Biodegradable plant-based anti-wear lubricating oil and preparation method thereof

A biodegradable, plant-based technology, applied in the field of biodegradable plant-based anti-wear lubricating oil and its preparation, can solve the problems of poor anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

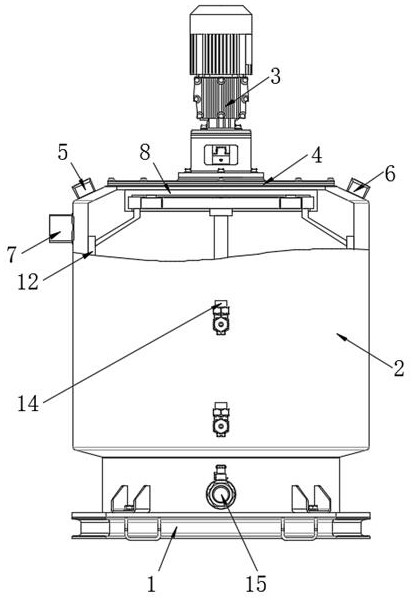

[0036] see Figure 1-2 As shown, a biodegradable plant-based anti-wear lubricant, including vegetable oil, synthetic ester and vulcanization aid;

[0037] The preparation method of the biodegradable plant-based anti-wear lubricating oil is as follows:

[0038]Step 1, feed the vegetable oil into the mixing equipment, then add synthetic ester and vulcanized compound to the mixing equipment, and start the mixing equipment;

[0039] Step 2: Open the feeding pipe 7, put vegetable oil into the inside of the mixing tank 2 through the feeding pipe 7, close the feeding pipe 7, then put the synthetic ester and vulcanization aid into the inside of the mixing tank 2 through the feeding pipe 5, and close the feeding Pipe 5, the interior of the mixing tank 2 is evacuated into a vacuum state through the air guide pipe 6, and then the driving motor 3 is started;

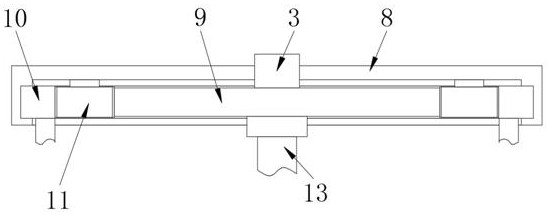

[0040] Step 3, the output shaft of the drive motor 3 drives the drive gear 9 to rotate, the drive gear 9 drives the surface-enga...

Embodiment 2

[0051] see Figure 1-2 As shown, a biodegradable plant-based anti-wear lubricant, including vegetable oil, synthetic ester and vulcanization aid;

[0052] The preparation method of the biodegradable plant-based anti-wear lubricating oil is as follows:

[0053] Step 1, feed the vegetable oil into the mixing equipment, then add synthetic ester and vulcanized compound to the mixing equipment, and start the mixing equipment;

[0054] Step 2: Open the feeding pipe 7, put vegetable oil into the inside of the mixing tank 2 through the feeding pipe 7, close the feeding pipe 7, then put the synthetic ester and vulcanization aid into the inside of the mixing tank 2 through the feeding pipe 5, and close the feeding Pipe 5, the interior of the mixing tank 2 is evacuated into a vacuum state through the air guide pipe 6, and then the driving motor 3 is started;

[0055] Step 3, the output shaft of the drive motor 3 drives the drive gear 9 to rotate, the drive gear 9 drives the surface-eng...

Embodiment 3

[0066] The mixing equipment includes a base 1, a mixing tank 2 and a drive motor 3, the top of the base 1 is fixedly connected to the bottom of the mixing tank 2, and the top of the mixing tank 2 is provided with a tank cover 4, and the top of the tank cover 4 is fixed A drive motor 3 is connected, and one end of the output shaft of the drive motor 3 passes through the tank cover 4 and the mixing tank 2 and extends to the inside of the mixing tank 2, and the two sides of the top of the mixing tank 2 are respectively connected with a feeding pipe 5 and an air guide pipe 6 , and the top of one side of the mixing tank 2 is communicated with a feed pipe 7, the bottom of the tank cover 4 is fixedly connected with a transmission block 8, and the inside of the transmission block 8 is connected with a drive gear 9 for rotation, and the inside of the drive gear 9 It is fixedly connected with one end of the output shaft of the driving motor 3 extending to the inside of the mixing tank 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com