided with a large-opening end and a small-opening end, the large-opening end of the receiving pipe is arranged to be closed, the small-opening end of the receiving pipe is communicated with a buffer pipe, the diameter of the receiving pipe is gradually decreased along the axis of the receiving pipe from the large-opening end to the small-opening end, the side wall of the receiving pipe is provided with a receiving hole for receiving the entry of gas, the large-opening end of the receiving pipe clings to an outer wall of the melting furnace, and a gap is preserved between the large-opening end and the outer wall. According to the furnace pressure detecting device, the inner and external pressure detecting pipelines are arranged, meanwhile, the pressure tapping accuracy of each of the pressure detecting pipelines is ensured, and thus the pressure detecting accuracy is improved.

Owner:河北视窗玻璃有限公司

Detachable flame-retardant automobile storage battery shell and using method thereof

PendingCN112216924AEffectively fixedPlay a relieving effectDispersed particle filtrationSecondary cellsStructural engineeringProcess engineering

The invention relates to the technical field of automobile storage batteries, in particular to a detachable flame-retardant automobile storage battery outer shell and a using method thereof. The detachable flame-retardant automobile storage battery outer shell comprises a protective outer shell, a sealing cover is fixed to the upper end of the protective outer shell, and a protective inner shell is placed in the protective outer shell; a fixing cover is fixed to the upper end of the protective inner shell, a plurality of containing grooves are formed in the bottom end of the interior of the protective inner shell, and first compression springs are placed in the containing grooves. Through the design of the fixing structure, the device can effectively fix a battery pack placed in the device, can fix the battery pack according to different sizes of batteries, can also play a certain role in relieving the fixed batteries, and through the design of the heat dissipation structure, the device can effectively dissipate heat of high temperature generated in the device, and the filtering structure can be conveniently and rapidly replaced without being affected by space.

Owner:江苏爱力生蓄电池有限公司

Bioactive star fish food

The present invention discloses a starfish biological activity food. Its preparation method includes: cleaning starfish, cooking, taking out digestive gland (liver) genital gland (sperm and ovary) from brachiole, etc., soaking it in dilute phosphoric acid solution and dilute sodium hydrogen carbonate solution to make acid-base detoxication, then desiccating, grinding to obtain fine powder and capsulizing.

Owner:ZHIFU ISLAND SEA PROD YANTAI

Low-calorific-value operating method of blast furnace gas-fired 300MW generator set

ActiveCN104593533AImprove balancePlay a relieving effectBlast furnace detailsCombustion chamberEngineering

The invention discloses a low-calorific-value operating method of a blast furnace gas-fired 300MW generator set. According to the low-calorific-value operating method, when a unit is in operation, a control value of a gas calorific value can be reduced by modifying a logical constant value. The method performed by adopting a low-calorific-value mode comprises the following steps: reducing a set gas calorific value; adjusting high and low alarm values of the gas calorific value, and rapidly reducing load to protect alarm values of an operating value and a wet-state calorific value; and adding high sound-light alarm of combustion chamber pressure and the like. The low-calorific-value operating method disclosed by the invention has the advantages of reducing the combustion quantity of coke oven gas, ensuring high-load and high-efficiency operation of the unit, and saving the power generation cost.

