Method for preparing catalytic layer structure of proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cell parts, nanotechnology for materials and surface science, battery electrodes, etc. The three-phase reaction interface needs to be improved, the porosity of the catalytic layer is low, etc., to achieve the effect of increasing the three-phase reaction interface of the membrane electrode, reducing the proton conduction path and gas diffusion path, and reducing the proton and electron conduction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

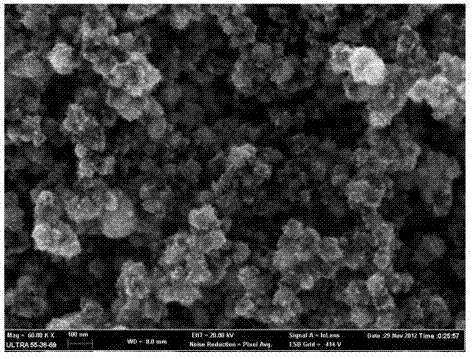

[0034](1) Add 1.0mg carbon powder and 2.5mg Nafion solution (Nafion resin alcohol solution with a mass fraction of 10%) to 1ml of isopropanol, ultrasonically disperse the solution, and then spray it evenly on the Nafion proton exchange On the film, a uniform thin layer of carbon powder is formed on the film (area 3.3×3.3cm 2 ), and finally dried at 50° C. for 30 minutes to obtain a base layer.

[0035] (2) Immerse the proton exchange membrane sprayed with a thin layer of carbon powder into a solution containing chloroplatinic acid and formic acid, wherein chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) 8.0mg, 1ml of formic acid (mass fraction 88%) and 40ml of water. It was then left at room temperature for 48 hours to deposit 0.3 mg / cm 2 platinum. After the reaction, the proton exchange membrane was repeatedly washed with deionized water, and then dried in an environment of 50° C. for 10 minutes.

[0036] (3) Add 2.5 mg of Nafion solution (10% alcohol solution by mass fraction)...

Embodiment 2

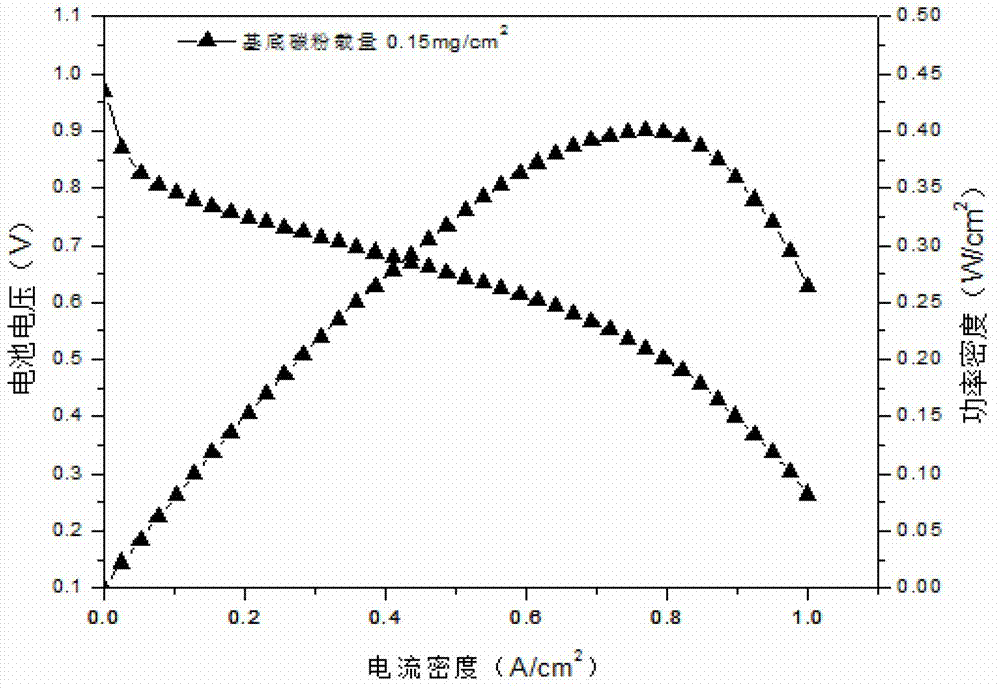

[0041] Except adopting 1.5mg carbon powder and 3.75mg Nafion solution (mass fraction is 10% Nafion resin alcohol solution) to join in 1 milliliter isopropanol, prepare carbon powder feed liquid, other processes are identical with embodiment 1.

[0042] image 3 The polarization performance (I-V) curve of a fuel cell assembled using the catalytic layer prepared in this example as a cathode electrode. from image 3 It can be seen that the highest power density of the battery is 0.40W / cm 2 , at 0.3V, the achieved current density is 1.0A / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com