Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Increase metallic luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

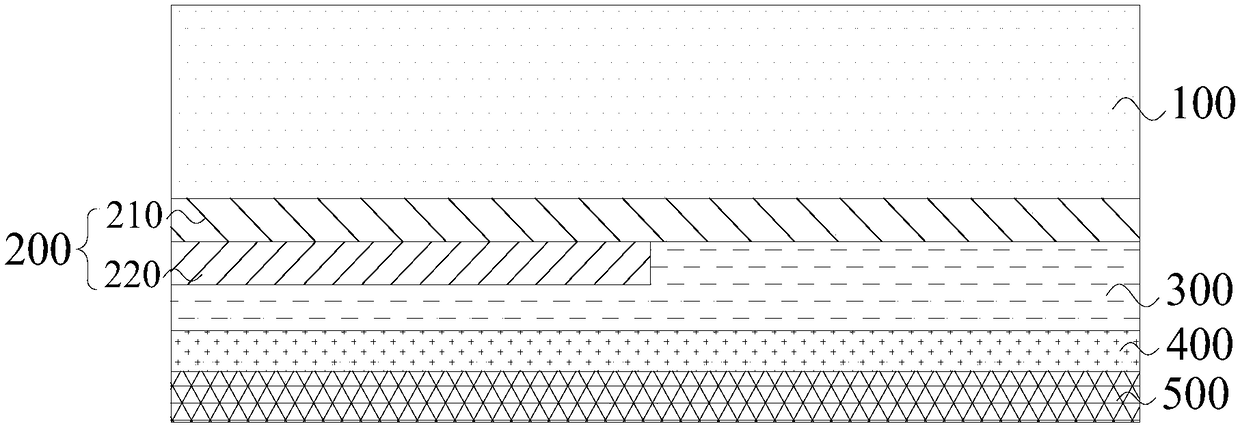

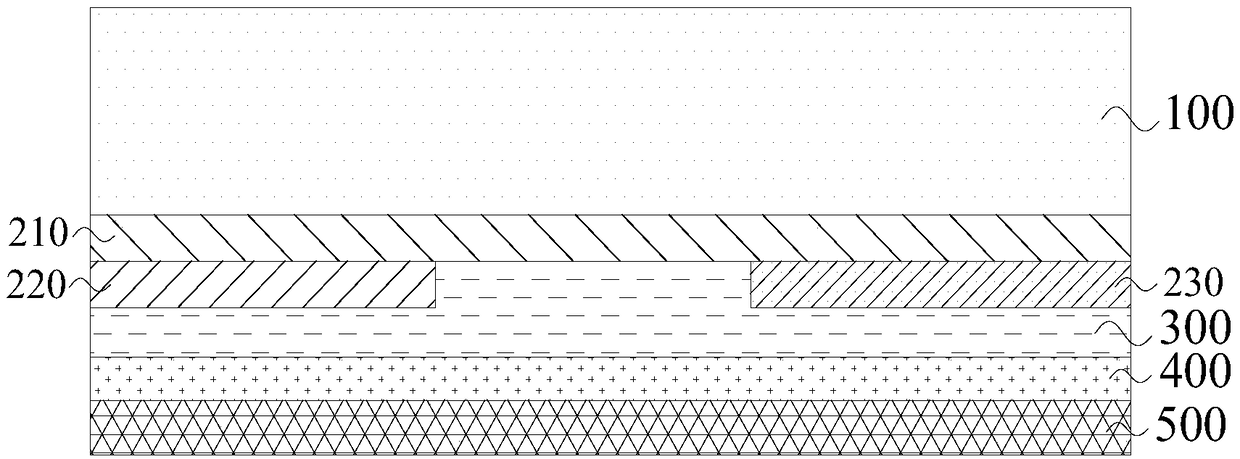

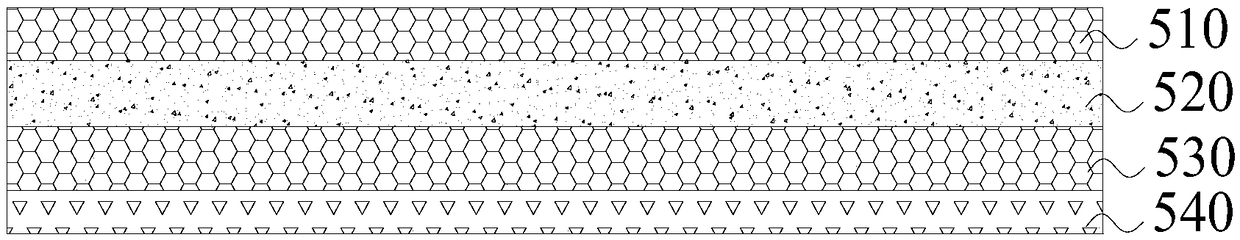

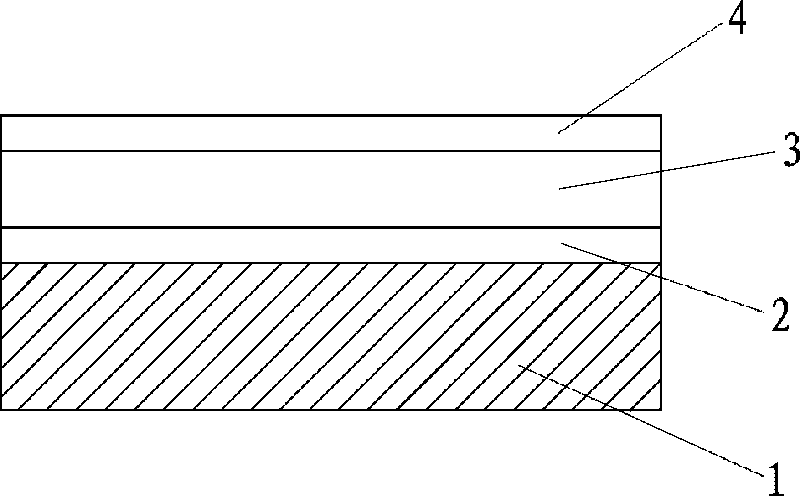

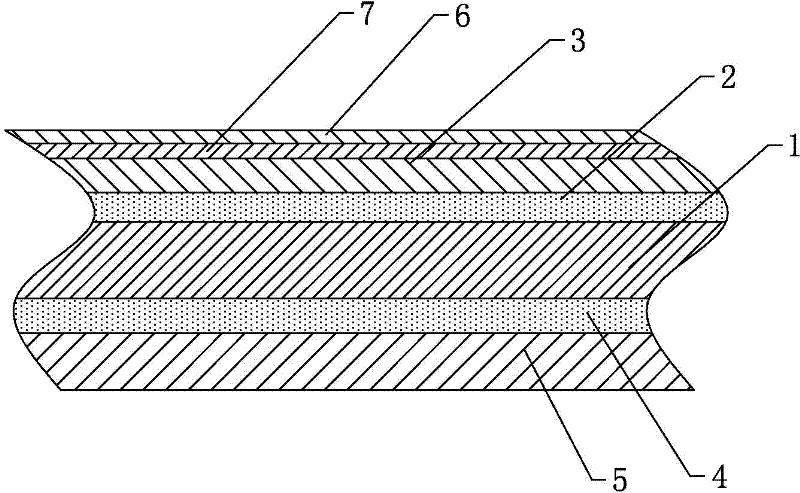

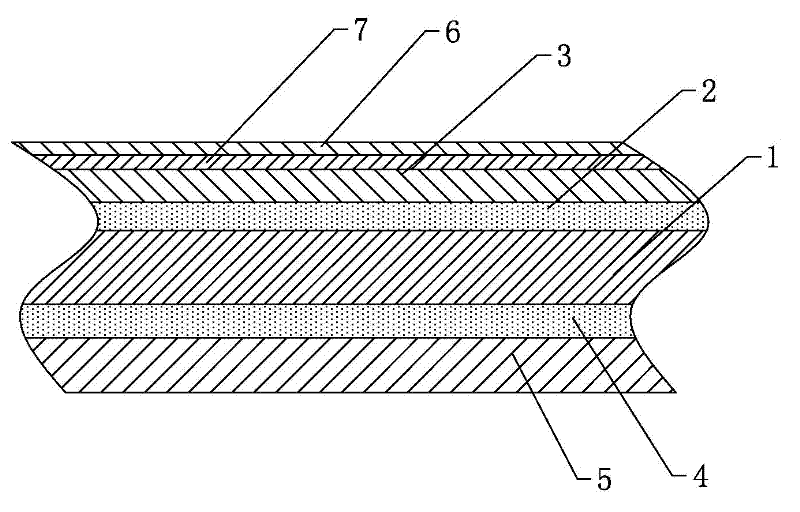

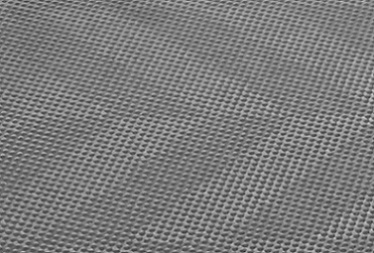

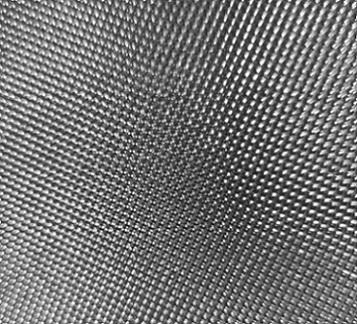

Housing of electronic device, manufacturing method thereof, and electronic device

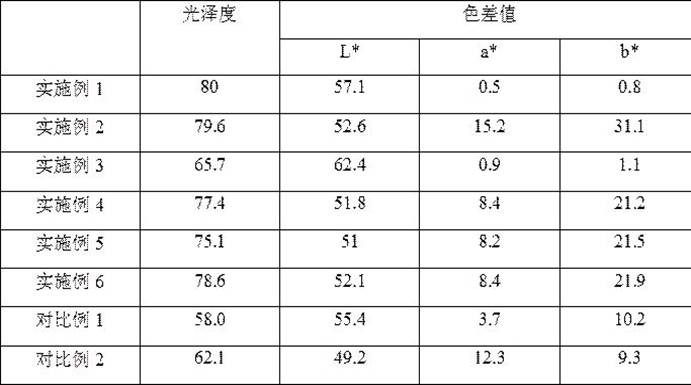

InactiveCN108966548AWith metallic textureIncrease metallic lusterNatural patternsOrnamental structuresGratingOptical coating

The invention provides a housing of an electronic device, a manufacturing method thereof, and an electronic device, wherein the housing of the electronic device comprises a transparent housing body, agradient color layer, a gloss oil layer, an optical texture layer and an optical coating layer which are stacked. The gradient color layer includes a first transparent color layer and a second transparent color layer which are stacked. The orthographic projection of the first transparent color layer on the transparent housing body completely covers the orthographic projection of the second transparent color layer on the transparent housing body. According to the housing of the electronic device of the present invention, the gradient color layer, the optical texture layer and the optical coating layer are disposed on a side of the transparent housing body. Viewed from the other side of the transparent housing body, the housing has an appearance with more than two uniformly and gradually varied colors and with high metallic gloss having a grating effect, so that the appearance of the electronic device can satisfy a consumer's demand for the variable appearance of the electronic device.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

VMPET coated thin film, and production method

InactiveCN101092069AGood heat sealingImprove barrier propertiesFlexible coversWrappersPolyvinyl alcoholRaw material

The invention relates to a novel coated film and the producing method thereof. And it is a VMPET coated film, produced by coating PVDC, PVOH and AC as main raw materials on VMPET.

