Pseudo-metal composite film

A technology of composite film and metal imitation, applied in the field of composite film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below through specific examples.

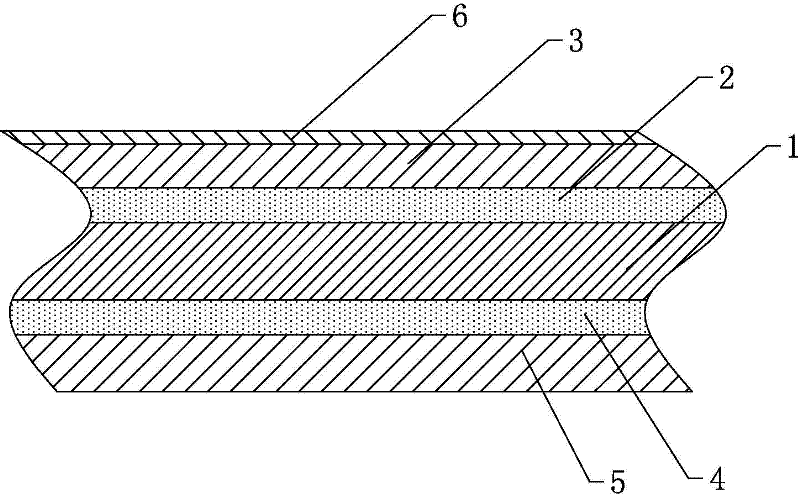

[0013] Such as figure 1 Shown, a kind of imitation metal composite film comprises metal foil layer 1, PET film layer 3 and PVC film layer 5, and described PET film layer 3 and PVC film layer 5 are bonded on the metal foil layer 1 by adhesive layer respectively. two surfaces. Specifically, the metal foil layer 1 is a metal aluminum foil layer. Of course, other metal foil layers 1 may also be used, such as copper and zinc. The PET film layer 3 is bonded to one surface of the metal foil layer 1 through the adhesive layer one 2 , and the PVC film layer 5 is bonded to the other surface of the metal foil layer 1 through the adhesive layer two 4 .

[0014] Preferably, a protective layer 6 is provided on the upper surface of the PET. The protection layer 6 is a protection layer 6 formed by UV process hard treatment on the upper surface of the PET film layer 3, and its composition i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com