Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Increase the three-phase reaction interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrode and membrane electrode of proton exchange membrane fuel cell, and making method and application

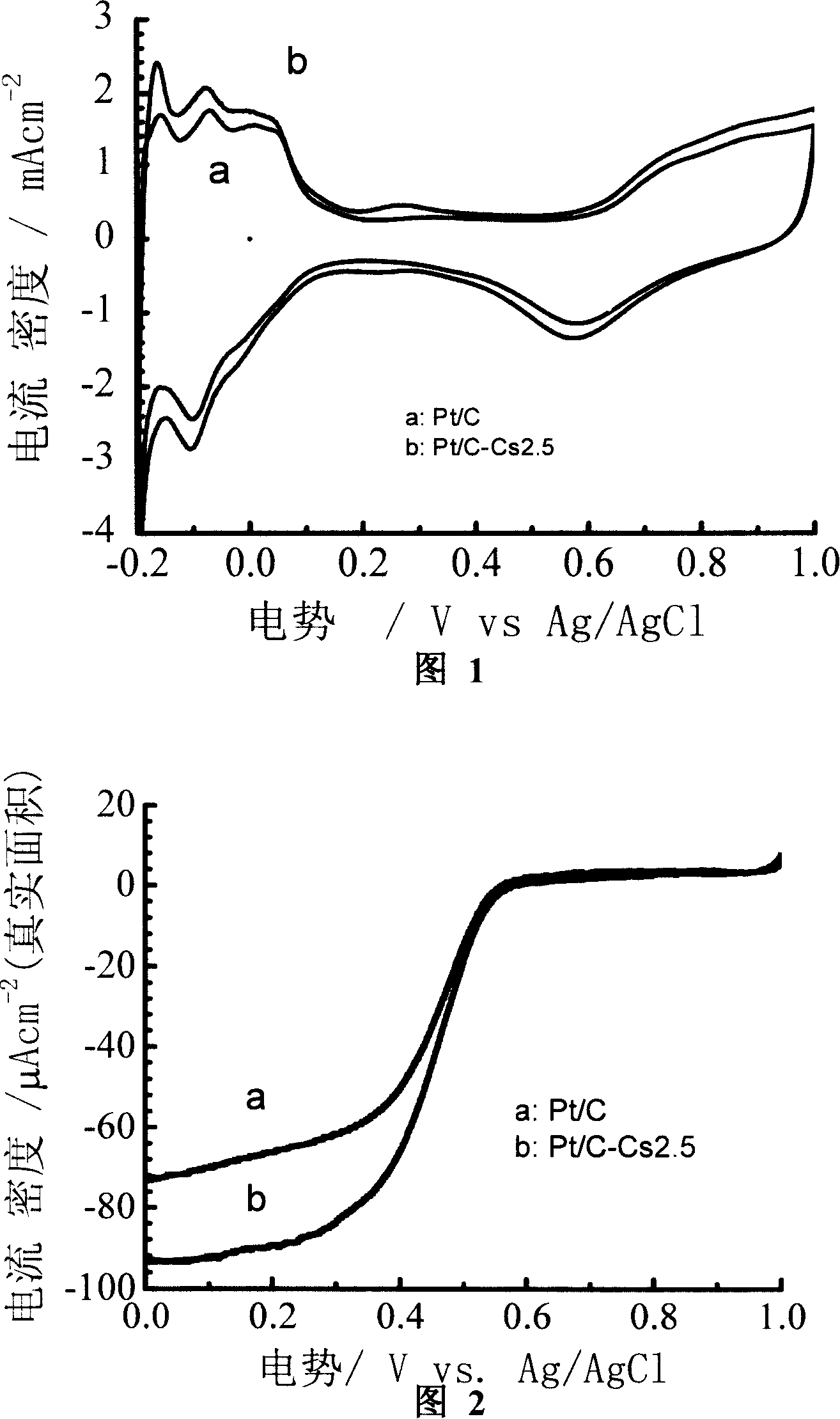

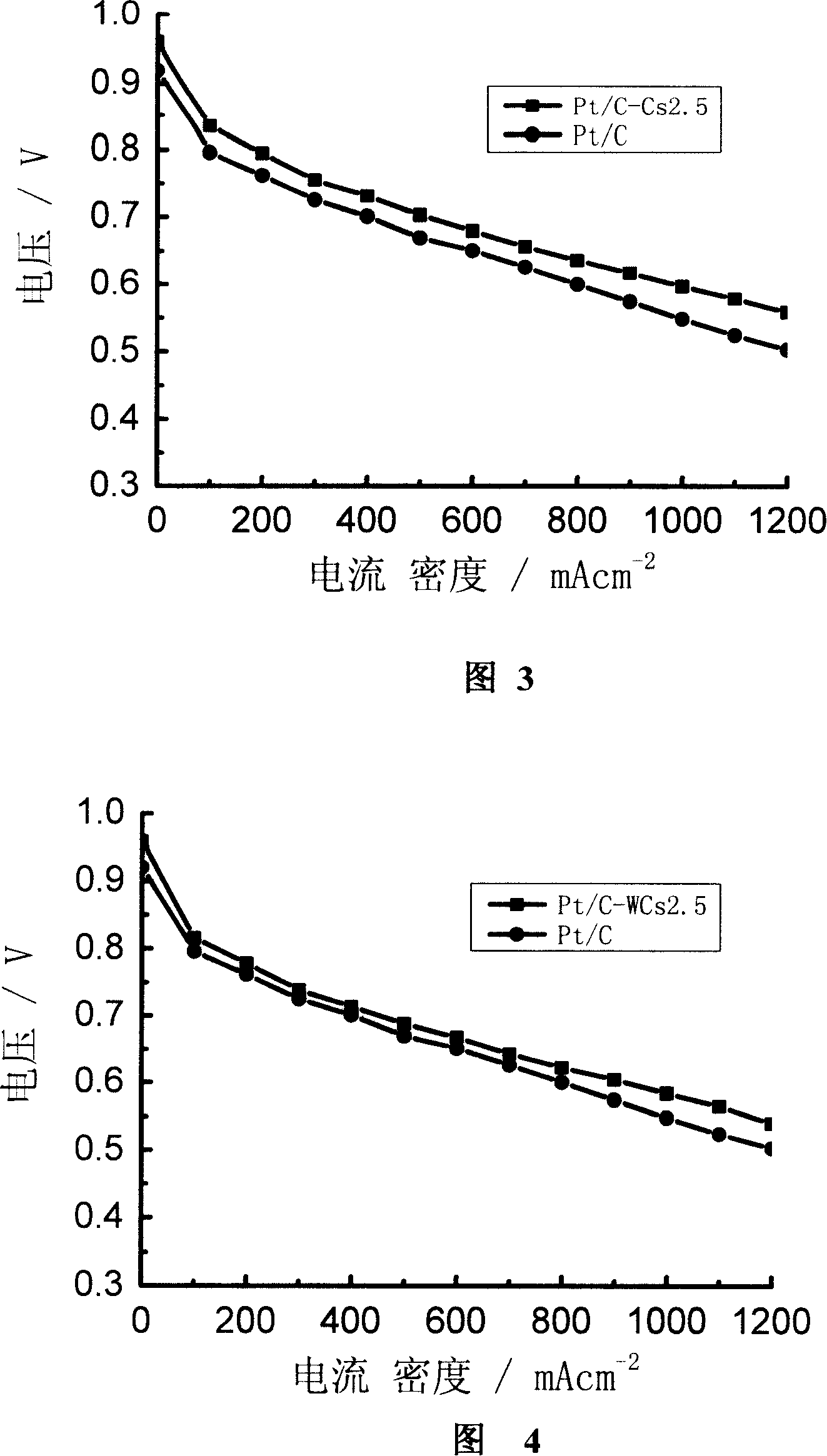

InactiveCN1964111AAdvantages Manufacturing MethodAdvantage Membrane Electrode PerformanceCatalyst carriersFinal product manufactureMass transferHole size

The preparation method for electrode and membrane electrode of proton exchange membrane fuel cell comprises: when preparing the catalysis layer with thickness in 3-100 mum, adding pore-forming agent, and adjusting the rate between alcohol and water in dispersing agent to change the recrystallized pore-forming agent size for adjusting electrode hole size and porosity in 30-75%. This invention can improve gas mass transfer and cell performance, and has wide application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

