Preparation method of water-based PVD (physical vapor deposition) aluminum pigment

An aluminum pigment, water-based technology, used in fibrous fillers, dyed low-molecular-weight organic compound treatment, dyed high-molecular organic compound treatment, etc. The stability of production is difficult to control, etc., to achieve the effect of excellent density and uniformity, thin coating film, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

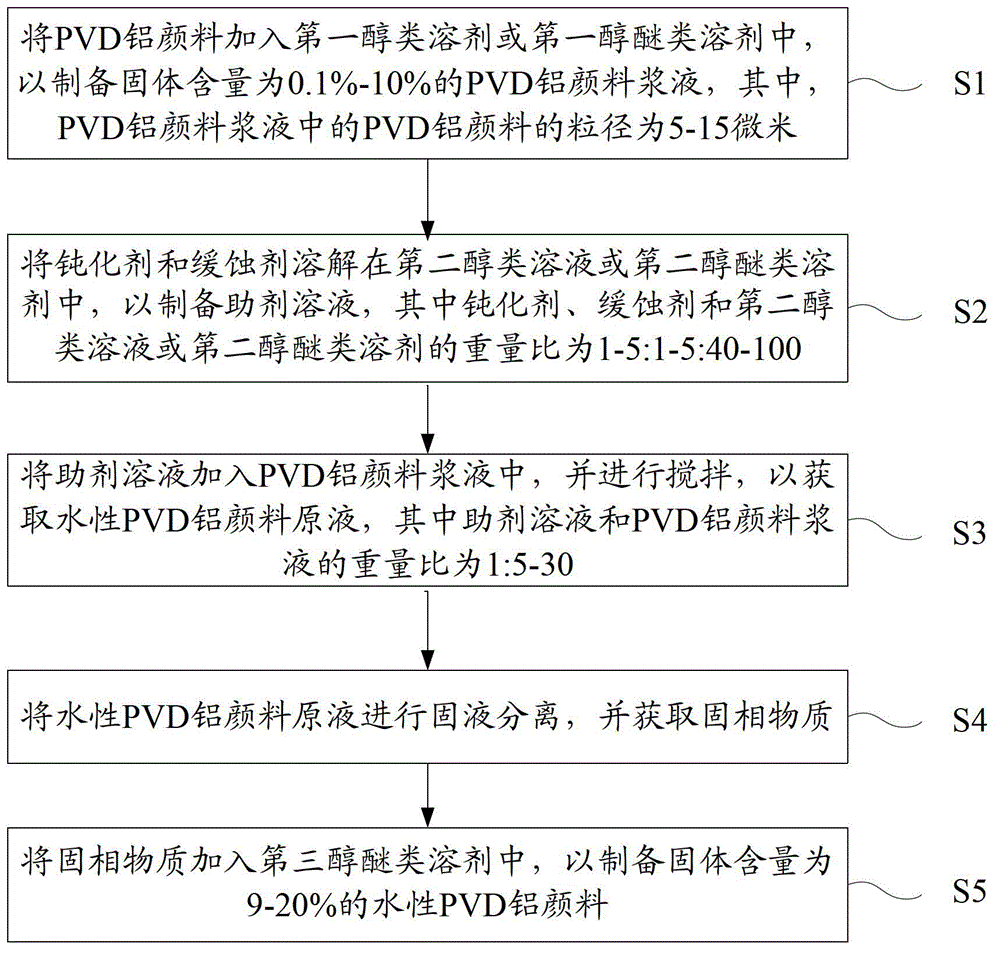

[0023] figure 1 It is a flowchart of the preparation method of the water-based PVD aluminum pigment of the present invention. like figure 1 As shown, the preparation method of the water-based PVD aluminum pigment of the present invention comprises steps S1, S2, S3, S4 and S5, wherein,

[0024] Step S1: adding the PVD aluminum pigment into the first alcohol solvent or the first alcohol ether solvent to prepare a PVD aluminum pigment slurry with a solid content of 0.1%-10%, wherein the PVD aluminum pigment in the PVD aluminum pigment slurry The particle size is 5-15 microns;

[0025] Step S2: Dissolving the passivator and the corrosion inhibitor in the second alcohol solution or the second alcohol ether solvent to prepare the auxiliary agent solution, wherein the passivator, the corrosion inhibitor and the second alcohol solution or the second alcohol The weight ratio of ether solvent is 1-5:1-5:40-100;

[0026] Step S3: adding the auxiliary agent solution into the PVD alumi...

Embodiment 1

[0041] 1. Take 100 grams of nano-aluminum pigments with an average particle size of 98.52 microns, a solid content of 14%, and an isopropanol content of 86%, dilute it to 2000 grams with ethylene glycol butyl ether, stir evenly, and make a1 liquid;

[0042] 2. Use an ultrasonic pulverizer to pulverize the a1 liquid above to a particle size of 10.5 microns to produce a b1 liquid. The conditions for the ultrasonic pulverization are as follows: the frequency is 1000HZ, the time is 3 seconds, and the interval is 5 seconds;

[0043] 3. Add 2.5 grams of phosphoramide (passivator) and 2.5 grams of dimer fatty acid (corrosion inhibitor) into 90 grams of ethylene glycol butyl ether to disperse to make c1 solution;

[0044] 4. Add 5 grams of liquid c1 to liquid b1, and stir for 30 minutes under a paddle stirrer at a speed of 500r / min to make liquid d1;

[0045] 5. Centrifuge the d1 liquid with a centrifuge, discard the supernatant liquid, add ethylene glycol butyl ether to the lower pig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com