Owner:海南现代高科实业有限公司

Method for plating chromium on surface of plastic material

InactiveCN101760721AIncrease metallic lusterHigh hardnessVacuum evaporation coatingSputtering coatingPolymeric surfacePlastic materials

The invention relates to the technical field of plating films on the surface of organic polymers. The invention is realized through the following technical scheme that: the method for plating chromium on the surface of plastic materials sequentially comprises (1) a step for pretreatment; (2) a step for preparing a bottom plating layer; (3) a step for preparing a metallic chromium plating layer; (4) a step for preparing a surface plating layer; (5) inspection; and (6) packaging. The invention is suitable for the mechanical industry, transparent materials and other aspects.

Owner:安徽翰邦科技咨询有限公司

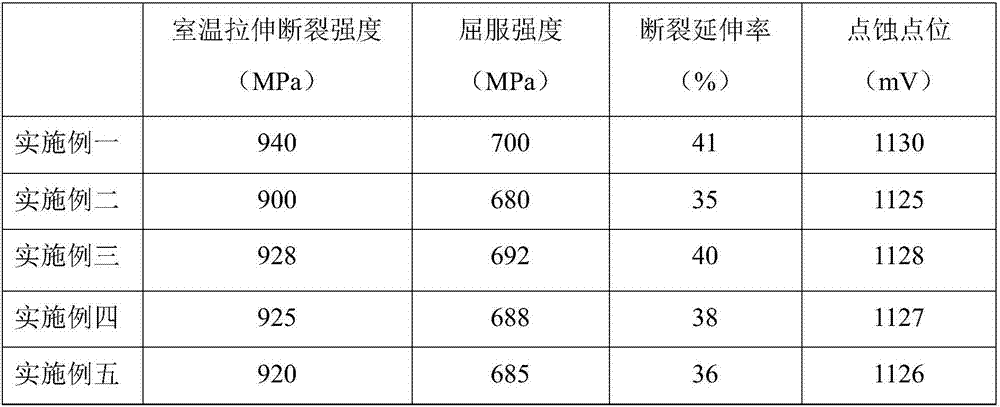

Manufacturing method of high manganese high nitrogen low nickel non-magnetic stainless steel and product thereof

ActiveCN106868423AHigh symmetrical stabilityIncreased symmetrical stabilityFoundry mouldsElectric furnaceNiobiumNon magnetic

The invention provides a manufacturing method of a high manganese high nitrogen low nickel non-magnetic stainless steel and a product thereof. The stainless steel is single phase austenite stainless steel which comprises the following chemical components in percentages by mass: greater than 0 but less than or equal to 0.1% of C, less than or equal to 0.01% of S, less than or equal to 0.015% of P, greater than 0 but less than or equal to 1.0% of Si, greater than or equal to 16% but less than or equal to 18% of Mn, greater than 0 but less than or equal to 2% of Ni, greater than or equal to 10% but less than or equal to 14% of Cr, greater than or equal to 1% but less than or equal to 2% of N, greater than or equal to 0.3% but less than or equal to 1% of Cu, greater than or equal to 0.3% but less than or equal to 5% of Mo, greater than or equal to 0.3% but less than or equal to 1% of Nb and the balance of Fe. The manufacturing method comprises the following steps: heating and smelting raw materials, and performing decarbonization, desulfuration and deoxygenation; raising the temperature to 1600 DEG C and adding nickel; adjusting the temperature of a bath to 1550 DEG C, and adding ferromolybdenum, ferrocolumbium and a metal copper; adding a desoxidant for secondary deoxidization, introducing nitrogen, adjusting the temperature of the bath to 1610-1620 DEG C, and adding nitrogen containing ferrochromium; adjusting the temperature of the bath to 1150-1250 DEG C, introducing nitrogen, adding nitrided ferromanganese, pouring, quenching and air cooling, and machining to form a panel, heating the panel to 650-700 DEG C, keeping the temperature for 30min, and performing furnace cooling to room temperature. The stainless steel through deep punching is still non-magnetic, and needs not to be annealed and demagnetized. The manufacturing method is high in nitrogen-increasing efficiency and low in loss of equipment.

Owner:宁波市博祥新材料科技有限公司

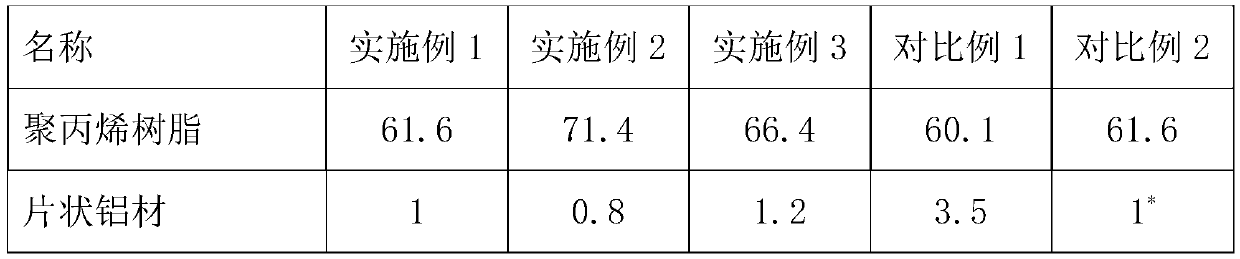

Spraying-free polypropylene composite material

The invention relates to a spraying-free polypropylene composite material. The spraying-free polypropylene composite material is prepared by using a method comprising the steps: modifying an aluminummaterial by using polyethylene wax, performing uniform mixing on raw materials, performing melting and extrusion, performing cooling by using circulating water, and performing granulation so as to obtain a finished product, wherein the aluminum material includes sheet-like aluminum and spherical aluminum. Through combined use of the aluminum powder of a sheet shape, a spherical shape and other shapes, the metallic luster of the material is improved, and the material is provided with better and more beautiful color; and meanwhile, surface treatment is performed on the aluminum material by usingthe polyethylene wax, so that the aluminum material has better dispersion in the polypropylene material and better contact with the polypropylene material, and the metallic luster and mechanical properties of the material are improved. In addition, the surface of a prepared component has no air marks, flow marks and weld bonds, and the problem of material delamination is solved.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

Metal glaze as well as preparation method and application method thereof

The invention belongs to the technical field of ceramic glaze, and relates to metal glaze as well as a preparation method and an application method thereof. The metal glaze comprises the following raw materials in percentage by weight: 30-37% of albite, 8-15% of quartz, 0-4% of wollastonite, 9-16% of calcined kaolin, 4-6% of calcined zinc oxide, 19-23% of calcined iron phosphate and 13-20% of self-made high-phosphorus frit powder. On the basis of calcined iron phosphate, self-made high-phosphorus frit powder is added as a crystallization accelerant into the metal glaze, so that the metal luster is more easily presented. The element P is introduced into the self-made high-phosphorus frit powder in a frit form, and compared with a high-phosphorus raw material system, the self-made high-phosphorus frit powder has a wider firing temperature range, and the metal effect is more stably presented. By finely adjusting the ratio of the self-made high-phosphorus frit powder to the silicon-aluminum of the metal glaze, the adjustment of metal to different colors can be realized. In addition, the metal glaze is combined with a roller printing process, so that the glaze surface can present a good three-dimensional effect.

Owner:FOSHAN SANSHUI CREATE TIDE

High temperature resistance mirror-like silver resin

The invention relates to a high temperature resistance mirror-like silver resin. A method for preparing the mirror-like silver resin comprises the following steps: based on 100 parts of the total weight parts, weighing 80 parts of a linear polymer compound, 7 parts of a double-bond-containing linear oligomer, 5 parts of MIBK (methyl isobuty ketone) 4-methyl-2-pentanon, 3 parts of isopropanol, and 5 parts of polymethyl acrylate; putting the materials in a stainless steel pot of 500-1,000ml sequentially; preparing a variable-speed high-speed disperser, mounting an explosion-proof motor and an anti-static switch on the disperser, and performing high-speed dispersion and low-speed dispersion sequentially. The high temperature resistance mirror-like silver resin has the beneficial effects of enduring high temperature of 300 DEG C without color changing, effectively improving the whiteness of the aluminum powder, increasing the covering power of metal pigment, resisting scrubbing of alcohol and other solvents and being excellent in aluminum powder arrangement and excellent in adhesion to various metals, glass and plastics, and can be cured at normal temperature, heated and cured at 180 DEG C for 30 minutes and cured by UV (ultraviolet ray).