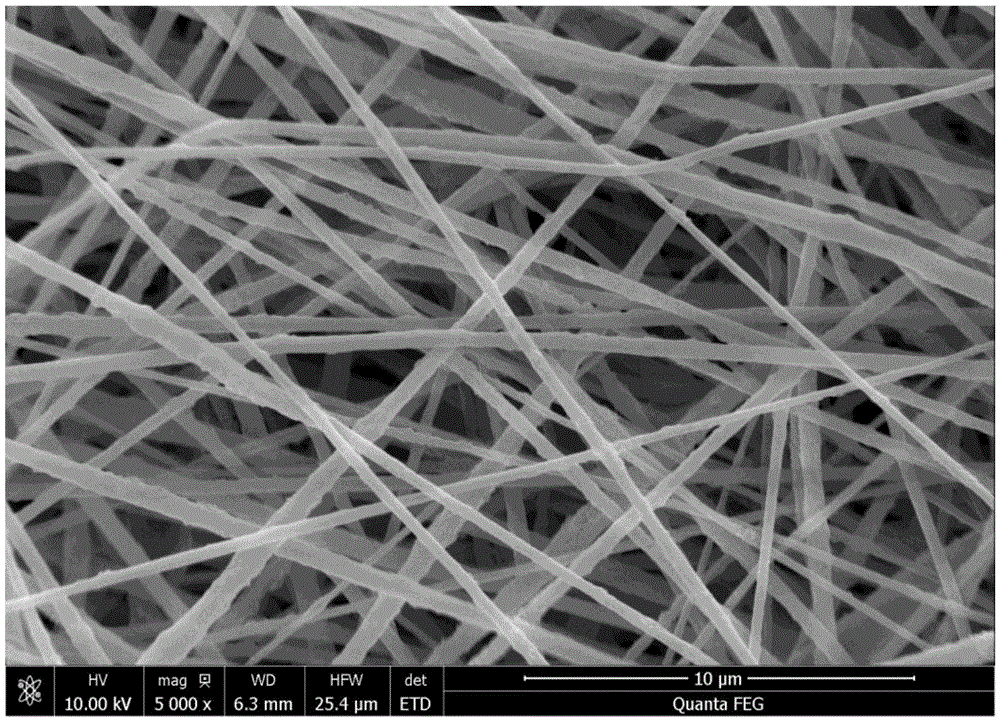

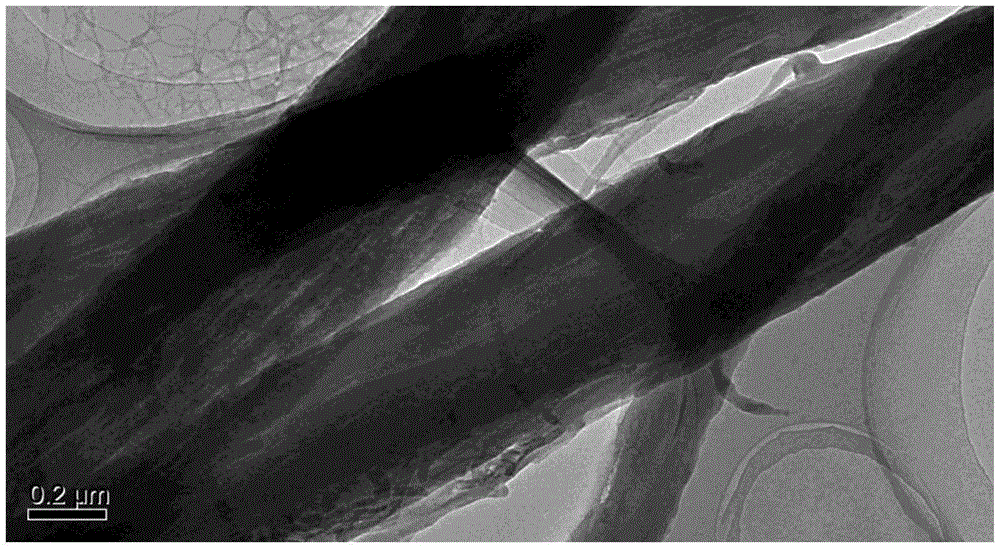

Nano carbon-doped porous fiber single electrode, membrane electrode and preparation method

InactiveCN105261767AQuality improvementLight in massMaterial nanotechnologyCell electrodesElectrospinningNanofiber

The invention relates to a nano carbon-doped porous fiber single electrode, a membrane electrode and a preparation method. According to the nano carbon-doped porous fiber single electrode, a semi-ordered porous nano fiber thin film is deposited at one side of a gas diffusion layer material; and a layer of metal nanoparticles with catalytic activity is evenly deposited on the nanofiber surface of the semi-ordered porous nano fiber thin film to form the nano carbon-doped porous fiber single electrode, wherein the semi-ordered porous nano fiber thin film is formed by a co-spun high-molecular polymer nano charged superfine fiber attached with a nano carbon material on the surface, and comprises a co-spun high-molecular polymer doped with the nano carbon material as the component. According to the nano carbon-doped porous fiber single electrode, the semi-ordered porous nano fiber layer is formed by the nano carbon material and a high-molecular polymer solution through electrostatic spinning and cospinning for the first time; a catalyst is sprayed on the porous nano fiber layer; and a mico-pore layer and a catalyst layer are combined into one, so that the properties of a prepared single battery are greatly improved; and the lifetime is greatly prolonged.

Owner:WUHAN UNIV OF TECH

Efficient electrochemical reactor of electro-catalysis in-situ hydrogen peroxide

ActiveCN101748423AEasy to assembleIncrease profitCellsIon-exchange membranesElectrochemical response

The invention discloses an efficient electrochemical reactor of electro-catalysis in-situ hydrogen peroxide. The reactor consists of a two-cavity reaction system and an external circuit. A solid polymer electrolyte membrane is arranged in the middle of the two-cavity reaction system and can separate a cathode reaction and an anode reaction. The two-cavity reaction system mainly comprises a cathode end plate, a cathode gas diffusion electrode, a cathode chamber, an ion exchange membrane, an anode chamber, an anode gas diffusion electrode and an anode end place from left to right. The external circuit consists of an ammeter, a voltmeter and a variable resistor. The reactor effectively improves a three-phase reaction interface and a reaction rate by utilizing the gas diffusion electrodes loaded with a catalyst. Electrolyte in the cathode and anode chambers for participating in the reaction can rapidly diffuse a reaction product in a solution, so that the reaction products are enriched and the concentration of the reaction product is improved. A current and the reaction speed can be adjusted by adjusting the variable resistor. The electrolyte at a cathode and at an anode can circulate under the action of a circulating pump to maintain a higher conductivity of the system and the high reaction rate of the electrode reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Electrospinning and electrostatic spraying method for membrane electrode CCM

PendingCN106848355AIncrease active areaIncrease profitLiquid surface applicatorsCell electrodesPorosityConcentration polarization

The present invention discloses an electrospinning and electrostatic spraying method for a membrane electrode CCM. According to the present invention, the catalyst layer having the nanometer film structure is obtained by using the electrospinning and electrostatic spraying method, wherein the catalyst layer structure has a high specific surface area so as to increase the three-phase reaction interface, increase the active area of the catalytic layer, and improve the catalyst utilization rate; the polymer nano-fiber membrane has high porosity, such that the mass transfer is easily performed, and the concentration polarization is effectively reduced; and the nano-scale catalytic particles obtained through electrostatic spraying are uniformly distributed on the nano-fiber structure so as to reduce the platinum loading and improve the catalytic performance.

Owner:NANJING UNIV

Fuel batter with proton exchange film electric pole catalyze layer and producing thereof

ActiveCN101140991AIncrease the three-phase reaction interfaceFully contactedCell electrodesPlatinumElectrical conductor

The invention relates to a proton exchanging membrane fuel cell electrode, concretely, a proton exchanging membrane fuel cell electrode catalysis layer and its device, which comprises catalyzer, organic proton conductor and heteropoly hydrochloric acid with a mass ratio of 10:1 to 10:1 to 10. The method is to mix the insoluble heteropoly hydrochloric acid into electrode catalysis layer, and partly replace macromolecule electrolyte like Nafion, which increases three phase reactor interface of the electrode catalysis layer, ensures the active component in electrode catalysis layer good contact with proton conductor and electron conductor and improves the performance of cell. Besides, heteropoly hydrochloric acid can transmit proton and increase the catalytic activity of platinum catalyzer, which can improve the performance of cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

