A kind of paint repair paste for car scratch repair and preparation method thereof

A paint and scratch technology, applied in the field of repair paint paste for automobile scratch repair and its preparation, can solve the problems of poor dispersibility of bacterial cellulose powder and aluminum powder, affecting the repair effect, etc., so as to shorten the surface drying time , maintenance repair effect, foam reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

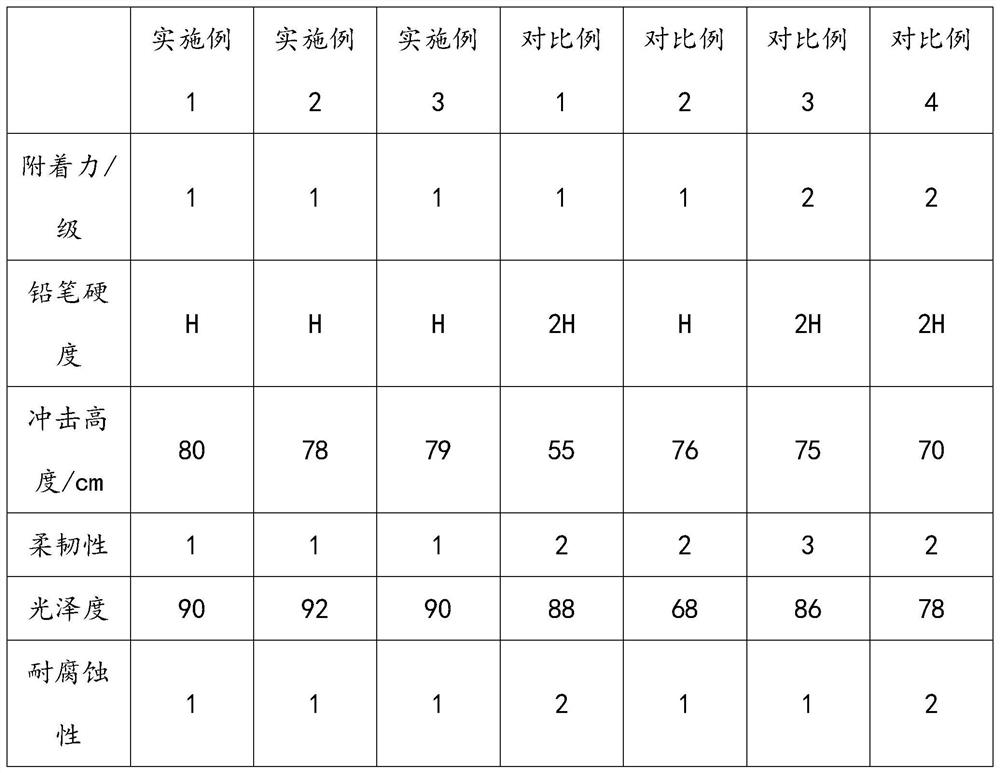

Examples

preparation example Construction

[0051] The preparation method of described paint touch-up paste, comprises the steps:

[0052] The first step is to add the silicone oligomer into the water-based epoxy resin, stir and mix at room temperature 150r / min for 2-3h, and prepare the matrix;

[0053] Step 2: After adding deionized water into the matrix for dilution, add the modified filler, aluminum zinc tripolyphosphate powder, modified metal powder and wetting and dispersing agent into the matrix, and continue stirring for 30-40 minutes;

[0054] The third step is to continue to add pigments and defoamers, stir for 20-30 minutes, add thickener, stir and mix evenly, and make a paint touch-up paste;

[0055] The specific method of using the paint repair paste is as follows:

[0056] Pre-treatment of paint repair: remove the plastic parts in the repair area to avoid deformation due to baking and heat; use suitable sandpaper for the defects that need paint repair, and choose the type of sandpaper from small to large (...

Embodiment 1

[0063] A paint touch-up paste for car scratch repair, made of the following raw materials in parts by weight: 40 parts of water-based epoxy resin, 6 parts of silicone oligomer, 8 parts of pigment, 2 parts of modified filler, tripolyphosphoric acid 2 parts of aluminum zinc powder, 5 parts of modified metal powder, 0.6 part of wetting and dispersing agent, 0.5 part of defoamer, 0.5 part of ethyl hydroxyethyl cellulose, 10 parts of deionized water;

[0064] The touch-up paste is made by the following steps:

[0065] The first step is to add the silicone oligomer into the water-based epoxy resin, stir and mix at room temperature 150r / min for 2h, and prepare the matrix;

[0066] Step 2: After adding deionized water into the matrix for dilution, add the modified filler, aluminum zinc tripolyphosphate powder, modified metal powder and wetting and dispersing agent into the matrix, and continue to stir for 30 minutes;

[0067] The third step is to continue to add pigment and defoamer,...

Embodiment 2

[0069] A paint touch-up paste for car scratch repair, made of the following raw materials in parts by weight: 45 parts of water-based epoxy resin, 7 parts of silicone oligomers, 9 parts of pigments, 2.5 parts of modified fillers, tripolyphosphoric acid 2.5 parts of aluminum zinc powder, 6.5 parts of modified metal powder, 0.8 part of wetting and dispersing agent, 0.6 part of defoamer, 0.6 part of methyl hydroxypropyl cellulose, 13 parts of deionized water;

[0070] The touch-up paste is made by the following steps:

[0071] The first step is to add the silicone oligomer into the water-based epoxy resin, stir and mix at room temperature 150r / min for 2.5h, and prepare the matrix;

[0072] Step 2: After adding deionized water to the matrix for dilution, add the modified filler, aluminum zinc tripolyphosphate powder, modified metal powder and wetting and dispersing agent into the matrix, and continue stirring for 35 minutes;

[0073] The third step is to continue to add pigments ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com