A method for preparing nio/apatite type lanthanum silicate submicro-nano porous anode functional layer

A nanoporous, functional layer technology, applied in sustainable manufacturing/processing, battery electrodes, final product manufacturing, etc., can solve problems such as the unsatisfactory porous anode functional layer, and achieve the effect of increasing the three-phase reaction interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

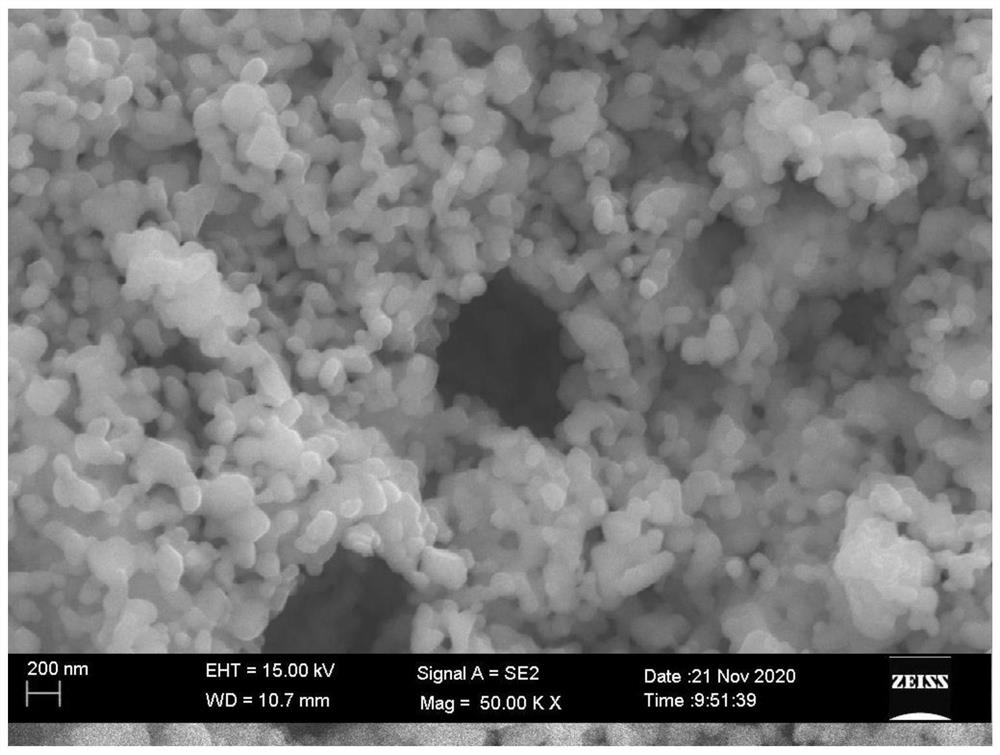

[0037] Example: Preparation of NiO / apatite-type lanthanum silicate submicron-nanoporous anode functional layer

[0038] In this embodiment, the preparation of the NiO / apatite type lanthanum silicate submicron-nanoporous anode functional layer includes the following steps:

[0039]The first step: prepare functional layer powder, weigh 80nm apatite type lanthanum silicate (La 10 Si 5.8 Mg 0.2 o 26.8 ) nanopowder, 30nm NiO nanopowder, where La 10 Si 5.8 Mg 0.2 o 26.8 The nano powder is prepared according to the Chinese invention patent CN201310357158.X; absolute ethanol is added into the ball mill tank, and the weighed apatite-type lanthanum silicate nano powder and NiO nano powder are put into the ball mill tank and mixed by ball milling to obtain Suspension; Specifically, the ball material in the ball mill jar is agate;

[0040] Step 2: Pour the suspension obtained after mixing the ball mill into a container, put it into a constant temperature drying oven, dry it at 55°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com