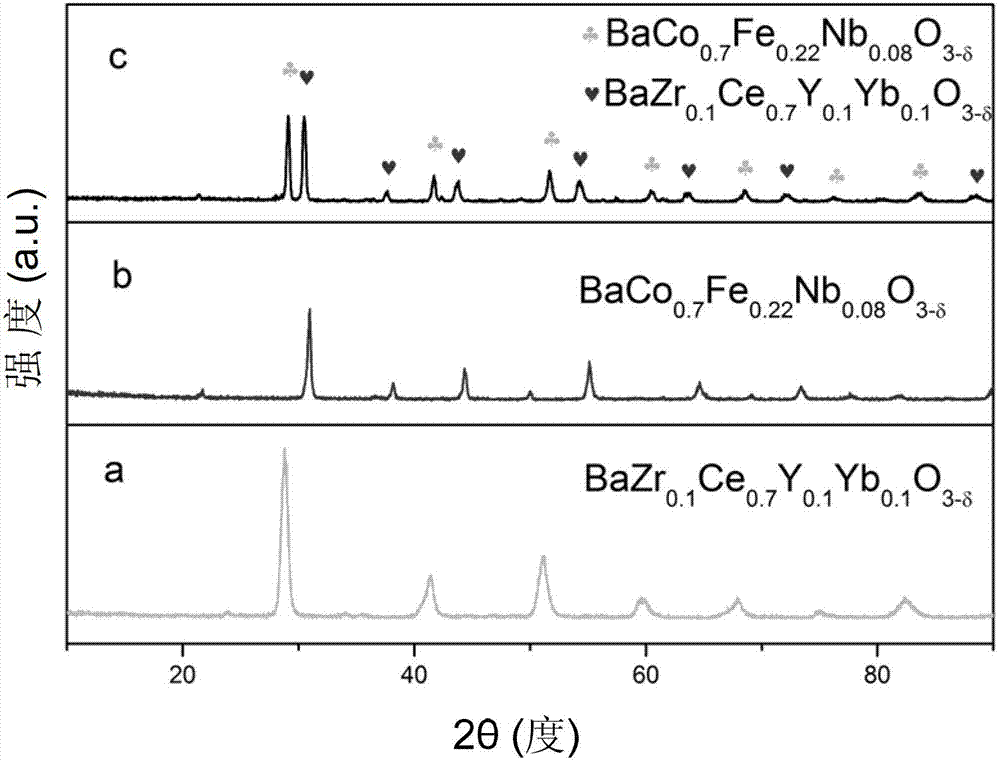

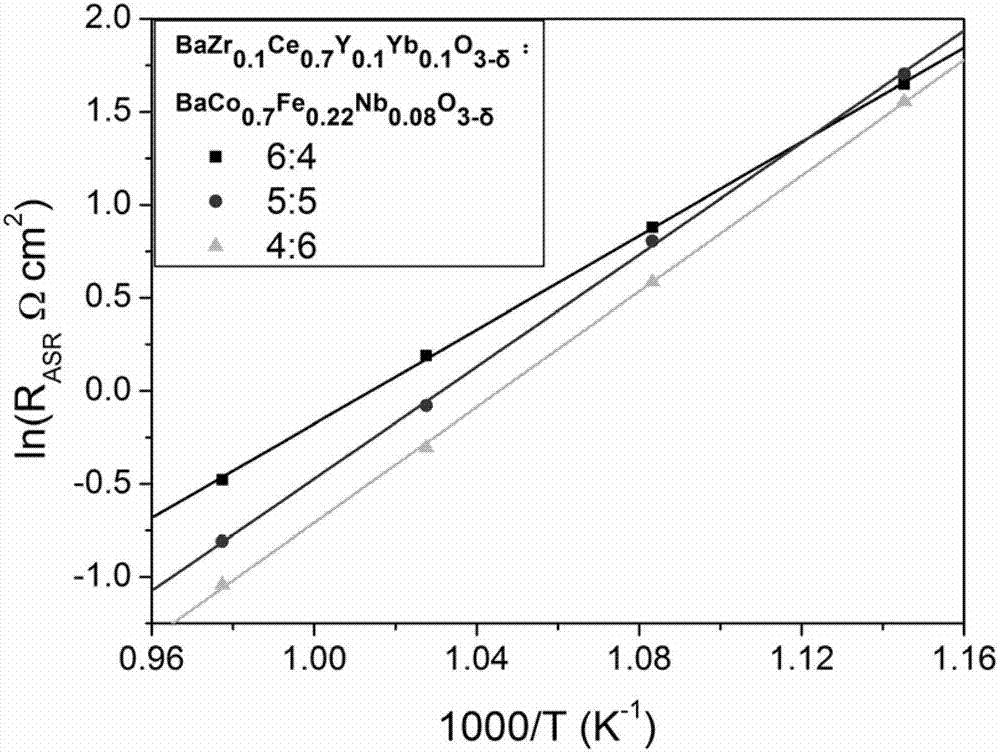

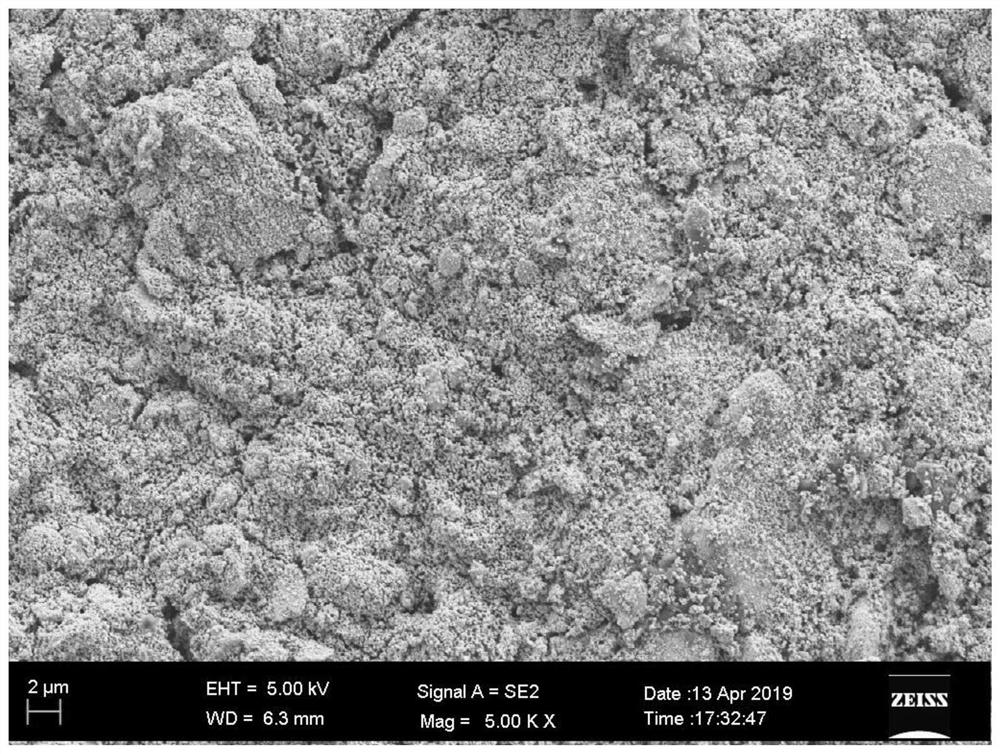

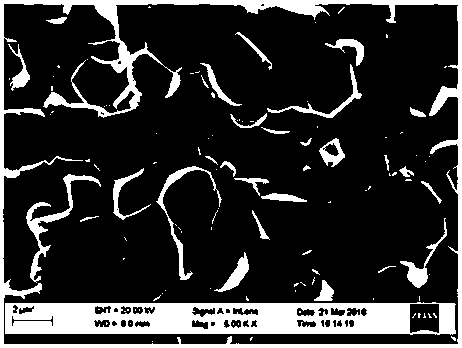

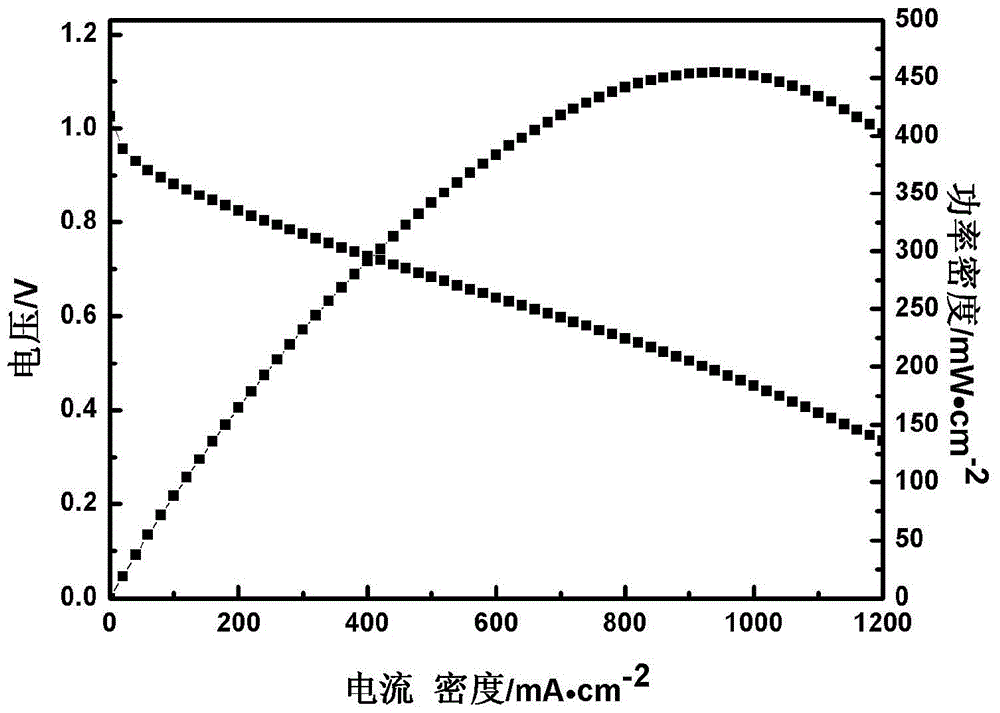

Composite cathode material for medium and low-temperature proton-conductive solid oxide fuel cells

ActiveCN103208634AInhibition of phase transitionImprove electrocatalytic performanceCell electrodesChemical compatibilityElectron

The invention discloses a composite cathode material for medium and low-temperature proton-conductive solid oxide fuel cells, and belongs to the field of fuel cells. The composite cathode material is characterized in that BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> with high oxygen ionic conductivity and high electronic conductivity and BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> with high proton conductivity are composited with each other to manufacture the novel cathode material, a chemical formula of the novel cathode material is BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta>-BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta>, and a ratio of the phase BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> to the phase BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> is changeable. The composite cathode material can be used for the medium and low-temperature proton-conductive solid oxide fuel cells. The composite cathode material has the advantages that after the BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta> and the BaZr<0.1>Ce<0.7>Y<0.1>Yb<0.1>O<3-delta> are composited, the cathode material has oxygen ionic conductivity, proton conductivity and electronic conductivity, a three-phase interface is expanded, the composite cathode material is excellent in electrode performance, the two phases of the composite cathode material are excellent in chemical compatibility and stable in performance, the cathode material is good in electro-catalysis performance owing to the presence of Co in the phase BaCo<0.7>Fe<0.22>Nb<0.08>O<3-delta>, interface resistance of each cell can be reduced, and the working performance of each cell can be improved.