Owner:广州致辉精化股份有限公司

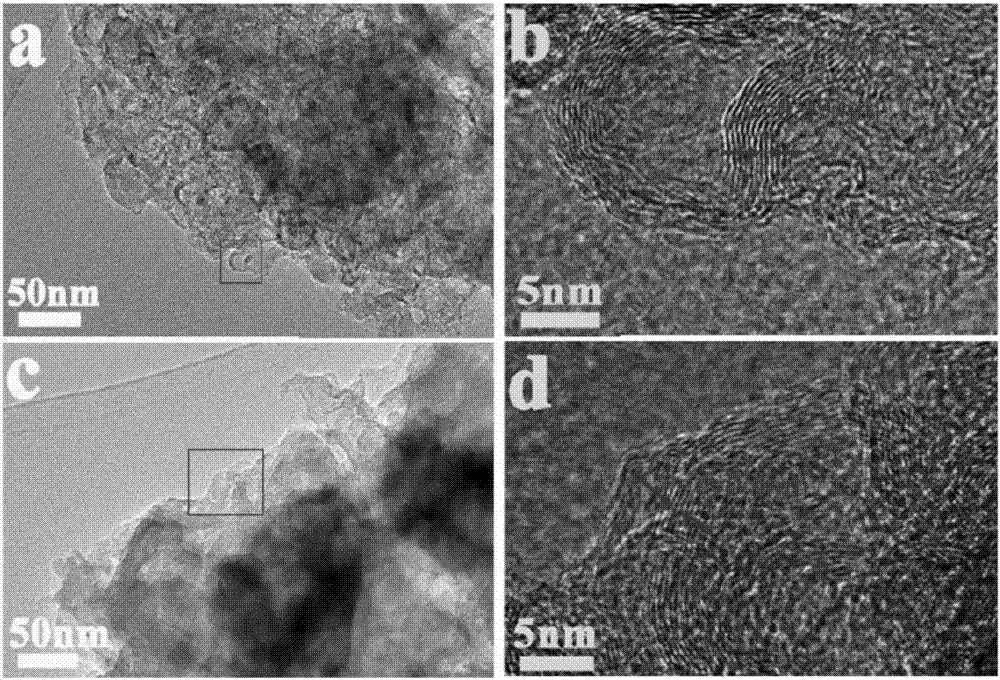

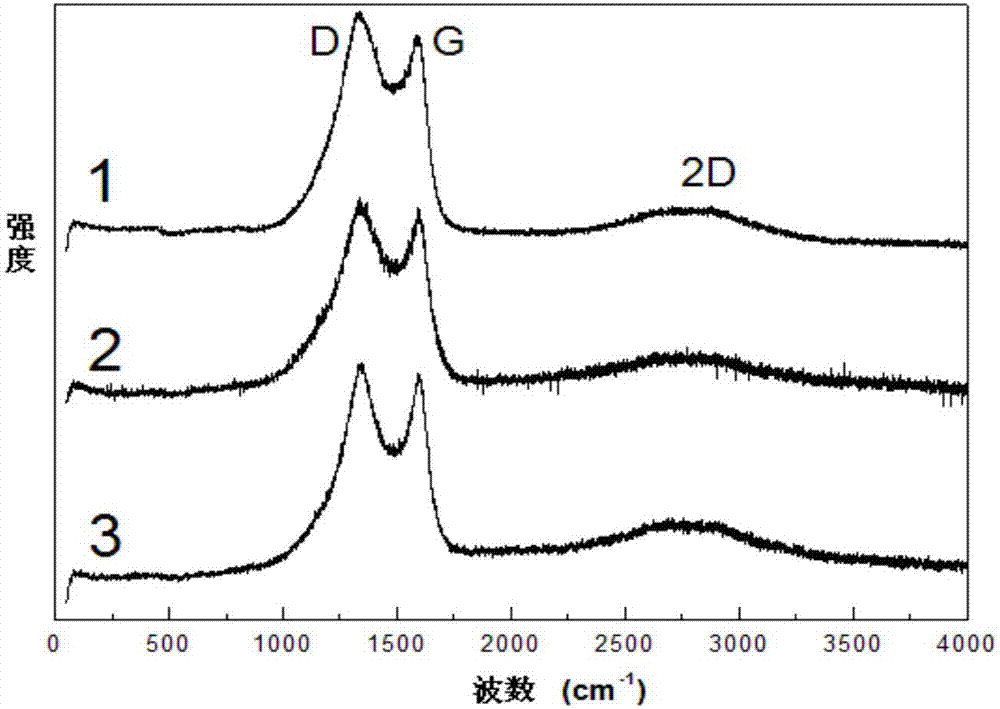

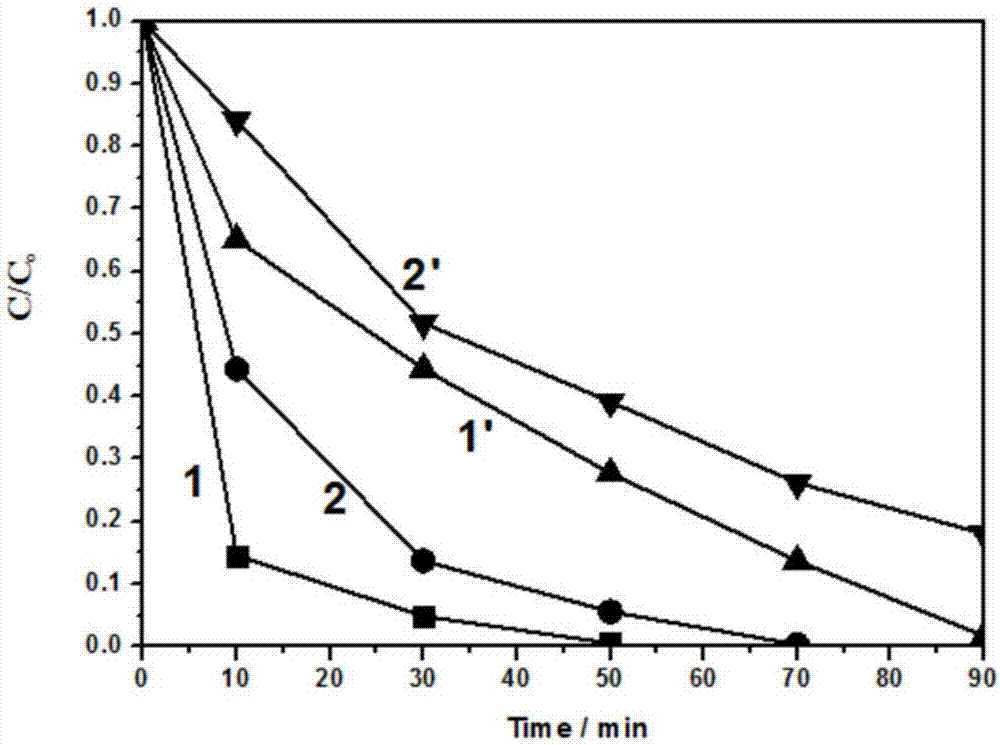

Preparation method and application of carbon material with high specific surface and high graphitization degree

ActiveCN106976860AIncrease metallic lusterLow densityCarbon preparation/purificationTube furnaceHeavy metals

The invention discloses a preparation method and an application of a carbon material with a high specific surface and a high graphitization degree. The preparation method comprises the following steps: 1, selecting oligomeric micro-molecules, and controlling reaction conditions to obtain an oligomer; 2, preprocessing the oligomer obtained in step 1; 3, sulfonating a product obtained in step 2; 4, adding a metal salt solution into the sulfonated oligomer obtained in step 3 in order to obtain metal ion-adsorbed sulfonated oligomer; 5, mixing the metal ion-adsorbed sulfonated oligomer with a metal salt; 6, placing a mixture obtained in step 5 in a ball milling tank, and carrying out high-speed ball milling in Ar atmosphere; and 7, placing a ball milled product obtained in step 6 in a tubular furnace, and heating the tubular furnace to 900-1100 DEG C to obtain carbon powder. The method has the advantages of simplicity and low cost, and the carbon material prepared in the invention has a very high adsorption rate to heavy metals, has high activity as a fuel cell catalyst, and has high capacity and long life in lithium ion cells.

