Spraying-free polypropylene composite material

A composite material, polypropylene technology, applied in the field of polypropylene materials, can solve the problems of material metallic luster, unsatisfactory color, molding fluidity, etc., to achieve improved metallic luster and mechanical properties, good dispersion and contact, and good metallic luster Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

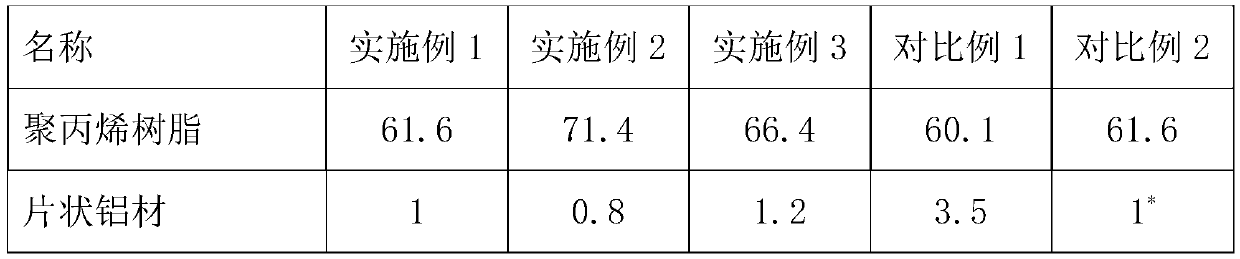

[0024] The invention provides a spray-free polypropylene composite material, and the composition of raw materials for preparing the material is shown in Table 1.

[0025] Wherein: the flow rate of the polypropylene resin under a load of 2.16kg is 50-65g / min at a temperature of 230°C.

[0026] Aluminum materials include flake aluminum and spherical aluminum; through the combined use of different shapes of aluminum powder, the reflection and diffuse reflection effects are improved, and the metallic luster of the material is improved; the length of the flake aluminum and the diameter of the spherical aluminum Both are between 5-25μm; aluminum materials are coated and modified with wax to improve compatibility with polypropylene matrix; the wax is polyethylene wax with a molecular weight of 3000-5000.

[0027] The modified powder material is a mixed powder of talcum powder and titanium dioxide coated with epoxy resin, wherein the mass ratio of talc powder and titanium dioxide is 9...

Embodiment 2

[0039] Compared with Embodiment 1, this embodiment differs in that:

[0040] (1) The composition of raw materials for preparing spray-free polypropylene composite materials is different, see Table 1 for details.

[0041] (2) In step (1) of the preparation method: heat the polyethylene wax to 100°C to melt it, then add the aluminum material to the polyethylene wax; the mass ratio of polyethylene wax to aluminum material is 8:1; stir and sonicate 50min (stirring speed is 200rpm), so that the aluminum material is uniformly dispersed in the molten polyethylene wax; after that, it is cooled and solidified to obtain a modified aluminum material.

Embodiment 3

[0043] (1) The composition of raw materials for preparing spray-free polypropylene composite materials is different, see Table 1 for details.

[0044] (2) In step (1) of the preparation method: heat the polyethylene wax to 115°C to melt it, then add the aluminum material to the polyethylene wax; the mass ratio of polyethylene wax to aluminum material is 6.5:1; stir and sonicate 30min (the stirring speed is 500rpm), so that the aluminum material is uniformly dispersed in the molten polyethylene wax; after that, it is cooled and solidified to obtain a modified aluminum material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com