Owner:UNIV OF SCI & TECH BEIJING

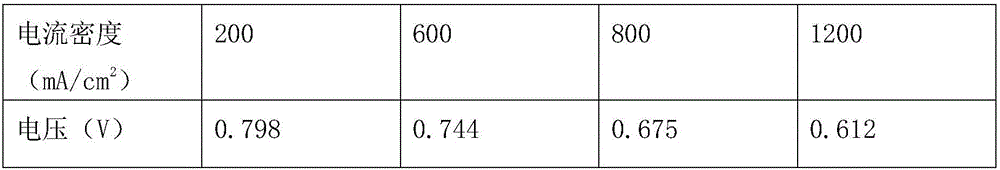

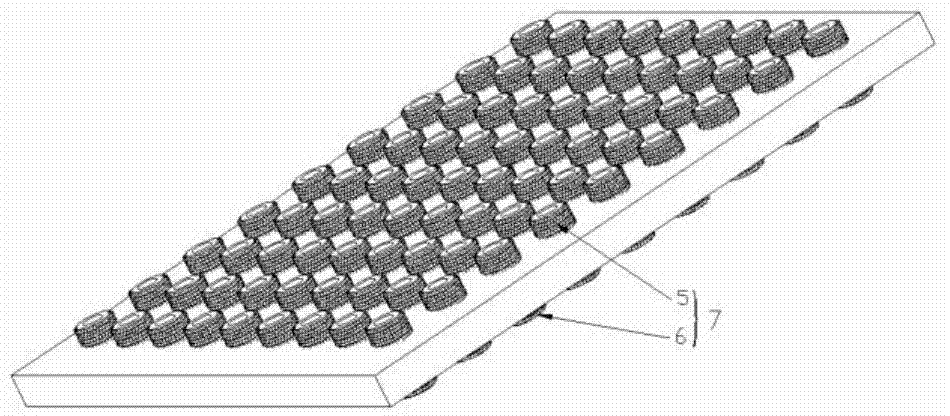

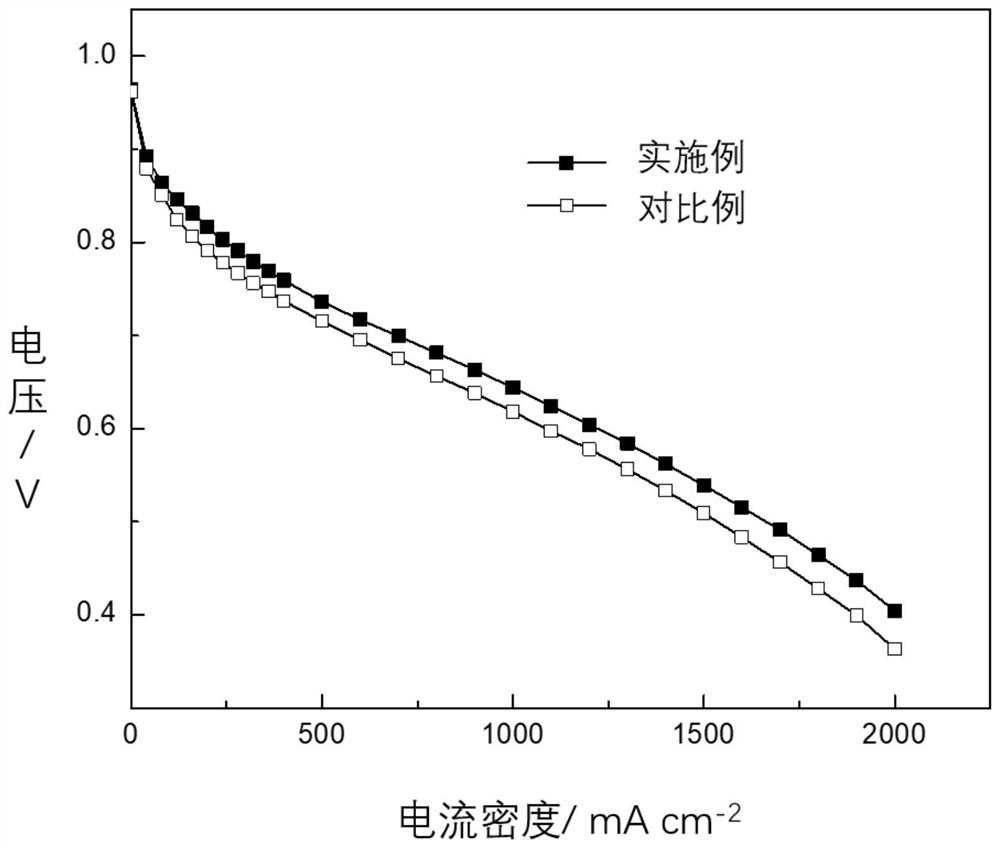

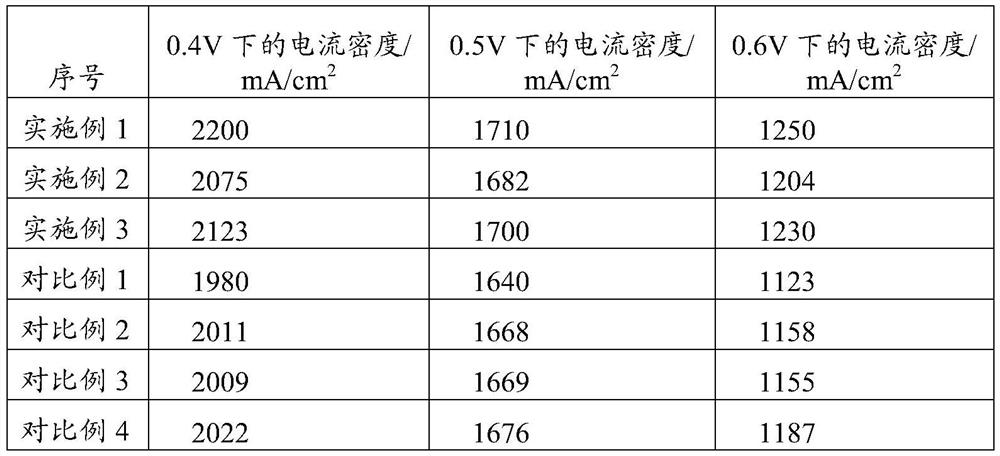

Preparation method of electrode and membrane electrode for fuel cell with fully-ordered catalyst layer structure

ActiveCN108448138AHigh catalytic activityImprove catalytic stabilityCell electrodesFuel cellsElectrochemical responseElectrical conductor

The invention discloses a preparation method of an electrode and a membrane electrode for a fuel cell with a fully-ordered catalyst layer structure, and relates to the field of fuel cells. In the electrode and the membrane electrode for the fuel cell prepared by the method, the components of the catalyst layer comprise a catalyst activity component, a catalyst carrier and an ion conductor which are of ordered array structures. The fully-ordered catalyst layer structure is of an extremely high three-phase reaction interface, and efficient electron, ion and matter transfer passages can be provided, so that the matter transfer resistance, load transfer resistance and electrochemical polarization resistance inside the electrode are reduced effectively, and the electrochemical reaction efficiency and energy conversion efficiency in the electrode are improved effectively. Through monocell performance test and electrochemical characterization, the electrode and the membrane electrode preparedby the preparation method is obviously improved in the aspects of monomer performance and catalyst layer activity compared with an electrode and a membrane electrode prepared by a traditional method.

Owner:广东泰极动力科技有限公司

Solid oxide fuel cell and functional gradient composite cathode and preparation method thereof

ActiveCN102683721AImproving the Kinetic Performance of Oxygen Reduction ReactionHigh catalytic activityCell electrodesSolid electrolyte fuel cellsComposite cathodeFuel cells

The invention relates to a solid oxide fuel cell and a functional gradient composite cathode and a preparation method thereof. The functional gradient composite cathode for the solid oxide fuel cell comprises a chromium poisoning resistant layer, an activation layer and a current collection layer, wherein the chromium poisoning resistant layer is made of LNF (LaNi0.6Fe0.4O3) and doped CeO2, the activation layer is positioned above the chromium poisoning resistant layer and made of LSM (La0.8Sr0.2MnO3) and doped CeO2, and the current collection layer is positioned above the activation layer and made of LSM. The preparation method of the functional gradient composite cathode for the solid oxide fuel cell includes the steps: a, attaching paste of the chromium poisoning resistant layer onto an electrolyte layer and drying to obtain the chromium poisoning resistant layer; b, attaching paste of the activation layer onto the chromium poisoning resistant layer and drying to obtain the activation layer; c, attaching paste of the current collection layer to the activation layer and drying to obtain the current collection layer, so that a blank is obtained; and d, sintering the blank to obtain the functional gradient composite cathode. Chromium deposition of high-volatility CrO3 and CrO2 (OH)2 on cathode / electrolyte interfaces is reduced.

Owner:中氢新能源(江苏)有限公司

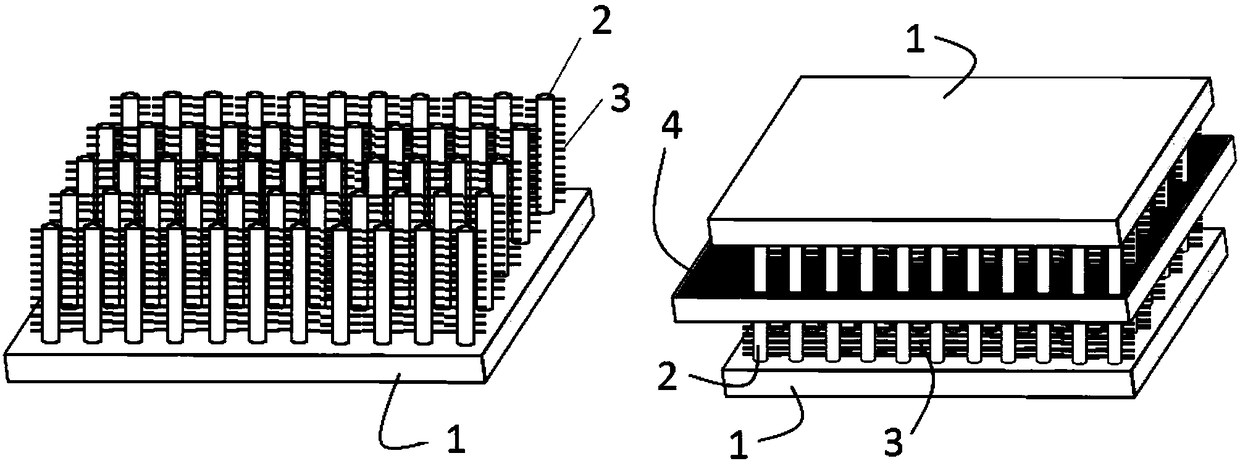

Ordered solid oxide membrane electrode

ActiveCN103515633ALower polarization resistanceIncrease the three-phase reaction interfaceCell electrodesFuel cell detailsReaction rateThree-phase

The invention belongs to the technical field of membrane electrodes, and specially relates to an ordered solid oxide membrane electrode. The support of catalysts in the ordered solid oxide membrane electrode is array solid oxide rods. The highly-ordered array solid oxide rods are capable of deciding the electrode voidage and the catalyst surface area in the ordered solid oxide membrane electrode, so that the controllable preparation on the ordered electrode is realized. The particles of anode catalysts and cathode catalyst are interpenetrated, are connected with a current collector and are highly dispersed, and the catalysts have relatively high specific surface area and catalytic activity, so that the three-phase reaction interface of SOFC and SOEC are substantially increased, the polarization resistance of the electrode is reduced, and the reaction rate of fuel and the reduction conversion rate of a raw material gas are improved. The ordered membrane electrode is expected to substantially reduce polarization electromotive force of the electrode, improve conversion efficiency and stability, and prolong operation life.

Owner:TSINGHUA UNIV

Preparation method of ordered solid oxide membrane electrode

ActiveCN103474675ALower polarization resistanceReach controllableCell electrodesVoid ratioReaction rate

The invention belongs to the technical field of an electrode preparation method, and in particular relates to a preparation method of an ordered solid oxide membrane electrode. In the method, a supporter array solid oxide bar of a catalyst can be prepared by a template method, and can be roasted and integrally fused with a compact solid oxide electrolyte membrane. The highly ordered array solid oxide bar defines the electrode void ratio and the catalyst surface size in the ordered solid oxide membrane electrode, so as to realize the controllable preparation of the ordered electrode. An anode catalyst and a cathode catalyst are prepared respectively on the array solid oxide bar, the catalysts are combined on the surface of the solid oxide bar in a nano- or micro-particle state to form a catalysis layer, the catalyst particles are communicated with each other and are connected to a collector, and the catalyst particles are dispersed highly and have higher specific surface area and catalysis activity, therefore, the three-phase reaction interface of an SOFC (solid oxide fuel cell) and an SOEC (solid oxide electrolysis cells) is increased greatly, the polarization resistance of the electrode is reduced, and consequently, the reaction rate of the fuel and the raw material gas reducing transforming rate are improved.

Owner:TSINGHUA UNIV

Preparation method of self-humidifying ordered polymer membrane electrode

ActiveCN103887521ARealize self-humidification energy conversionIncrease the three-phase reaction interfaceCell electrodesFuel cellsElectrochemical responseConcentration polarization

The invention discloses a preparation method of a self-humidifying ordered polymer membrane electrode, belonging to the technical field of membrane electrode preparation. An ordered ion exchange polymer nanotube array prepared through the method is fused together with a polymer membrane and is provided with highly ordered ion, electron and gas mass transfer channels, and electrochemical three-phase reaction interfaces are distributed in the outer surfaces of polymer nanotubes with water storage functions, so that a high-efficiency energy conversion process can be carried out in a self-humidifying manner. A catalyst in a nanoparticle or microparticle state is bonded on the surface of the ion exchange polymer nanotube array to form a catalysis layer and is relatively high in specific surface area and catalytic activity, so that the three-phase reaction interfaces of the membrane electrode are greatly added, the electrochemical polarization, the ohmic polarization and the concentration polarization of the electrode are reduced, the energy conversion efficiency is improved, and the reaction speed is increased. According to the preparation method, a membrane electrochemical reactor system is expected to be remarkably simplified, the energy conversion efficiency and the stability are improved, and the operation life is prolonged.

