Modified polylactic acid material used for 3D printing and having metal effect

A polylactic acid material and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of polylactic acid consumables such as brittleness, single effect, and easy cracking, and achieve the effect of not easy to degrade, good metal effect, and prevent oxidation of polylactic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

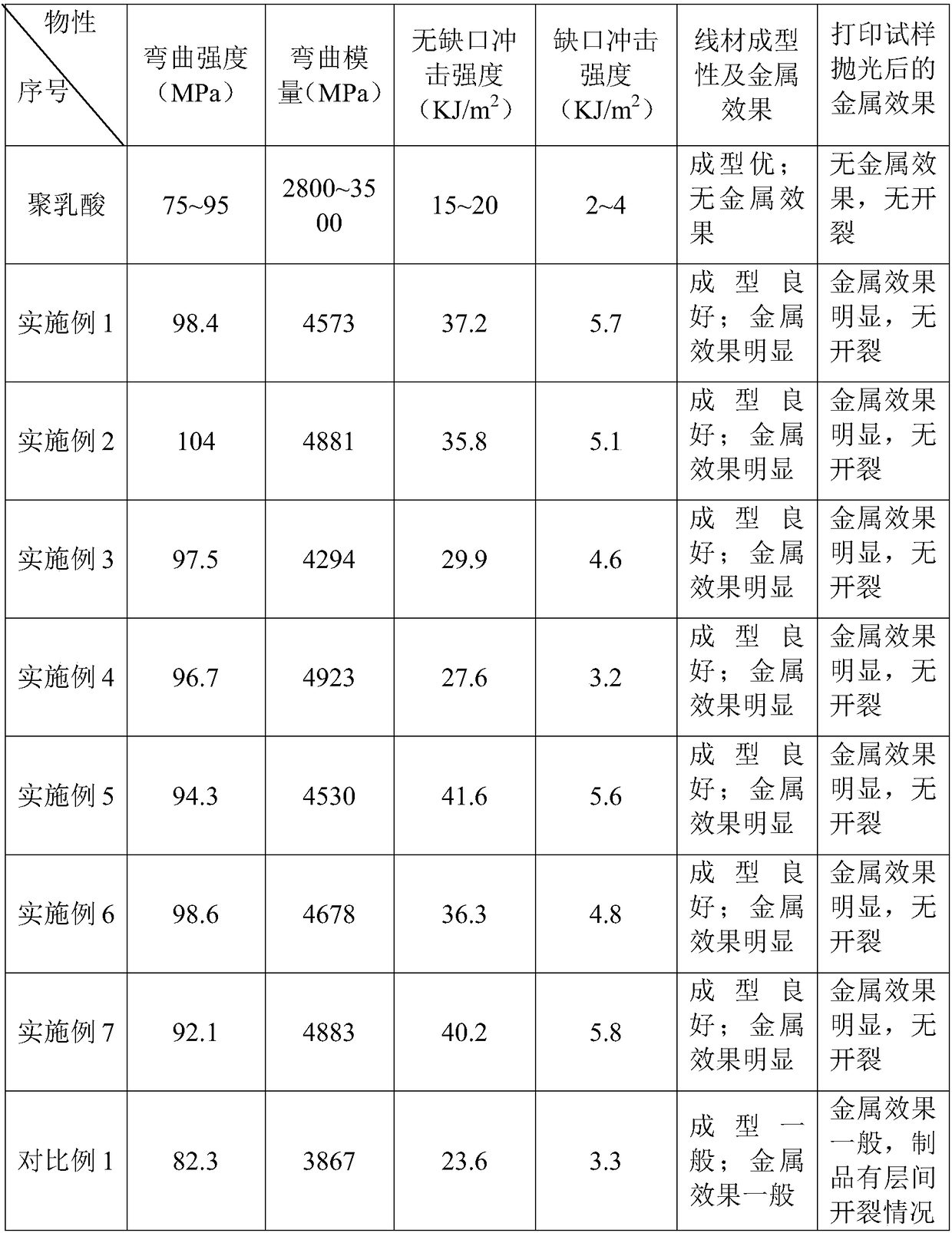

Examples

Embodiment 1

[0034] This embodiment provides a modified polylactic acid material with metal effect for 3D printing, comprising the following components in parts by weight: 100 parts of polylactic acid, 100 parts of metal powder, 2 parts of metal pigment, 10 parts of toughening agent, coupling 0.5 part of lubricant, 0.5 part of lubricant, 0.3 part of hindered phenolic antioxidant, and 0.2 part of phosphite antioxidant; the polylactic acid is selected from the 4032D brand of natureworks company (as long as the polylactic acid is suitable for extruding polylactic acid grades can be applied to the present invention), the metal powder is 500 purpose granular copper powder, the metal pigment is 500 purpose scaly copper powder, and the toughening agent is methyl methacrylate-butadiene - Styrene core-shell copolymer, the coupling agent γ-(2,3-glycidoxy) propyl trimethoxysilane, the lubricant is ethylene bis stearic acid amide, the hindered phenols The antioxidant is β-(3,5-di-tert-butyl-4-hydroxyp...

Embodiment 2

[0043] This embodiment provides a modified polylactic acid material for 3D printing with a metallic effect, comprising the following components in parts by weight: 100 parts of polylactic acid, 120 parts of metal powder, 3 parts of metal pigment, 10 parts of toughening agent, coupling 0.8 part of lubricant, 0.5 part of lubricant, 0.3 part of hindered phenolic antioxidant, 0.2 part of phosphite antioxidant; the polylactic acid selects the 4043D brand of natureworks company, and the metal powder is 400 mesh granular bronze powder , the metal pigment is 500 mesh scaly bronze powder, the toughening agent is methyl methacrylate-butyl acrylate core-shell copolymer, and the coupling agent is tetraoctyloxytitanium [two (dilauryl Phosphite)], the lubricant is pentaerythritol stearate, and the hindered phenolic antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, and the phosphite antioxidant is bis(2,4-di-tert-butylphenol) pentaerythrito...

Embodiment 3

[0052] This embodiment provides a modified polylactic acid material with metal effect for 3D printing, which contains the following components in parts by weight: 100 parts of polylactic acid, 80 parts of metal powder, 5 parts of metal pigment, 8 parts of toughening agent, coupling 2 parts of lubricants, 1.5 parts of lubricants, 0.2 parts of hindered phenol antioxidants, and 0.4 parts of thioester antioxidants; the polylactic acid uses REVODE190 from Zhejiang Hisun Biomaterials Co., Ltd., and the metal powder is 800 Purpose granular aluminum powder, described metal pigment is 600 purpose scaly aluminum silver powders, and described toughening agent is organosilicon modified methyl methacrylate-butyl acrylate core-shell copolymer, and described coupling agent is tri( Dioctyl pyrophosphoryloxy) isopropyl titanate, the lubricant is a polyester hyperbranched resin, and the hindered phenolic antioxidant is 4,6-three (3,5-di-tert-butyl -4-hydroxybenzyl) benzene, the thioester antiox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com