Owner:佛山市利元合创科技有限公司

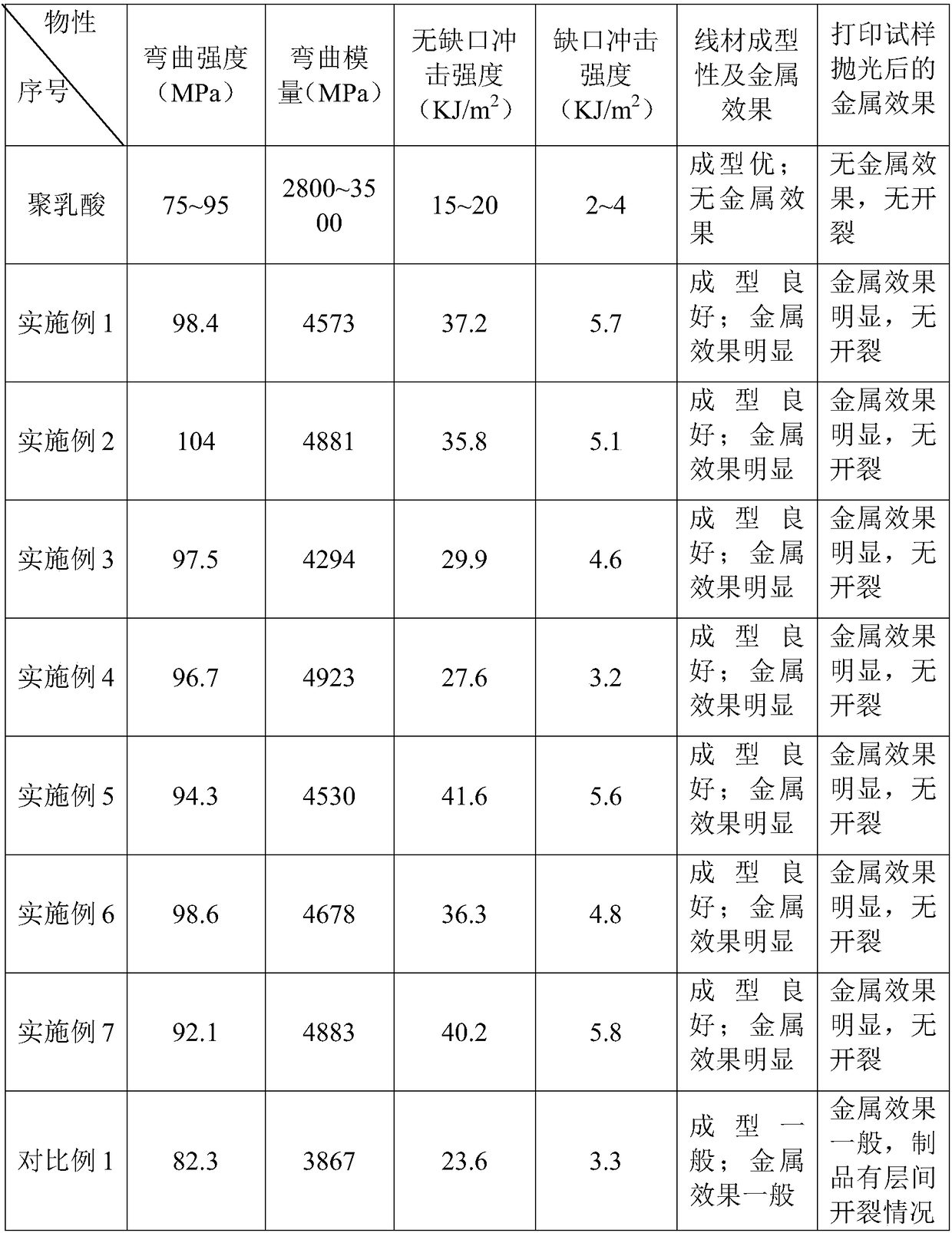

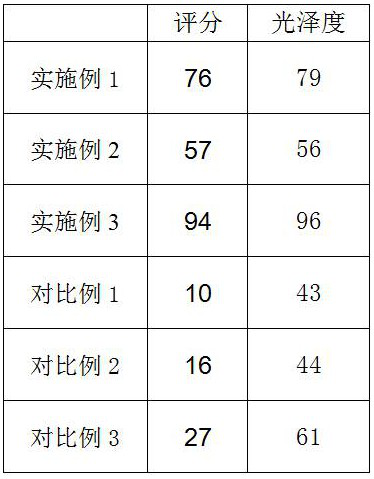

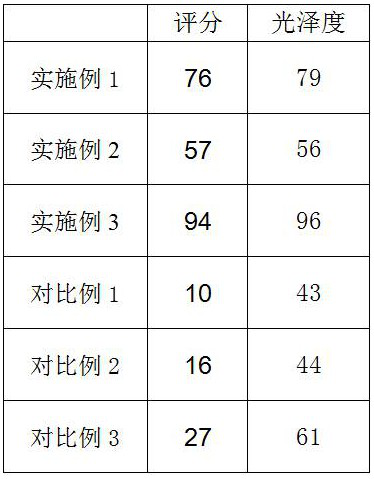

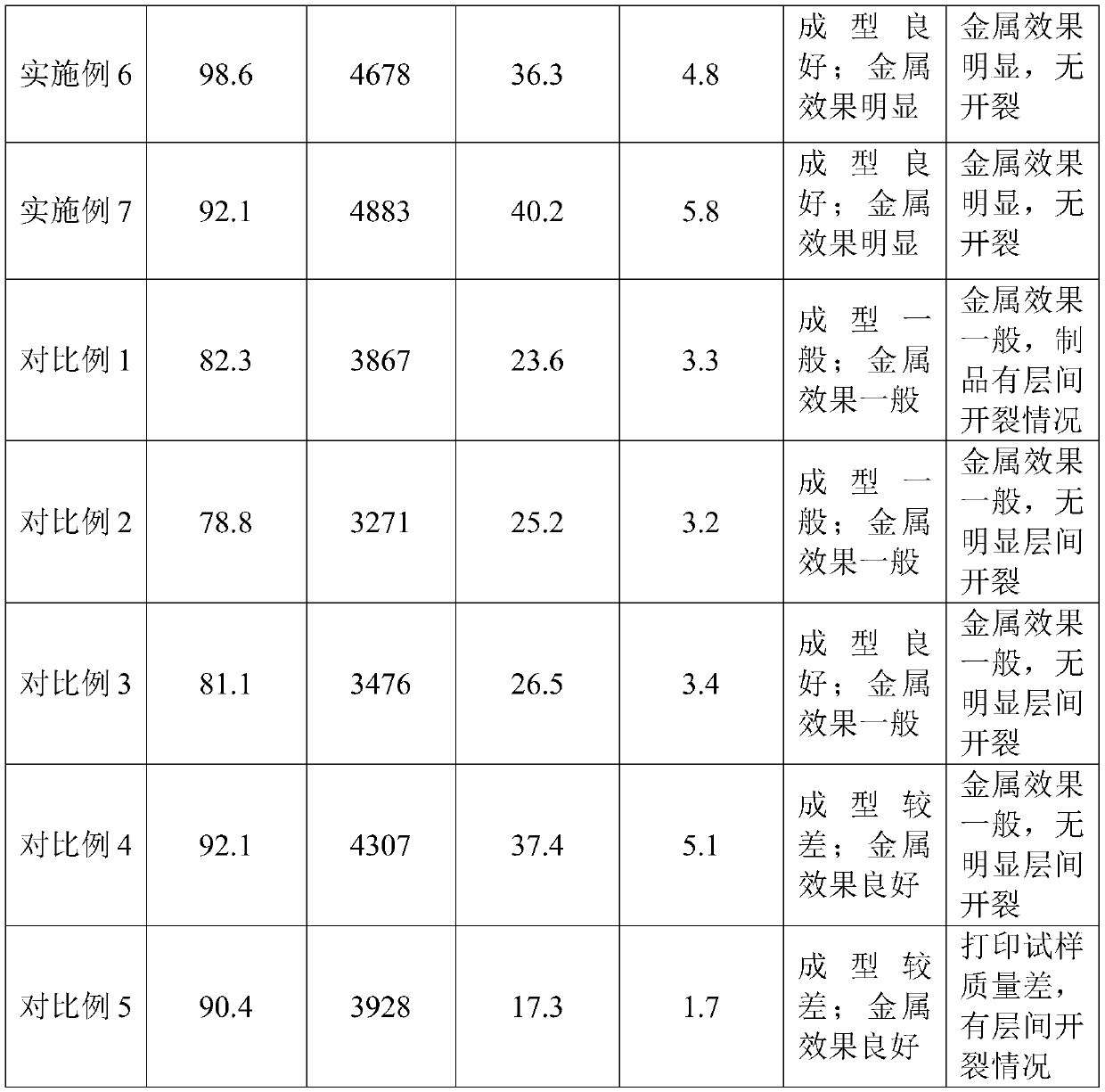

Modified polylactic acid material used for 3D printing and having metal effect

ActiveCN108178907ASolve the problem of brittleness and single effectSolve the degradabilityAdditive manufacturing apparatusPhenolPolymer chemistry

The invention relates to a modified polylactic acid material used for 3D printing and having a metal effect, wherein the modified polylactic acid material comprises, by weight, 100 parts of polylacticacid, 80-150 parts of metal powder, 1-5 parts of a metal pigment, 8-18 parts of a toughening agent, 0.5-2 parts of a coupling agent, 0.5-1.5 parts of a lubricant, 0.2-0.8 part of a hindered phenol antioxidant, and 0.1-0.5 part of a phosphite-based or thioester-based antioxidant, wherein the toughening agent is a soft core and hard shell type core-shell copolymer with a methyl methacrylate shell.According to the present invention, the modified polylactic acid material solves the problems of brittleness, single effect and easy degradation of the existing polylactic acid consumptive material, has advantages of good metal effect, good toughness and less degradation, and can provide excellent printing effect in 3D printing.

Owner:诺思贝瑞新材料科技(苏州)有限公司

Ceramic tile with copper metal texture and preparation method thereof

The invention relates to the field of ceramic tile production, provides a ceramic tile with copper metal texture and a preparation method thereof, and is used for providing a ceramic tile with copperimitation texture. The ceramic tile with the copper metal texture is prepared from 5-8 parts by mass of iron phosphate, 20-25 parts by mass of hybrid aluminum hypophosphite, 6-8 parts by mass of quartz, 40-60 parts by mass of albite, 1-3 parts by mass of calcined kaolin, 3-7 parts by mass of aluminum oxide, 2-5 parts by mass of calcined talc, 3-5 parts by mass of zinc oxide and 8-12 parts by massof high-boron frit. The materials are mixed and then subjected to ball milling to obtain glaze, and the glaze is applied to a green body to form ground coat; transparent glaze is applied to the groundglaze, firing is conducted for 20-24 h, and the ceramic tile with the copper metal texture is obtained. The metal texture can be improved, and particularly, the ceramic tile has the texture and colorsimilar to those of copper.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

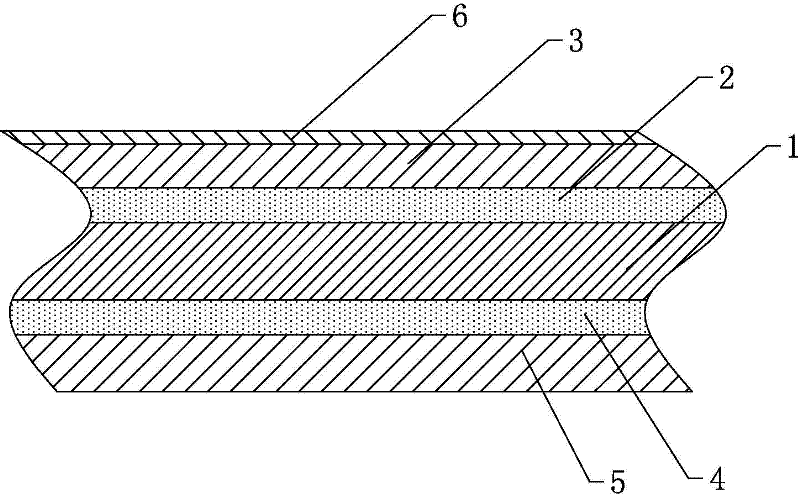

Metal-simulated composite film with wire-drawing effect

InactiveCN102371727APrevent oxidationWith brushed effectNatural patternsMetal layered productsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a metal-simulated composite film with a wire drawing effect, comprising a metal foil layer, a PET (Polyethylene terephthalate) film layer and a PVC (Poly Vinyl Chloride) film layer, of which surfaces are implemented with a wire drawing treatment; the PET film layer and the PVC film layer are respectively bonded on the two surfaces of the metal foil layer through bonding layers, a printing colouring layer is arranged on the another surface of the PET film layer, a protection layer is arranged on the another surface of the printing colouring layer. When being adhered on non-metal, the metal-simulated composite film can have a metal-simulated gloss with the wire-drawing effect, and can improve appearance grades of products.