Owner:国鸿氢能科技(嘉兴)股份有限公司

Gradient composite cathode for solid oxide fuel cell and preparation method thereof

InactiveCN102683720AQuick and easy to manufactureNovel preparation routeCell electrodesFuel cellsComposite cathode

The invention relates to a cathode for a solid oxide fuel cell and a preparation method thereof. A gradient composite cathode for the solid oxide fuel cell comprises a barrier layer, an activating layer and a current collection layer, wherein the barrier layer is made of an LNF-doped CeO2 material; the activating layer is located on the barrier layer and is made of the LNF-doped CeO2 material; and the current collection layer is located on the activating layer and is made of an LNF material. The preparation method for the gradient composite cathode comprises the following steps of: 1) attaching slurry of the barrier layer to an electrolyte and drying, thereby obtaining the barrier layer; 2) attaching the slurry of the activating layer to the barrier layer and drying, thereby obtaining the activating layer; 3) attaching the slurry of the current collection layer to the activating layer and drying, thereby preparing into the current collection layer and obtaining a blank; and 4) sintering the blank. The gradient composite cathode for the solid oxide fuel cell prepared according to the preparation method provided by the invention is excellent in electrochemical catalysis property. The preparation method for the gradient composite cathode is simple; the preparation period is short; and the gradient composite cathode is low in cost and is suitable for industrial application.

Owner:SHANGHAI JIAO TONG UNIV

Catalyst slurry for fuel cell, preparation method thereof and membrane electrode

The invention relates to the field of fuel cells, and particularly discloses catalyst slurry for a fuel cell, a preparation method of the catalyst slurry and a membrane electrode. The preparation method of the catalyst slurry for the fuel cell comprises the following steps of S1) carrying out ultrasonic dispersion treatment on a perfluorosulfonic acid solution at 50-90 DEG C to obtain a perfluorosulfonic acid dispersion liquid; and S2) mixing the perfluorosulfonic acid dispersion liquid with a catalyst, a dispersing agent and deionized water, and emulsifying and dispersing to obtain the fuel cell catalyst slurry. By utilizing the preparation method, the problem of uneven dispersion of the proton conduction ionomer in the existing catalyst slurry can be solved, and the preparation method isused for improving the dispersity of the proton conduction ionomer in the catalyst slurry.

Owner:SHANGHAI ELECTRICGROUP CORP

Preparation method for anode support layer of solid oxide fuel cell

InactiveCN102394307ADoes not affect the catalytic reactionSimple methodFinal product manufactureFuel cell auxillariesFuel cellsHigh intensity

The invention relates to a preparation method for an anode support layer of an anode support type solid oxide fuel cell. According to the invention, the anode is in gradient design and divided into a functional layer and a support layer; the anode functional layer and an electrolyte layer both with about 20 microns in thickness are made through a tape casting method; in order to ensure the battery strength, a superfine A12O3 with less than 200nm particle diameter is made, and a Nio, a sintering assistant MgO and a needle-shaped A12O3 are added at the same time, so as to form an anode support layer powder body which is compressed together with the functional layer and the electrolyte layer, thereby obtaining an anode support type / film layer electrolyte composite material half cell. The method has a simple process and a low cost, and is suitable for industrialized production, and accordingly the mono-cell made through the method has high strength and favorable electrochemical property.

Owner:JINGDEZHEN CERAMIC INSTITUTE

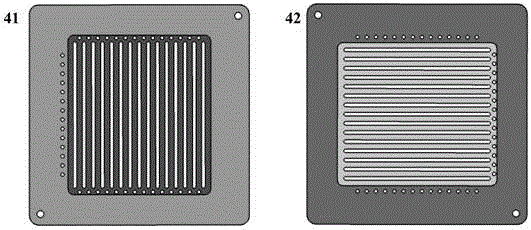

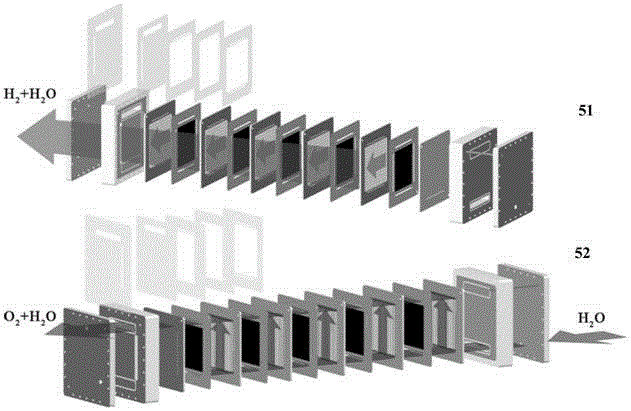

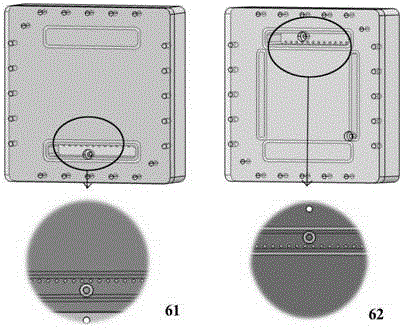

Solid polymer electrolyte electrolytic bath

The invention discloses an electrolysed water hydrogen production electrolytic bath structure of solid polymer electrolyte (SPE), wherein the structure mainly comprises a mass transfer passage structure and a sealing structure of an electrolytic bath system. The mass transfer passage design is mainly for working medium transmission passages of positive and negative two poles of the electrolytic bath; the sufficient water supply to the positive pole of the electrolytic bath is guaranteed; hydrogen on the negative pole and oxygen and water on the positive pole can be smoothly output; meanwhile, the independence between the passages on the positive and negative poles is guaranteed; and mass transfer paths are not interfered mutually. The sealing structure is mainly for the sealing piece design in a working medium transmission area in an electric pile structure of the electrolytic bath; and the sealing performance of all components of the electric pile is guaranteed. The electrolytic bath can guarantee stable and efficient actuation of the electrolysis process, is higher in electrolysis efficiency and safety, and reduces the machining cost of structural parts thereof.

Owner:TONGJI UNIV

Method for preparing solid-oxide fuel battery cathode

InactiveCN101281966ALarge specific surface areaHigh catalytic activityCell electrodesFuel cellsHYDROSOL

A preparation method for a solid oxide fuel cell cathode relates to a preparation method for a fuel cell cathode, which resolves problem in prior art that catalytic activity of a solid oxide fuel cell cathode is low under middle and low temperature. The preparation method includes: preparing sol from La1-xSrx(NO3)3M(NO3)2 and citric acid solution, filling the sol into a hole of an anode aluminum oxide template, calcining under high temperature, dipping into NaOH solution, and obtaining the solid oxide fuel cell cathode. Catalytic activity of the solid oxide fuel cell cathode of present invention is high under middle and low temperature.

Owner:HARBIN INST OF TECH

Fuel cell proton exchange membrane with micro texture and processing method of fuel cell proton exchange membrane

ActiveCN111864244AIncrease profitIncrease the three-phase reaction interfaceFuel cellsFuel cellsPtru catalyst

The invention provides a fuel cell proton exchange membrane with a micro texture and a processing method of the fuel cell proton exchange membrane. A plurality of petal-shaped concave-convex compositetextures are distributed on the surface of a cathode of the fuel cell proton exchange membrane in a gradient manner that the inside is dense and the outside is sparse. The concave-convex composite texture comprises pits and protrusions, a circle of protrusions are arranged on the edges of the pits, and a plurality of semi-ellipsoid micro pits are evenly distributed in the inner surfaces of the pits. The surface of the cathode is divided into a central area, a middle area and a peripheral area according to the distance between every two adjacent concave-convex composite textures, and in each area, the distance between every two adjacent concave-convex composite textures is gradually increased from inside to outside in a gradient mode. The concave-convex composite texture can effectively increase the surface area of the cathode surface of the proton exchange membrane, facilitates full contact between the catalyst and reaction gas, and improves the reaction efficiency; and the carbon-supported platinum catalyst can be stably embedded in the structure, and the active area of the catalyst is increased, so that the utilization rate of the catalyst is increased.

Owner:JIANGSU UNIV

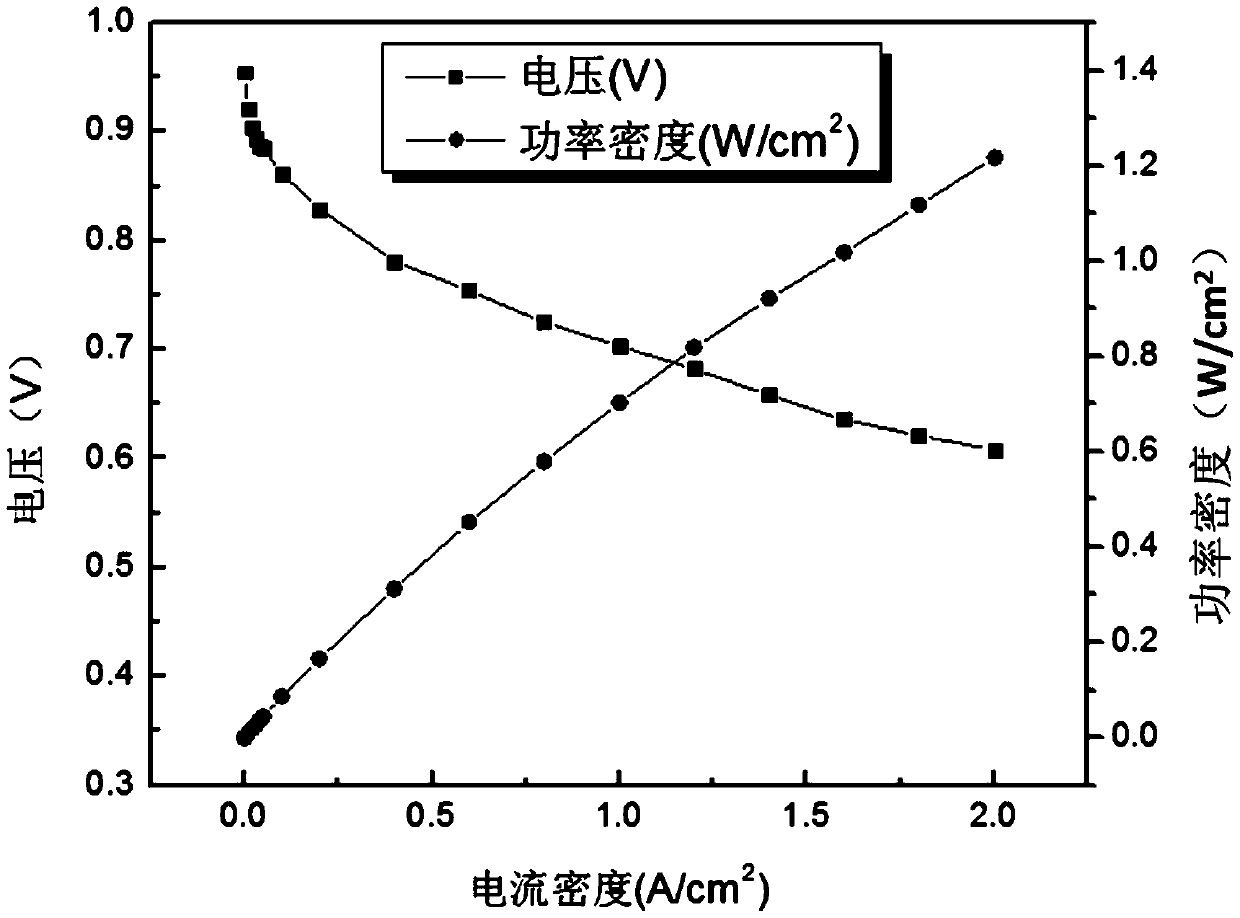

Ordered mesopore catalyst layer and preparation method thereof, application of ordered mesopore catalyst layer, and film electrode and preparation method thereof