Owner:ANGANG STEEL CO LTD

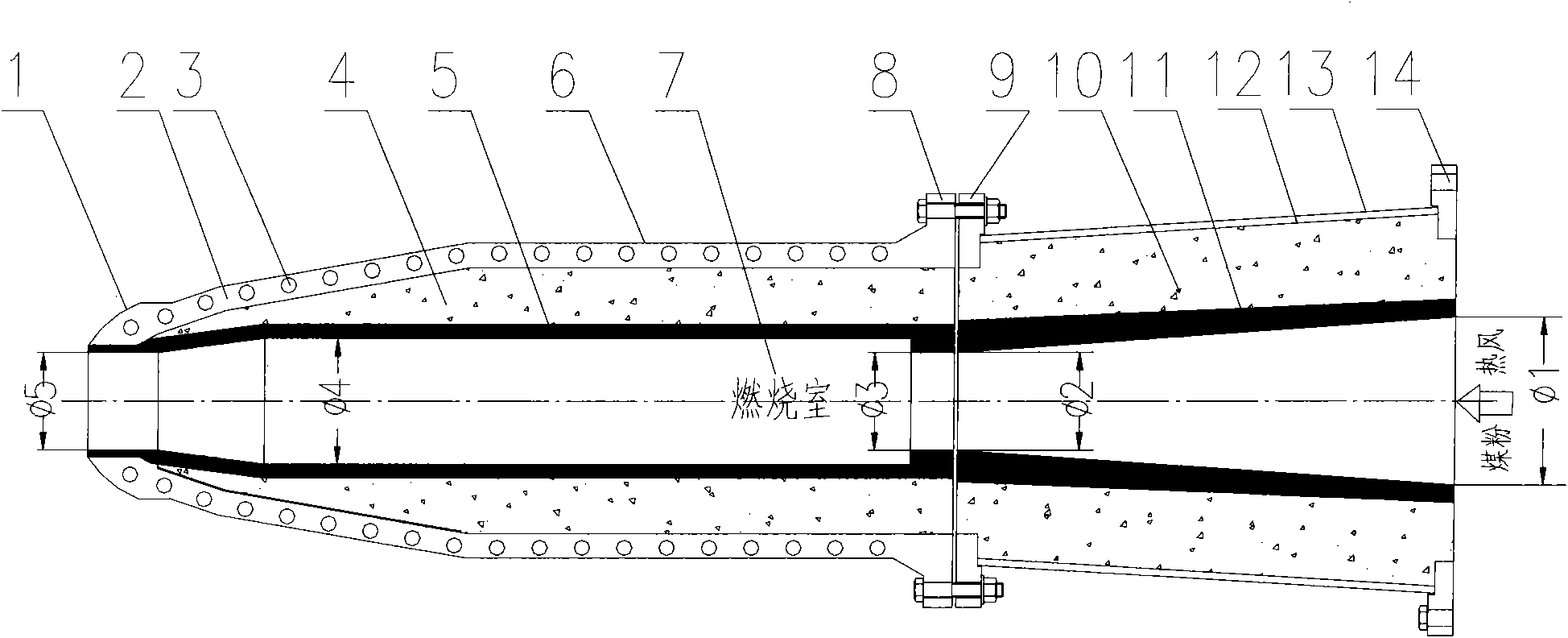

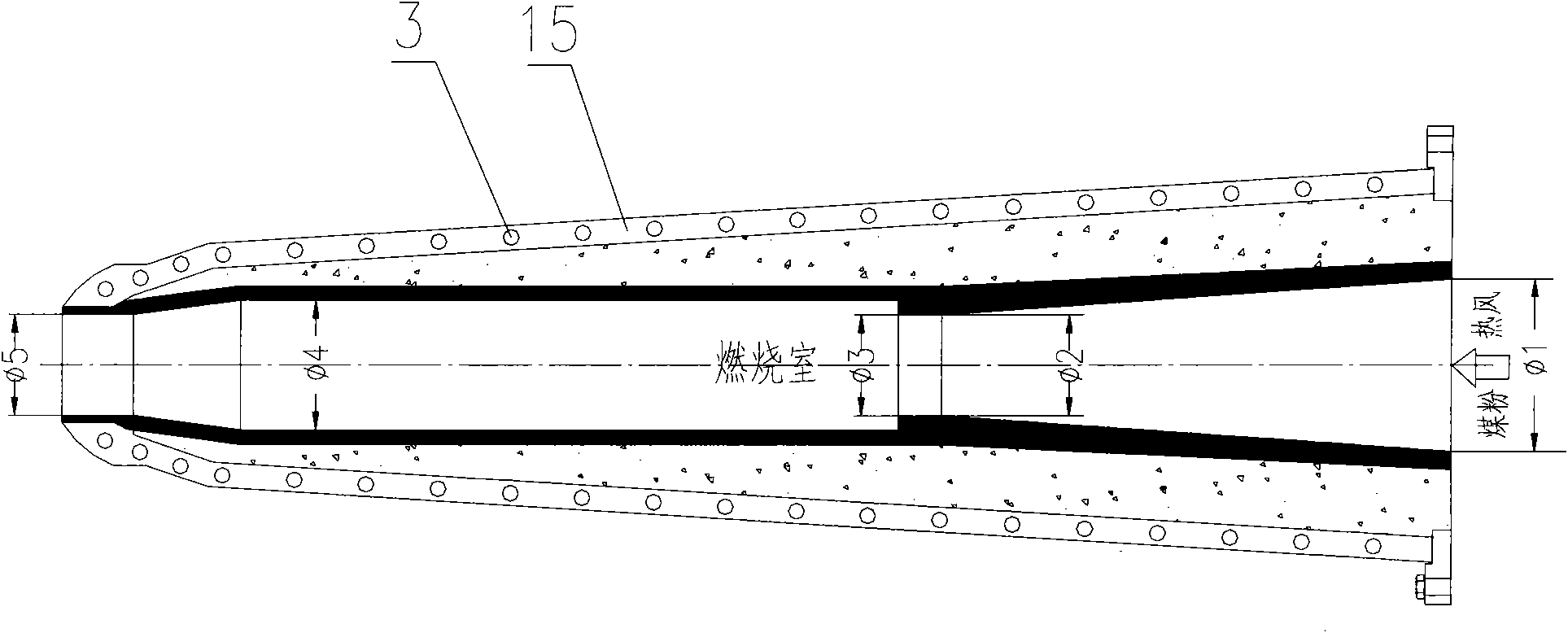

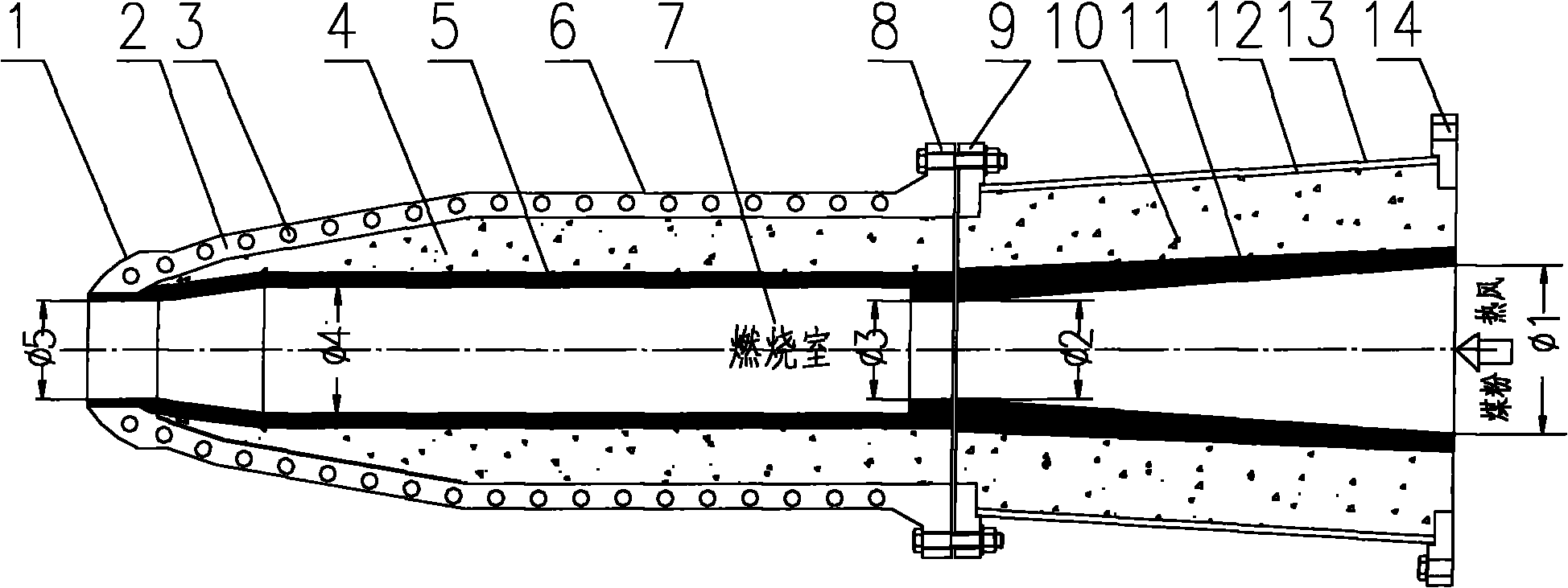

Belly pipe with pulverized coal burning function

InactiveCN102485916AIncrease burn rateIncrease the number of burnsTuyeresHot blastCombustion chamber

The utility model provides a belly pipe with a pulverized coal burning function, which comprises a premix burner and a burner. The premix burner and the burner are connected through a flange; hot-blast air and pulverized coal simultaneously enter from the inlet of the premix burner; an internal channel in the premix burner is of a reducing pipe structure; the diameter of the outlet of the premix burner is less than that of the inlet of the premix burner and is equal to that of the inlet of the burner; a suddenly expanding combustion chamber is arranged in the burner; the inner diameter of the combustion chamber is greater than the diameter of the inlet of the burner, whereas the outlet section of the burner is also of a reducing pipe structure; and the diameter of the outlet of the burner is less than the inner diameter of the combustion chamber and is also less than the diameter of the inlet of an air inlet. Due to the fact that the pulverized coal starts to be injected into the hot-blast air nearby the inlet of the premix burner, equivalently the existing pulverized coal injected into a blast furnace is injected into the blast furnace again after being burnt outside the furnace, thus, the burning rate of the injected pulverized coal is greatly improved and the burning amount of the pulverized coal in the hot-blast air is increased, thereby the amount of the injected pulverized coal which can be accepted by the blast furnace is obviously increased. At the same time, partially burnt pulverized coal causes the volume and the temperature of combustion products to be increased sharply and the blast kinetic energy is also obviously improved, and therefore, the beneficial effect of improving the work of a blast furnace hearth is brought.

Owner:张昭贵

Three-yield-in-two-year multi-lamb technology for mutton sheep in farming-pasturing interlaced area

InactiveCN105660527AReduce the feeding ratioReduce the number of feedersAnimal husbandryAnimal scienceOvulation

The invention relates to the field of animal-husbandry breeding, and discloses a three-yield-in-two-year multi-lamb technology for mutton sheep in a farming-pasturing interlaced area. The technology includes a production cycle control method, an estrus ovulation regulating method, artificial insemination and nutrition regulation. The production cycle control method is the three-yield-in-two-year breeding technology; the estrus ovulation regulating method is the CDIR, FSH and PMSG method; nutrition regulation includes medicine nourishing and food nourishing. According to the three-yield-in-two-year multi-lamb technology, the super-ovulation and artificial-insemination technology is carried out with exogenous hormones, the breeding cycle of sheep is shortened to 8 months from 12 months, the feeding proportion of colonial rams and colonial ewes is decreased while the hybridization success rate is guaranteed, and the culture benefits of the sheep are remarkably increased.

Owner:JILIN AGRICULTURAL UNIV

Preparation method of long-term antibacterial and fresh edible coating liquid

InactiveCN110024848AExtend freshnessImprove antioxidant capacityFruits/vegetable preservation by coatingBiotechnologyPhenolic content in tea

The invention relates to a preparation method of long-term antibacterial and fresh edible coating liquid, and belongs to the technical field of food processing. TP (tea polyphenol) extract liquid is taken as a raw material, by adding casein and theaflavin extracts, the long-term antibacterial and fresh edible coating liquid is prepared, TP is subjected to a complexation reaction with proteins in casein, precipitation will be formed under the action of hydrophobic-hydrogen bonding, with degree of association increasing, complexes show colloidal properties, and the solubility of the complexes will be changed with temperature; furthermore, the proteins are precipitated after phenolic hydroxyl groups interacting with the proteins and amino acids, so that the TP has the effects of sterilization, antivirus and the like. The complexation reaction is invertible. Curcumin has the double activity of oxidation loving and anti-oxidation, and has certain inhibitory effect on most of the bacteria and the inhibitory effect is significant, which is a good natural antibacterial agent and can effectively improve antibacterial energy of the edible coating liquid and preservation time of food.