Owner:JIANGSU OBON PLASTIC

Dedicated ink for bags and suitcases and printing method thereof

The invention discloses dedicated ink for bags and suitcases and belongs to the technical field of ink for bags and suitcases. The dedicated ink is prepared from the following raw materials in parts by weight: 40 to 50 parts of polyamide resin, 10 to 15 parts of epoxy resin, 5 to 8 parts of kiwifruit tartaric acid ester, 20 to 25 parts of vegetable oil, 2 to 5 parts of butyl glycidyl ether, 10 to 20 parts of pigment, 8 to 12 parts of silver powder, 6 to 8 parts of pollen, 15 to 18 parts of optical-variable powder, 4 to 8 parts of mixed additive and 12 to 16 parts of deionized water. The invention further discloses a printing method of the dedicated ink for bags and suitcases. The dedicated ink disclosed by the invention has no strong odor, can change color, is not prone to fading and has higher wear resistance and long service time.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Pseudo-metal composite film

InactiveCN102416731APrevent oxidationGood metallic lusterNatural patternsMetal layered productsPolymer sciencePolyethylene terephthalate

The invention discloses a pseudo-metal composite film, which comprises a metal foil layer, a PET (polyethylene terephthalate) film layer and a PVC (polyvinyl chloride) film layer. The PET film layer and the PVC film layer are respectively bonded on the two surfaces of the metal foil layer through an adhesive layer. The pseudo-metal composite film has a strong metallic luster, and the pseudo-metal effect can be achieved through bonding the metal film layers on a non-metallic material.

Owner:JIANGSU OBON PLASTIC

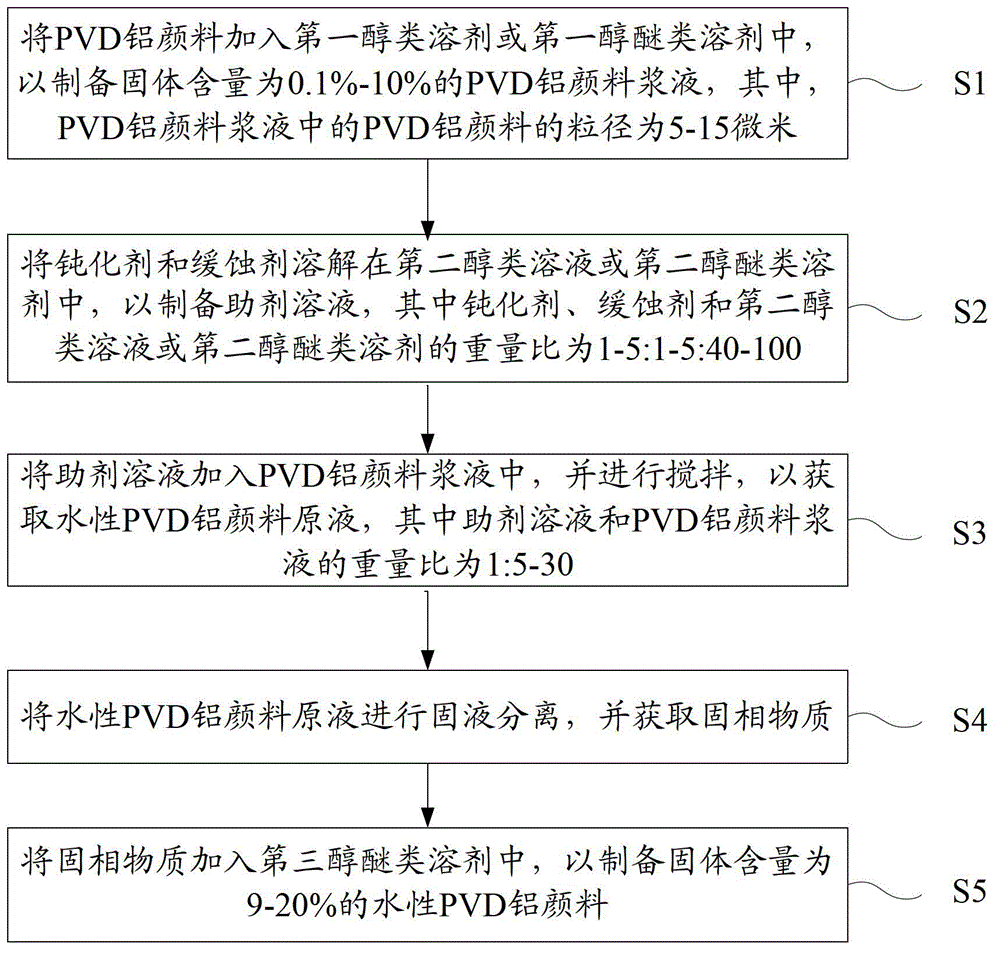

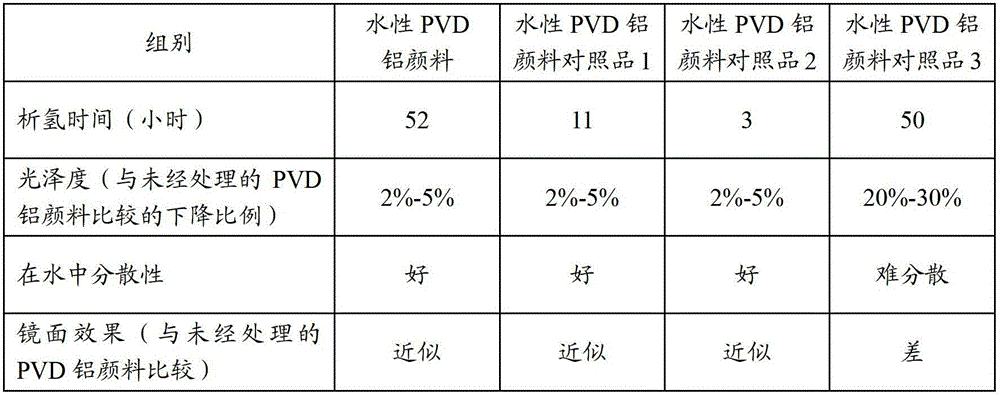

Preparation method of water-based PVD (physical vapor deposition) aluminum pigment

ActiveCN102911532AGood dispersionGood mirror effectPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsWater basedAlcohol

The invention provides a preparation method of water-based PVD (physical vapor deposition) aluminum pigment. The preparation method includes steps of adding PVD aluminum pigment into a first alcohol solvent or a first alcohol ether solvent to prepare PVD aluminum pigment slurry; dissolving passivator and corrosion inhabitor into a second alcohol solvent or a second alcohol ether solvent according to the weight ratio of (1-5): (1-5) : (40-100) so as to prepare additive solution; adding the additive solution into the PVD aluminum pigment slurry according to the weight ratio of 1:(5-30) to obtain water-based PVD aluminum pigment stock solution; subjecting the water-based PVD aluminum pigment stock solution to solid and liquid separation and obtaining solid-phase substance; and finally adding the solid-phase substance into a third alcohol ether solvent to obtain the water-based PVD aluminum pigment. The PVD aluminum pigment prepared by the method has good dispersibility in water while keeping good mirror finish and gloss.