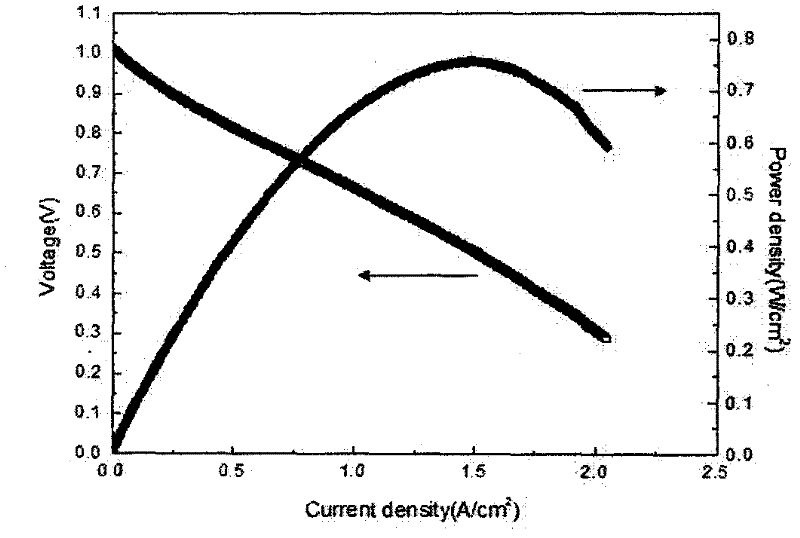

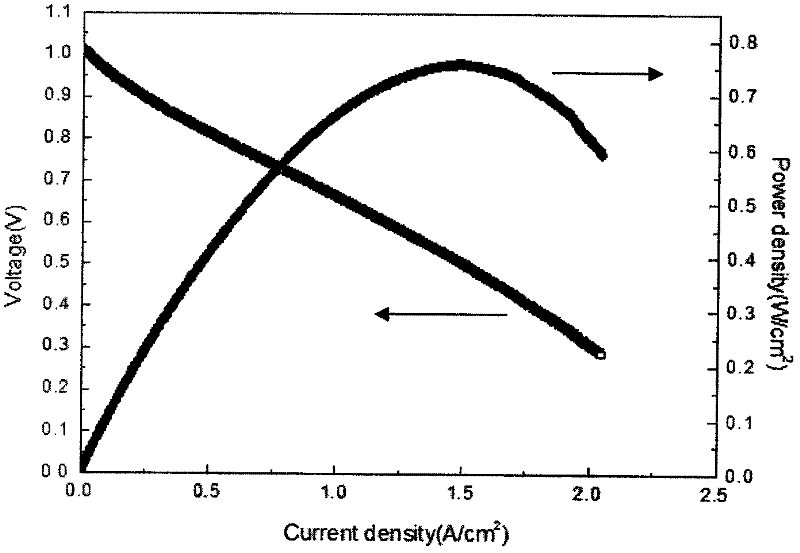

ActiveCN109860633AImprove electrochemical performanceImprove distributionCell electrodesFuel cellsPower flowCarbonization

The present invention relates to an ordered mesopore catalyst layer and a preparation method thereof, application of an ordered mesopore catalyst layer, and a film electrode and a preparation method thereof. The preparation method of the ordered mesopore catalyst layer comprises the steps of: mixing a resin precursor, a soft template, a precious metal precursor and a solvent to obtain a mixed solution, performing film formation, evaporating the solvent, performing heat treatment and carbonization treatment of the mixed solution to obtain an ordered mesopore catalyst layer. When Pt is selectedas the precious metal, the film electrode prepared by employing the ordered mesopore catalyst layer has the highest power density up to 0.7W / cm2 when having the current density being 1.0A / cm2, and hasthe highest power density up to 1.21W / cm2 when having the current density being 2.0A / cm2.

Owner:上海海擎新能源科技有限公司

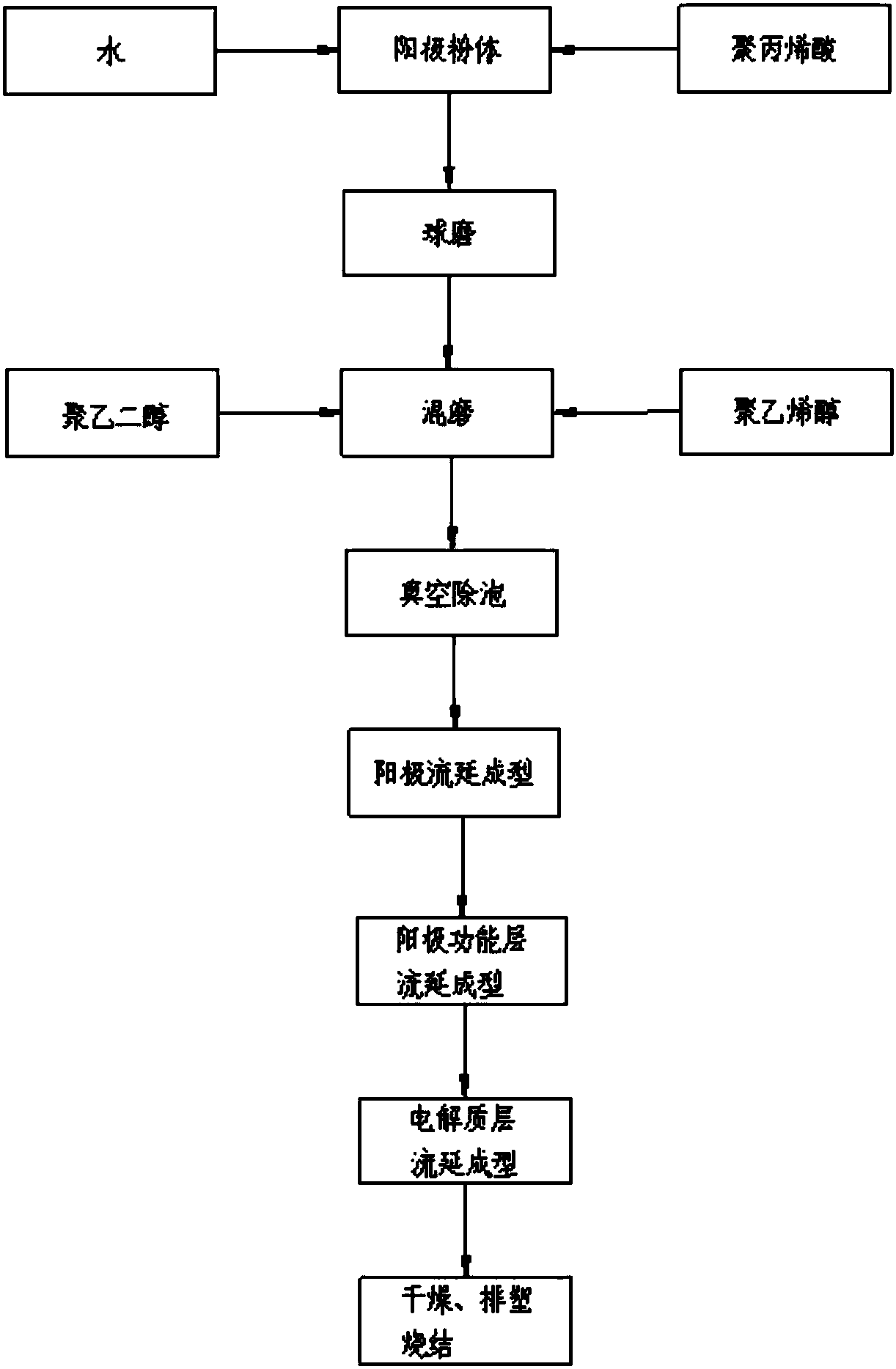

Method for preparing medium temperature SOFC monocell with anode functional layer by multi-layer aqueous tape casting

InactiveCN108615902AFacilitate catalytic reactionsImprove microstructureCell electrodesFuel cellsHot TemperatureElectrolyte

The invention discloses a method for preparing a medium temperature SOFC monocell with an anode functional layer by multi-layer aqueous tape casting. The method comprises the following steps: A, preparing an anode layer blank membrane; B, preparing an anode functional layer blank membrane; C, preparing an electrolyte blank membrane; and D, performing molding and high temperature sintering on the anode layer blank membrane, the anode functional layer blank membrane and the electrolyte blank membrane. According to the method disclosed by the invention, the multi-layer aqueous tape casting process is adopted to obtain an SOFC half-cell without using the hot press lamination process, thereby reducing the phenomenon that deformation is generated in the hot press lamination process due to unevenstress, such that the half-cell cracks finally due to the stress generated in the blank in a high temperature sintering process.