Owner:杭州奥冰生物科技有限公司

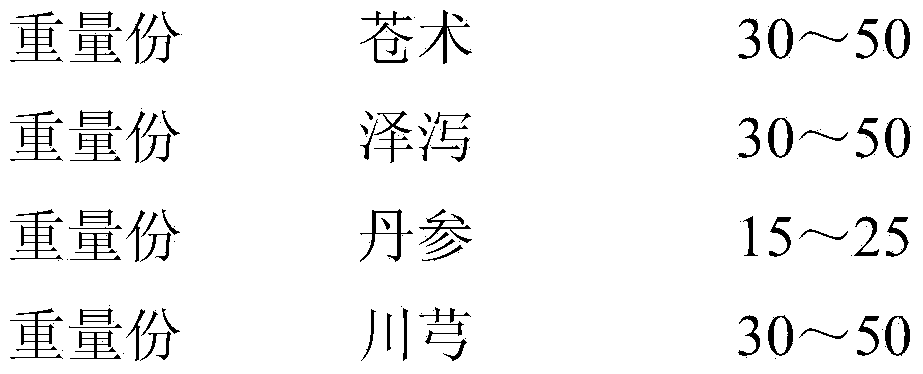

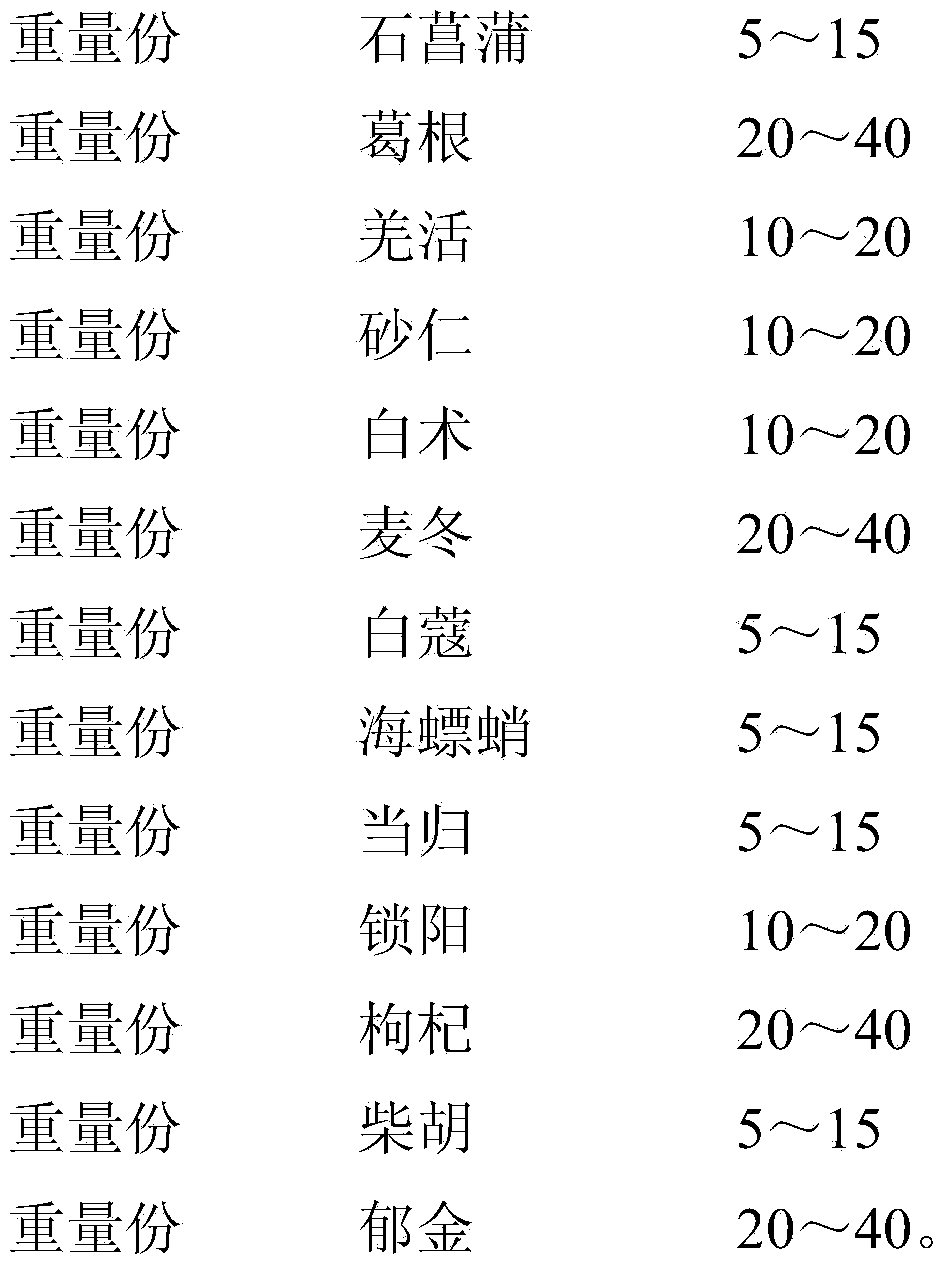

Traditional Chinese medicine formula for treating cardio-cerebro vascular diseases

InactiveCN103611063AGood effectWill not polluteCardiovascular disorderMolluscs material medical ingredientsDiseaseSalvia miltiorrhiza

The invention discloses a traditional Chinese medicine formula for treating cardio-cerebro vascular diseases, and relates to the technical field of drugs for treating cardio-cerebro vascular diseases. The traditional Chinese medicine formula is characterized by comprising the following components in parts by weight: 30 to 50 parts of rhizoma atractylodis, 30 to 50 parts of oriental waterplantain rhizome, 15 to 25 parts of red sage root, 30 to 50 parts of ligusticum wallichii, 5 to 15 parts of acorus tatarinowii, 20 to 40 parts of kudzu vine root, 10 to 20 parts of notopterygium root, 10 to 20 parts of villous amomum fruit, 10 to 20 parts of bighead atractylodes rhizome, 20 to 40 parts of dwarf lilyturf root, 5 to 15 parts of fructus amomi rotundus, 5 to 15 parts of cuttlebone, 5 to 15 parts of Chinese angelica, 10 to 20 parts of cynomorium songaricum, 20 to 40 parts of wolfberry, 5 to 15 parts of radix bupleuri, and 20 to 40 parts of curcuma tuber. The traditional Chinese medicine formula can treat cardio-cerebro vascular diseases, maximally reduces the harms caused by the cardio-cerebro vascular diseases to human body, prolongs patients' life, and has the advantages of good medicinal property, good safety, pure natural property, no pollution, and no side effect.

Owner:陈维娜

Biodegradable plant-based anti-wear lubricating oil and preparation method thereof

PendingCN112552989AImprove anti-wear performanceHigh strengthLubricant compositionIron sulfateVegetable oil

The invention discloses biodegradable plant-based anti-wear lubricating oil and a preparation method thereof. The biodegradable plant-based anti-wear lubricating oil comprises vegetable oil, a synthetic ester and a vulcanizing aid. According to the biodegradable plant-based anti-wear lubricating oil, the synthetic ester and the vulcanizing aid are added into the raw materials of the lubricating oil, and polar functional groups are added into the molecular structure of the lubricating oil by utilizing the synthetic ester, so that on one hand, the strength of an anti-wear oil film in a metal contact area is improved, and the anti-wear efficiency is improved; the vulcanizing aid and vegetable oil are used for compounding treatment, sulfur bonds of low-sulfur-content vulcanized ester are mainly episulfide bonds, firstly, the episulfide bonds of the vulcanized ester adsorbed on the friction surface are broken in the friction process to generate hydrocarbon free radicals and sulfur free radicals, the sulfur ion free radicals further react with iron to generate iron sulfide, the amount of the iron sulfide converted into ferric sulfate is increased along with the increase of retention timein air and oil temperature, and substances containing the iron sulfide form a reaction film with low shear strength on the metal surface, so that the wear resistance of the lubricating oil is effectively improved.