Owner:HUIZHOU FORYOU OPTICAL TECH

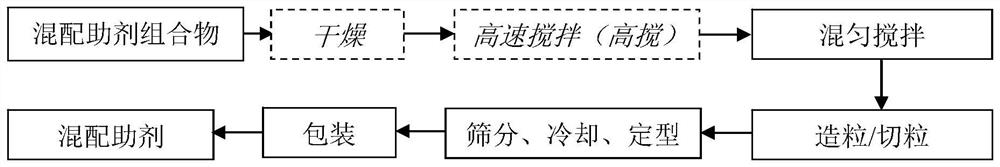

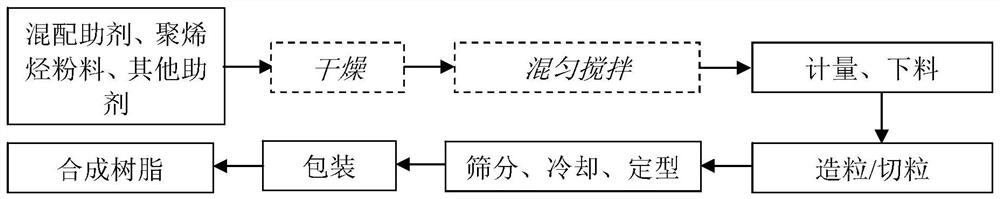

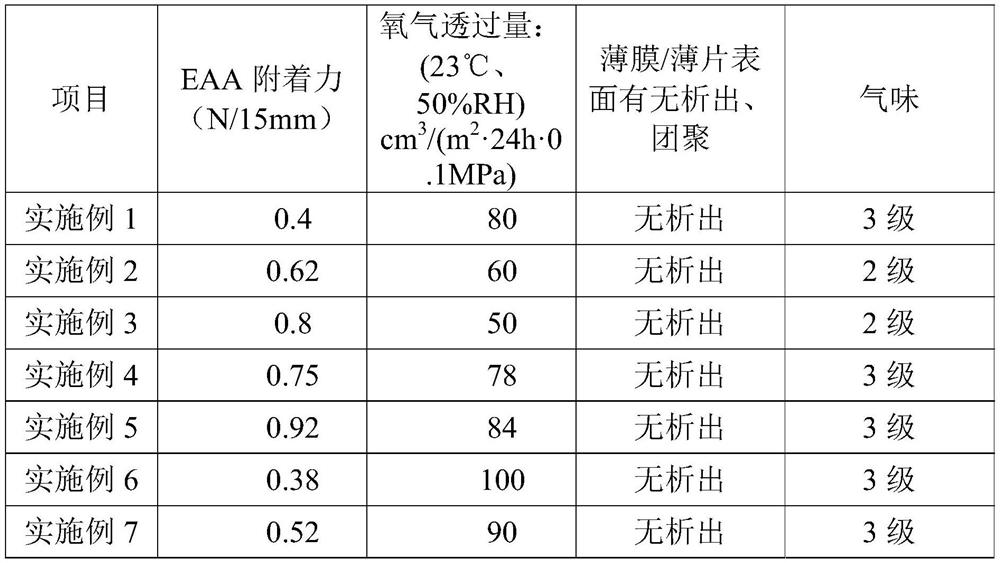

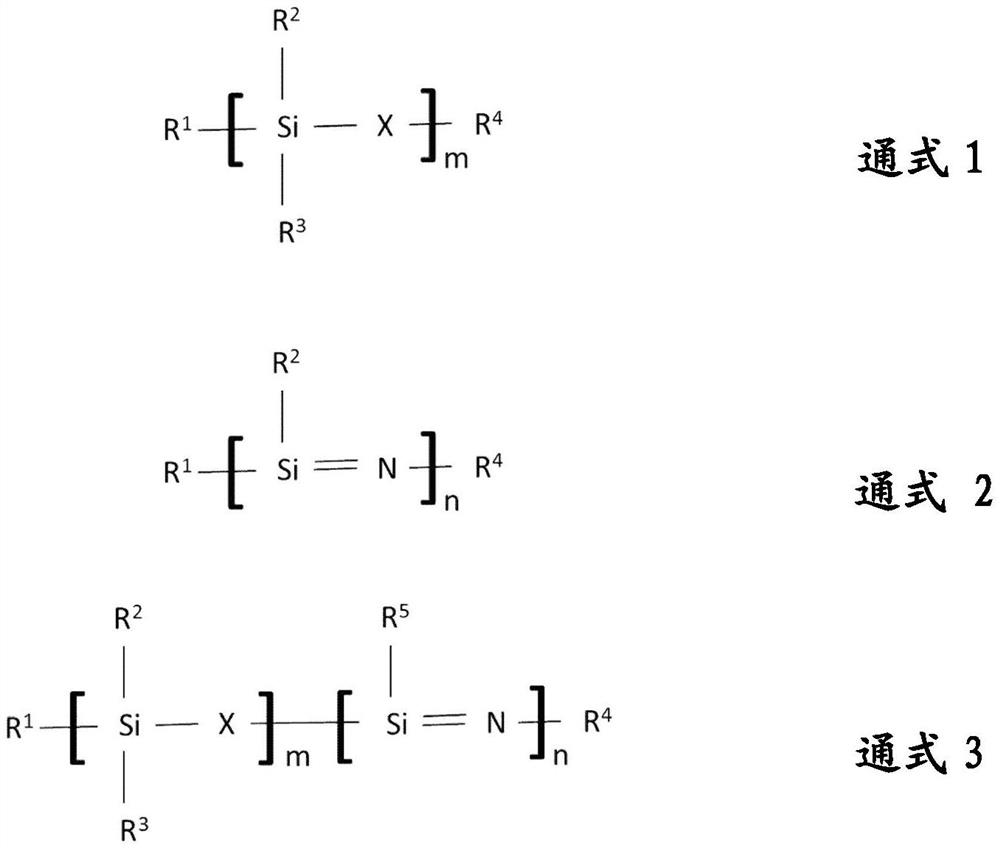

Blending aid composition, synthetic resin, and polyolefin film/sheet

The invention relates to the technical field of polyolefin film processing, and discloses a mixed additive composition, synthetic resin and a polyolefin film / sheet. The mixed additive composition comprises one or more of an antioxidant, a stabilizer and an adhesion enhancer, and the adhesion enhancer is selected from one or more of an alpha nucleating agent, a beta nucleating agent, an optional elastomer, petroleum resin and a synergistic anti-blocking agent; on the basis of the total weight of the blending auxiliary agent composition, the content of the antioxidant is 0.005-10 wt%, the content of the stabilizer is 0.005-10 wt%, and the content of the adhesion enhancer is 80-99.99 wt%. The polyolefin film / sheet has good adhesive force.

Owner:SHANGHAI ROYAL NEW MATERIALS TECH CO LTD

Application of biological cellulose dry powder for preparation of vehicle paint repairing product

InactiveCN105176204AFine spatial networkImprove stabilityAntifouling/underwater paintsCellulose coatingsCelluloseZinc

The invention relates to an application of a biological cellulose dry powder for preparation of a vehicle paint repairing product. The biological cellulose dry powder is used as a main raw material, and deionized water, a compound iron titanium powder, a zinc powder, an aluminum powder, a levelling agent, a defoamer and a bactericide are further added to prepare a pasty vehicle paint repairing product; the vehicle paint repairing product is smeared at scratches before a paint repairing pen is used, and then the paint repairing pen is used for performing paint repairing. Because biological cellulose has an ultra-fine reticulate structure, the scratches can be filled and levelled up, rust is effectively prevented, the bonding fastness degree of a paint surface with a vehicle body can be further increased, and the aesthetic property after paint repairing is improved.

Owner:HAINAN GUANGYU BIOTECH

Preparation process for metal glaze outer-wall bricks

The invention discloses a preparation process for metal glaze outer-wall bricks. The process for the metal glaze outer-wall bricks comprises the following steps: step 1, raw material preparation; step2, preparation of metal glaze; step 3, preparation of outer wall bricks; and step 4, glazing of the prepared outer-wall bricks. The preparation process for the metal glaze outer-wall bricks disclosedby the invention adopts 12 kg of clay as a raw material in the process of preparing mud, the clay with the weight cooperates with other materials to prepare the outer wall bricks, so that metal luster of the glaze surfaces of the outer wall bricks can be effectively improved in the same preparation process.

Owner:江西金泰源陶瓷有限公司

Paint repair paste used for automobile scratch restoration, and preparation method thereof

ActiveCN109929388AHigh barrierImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPliability

The invention discloses a paint repair paste used for automobile scratch restoration. The paint repair paste used for automobile scratch restoration is prepared from, by weight, 40 to 50 parts of aqueous epoxy resin, 6 to 8 parts of organosilicon oligomer, 8 to 10 parts of a pigment, 2 to 3 parts of a modified filler, 2 to 3 parts of aluminum triphosphide powder, 5 to 8 parts of modified metal powder, 0.6 to 1 part of a wetting dispersant, 0.5 to 0.7 part of a defoaming agent, 0.5 to 0.7 part of a thickening agent, and 10 to 16 parts of deionized water. The invention also discloses a preparation method of the paint repair paste. According to the preparation method, the aqueous epoxy resin is taken as a base body of the paint repair paste, and the organosilicon oligomer is adopted for modification, so that the flexibility and the surface tension of the aqueous epoxy resin are improved; no organic solvent containing volatile substances is adopted, the preparation method is friendly to the environment; the modified filler is added, so that paint film is provided with excellent corrosion resistance, modified metal powder can be steadily and highly dispersed in the paint repair paste, and paint film metal luster is improved; the obtained paint repair paste is friendly to the environment, and repairing effect lasts long.

Owner:广州元泽汽车有限公司

Silver paste and coatings produced therefrom

PendingCN112500796AIncrease metallic lusterImprove adhesionRosin coatingsDuplicating/marking methodsMetal coatingSilver paste

The invention relates to an oxidation-stable silver paste comprising silver nanoparticles, and to the use of such a paste for producing decorative elements with metallic luster on articles having silicate outer surfaces, such as porcelains, ceramics, bone porcelains, glasses or enamels, metal coatings on such substrates, and to a method for producing such coatings.

Owner:MERCK PATENT GMBH

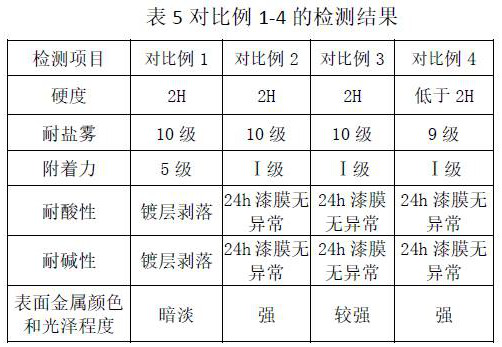

Method for preparing faucet with metallic luster by coating brass or zinc alloy base material

ActiveCN113617610AImprove bindingIncrease metallic lusterVacuum evaporation coatingSputtering coatingZinc alloysAcrylate ester

The invention relates to the technical field of bathroom decoration, in particular to a method for preparing a faucet with metallic luster by coating a brass or zinc alloy base material. The method comprises the following steps: pretreating and preheating the surface of the base material; spraying organic silicon primer on the surface of the base material, and curing; placing the base material treated in the above step in a multi-arc ion coating box for vacuum coating, wherein the vacuum coating mode is multi-arc ion coating, biasing and magnetron sputtering coating; spraying a PP treating agent on the surface of the coated base material, and curing; and spraying polyacrylate baking varnish on the surface of the cured base material, and curing to obtain the faucet with the metallic luster. According to the method, a layer of organic silicon primer is sprayed on the surface of the base material, a layer of pp treating agent is firstly sprayed after vacuum coating, and then polyacrylate stoving varnish is sprayed, so that the binding force between coatings is greatly enhanced, the metallic luster is enhanced, and the problems that the binding force is low and the metallic luster is not lasting when a brass or zinc alloy base material is coated in the prior art can be solved.