Owner:SHENZHEN POLYTECHNIC

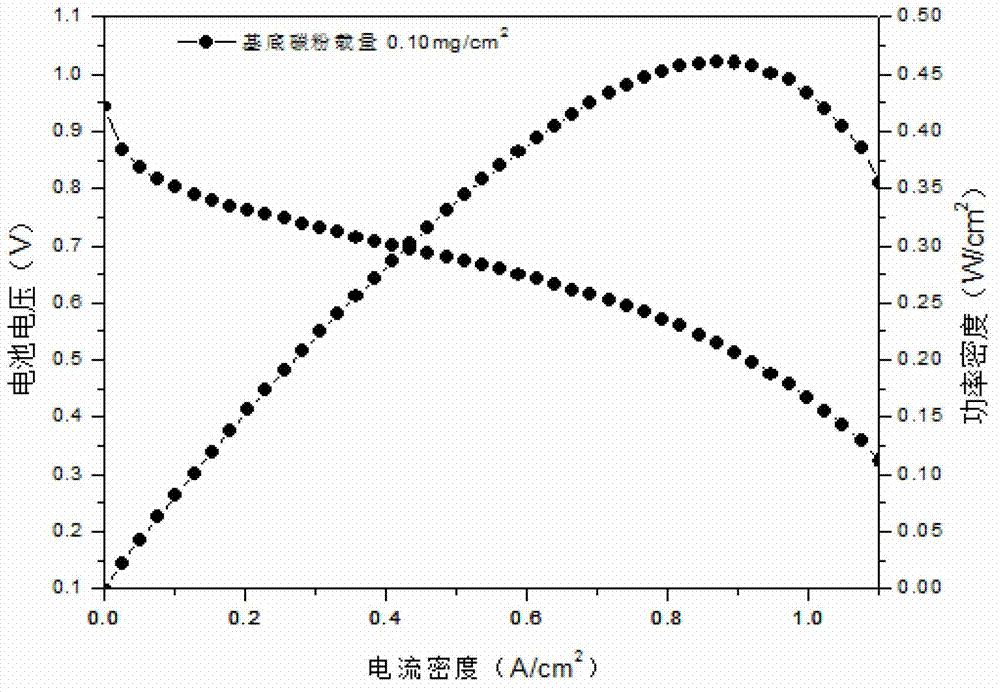

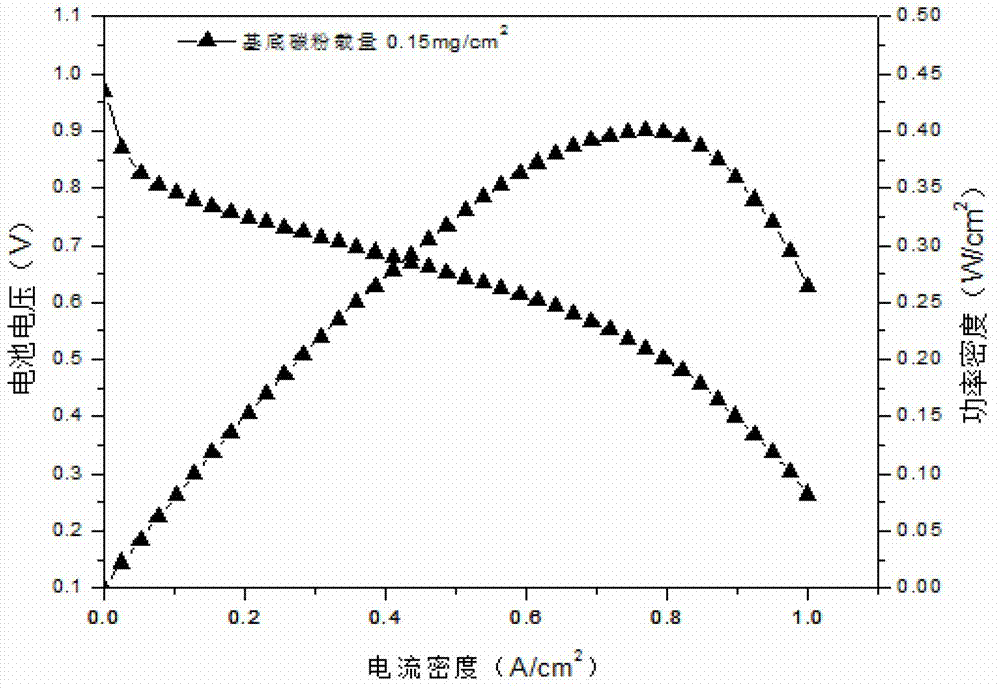

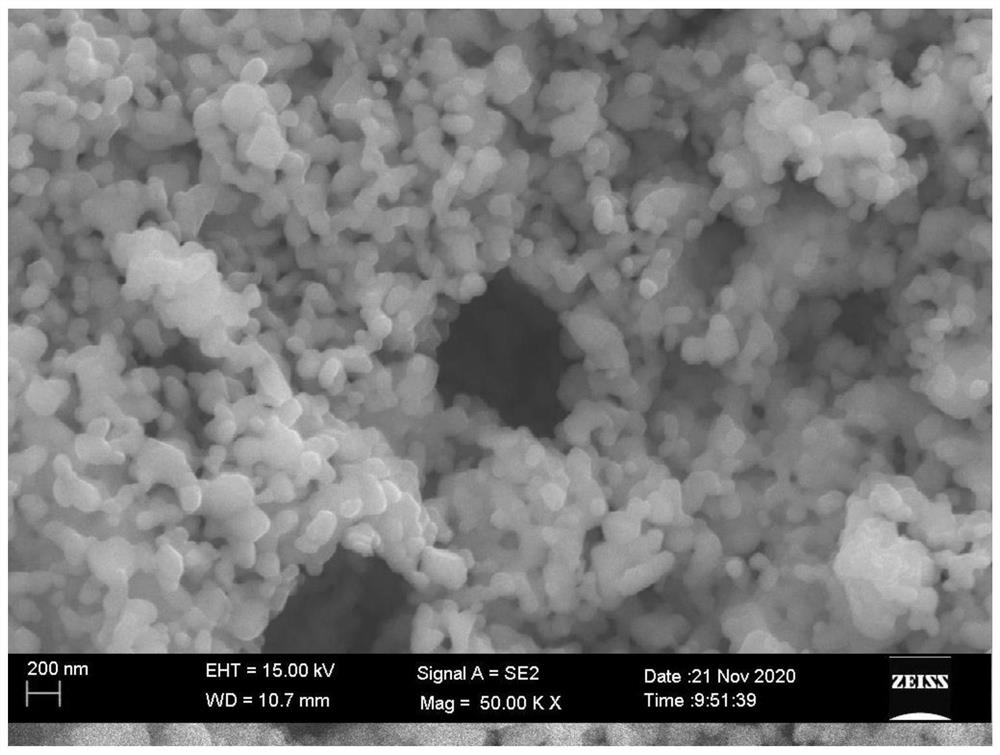

Method for preparing catalytic layer structure of proton exchange membrane fuel cell

ActiveCN103280583BLarge specific surface areaIncrease profitMaterial nanotechnologyFinal product manufacturePlatinumNanowire

The invention relates to a method for preparing a catalytic layer structure of a proton exchange membrane fuel cell. The method comprises the following steps of: (1) adding carbon powder and an electrolyte resin solution to isopropanol to obtain mixed liquid, carrying out ultrasonic treatment to uniformly mix the mixed liquid, then dispersing the mixed liquid into a proton exchange membrane, and carrying out drying treatment to form a carbon powder layer on the membrane so as to obtain the proton exchange membrane with the carbon powder layer; (2) dipping the proton exchange membrane with the carbon powder layer into a solution containing a platinum precursor and a weak reducing agent, standing for 48-72 hours at room temperature, taking the proton exchange membrane out, repeatedly rinsing the proton exchange membrane for multiple times by deionized water, and then carrying out drying treatment to obtain the proton exchange membrane with a platinum nanowire catalyst deposited on the carbon powder layer; and (3) spraying a layer of electrolyte solution on the surface of the platinum nanowire catalyst and then carrying out drying treatment to obtain the catalytic layer structure of the proton exchange membrane fuel cell.

Owner:温州高企氢能科技有限公司

A solid oxide fuel cell, a functionally graded composite cathode, and a preparation method thereof

ActiveCN102683721BImproving the Kinetic Performance of Oxygen Reduction ReactionHigh catalytic activityCell electrodesSolid electrolyte fuel cellsComposite cathodeFuel cells

The invention relates to a solid oxide fuel cell and a functional gradient composite cathode and a preparation method thereof. The functional gradient composite cathode for the solid oxide fuel cell comprises a chromium poisoning resistant layer, an activation layer and a current collection layer, wherein the chromium poisoning resistant layer is made of LNF (LaNi0.6Fe0.4O3) and doped CeO2, the activation layer is positioned above the chromium poisoning resistant layer and made of LSM (La0.8Sr0.2MnO3) and doped CeO2, and the current collection layer is positioned above the activation layer and made of LSM. The preparation method of the functional gradient composite cathode for the solid oxide fuel cell includes the steps: a, attaching paste of the chromium poisoning resistant layer onto an electrolyte layer and drying to obtain the chromium poisoning resistant layer; b, attaching paste of the activation layer onto the chromium poisoning resistant layer and drying to obtain the activation layer; c, attaching paste of the current collection layer to the activation layer and drying to obtain the current collection layer, so that a blank is obtained; and d, sintering the blank to obtain the functional gradient composite cathode. Chromium deposition of high-volatility CrO3 and CrO2 (OH)2 on cathode / electrolyte interfaces is reduced.

Owner:中氢新能源(江苏)有限公司

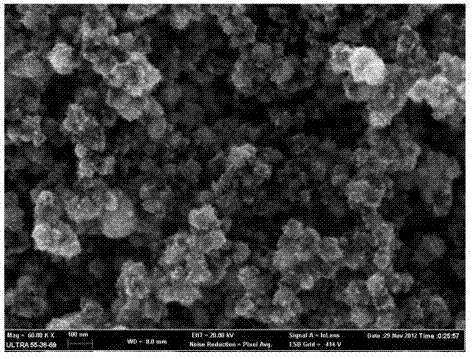

A method for preparing nio/apatite type lanthanum silicate submicro-nano porous anode functional layer

ActiveCN112751041BFlat surfaceAchieve thin filmCell electrodesFinal product manufactureCelluloseMicro nano

The invention relates to a method for preparing a NiO / apatite type lanthanum silicate submicro-nano porous anode functional layer, which adopts functional layer nanopowder, ethyl cellulose and terpineol to be added to a container filled with absolute ethanol In a rotary evaporator, ultrasonically disperse the mixed suspension; use a rotary evaporator to remove absolute ethanol in the suspension, and when the suspension becomes a viscous paste, take out the paste and grind it to complete the function Layer slurry preparation. Brush the functional layer slurry on the anode substrate, brush three layers, perform corresponding heat treatment and sintering after drying, control the heating and cooling rate and holding time during the heating process, and make the anode functional layer. The benefit of the present invention is that the prepared NiO / apatite type lanthanum silicate submicro-nano porous anode functional layer has a maximum pore size of less than 1 μm and a smooth surface without cracks, and is prepared several microns thick by magnetron sputtering on it. The dense electrolyte film provides the substrate; the functional layer contains a large number of nanometer pores to greatly increase the three-phase interface.