Owner:田志红

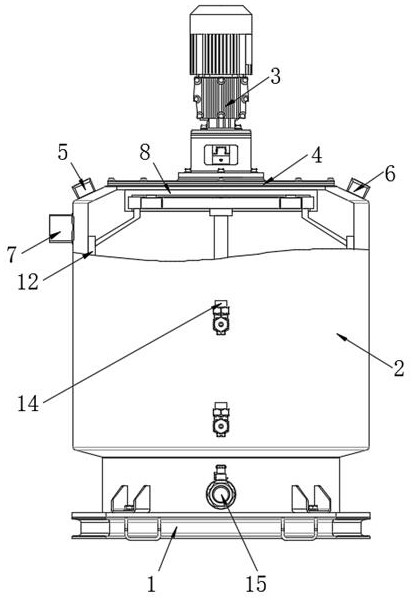

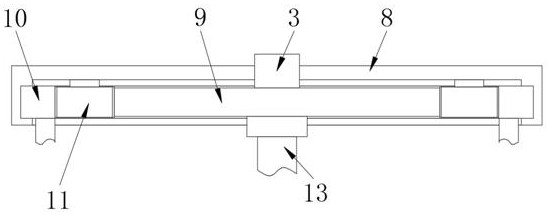

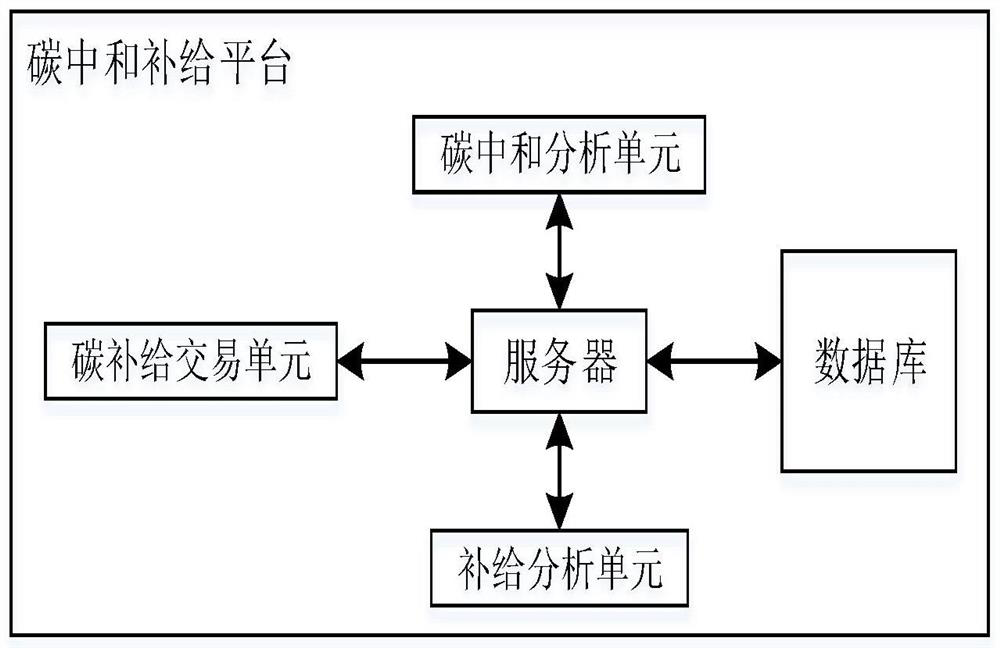

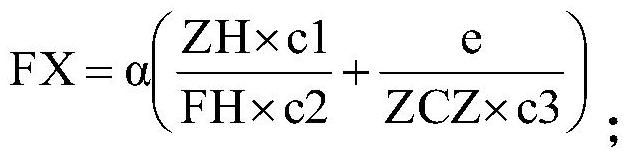

Carbon neutralization and replenishment system in operating buildings

PendingCN114022034AEmission controlExtended durationTechnology managementResourcesArchitectural engineeringProcess engineering

The invention discloses a carbon neutralization and replenishment system in operating buildings, and belongs to the technical field of carbon neutralization and replenishment. The carbon neutralization and replenishment system comprises a carbon neutralization and replenishment platform for carrying out carbon replenishment on each operating building. The carbon neutralization and replenishment platform comprises a carbon neutralization analysis unit for carrying out carbon neutralization analysis on each operating building; and a carbon supply transaction unit, which is used for carrying out carbon supply transaction on each operating building. A server is in communication connection with the carbon neutralization analysis unit, the carbon supply transaction unit and a replenishment analysis unit. After the carbon neutralization analysis unit sends information obtained through analysis to the server, the server generates a carbon replenishment transaction signal and sends the signal to the carbon supply transaction unit, and the carbon supply transaction unit performs carbon supply transaction on a positive neutralization operation building and a negative neutralization operation building. According to the invention, through replenishment, a relieving effect can be achieved on operating buildings with carbon emission exceeding the standard, and the duration of carbon neutralization can be prolonged, so that the carbon emission is controlled at the lowest cost, and the carbon neutralization efficiency is improved.

Owner:TERMINUSBEIJING TECH CO LTD

Mouthwash and preparation method and application thereof

InactiveCN108379098ATypes of reduced dosageReduce energy consumptionCosmetic preparationsImpression capsEscherichia coliSide effect

The invention provides mouthwash and a preparation method and application thereof. The mouthwash is prepared from, 0.2-0.25% of sodium chlorite, 0.5-1% (v / v) of pH conditioning agent, 1.1-2.1 % of stablilzer, 0.1-0.2 % of flavoring agent, 0.1-0.2 % of preservative, 0.1-0.2 % of solubilizer, and the balance purified water. The invention further provides a preparation method and application of the mouthwash. The material combination and component effects better complement one another, and the prepared mouthwash has antibacterial effects on staphylococcus aureus, escherichia coli and candida albicans, thereby relieving discomfort of periodontits, gingivitis, canker sore, dental plaque, gingival bleeding, ozostomia and the like which are caused by pathogenic bacteria, is safe, non-toxic and nonirritating, has no side effects, is a novel cleaning product for oral sterilization and disinfection, and can be applicable to denture soaking and sterilization and disinfection.

Owner:CHENGDU MEDICAL COLLEGE

Processing method of protein peptide product from low-value fishes

InactiveCN107156861AExtended shelf lifeHigh purityFood ingredient functionsProtein food ingredientsTreatment effectProtein C

The invention discloses a processing method of a protein peptide product from low-value fishes. The processing method comprises the steps as follows; 1) pretreatment; 2) degreasing; 3) fishy smell removing; 4) enzymolysis; 5) dialysis; 6) spray drying; and 7) finished product obtaining. The processing method has the benefits as follows: the prepared protein peptide product from low-value fishes has small molecular weight, has the average molecular weight being 1,200 Da and can be digested and absorbed by the human body easily, and the protein peptide can effectively relax nerves, promote sleep and relieve depression; the protein peptide product has very low fat content, cannot be oxidized to deteriorate easily, has long shelf life and has high protein peptide purity; the content of vitamins and minerals is high, DHA is also contained, the product is high in nutritional value and scientific in matching, and the nerve relaxing effect and the depression treatment effect are improved. The processing method is simple to operate and good in reproducibility, less equipment is required and low in production cost, the low-value fishes are adopted as raw materials, the resources are fully utilized, the added value of the low-value fishes is increased, and the method is suitable for mass production.

