Preparation method and application of carbon material with high specific surface and high graphitization degree

A technology with high specific surface area and high graphite, applied in the preparation/purification of carbon, etc., can solve the problem that graphite cannot meet the requirements of high capacity, and achieve good market prospects and development potential, low cost, and increased degree of graphitization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

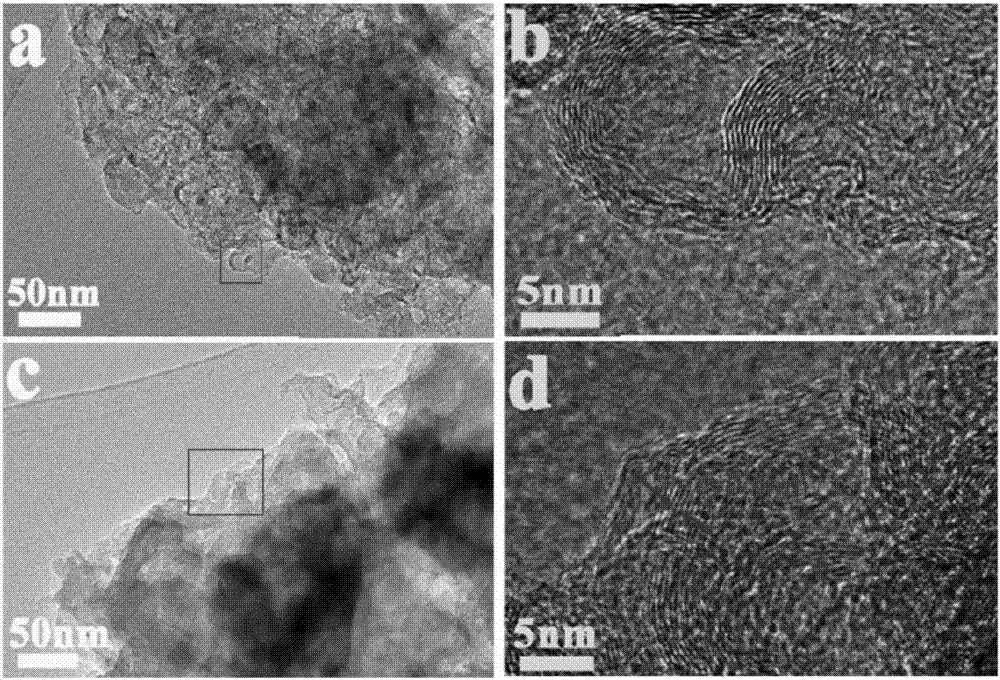

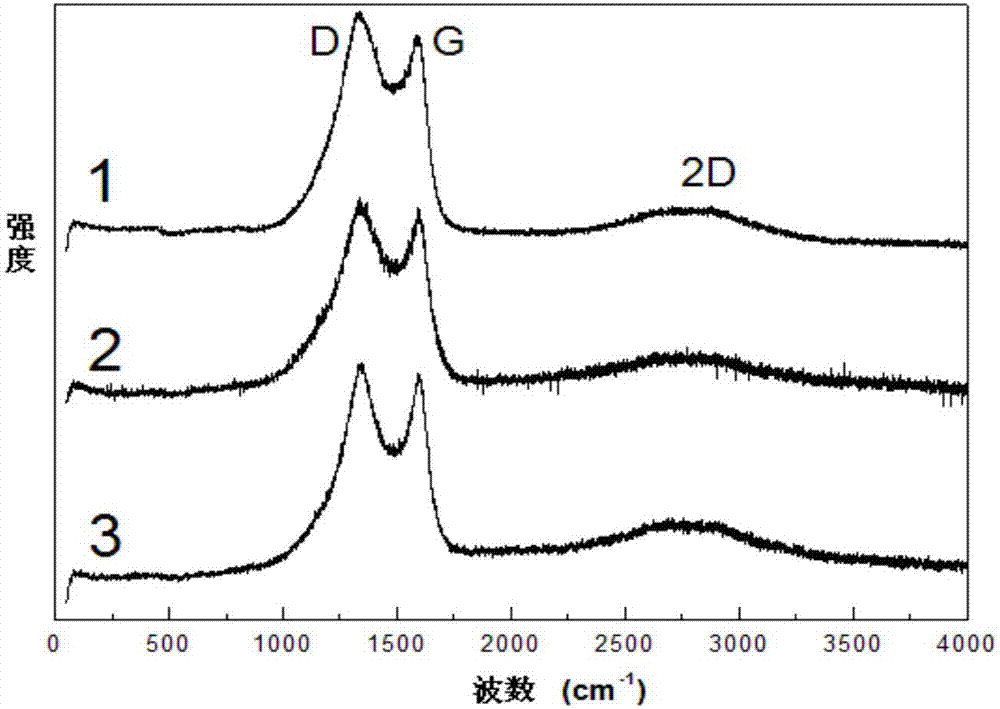

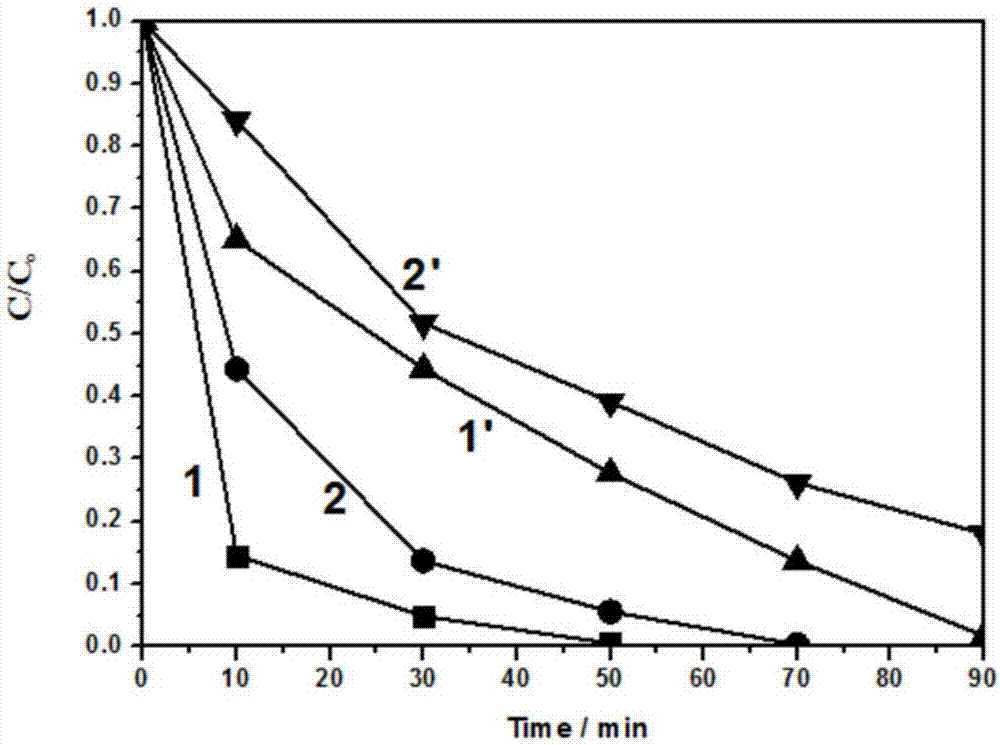

[0041] The invention discloses a rapid preparation method and application of a carbon material with high specific surface area and high graphitization degree. The characteristics and key points of this rapid preparation method include the following points:

[0042] 1) Precursor selection, select oligomeric small molecules as precursors to control the degree of polymerization; 2) New sulfonation means; 3) The introduction of ball milling promotes the formation of surface defects; 4) The secondary mixing method of precursors and metal salts ; 5) The precursor is subjected to pyrolysis and graphitization treatment to obtain a carbon material with a high specific surface area and a high degree of graphitization.

[0043] The method of the invention is simple and low in cost. The prepared carbon material has high adsorption efficiency for heavy metals, has high activity as a fuel cell catalyst, and exhibits high capacity and lifespan in lithium-ion batteries. The prepared carbon ...

Embodiment 1

[0047] A carbon material with a high specific surface area and a high degree of graphitization, prepared by the following preparation method:

[0048] 1) Add 200 ml of deionized water and 50 ml of 10% (mass percentage concentration) polyvinyl alcohol solution in the reaction vessel, mix 5 ml of styrene in another vessel, 2 ml of divinylbenzene and 0.3 g of benzoyl peroxide, both Mix and stir at a speed of 500 rpm, and react at 80° C. for 30 minutes to obtain an oligomer. Wash, filter, and vacuum dry for later use.

[0049] 2) Under the condition of stirring, pretreat 5-20 g of small oligomeric molecules with 50-1000 mL of acid solution for 12-24 hours; the volume percentage concentration of the acid solution is 0.5-1 M; the acid solution is HCl solution; The rotational speed of the stirring is 200-1000 rpm; the deionized water is used for rinsing; the drying condition is drying at 60-80° C. for 6-12 hours.

[0050] 3) Add 5 g of the oligomeric small molecule product obtained...

Embodiment 2

[0063] A carbon material with a high specific surface area and a high degree of graphitization, prepared by the following preparation method:

[0064] 1) Add 200 ml of deionized water and 50 ml of 10% polyvinyl alcohol solution to the reaction container, mix 5 ml of styrene, 10 ml of vinyl chloride benzene and 1 g of benzoyl peroxide in another container, mix the two at a speed of 500 rpm Stir and react at 80°C for 30 minutes to obtain an oligomer. Wash, filter, and vacuum dry for later use.

[0065] 2) Under the condition of stirring, pretreat 5-20 g of small oligomeric molecules with 50-1000 mL of acid solution for 12-24 hours; the concentration of the acid solution is 0.5-1 M; the acid solution is HCl solution; the stirring The rotation speed is 200-1000 rpm; the deionized water is used for rinsing; the drying condition is to dry at 60-80° C. for 6-12 hours.

[0066] 3) Add 5 g of the oligomeric small molecule product obtained in step 2), add 30 ml of dichloroethane, soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com