Owner:DALIAN UNIV OF TECH

Anode/electrolyte half-cell, anode-supported solid oxide fuel cell and manufacturing method thereof

PendingCN114094123AImprove electrochemical performanceImprove structural stabilityFinal product manufactureCell electrodesComposite cathodeFuel cells

The invention provides an anode / electrolyte half-cell, an anode-supported solid oxide fuel cell and a manufacturing method thereof. The manufacturing method of the anode / electrolyte half-cell comprises the following steps: producing a NiO-YSZ anode support body casting sheet; carrying out micromachining treatment on the surface of one side of the NiO-YSZ anode support body casting sheet to form a special orthogonal net-shaped structure on the surface of the NiO-YSZ anode support body casting sheet; pre-sintering the treated NiO-YSZ anode support body casting sheet; coating a nano powder slurry on the surface of the pre-sintered anode support body, and drying to form an anode functional layer; and coating the YSZ electrolyte layer on the anode functional layer and then sintering at a high temperature. The anode-supported solid oxide fuel cell comprises an anode / electrolyte half cell and an LSM-YSZ composite cathode layer coated on the surface of a YSZ electrolyte layer of the anode / electrolyte half-cell. The anode-supported solid oxide fuel cell has excellent structural stability, activity and electrochemical performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Tabletting and molding method for nano sticky powder

ActiveCN105047974ASolve molding difficultiesEasy to operateSolid electrolyte fuel cellsNanometreBlocking layer

The invention discloses a tabletting and molding method for nano sticky powder. The method comprises the following steps: uniformly filling a mold with a certain amount of nano sticky powder, and manually pressing the powder lightly; reversing the mold, taking out a mold gasket above, paving a layer of relatively thin blocked layer powder on the nano powder or putting a paper scrap which is equal to the mold gasket in area on the powder, and then putting the mold gasket again; reversing the mold again, taking out a mold pressing shaft, paving a blocked layer or the paper scrap on the other side of a green body and then putting the mold gasket or the mold pressing shaft again; and molding the powder on a tablet machine under the pressure of 10-500MPa, and demolding the powder, so as to obtain the product. The tabletting and molding method for the nano sticky powder disclosed by the invention is simple to operate and high in repeatability; and the problem that the nano sticky powder is difficult to mold and demold is effectively solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

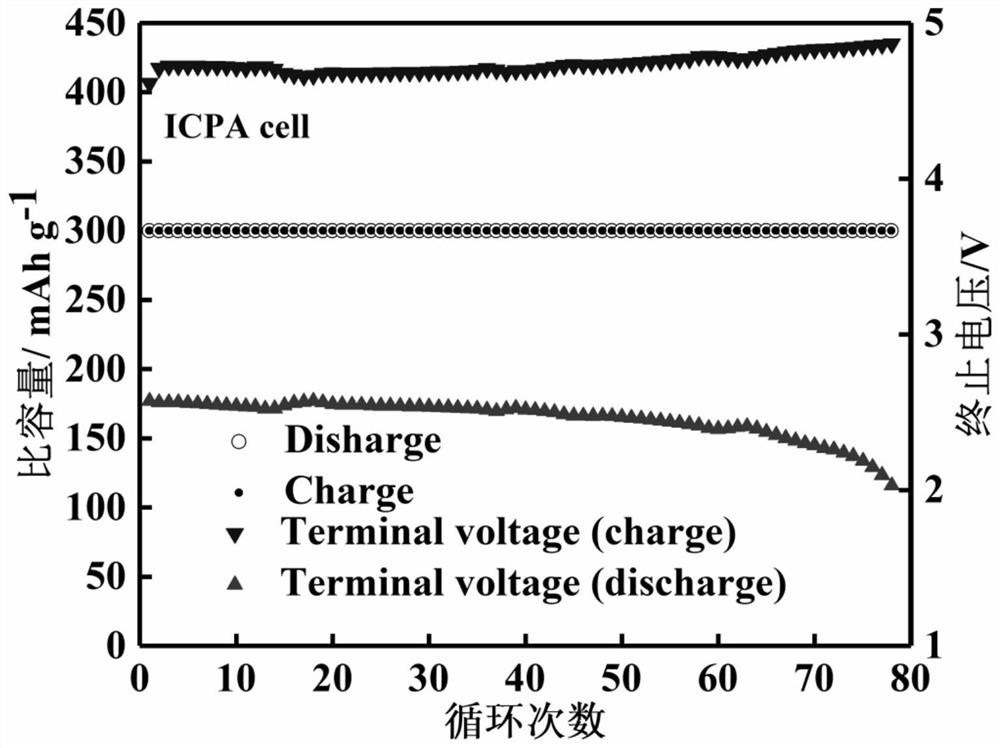

Integrated composite oxygen electrode, and preparation method and application thereof

InactiveCN113130920AReduce interface impedanceImprove battery performanceFuel and secondary cellsCell electrodesComposite electrolytePtru catalyst

The invention discloses an integrated composite oxygen electrode, and a preparation method and application thereof. The preparation method comprises the following steps: dissolving polyoxyethylene in acetonitrile, and adding lithium salt and inorganic electrolyte to prepare uniform electrolyte membrane slurry; dissolving polyoxyethylene in N-methyl pyrrolidone, and adding lithium salt and inorganic electrolyte to prepare composite binder slurry; grinding the composite binder slurry and a catalyst, uniformly coating a current collector with the composite binder slurry and the catalyst, and drying to obtain a composite oxygen electrode; and pouring the electrolyte membrane slurry on the composite oxygen electrode, slicking and drying to obtain the integrated composite oxygen electrode. According to the integrated oxygen electrode, the composite electrolyte material with the ion conducting characteristic is used for replacing an inert binder, a lithium ion continuous transmission channel from the oxygen electrode to the electrolyte is constructed, low oxygen electrode / electrolyte interface impedance is achieved, a three-phase reaction interface in the oxygen electrode is expanded, and the charge-discharge cycle performance of the solid-state lithium-oxygen battery is improved.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing NiO/apatite type lanthanum silicate submicron-nano porous anode functional layer

ActiveCN112751041AFlat surfaceAchieve thin filmFinal product manufactureCell electrodesCelluloseMicro nano

The invention relates to a method for preparing a NiO / apatite type lanthanum silicate submicron-nano porous anode functional layer. The method comprises the following steps of: adding functional layer nano powder, ethyl cellulose and terpilenol into a rotary evaporation bottle filled with absolute ethyl alcohol, and carrying out ultrasonic dispersion on the mixed suspension; removing absolute ethyl alcohol in the turbid liquid by adopting a rotary evaporator, and when the turbid liquid becomes thick paste, taking out the paste and grinding to finish the preparation of the functional layer slurry; and brushing the functional layer slurry on an anode base body for three layers, carrying out corresponding heat treatment and sintering after drying the functional layer slurry, controlling the heating and cooling rate and the heat preservation time in the heating process, and manufacturing the anode functional layer. The method has the advantages that the maximum aperture of the prepared NiO / apatite type lanthanum silicate submicron-nano porous anode functional layer is smaller than 1 micron, the surface is smooth and free of cracks, and a substrate is provided for preparing a compact electrolyte film with the thickness of several microns on the NiO / apatite type lanthanum silicate submicron-nano porous anode functional layer through magnetron sputtering; and the functional layer contains a large number of nano pores, so that the three-phase interface is greatly increased.

Owner:DALIAN UNIV OF TECH

Carbon-resistant and sulfur poisoning-resistant solid-state oxide fuel cell positive electrode and preparation method thereof

InactiveCN110061248AGood structural stabilityNot easy to reuniteCell electrodesDesolvationThree-phase

The invention discloses a carbon-resistant and sulfur poisoning-resistant solid-state oxide fuel cell positive electrode and a preparation method thereof. Copper and samarium co-doped cerium oxide orcopper gadolinium co-doped cerium oxide powder is prepared by preparation of copper ions and samarium or gadolinium doped cerium oxide-based oxide, doped cerium oxide powder is used as precursor powder to prepare porous ceramic, a part of copper is permeated from lattices to obtain the carbon-resistant and sulfur poisoning-resistant solid-state oxide fuel cell positive electrode after hydrogen reduction on the porous ceramic. The conductivity of the positive electrode is improved, the three-phase reaction interface of the positive electrode is added, the carbon-resistant and sulfur poisoning-resistant solid-state oxide fuel cell positive electrode has favorable structure stability and excellent carbon-resistant and sulfur poisoning-resistant performance, and agglomeration can be prevented.According to the preparation method, copper is introduced to the positive electrode by ion doping and desolvation effect, a positive electrode-supported solid-state oxide fuel cell can be directly prepared by a traditional pressing or curtain coating and sintering method, the complicated process of the copper-containing positive electrode prepared by an impregnation reduction method is prevented,and the industrialization implementation becomes probable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY +1

Preparation method of membrane electrode with transition layer for alkaline anion exchange membrane fuel cell

ActiveCN104425829BImprove bindingImprove performanceCell electrodesFuel cellsIon-exchange resinMembrane electrode assembly

The invention relates to an alkaline anion exchange membrane fuel cell. Specifically, it is a preparation method of a membrane electrode with a transition layer: a basic anion exchange resin is coated between the basic anion exchange membrane and the catalytic layer as a transition layer, and then the catalytic layer composed of the catalyst and the basic anion exchange resin is coated It is coated on the transition layer to form a film-covered electrode with transition layer consisting of a basic anion exchange membrane, a transition layer and a catalytic layer. Then the electrode is placed between two gas diffusion layers to form a membrane electrode assembly, and a membrane electrode with a transition layer is prepared. The purpose of the film electrode with transition layer prepared by the present invention is to: improve the binding force of the catalytic layer and the basic anion exchange membrane phase interface, expand the three-phase reaction interface, promote the conduction of the anodic and anode catalytic layer and the basic anion exchange membrane OH, improve Alkaline anion exchange membrane fuel cell performance and cell operation stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing solid-oxide fuel battery cathode

InactiveCN100576613CLarge specific surface areaHigh catalytic activityCell electrodesFuel cellsHYDROSOL

Owner:HARBIN INST OF TECH

A preparation method of fuel cell electrode and membrane electrode with fully ordered structure of catalytic layer

ActiveCN108448138BHigh catalytic activityImprove catalytic stabilityCell electrodesFuel cellsElectrochemical responsePtru catalyst

The invention discloses a method for preparing fuel cell electrodes and membrane electrodes with a fully ordered structure of a catalytic layer, and relates to the field of fuel cells. In the fuel cell electrodes and membrane electrodes prepared by the method of the invention, the catalytic layer components include catalyst active groups Parts, catalyst supports and ion conductors all have an ordered array structure. This fully ordered catalytic layer structure has a high three-phase reaction interface, which can provide efficient electron, ion and material transport channels, thereby effectively reducing the material transport resistance, charge transport resistance and electrochemical polarization resistance inside the electrode. , effectively improving the electrochemical reaction efficiency and energy conversion efficiency in the electrode. Through single cell performance testing and electrochemical characterization, the electrode and membrane electrode prepared by the preparation method of the present invention are significantly improved in terms of monomer performance and catalytic layer activity compared with electrodes and membrane electrodes prepared by the traditional method.

Owner:广东泰极动力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com