Owner:慈溪创璞食品科技有限公司

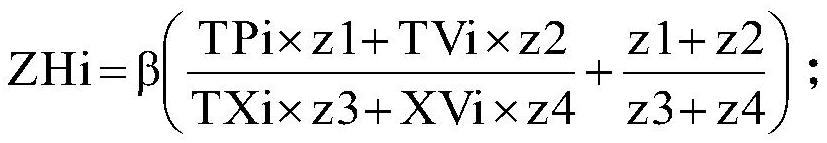

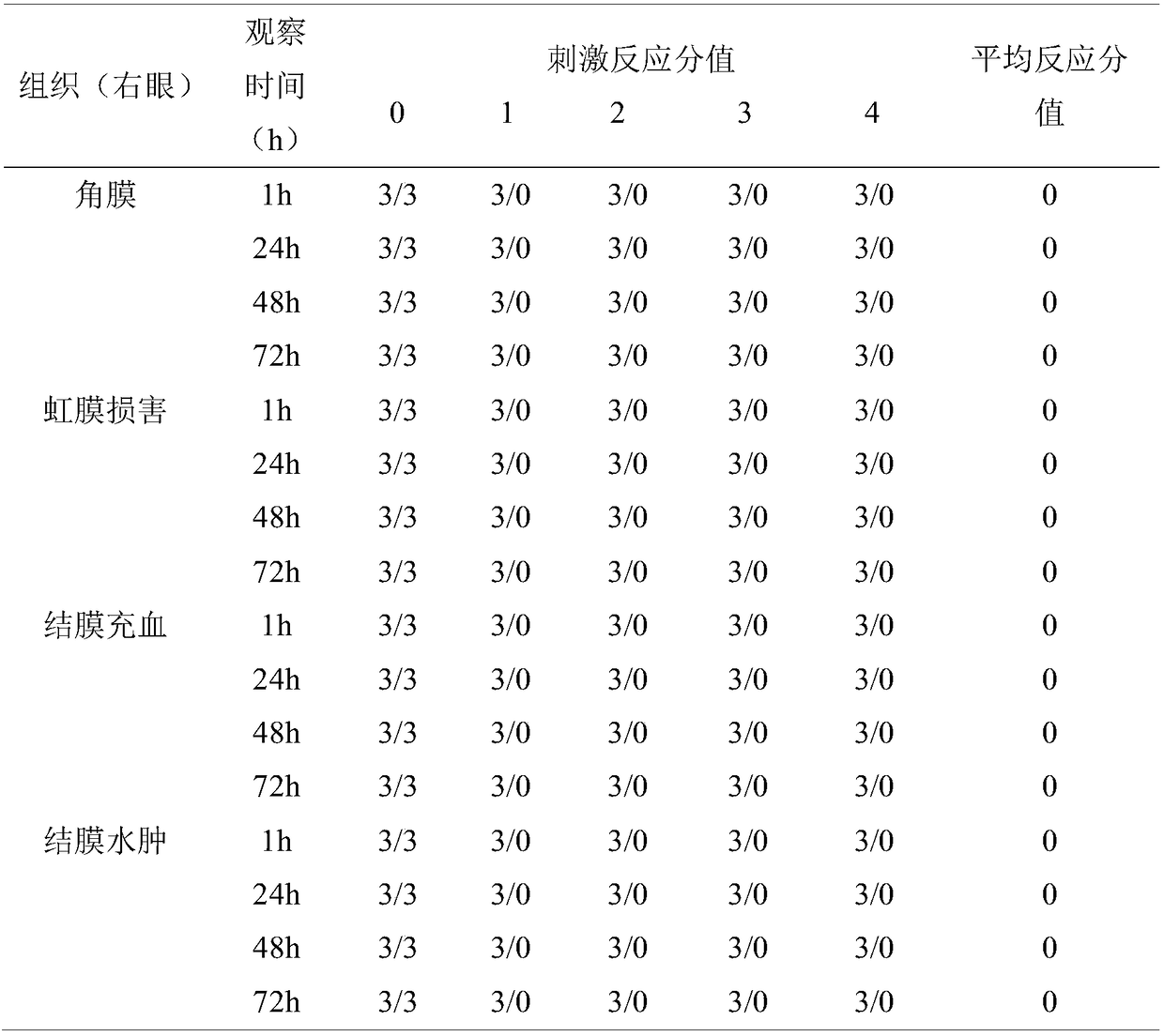

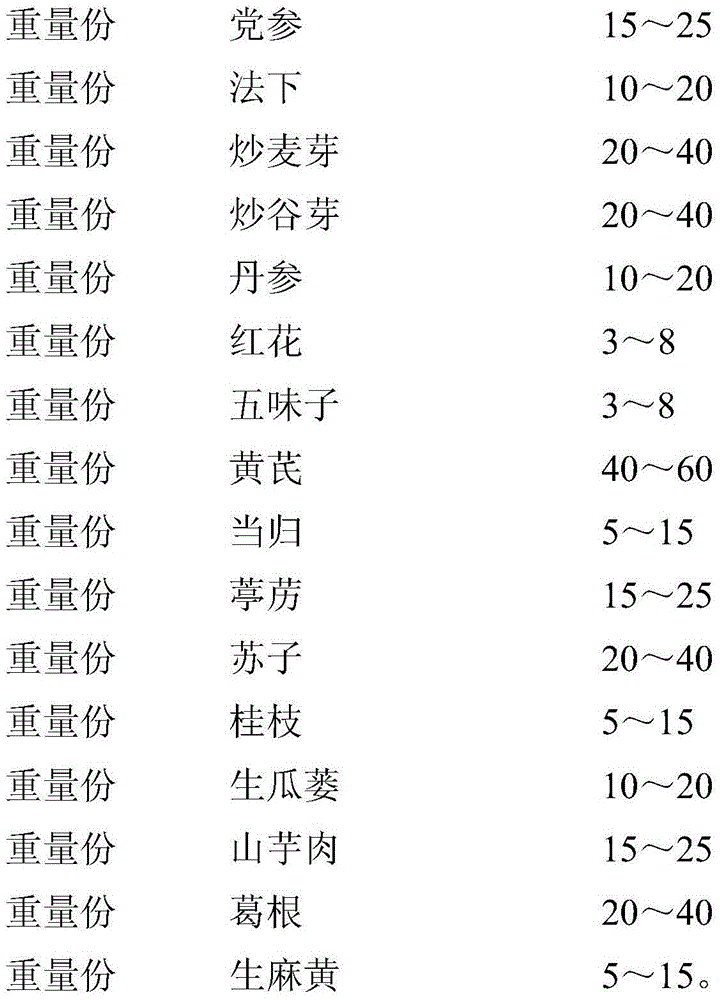

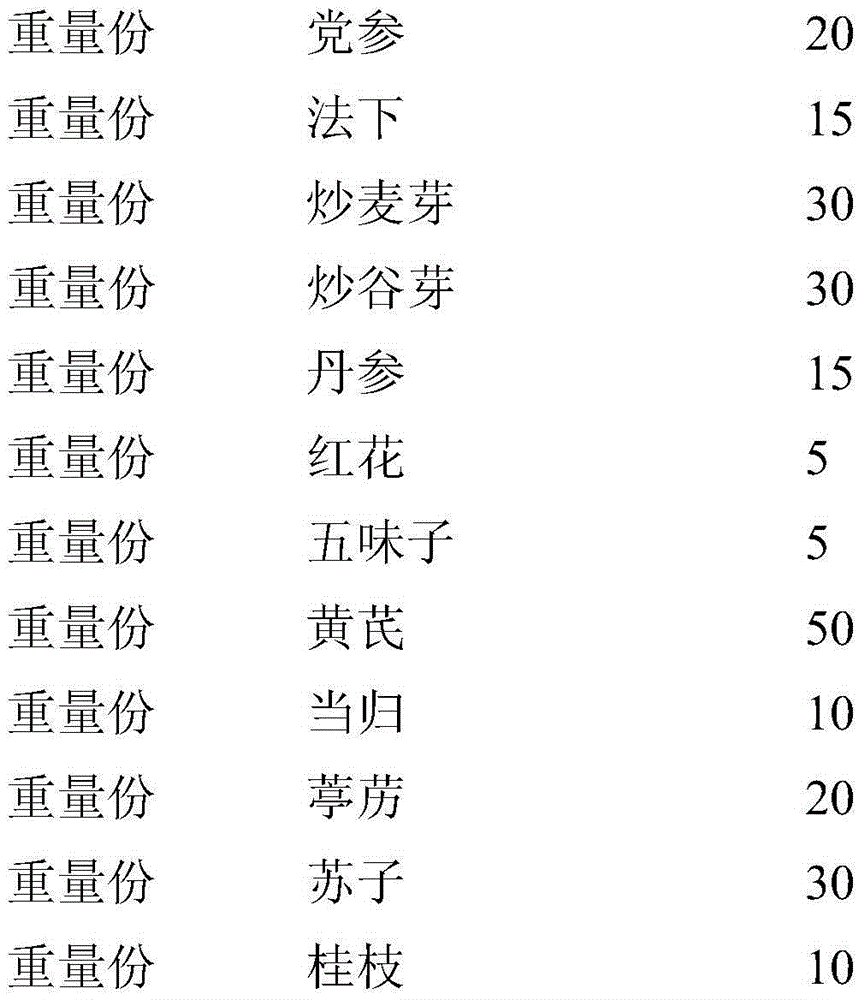

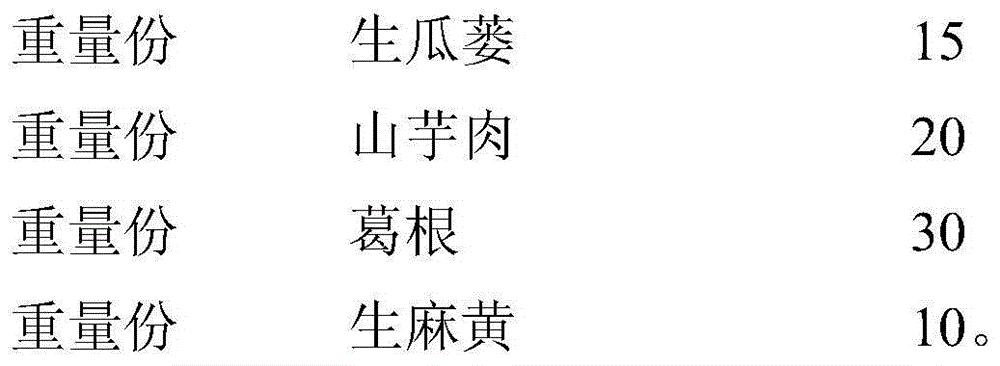

Traditional Chinese medicine formula for treating cardiac asthma

ActiveCN103599431AGood effectWill not polluteRespiratory disorderCardiovascular disorderSalvia miltiorrhizaDisease

A traditional Chinese medicine formula for treating cardiac asthma relates to the technical field of drugs for treating the cardiac asthma, and the traditional Chinese medicine composition is characterized by comprising the following components in parts by weight: 15-25 parts of parts of codonopsis pilosula, 10-20 parts of the prepared pinellia tuber, 20-40 parts of roasted malt, 20-40 parts of roasted rice sprout, 10-20 parts of salvia miltiorrhiza, 3-8 parts of safflower, 3-8 parts of Chinese magnoliavine, 40-60 parts of astragali radix, 5-15 parts of angelica sinensis, 15-25 parts of rorippa indica, 20-40 parts of perillaseed, 5-15 parts of cassia twig, 10-20 parts of fresh trichosanthes kirilowii maxim, 15-25 parts of fructus cormi, 20-40 parts of radix puerariae and 5-15 parts of fresh ephedra; the traditional Chinese medicine formula can treat cardiac asthma diseases, reduce harm to human body caused by the cardiac asthma in a maximum limit, and prolong the life of patients, and is good in drug potency, good in safety, purely natural, and free of pollution and side effect.

