Manufacturing method of high manganese high nitrogen low nickel non-magnetic stainless steel and product thereof

A technology of non-magnetic stainless steel and manufacturing method, applied in the field of steel, can solve the problems of irreversible discoloration of materials, failure to pass the magnetic inspection, increase of processes, etc., and achieve the effect of being beneficial to absorption, processing performance and wear resistance, and reducing inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

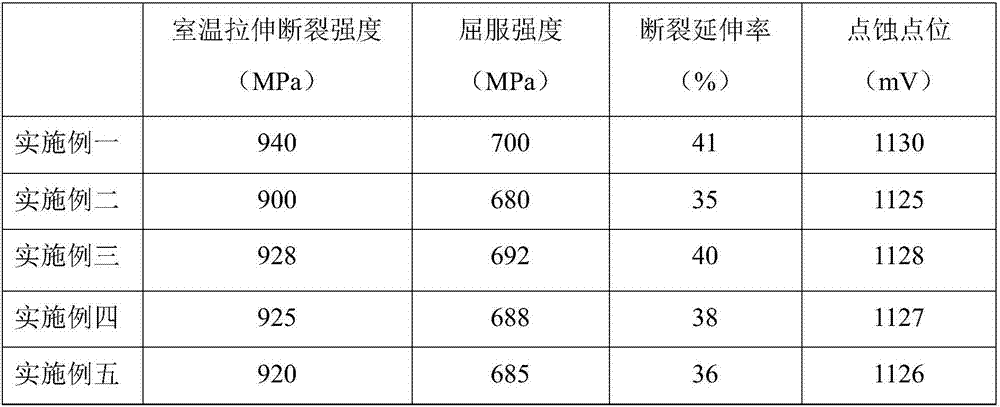

Examples

Embodiment 1

[0036] A high-manganese, high-nitrogen, low-nickel non-magnetic stainless steel, characterized in that the stainless steel is a single-phase austenitic stainless steel, and its chemical composition and mass percentage are shown in Table 1.

[0037] Table 1 Results of melting composition analysis of stainless steel in Example 1

[0038] C%S%P%Si% Mn% Ni%Cr%Cu%N% Mo% Nb% Target value----1811011.451 Measured value 0.030.010.0100.4517.880.9910.020.991.334.970.99

[0039] The stainless steel is deep-drawn into a ring fitting with a mass of 2g and a diameter of 25mm, with a magnetic permeability ≤1.0×10-6H / m, and a smooth surface with silver-white metallic luster.

[0040] The manufacturing method of the above-mentioned high manganese, high nitrogen and low nickel non-magnetic stainless steel includes the following steps:

[0041] 1. Preparation of ferrochromium nitride: In a nitrogen glove box, put 100 mesh metal chromium powder and metal iron powder into a stainless steel ball mill at...

Embodiment 2

[0054] A high-manganese, high-nitrogen, low-nickel non-magnetic stainless steel, characterized in that the stainless steel is a single-phase austenitic stainless steel, and its chemical composition and mass percentage are shown in Table 2.

[0055] Table 2 Analysis results of melting composition of stainless steel in Example 2

[0056] C%S%P%Si% Mn% Ni%Cr%Cu%N% Mo% Nb% Target value----160.5140.5220.5 Measured value 0.040.010.0120.5515.920.4913.970.501.841.980.50

[0057] The stainless steel is deep-drawn into a button with a mass of 1g and a diameter of 10mm, the magnetic permeability is ≤1.0×10-6H / m, and the surface is smooth with silver-white metallic luster.

[0058] The manufacturing method of the above-mentioned high-manganese, high-nitrogen, low-nickel non-magnetic stainless steel includes the following steps:

[0059] 1. Preparation of ferrochromium nitride: In a nitrogen glove box, put 100-200 mesh metal chromium powder and metal iron powder into a stainless steel ball mil...

Embodiment 3

[0072] A high-manganese, high-nitrogen, low-nickel non-magnetic stainless steel, characterized in that the stainless steel is a single-phase austenitic stainless steel, and its chemical composition and mass percentage are shown in Table 3.

[0073] Table 3 Results of melting composition analysis of stainless steel in Example 3

[0074] C%S%P%Si% Mn% Ni%Cr%Cu%N% Mo% Nb% Target value----171.5110.31.80.50.3 Measured value 0.020.010.0150.9116.941.4810.950.301.710.490.30

[0075] The stainless steel is deep-drawn into a square fitting with a mass of 5g and a side length of 20mm, with a magnetic permeability of ≤1.0×10 -6 H / m, smooth surface with silver-white metallic luster.

[0076] The manufacturing method of the above-mentioned high manganese, high nitrogen and low nickel non-magnetic stainless steel includes the following steps:

[0077] 1. Preparation of ferrochromium nitride: In a nitrogen glove box, put 100-200 mesh metal chromium powder and metal iron powder into a stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com