Owner:佛山市东鹏陶瓷发展有限公司 +2

Stainless steel neutral phosphorus-free degreasing and dewaxing agent and preparation method thereof

InactiveCN109594089AIncrease metallic lusterEasy constructionCleansing AgentsDodecylbenzenesulfonic acid

The invention discloses a stainless steel neutral phosphorus-free degreasing and dewaxing agent. Raw materials of the stainless steel neutral phosphorus-free degreasing and dewaxing agent comprise, byweight, tap water, dodecyl benzene sulfonate, silicate, carbonate, benzoate, a composite surfactant, sodium chloride and a corrosion inhibitor. The preparation method of the raw materials comprises the following steps of (1) preparing a heat-resistant alkali-resistant processing environment; and (2) performing stirring and dissolving. The stainless steel neutral phosphorus-free degreasing and dewaxing agent does not contain the phosphorus element contained in traditional cleaning agents of the same kind, and the working environment is nearly neutral. The metal luster of stainless steel is greatly improved. Construction can be conveniently carried out. The steel neutral phosphorus-free degreasing and dewaxing agent has the properties of being neutral, phosphorus-free and high in efficiency.

Owner:佛山市海明威生态科技股份有限公司

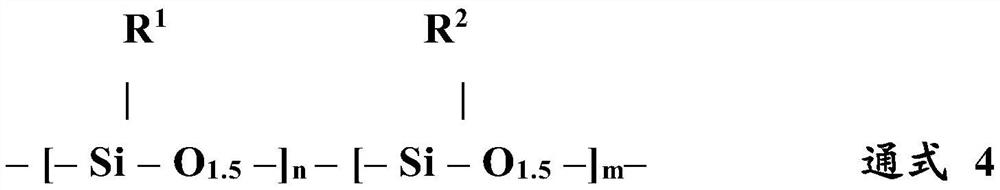

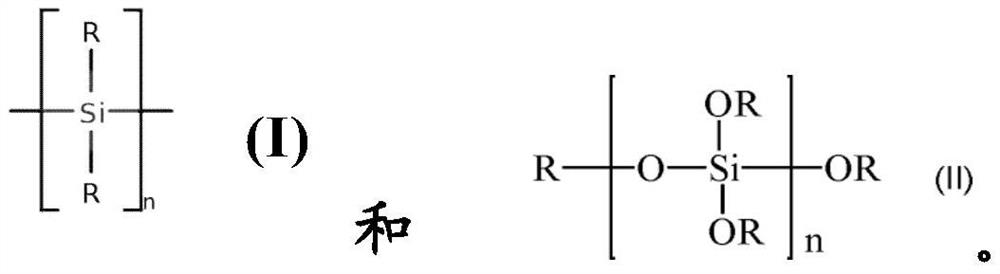

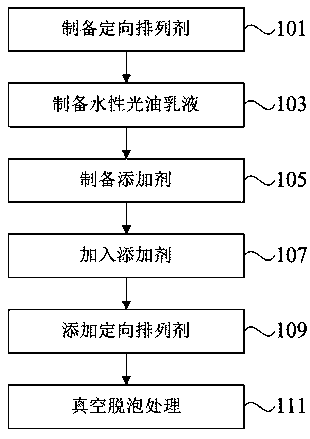

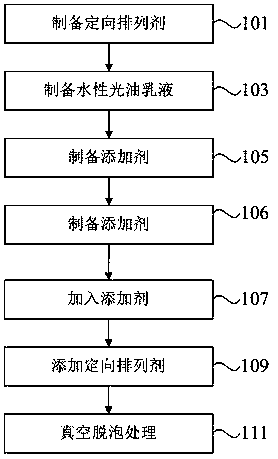

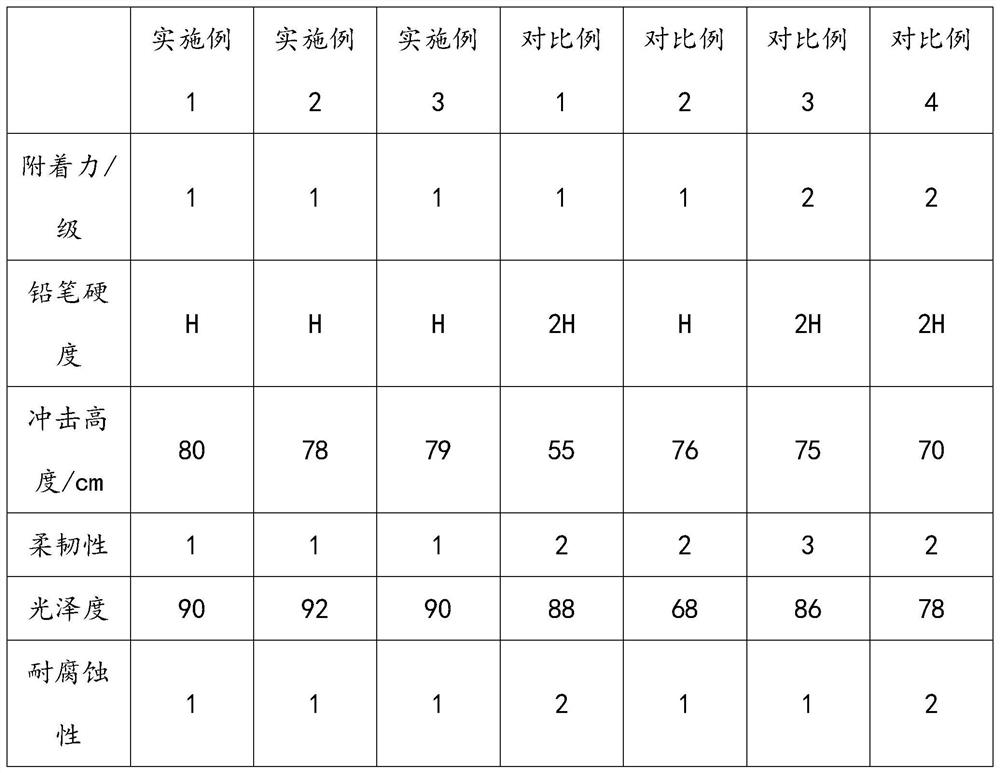

Aqueous gold powder gloss oil and preparation method thereof

InactiveCN109627883AImprove flammabilityImprove the condition of easy oxidation and blackeningFireproof paintsAntifouling/underwater paintsLow speedOil emulsion

The invention relates to aqueous gold powder gloss oil and a preparation method thereof. The method comprises the following steps of: preparing a directional alignment agent: prefabricating 0.3-0.7 part by mass of synthetic sheet silicate into a 10% aqueous solution for later use. Preparing an aqueous gloss oil emulsion: mixing and stirring 50-70 parts by mass of an aqueous polyacrylate dispersionand 0.3-0.7 part by mass of polyether modified organosiloxane. Preparing an additive: diluting 0.4-0.8 part by mass of a benzotriazole solution and 0.2-0.6 part by mass of fatty acid ester with equalmass of water, and mixing and stirring the diluted benzotriazole solution and the fatty acid ester. Adding the additive: adding the additive into the aqueous gloss oil emulsion by stirring at a low speed. Adding an the directional alignment agent: adding the directional alignment agent into the additive-containing aqueous gloss oil emulsion, and mixing, stirring and adding 30-35 parts by mass ofdeionized water.

Owner:惠州市惠阳区正邦企业有限公司

A kind of paint repair paste for car scratch repair and preparation method thereof

ActiveCN109929388BImprove barrier propertiesImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyOligomer

The invention discloses a paint repair paste for repairing scratches in automobiles. , 2-3 parts of modified filler, 2-3 parts of aluminum-zinc tripolyphosphate powder, 5-8 parts of modified metal powder, 0.6-1 part of wetting and dispersing agent, 0.5-0.7 part of defoamer, 0.5 part of thickener -0.7 parts and 10-16 parts of deionized water; the invention also discloses a preparation method of the paint repair paste. The invention adopts the water-based epoxy resin as the paint-repairing paste matrix, and modifies it with an organosilicon oligomer, improves the flexibility and surface tension of the epoxy resin, does not use an organic solvent containing volatile substances, and is environmentally friendly; By adding modified fillers, the paint film coating has excellent corrosion resistance, and the modified metal powder can be stably and highly dispersed in the paint paste, which can improve the metallic luster of the paint film; the obtained paint repair paste is green and environmentally friendly, and can maintain repair for a long time Effect.