Owner:武汉香云盖天然香业有限公司

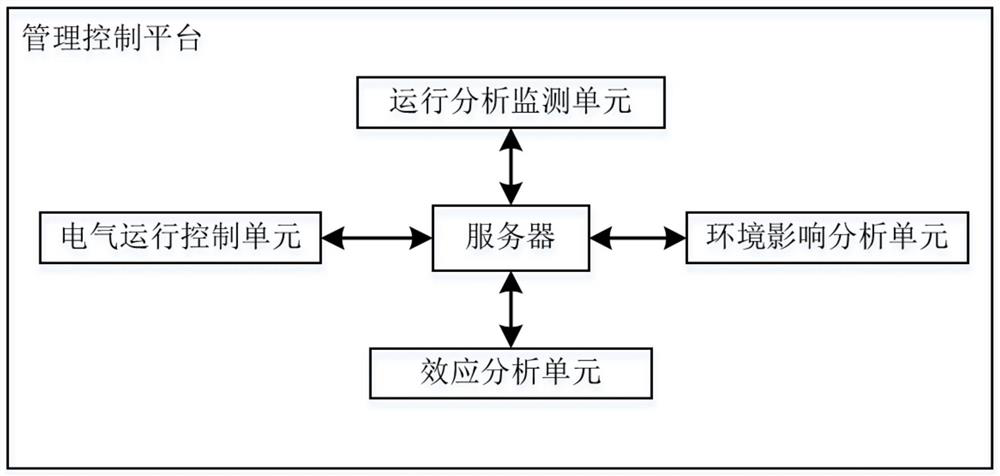

Lifting and transverse moving parking equipment management and control system based on intelligent control

PendingCN114370190AImprove the quality of useAvoid damageIndication of parksing free spacesTransmissionControl systemControl engineering

The invention discloses a lifting and transverse moving parking equipment management and control system based on intelligent control, relates to the technical field of intelligent control of lifting and transverse moving parking equipment, and solves the technical problem that parking equipment cannot be managed and controlled in real time to ensure the equipment effect in the prior art. Therefore, the equipment runs smoothly, the parking efficiency is ensured, the running quality is also ensured, and the use quality of a user is improved; the vehicle parking process of the lifting and transverse moving parking equipment is monitored, whether equipment operation is abnormal or not is judged, and therefore the safety performance of parking vehicles by users is determined, and the parking pressure is effectively relieved while the safety of the users is ensured. The surrounding environment of the analysis object is analyzed, and the situation that natural abrasion of parking equipment is accelerated due to environment abnormity is prevented; the use of the analysis object is analyzed, and the influence brought by the analysis object is judged, so that whether the parking equipment can relieve the parking pressure or not is judged.

Owner:湖南湘商智能科技有限公司

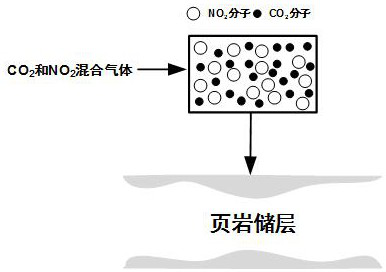

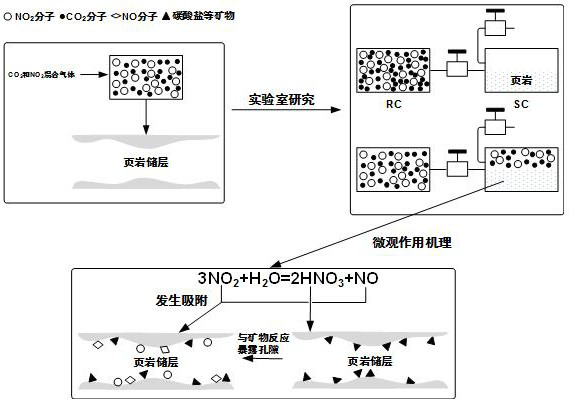

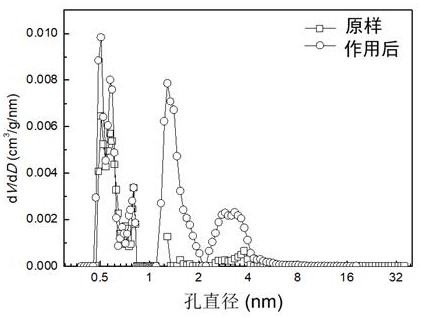

Method for enhancing shale carbon dioxide adsorption performance and cooperatively storing nitrogen dioxide

ActiveCN112403187AImprove adsorption performanceImprove storage performanceGas treatmentDispersed particle separationGreenhouse gasCarbon dioxide

The invention discloses a method for enhancing the carbon dioxide adsorption performance of shale and cooperatively storing nitrogen dioxide, which utilizes nitrogen dioxide to improve the adsorptionperformance of shale on carbon dioxide and achieves the purpose of reducing nitrogen dioxide emission at the same time. Specifically, nitrogen dioxide molecules with high chemical activity react withunderground water of a shale reservoir to generate nitric acid and nitric oxide; on one hand, the generated nitric acid can dissolve carbonate and other mineral components in the shale to expose partof pores of the shale, so that the carbon dioxide adsorption performance of the shale is enhanced; and on the other hand, the shale reservoir environment is an anoxic environment, the generated nitricoxide cannot be oxidized to generate nitrogen dioxide, and the shale has a strong chemical adsorption effect on the nitric oxide and is difficult to desorb, so that the long-term stable storage of the shale on the nitrogen dioxide is realized. According to the method, the nitrogen dioxide is cooperatively stored in the process of storing greenhouse gas carbon dioxide, thereby providing an effective way for reducing the coal-fired flue gas denitration treatment cost.

Owner:KUNMING UNIV OF SCI & TECH

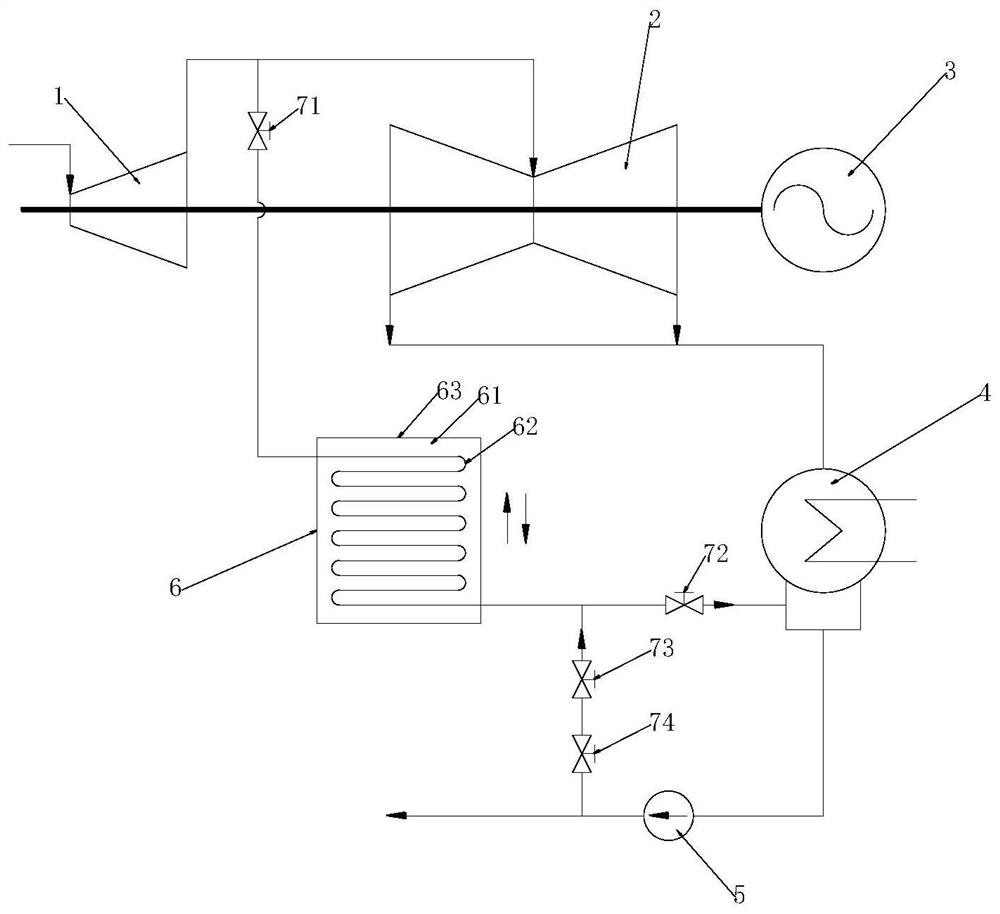

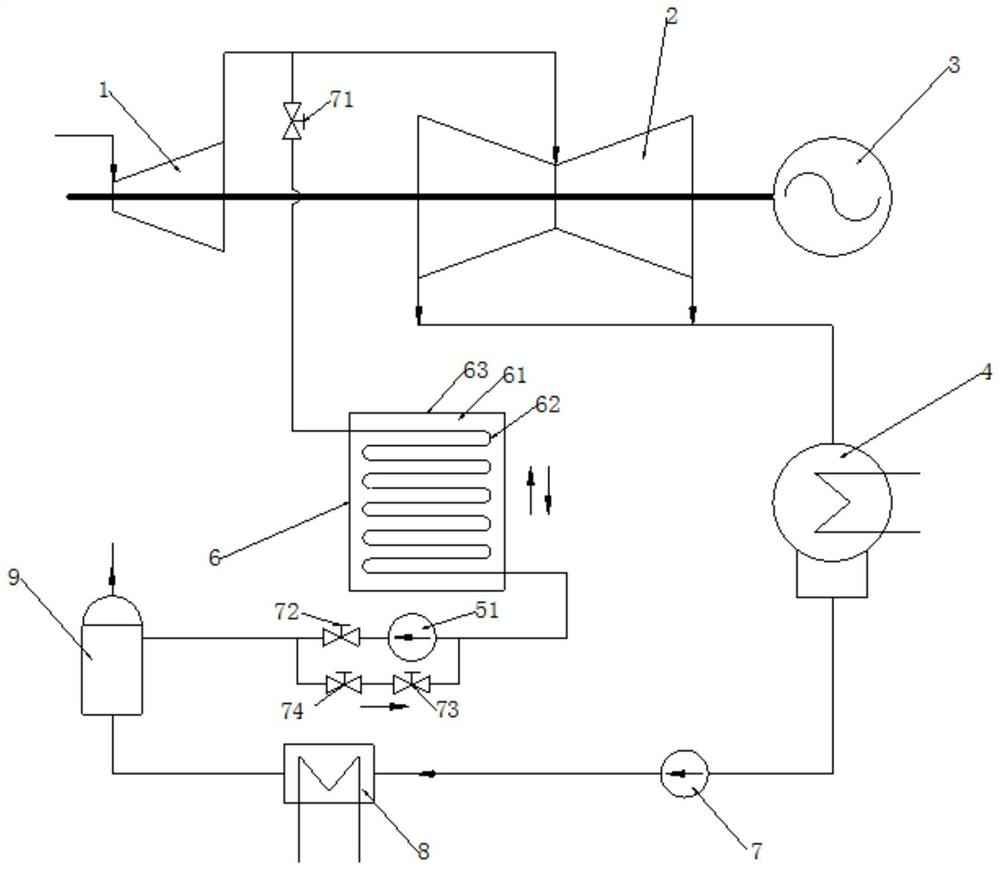

Straight condensing unit with phase change energy storage

PendingCN112648020ASolve the problem of relatively high peak shaving pressureMeet peak power requirementsHeat storage plantsSteam useSteam pressureHigh energy

The invention discloses a straight condensing unit with phase change energy storage. The straight condensing unit comprises a steam turbine, a generator in transmission connection with a rotating shaft of the steam turbine, a condenser communicating with a main outlet of the steam turbine and a phase change energy storage device capable of exchanging heat of internal flowing fluid and storing heat. A high-temperature port of the phase change energy storage device communicates with a steam inlet of a steam pressure cylinder of the steam turbine, a low-temperature port of the phase change energy storage device is connected with a supply device used for conveying fluid into the low-temperature port, and the low-temperature port is further connected with an energy storage and drainage switching valve. According to the straight condensing unit with the phase change energy storage, the phase change energy storage device can separate out a part of high-heat high-pressure fluid for heat storage in the valley period of a power grid, energy is released in the peak period of the power grid, and then the energy enters the steam turbine to convert heat energy into rotating mechanical energy to be output, so that correction and compensation are carried out on the peak-valley period of power utilization of the power grid, and the peak regulation pressure is reduced; and meanwhile, the energy utilization efficiency is improved.