Owner:广州元泽汽车有限公司

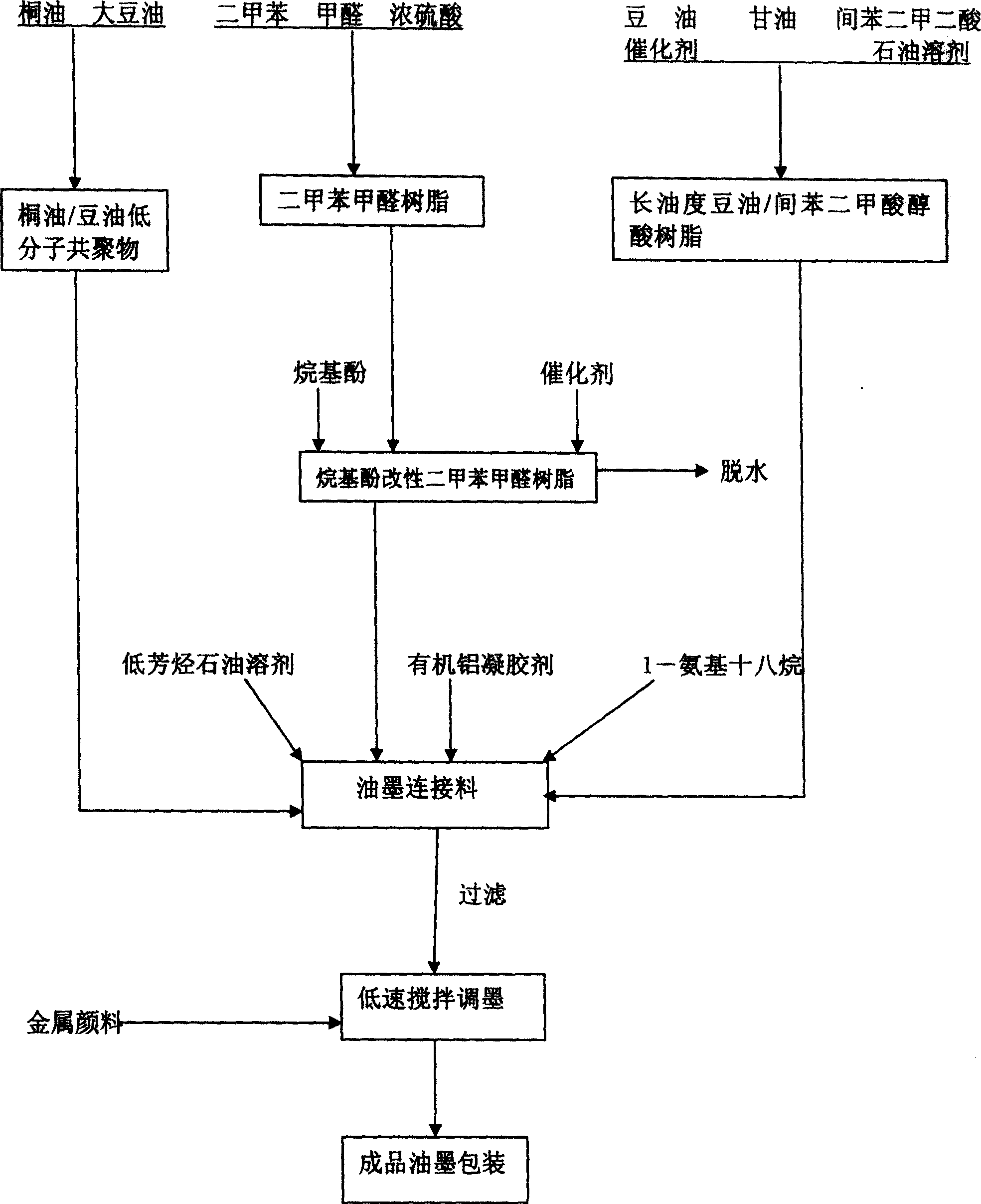

Environmental-protection soybean oil offset metal ink

The invention relates to environmental protection type soybean oil offset printing metal printing ink. It uses china wood oil / soybean oil low molecular copolymer, alkyl phenol modification xylene formaldehyde resin, and long oil length bean oil / isophthalic acid alkyd resin as main film forming matter which forms printing ink connecting material with soybean oil, low arene high boiling point petroleum solvent, organic alumina gel, and metallic pigment preservative agent 1-amino group octadecane. The printing ink connecting material cooperates with the metallic pigment to make blue-gold, red-gold, blue-red-gold, and aluminium ink according to material constituent weight percentage.

Owner:鹤壁百运佳大豆油墨科技有限公司

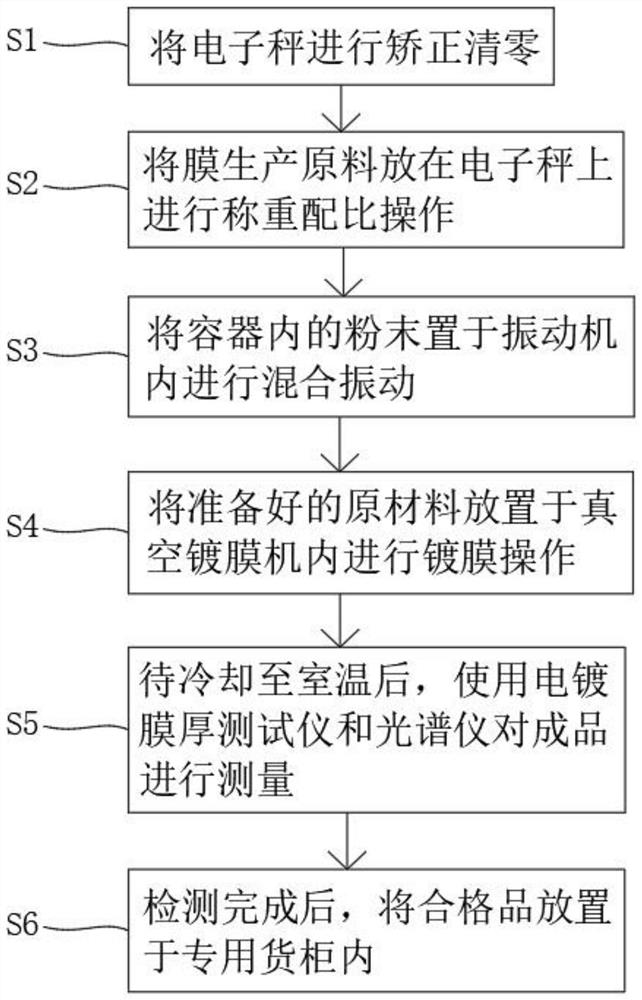

Optical vacuum coating with nano antibacterial function and preparation method thereof

PendingCN114318231AWith nano antibacterial functionImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingCopper oxideSilicon dioxide

The invention belongs to the technical field of high polymer materials, particularly relates to an optical vacuum coating film with a nano-antibacterial function and a preparation method thereof, and provides the following scheme aiming at the problem that the nano-antibacterial function is relatively weak: the optical vacuum coating film with the nano-antibacterial function is provided. Comprising the following components in parts by mass: 3 to 4 parts of nano titanium dioxide, 9 to 11 parts of nano titanium trioxide, 12 to 15 parts of nano silicon dioxide, 12 to 15 parts of silver, 10 to 15 parts of copper oxide and 10 to 15 parts of nano zinc oxide, and the diameter of the nano silicon dioxide is 20 to 60 nm. And the copper oxide is 5-8 parts. During preparation, the nano titanium dioxide is white loose powder, has strong ultraviolet shielding effect, good dispersibility and weather resistance, has anti-line, antibacterial, self-cleaning and anti-aging properties, and can endow the film with antibacterial and self-cleaning functions.

Owner:丹阳市科达镀膜材料有限公司

A kind of ceramic tile with copper metal texture and preparation method thereof

The invention relates to the field of ceramic brick production, and provides a ceramic brick with a copper metal texture and a preparation method thereof, which are used to provide a ceramic brick with a copper-like texture. The ceramic brick with copper metal texture provided by the invention comprises: 5-8 parts by mass of iron phosphate, 20-25 parts by mass of hybrid aluminum hypophosphite, 6-8 parts by mass of quartz, 40-60 parts by mass of albite, 1 to 3 parts by mass of burnt kaolin, 3 to 7 parts by mass of alumina, 2 to 5 parts by mass of burnt talc, 3 to 5 parts by mass of zinc oxide, and 8 to 12 parts by mass of high-boron frit; the above materials are mixed and ball milled to obtain The glaze is applied to the green body to form a bottom glaze; the transparent glaze is applied to the bottom glaze, and fired for 20-24 hours to obtain a ceramic tile with a copper metal texture. It can improve the metal texture, especially make the ceramic tile have a copper-like texture and color.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

A preparation method of modified polylactic acid material with metal effect for 3D printing

ActiveCN108164945BNot easy to degradeGood metal effectAdditive manufacturing apparatus3d printPolymer science

The invention relates to a preparation method of a modified polylactic acid material for 3D printing, having a metal effect. The method concretely comprises the following steps: preparing the following raw materials, by weight, 100 parts of polylactic acid, 80-150 parts of metal powder, 1-5 parts of a metal pigment, 8-18 parts of a soft-core and hard-shell type core-shell copolymer flexibilizer with methyl methacrylate as the shell, 0.5-2 parts of a coupling agent, 0.5-1.5 parts of a lubricant, 0.2-0.8 part of a hindered phenol antioxidant and 0.1-0.5 part of a phosphite or thioester antioxidant, mixing the metal powder with the metal pigment, spraying a coupling agent solution during mixing, drying the obtained material, mixing the obtained modified metal powder and metal pigment, the polylactic acid, the flexibilizer, the lubricant and the antioxidant, adding the obtained mixture into a double screw extruder, performing extruding granulation, drying obtained pellets, adding the driedpellets into a single screw extruder, extruding the pellets, and performing hot water treatment, cold water treatment and air drying to obtain wires. The modified polylactic acid material prepared inthe invention has the advantages of metal effect, good toughness and non-degradability.

Owner:诺思贝瑞新材料科技(苏州)有限公司

A high temperature resistant mirror silver resin

The invention relates to a high temperature resistance mirror-like silver resin. A method for preparing the mirror-like silver resin comprises the following steps: based on 100 parts of the total weight parts, weighing 80 parts of a linear polymer compound, 7 parts of a double-bond-containing linear oligomer, 5 parts of MIBK (methyl isobuty ketone) 4-methyl-2-pentanon, 3 parts of isopropanol, and 5 parts of polymethyl acrylate; putting the materials in a stainless steel pot of 500-1,000ml sequentially; preparing a variable-speed high-speed disperser, mounting an explosion-proof motor and an anti-static switch on the disperser, and performing high-speed dispersion and low-speed dispersion sequentially. The high temperature resistance mirror-like silver resin has the beneficial effects of enduring high temperature of 300 DEG C without color changing, effectively improving the whiteness of the aluminum powder, increasing the covering power of metal pigment, resisting scrubbing of alcohol and other solvents and being excellent in aluminum powder arrangement and excellent in adhesion to various metals, glass and plastics, and can be cured at normal temperature, heated and cured at 180 DEG C for 30 minutes and cured by UV (ultraviolet ray).

Owner:广州致辉精化股份有限公司

A kind of metallic glaze and its preparation method and application method

The invention belongs to the technical field of ceramic glazes, and relates to a metal glaze and a preparation method and an application method thereof; the weight percentages of each raw material in the metal glaze are: 30-37% albite, 8-15% quartz, 0-4 % wollastonite, 9-16% calcined kaolin, 4-6% calcined zinc oxide, 19-23% calcined iron phosphate, 13-20% self-made high phosphorus frit powder. On the basis of calcined iron phosphate, the metal glaze adds self-made high-phosphorus frit powder as a crystallization accelerator to make the metallic luster easier to appear, and the self-made high-phosphorus frit powder introduces P element in the form of frit, compared with High-phosphorus raw material system, the self-made high-phosphorus frit powder has a wider firing temperature range, making the metal effect more stable; by fine-tuning the ratio of the self-made high-phosphorus frit powder and silicon-aluminum glaze, that is It can realize the adjustment of metal effects of different colors. In addition, the metal glaze is combined with a roller printing process, which can make the glaze surface present a good three-dimensional effect.

Owner:FOSHAN SANSHUI CREATE TIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com