Owner:润电能源科学技术有限公司

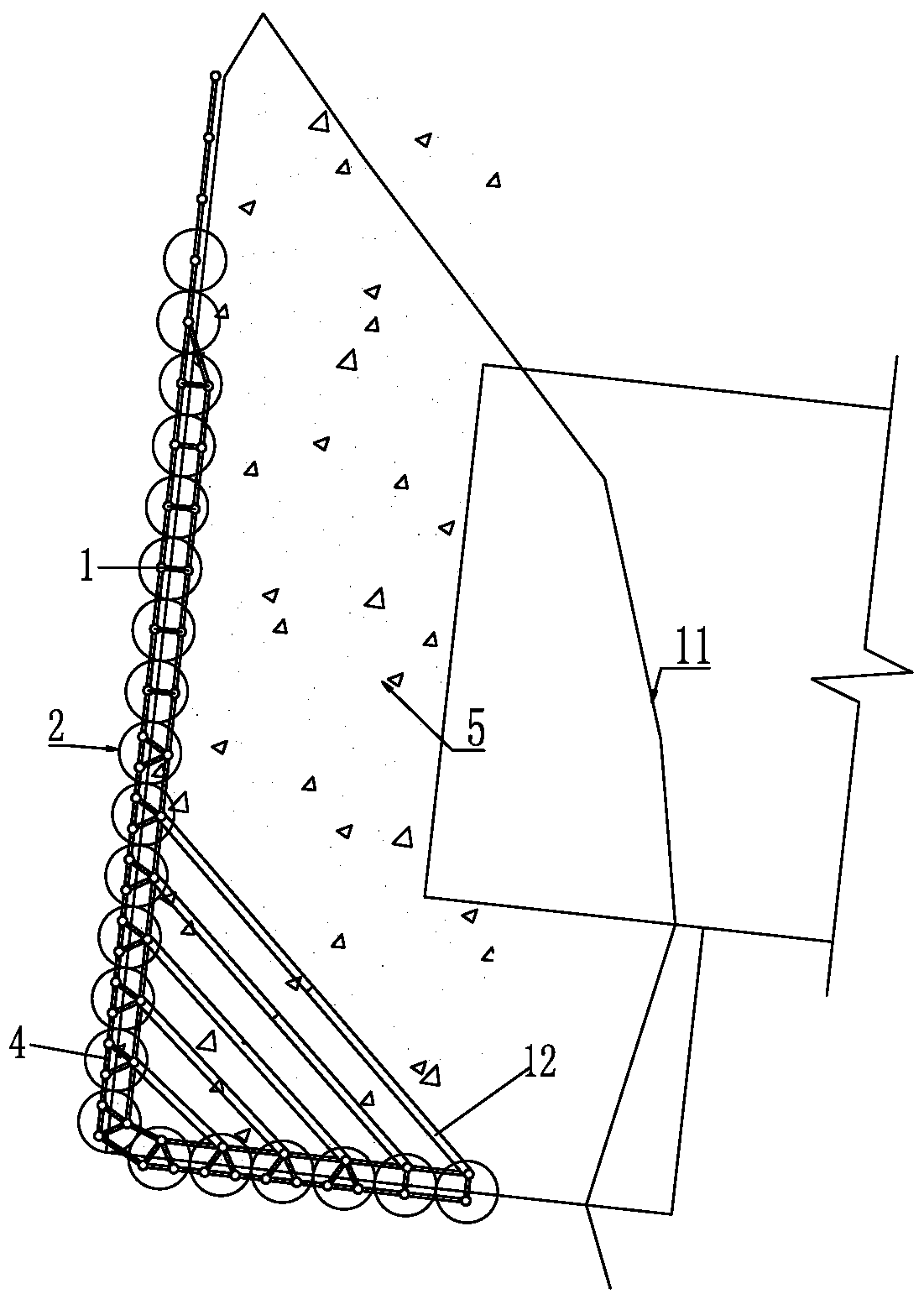

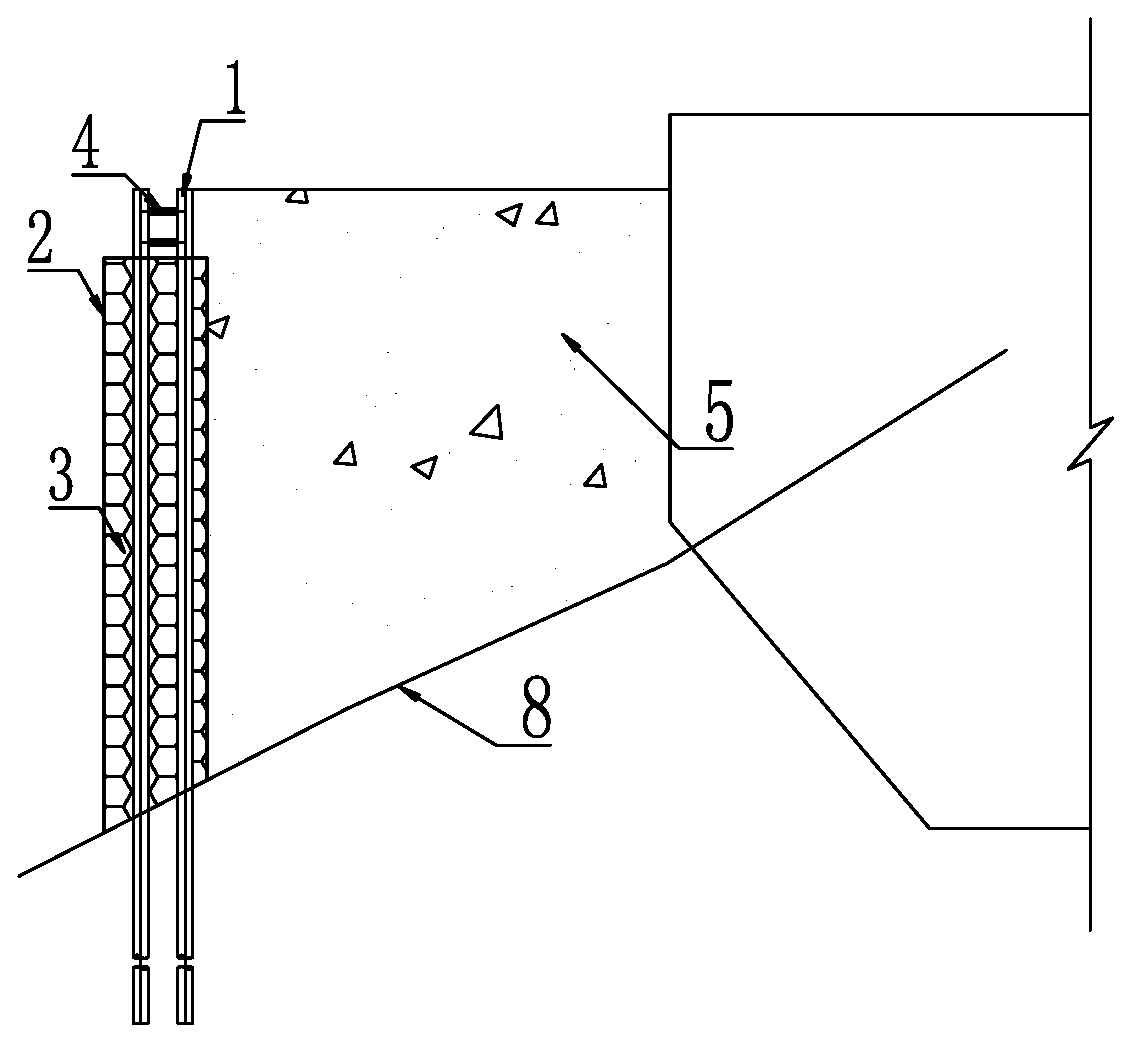

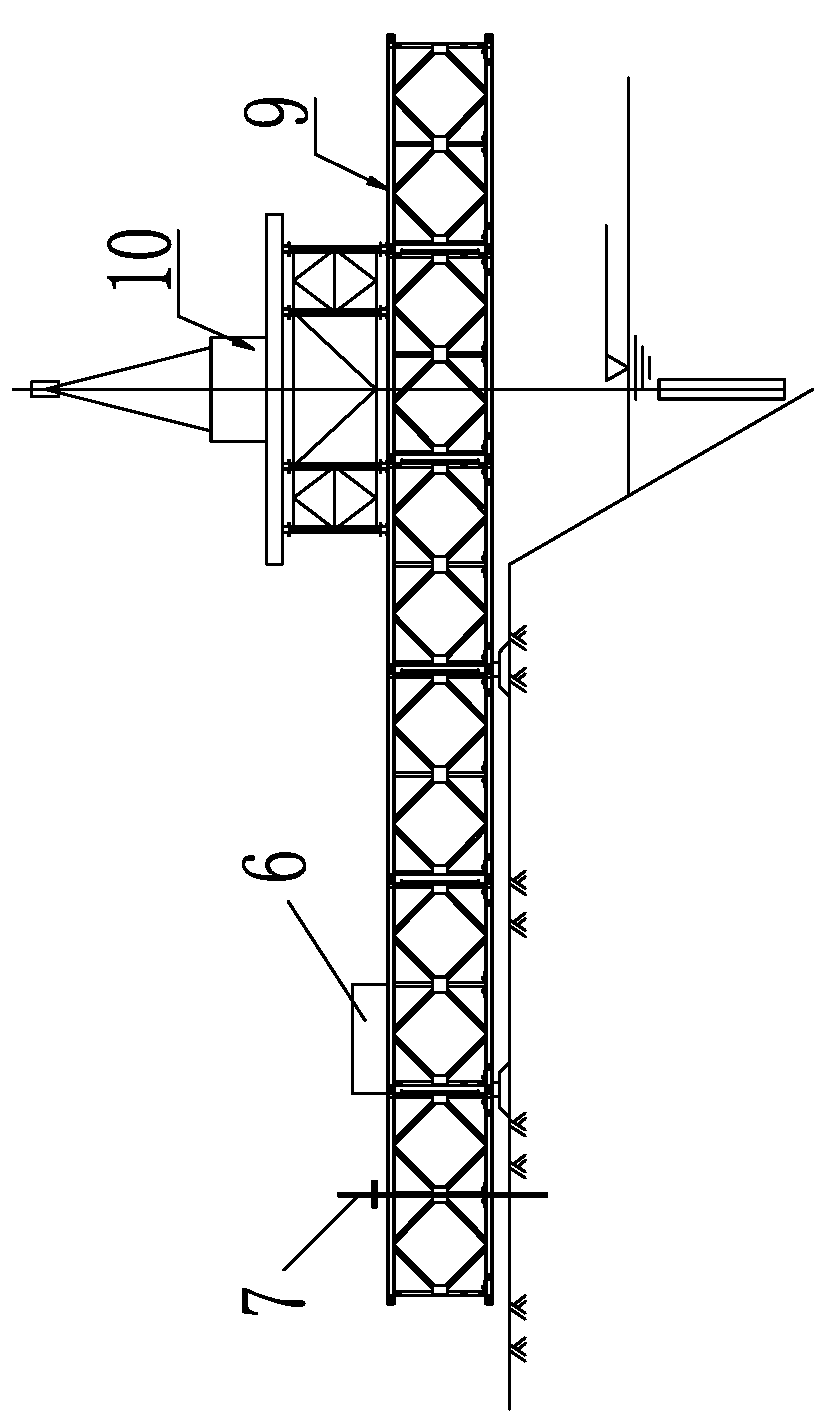

Grouting water-blocking cofferdam and construction method thereof

ActiveCN102704501AThe structural force is clearGood water stop effectBulkheads/pilesWater blockMaterials science

The invention discloses a grouting water-blocking cofferdam, which comprises steel anchor pipes inserted to below a riverbed line to form an anchor portion, a steel reinforcement cage fitted over the steel anchor pipe, a rubble or clay bag filled in the gap between the steel anchor pipe and the steel reinforcement cage, and a profile steel truss arranged at the top ends of the steel anchor pipes to connect the steel anchor pipes into an integer. A grouting water-blocking cofferdam construction method includes building a construction platform, drilling, mounting the steel anchor pipes in the holes, anchoring to bedrock, and fitting the steel reinforcement cage over the steel anchor pipes to form a closed wall; connecting the steel anchor pipes into an integer; and grouting in the area surrounded by the closed wall, to form the water-blocking cofferdam. The inventive cofferdam has clear force loading of structure, is stable and dense, and provides convenient conditions for follow-up foundation pit excavation or other base constructions.

Owner:THE 2ND ENG CO LTD MBEC +1

Solid beverage as well as preparation method and application thereof

The application relates to a solid beverage as well as a preparation method and application thereof. The solid beverage is characterized by comprising the following components of 20-100 parts of nobledendrobium leaves, 20-80 parts of Chinese jujubes, 20-80 parts of fructus momordicae, 20-60 parts of lotus seeds, 20-60 parts of fruit juice dry powder, and an appropriate quantity of auxiliary materials. The components are used, so that the solid beverage has good antioxidant activity, can effectively eliminate toxic components in bodies, and has the effect of synergistic synergy.

Owner:张艳飞

Compound with efficacy of reducing blood sugar and reducing blood pressure and application thereof

InactiveCN109806348AIt has the effect of promoting qi and relieving painPromote secretionMetabolism disorderDigestive systemAcute hyperglycaemiaIntestinal structure

The invention relates to the technical field of treatment of hypertension and hyperglycemia, in particular to a compound with efficacy of reducing blood sugar and reducing blood pressure and application thereof. The compound is prepared from the following components in parts by weight: 20-30 parts of semen cassiae, 30-50 parts of fructus crataegi, 30-50 parts of radix polygonati officinalis, 30-50parts of corn stigma, 10-20 parts of radix codonopsis, 10-20 parts of radix aucklandiae, 10-20 parts of uncaria, 30-50 parts of radix pueraiae, 25-35 parts of dandelion, 35-80 parts of semen coicis,30-55 parts of endothelium corneum gigeriae galli, 20-30 parts of flos chrysanthemi and 20-30 parts of green tea. By adopting the raw materials for preparing the compound, the compound has efficacy ofreducing the blood sugar and reducing the blood pressure at the same time, can repair blood vessels and protect the liver at the same time, and can clear waste in blood vessels, the intestines and stomach, the kidneys and the liver, and is beneficial for treatment of patients suffering from hypertension and diabetes at the same time.

Owner:乐清市足资初生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com